ASTM D2911-10

(Specification)Standard Specification for Dimensions and Tolerances for Plastic Bottles

Standard Specification for Dimensions and Tolerances for Plastic Bottles

ABSTRACT

This specification covers the thread configuration and dimensions for finishes for plastic bottles with screw-type closures. The bottle overflow and body dimensional tolerances are detailed. The test apparatus for determining bottle capacity consists of a balance, pipet, graduated cylinder, beaker, conditioned water, and stop watch. In addition, the test apparatus for determining finish and body dimensions includes micrometers, Vernier height gages or Vernier calipers, internal micrometers or telescoping gages, and commercial scale. The test methods discussed are for the determination of bottle capacity, body dimensions, and finish dimensions.

SCOPE

1.1 This specification covers the thread configuration and dimensions for finishes for plastic bottles with screw-type closures, having a maximum capacity of 18.9 L (5 gal) and a maximum bottle dimension of 305 mm (12 in.). Included are tolerances for bottle capacity and body dimensions.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 8 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2911 −10

StandardSpecification for

1

Dimensions and Tolerances for Plastic Bottles

This standard is issued under the fixed designation D2911; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 bottle thickness—the smaller dimension in a plane

parallel to the bottle base.

1.1 This specification covers the thread configuration and

3.1.4 bottle width—the larger dimension in a plane parallel

dimensions for finishes for plastic bottles with screw-type

to the bottle base.

closures, having a maximum capacity of 18.9 L (5 gal) and a

maximum bottle dimension of 305 mm (12 in.). Included are

4. Dimensions and Recommended Variations

tolerances for bottle capacity and body dimensions.

4.1 Recommended Variations in Overflow Capacity—In

1.2 The values stated in SI units are to be regarded as the

overflowcapacityrecommendedvariationsofplasticbottlesup

standard.

to 18.9 L (5 gal) in size shall be in accordance with Table 1.

1.3 The following precautionary caveat pertains only to the

4.2 Recommended Variations in Body Dimensions—The

test methods portion, Section 8 of this specification.This

recommended variations in the body dimensions of plastic

standard does not purport to address all of the safety concerns,

bottlescoveredbythisspecificationshallbeinaccordancewith

if any, associated with its use. It is the responsibility of the user

Table 2.

of this standard to establish appropriate safety and health

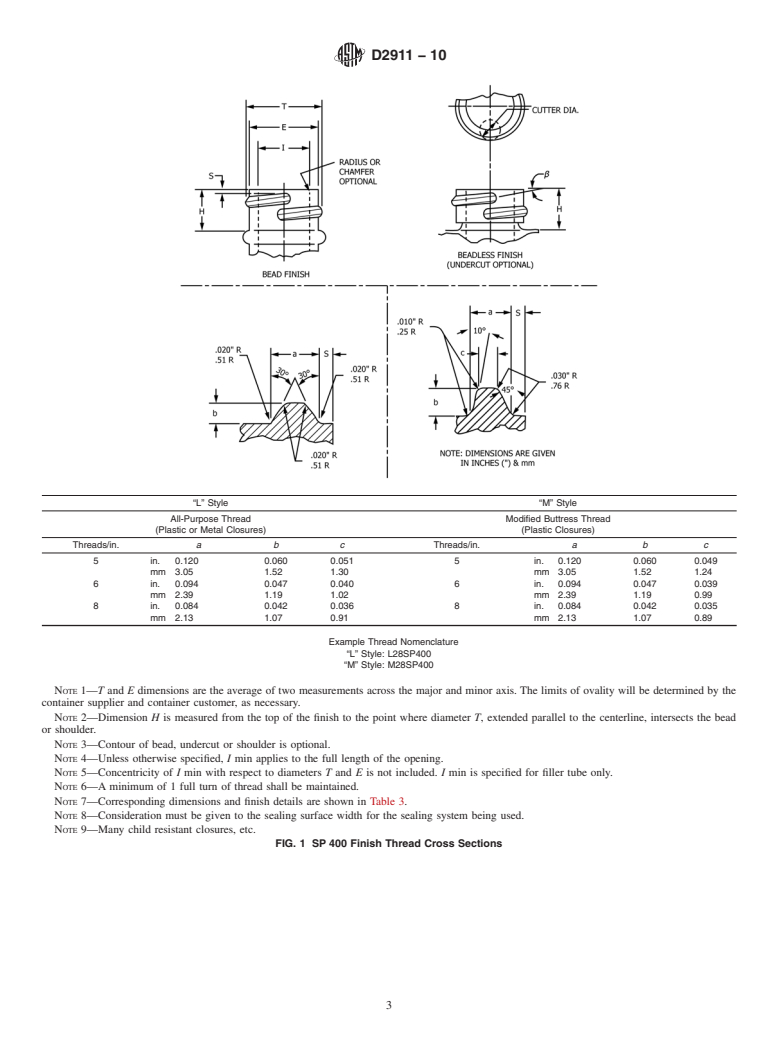

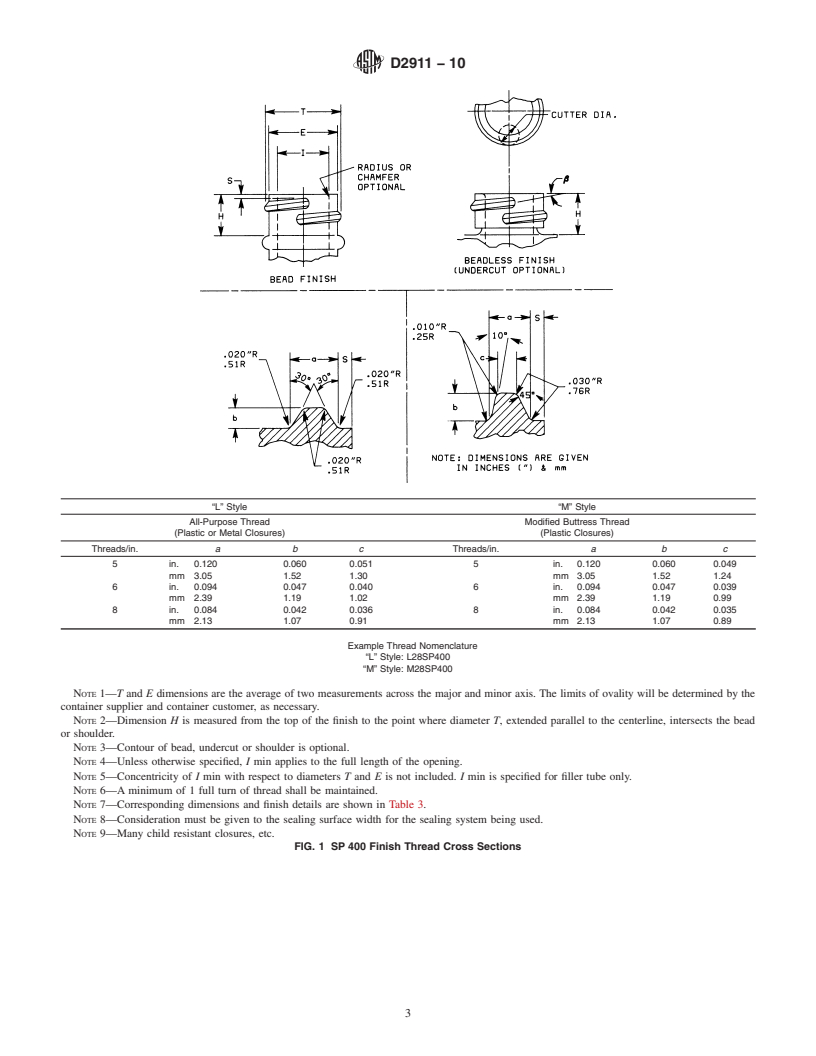

4.3 Finish Dimensions and Design—The bottle finish di-

practices and determine the applicability of regulatory limita-

mensions and design for the nine finishes covered by this

tions prior to use.

specification shall be in accordance with Figs. 1-8 and Tables

NOTE 1—There is no known ISO equivalent to this standard.

3-10.

2. Referenced Documents

5. Sampling

2

2.1 ASTM Standards:

5.1 A batch or lot shall be considered as a unit of manufac-

D618 Practice for Conditioning Plastics for Testing

ture.

3

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

5.2 Unless otherwise agreed upon between manufacturer

and purchaser, the material shall be sampled in accordance

3. Terminology

with the procedure described in Section 9 of Practice D1898.

3.1 Definitions:

Adequate statistical sampling prior to packaging shall be

3.1.1 bottle finish—the configuration of the neck or opening

considered an acceptable alternative.

of the bottle which serves to engage specific parts of the

6. Conditioning

closure in order to securely attach it to the bottle.

6.1 Conditioning—Condition the test specimens at 23 6

3.1.2 bottle height—the maximum dimension of a bottle in

2°C (73.4 6 3.6°F) and 50 6 5% relative humidity for not less

a plane perpendicular to the bottle base when the bottle is

than 40 h prior to test in accordance with Procedure A of

setting in its normal upright position.

Practice D618 for those tests where conditioning is required. In

cases of disagreement, the tolerances shall be 6 1°C (61.8°F)

and 62 % relative humidity.

1

This specification is under the jurisdiction of ASTM Committee D20 on

6.2 Test Conditions—Conduct tests in the standard labora-

Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting,

and Molded Products.

tory atmosphere of 23 6 2°C (73.4 6 3.6°F) and 50 6 5%

Current edition approved July 1, 2010. Published September 2010. Originally

relative humidity, unless otherwise specified in the test meth-

approved in 1970. Last previous edition approved in 2005 as D2911 - 94 (2005).

ods or in this specification. In cases of disagreement, the

DOI: 10.1520/D2911-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or tolerances shall be 61°C (61.8°F) and 62 % relative humid-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ity.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

7. Apparatus

3

The last approved version of this historical standard is referenced on

www.astm.org. 7.1 For Determining Bottle Capacity:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2911−10

TABLE 1 Bottle Overflow Capacity Tolerances for Plastic Bottles

Fluid Ounces Millilitres

Bottle Overflow Capacity Tolerance (±) Bottle Overflow Capacity Tolerance (±)

less than 0.75 0.05 less than 22 1.5

0.75 and less than 1.2 0.07 22 and less than 35 2.0

1.2 and less than 1.6 0.08 35 and less than 47 2.5

1.6 and less than 2.1 0.10 47 and less than 62 3.0

2.1 and less than 2.8 0.12 62 and less than 83 3.5

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2911–94 (Reapproved 2005) Designation: D2911 – 10

Standard Specification for

1

Dimensions and Tolerances for Plastic Bottles

This standard is issued under the fixed designation D2911; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the thread configuration and dimensions for finishes for plastic bottles with screw-type closures,

having a maximum capacity of 18.9 L (5 gal) and a maximum bottle dimension of 305 mm (12 in.). Included are tolerances for

bottle capacity and body dimensions.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 8 of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

3

D1898 Practice for Sampling of Plastics

3. Terminology

3.1 Definitions:

3.1.1 bottle finish—the configuration of the neck or opening of the bottle which serves to engage specific parts of the closure

in order to securely attach it to the bottle.

3.1.2 bottle height—the maximum dimension of a bottle in a plane perpendicular to the bottle base when the bottle is setting

in its normal upright position.

3.1.3 bottle thickness—the smaller dimension in a plane parallel to the bottle base.

3.1.4 bottle width—the larger dimension in a plane parallel to the bottle base.

4. Dimensions and Recommended Variations

4.1 Recommended Variations in Overflow Capacity—In overflow capacity recommended variations of plastic bottles up to 18.9

L (5 gal) in size shall be in accordance with Table 1.

4.2 Recommended Variations in Body Dimensions—The recommended variations in the body dimensions of plastic bottles

covered by this specification shall be in accordance with Table 2.

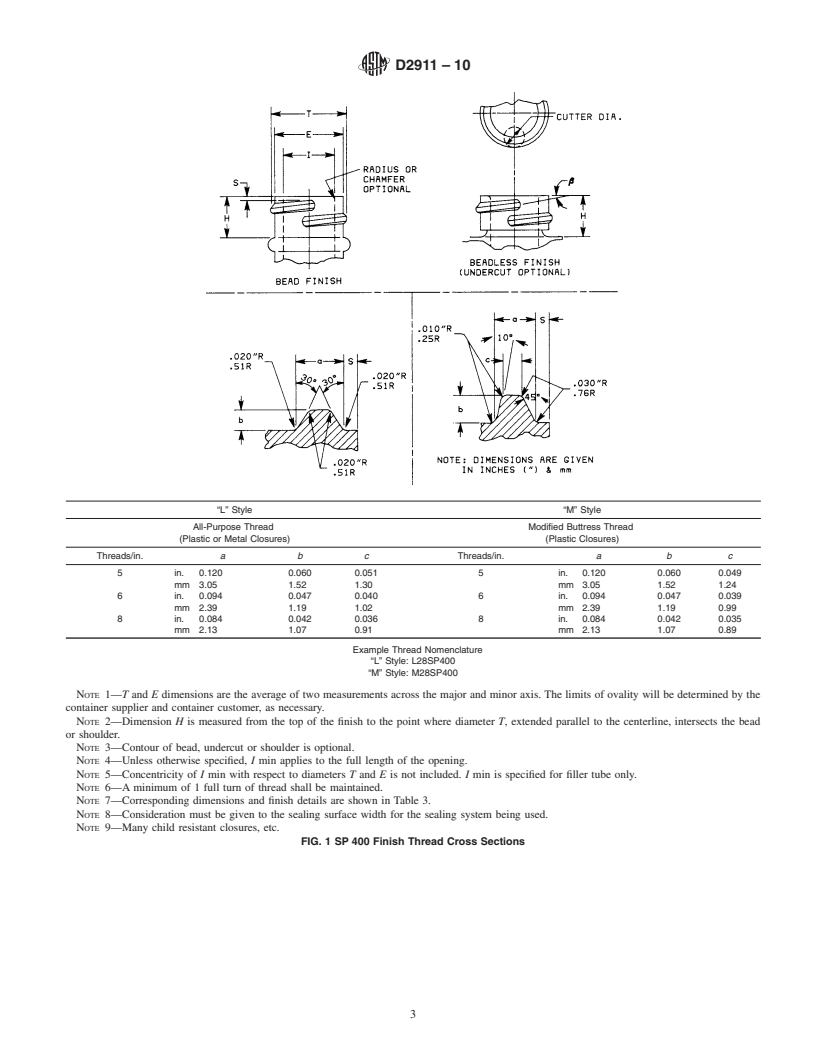

4.3 Finish Dimensions and Design—The bottle finish dimensions and design for the nine finishes covered by this specification

shall be in accordance with Figs. 1-8 and Tables 3-10.

5. Sampling

5.1 A batch or lot shall be considered as a unit of manufacture.

5.2 Unless otherwise agreed upon between manufacturer and purchaser, the material shall be sampled in accordance with the

procedure described in Section 9 of Practice D1898. Adequate statistical sampling prior to packaging shall be considered an

acceptable alternative.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting.

Current edition approved July 1, 2005. Published August 2005. Originally approved in 1970. Last previous edition approved in 2001 as D2911-94 (2001). DOI:

10.1520/D2911-94R05.on Molded and Extruded Products.

Current edition approved July 1, 2010. Published September 2010. Originally approved in 1970. Last previous edition approved in 2005 as D2911 - 94 (2005). DOI:

10.1520/D2911-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2911 – 10

TABLE 1 Bottle Overflow Capacity Tolerances for Plastic Bottles

Fluid Ounces Millilitres

Bottle Overflow Capacity Tolerance (6) Bottle Overflow Capacity Tolerance (6)

less than 0.75 0.05 less than 22 1.5

0.75 and less than 1.2 0.07 22 and less than 35 2.0

1.2 and less than 1.6 0.08 35 and less than 47 2.5

1.6 and less than 2.1 0.10 47 and less than 62 3.0

2.1 and less than 2.8 0.12 62 and less than 83 3.5

2.8 and less than 3.9 0.14 83 and less than 115 4

3.9 and less than 5.4 0.17 115 and less than 159 5

5.4 and less than 7.4 0.20 159 and less than 218 6

7.4 and less than 9.8 0.24 218 and less than 289 7

9.8 and less than 13 0.30 289 and less than 384 9

13 and le

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2911 − 10 D2911 − 10

Standard Specification for

1

Dimensions and Tolerances for Plastic Bottles

This standard is issued under the fixed designation D2911; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the thread configuration and dimensions for finishes for plastic bottles with screw-type closures,

having a maximum capacity of 18.9 L (5 gal) and a maximum bottle dimension of 305 mm (12 in.). Included are tolerances for

bottle capacity and body dimensions.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 8 of this specification.This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

3

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

3. Terminology

3.1 Definitions:

3.1.1 bottle finish—the configuration of the neck or opening of the bottle which serves to engage specific parts of the closure

in order to securely attach it to the bottle.

3.1.2 bottle height—the maximum dimension of a bottle in a plane perpendicular to the bottle base when the bottle is setting

in its normal upright position.

3.1.3 bottle thickness—the smaller dimension in a plane parallel to the bottle base.

3.1.4 bottle width—the larger dimension in a plane parallel to the bottle base.

4. Dimensions and Recommended Variations

4.1 Recommended Variations in Overflow Capacity—In overflow capacity recommended variations of plastic bottles up to 18.9

L (5 gal) in size shall be in accordance with Table 1.

4.2 Recommended Variations in Body Dimensions—The recommended variations in the body dimensions of plastic bottles

covered by this specification shall be in accordance with Table 2.

4.3 Finish Dimensions and Design—The bottle finish dimensions and design for the nine finishes covered by this specification

shall be in accordance with Figs. 1-8 and Tables 3-10.

5. Sampling

5.1 A batch or lot shall be considered as a unit of manufacture.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Molded

Products.

Current edition approved July 1, 2010. Published September 2010. Originally approved in 1970. Last previous edition approved in 2005 as D2911 - 94 (2005). DOI:

10.1520/D2911-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2911 − 10

TABLE 1 Bottle Overflow Capacity Tolerances for Plastic Bottles

Fluid Ounces Millilitres

Bottle Overflow Capacity Tolerance (±) Bottle Overflow Capacity Tolerance (±)

less than 0.75 0.05 less than 22 1.5

0.75 and less than 1.2 0.07 22 and less than 35 2.0

1.2 and less than 1.6 0.08 35 and less than 47 2.5

1.6 and less than 2.1 0.10 47 and less than 62 3.0

2.1 and less than 2.8 0.12 62 and less than 83 3.5

2.8 and less than 3.9 0.14 83 and less than 115 4

3.9 and less than 5.4 0.17 115 and less than 159 5

5.4 and less than 7.4 0.20 159 and less than 218 6

7.4 and less than 9.8 0.24 218 and less than 289 7

9.8 and less than 13 0.30 289 and less than 384 9

13 and less than 18 0.37 384 and less than 531 11

18 and less than 26 0.44 531 and less than 767 13

26 and less than 37 0.51 767 and less than 1092 15

37 and less than 51 0.68 1092 and less than 1505 20

51 and less than 72 0.81 1505 and less than 2125 24

72 and less than 98 1.01 2125 and less than 2892 30

98 and less than 119 1.30 2892 and less than 3512 38

119 and less than 139 1.50 3512 and less than

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.