ASTM D4894-07(2012)

(Specification)Standard Specification for Polytetrafluoroethylene (PTFE) Granular Molding and Ram Extrusion Materials

Standard Specification for Polytetrafluoroethylene (PTFE) Granular Molding and Ram Extrusion Materials

ABSTRACT

This specification focuses on granular polytetrafluoroethylene (PTFE) resins that have never been preformed or molded, and are normally processed by methods similar to those used in powder metallurgy or ceramics, or by special extrusion processes. These PTFE resins are homopolymers of tetrafluoroethylene, or, in some cases, modified homopolymers containing not more than one percent by weight of other fluoromonomers. The materials included herein do not include mixtures of PTFE resin with additives such as colorants, fillers or plasticizers; nor do they include reprocessed or reground resin or any fabricated articles. Included are specimen preparation, test methods and requirements for materials, melting characteristics, bulk density, particle size, water content, standard specific gravity, thermal instability index, and mechanical (tensile) properties.

SCOPE

1.1 This specification covers granular resins and test methods for polytetrafluoroethylene (PTFE) that have never been preformed or molded and are normally processed by methods similar to those used in powder metallurgy or ceramics, or by special extrusion processes. These PTFE resins are homopolymers of tetrafluoroethylene, or, in some cases, modified homopolymers containing not more than one percent by weight of other fluoromonomers. The usual methods of processing thermoplastics generally are not applicable to these materials because of their viscoelastic properties at processing temperatures. The materials included herein do not include mixtures of PTFE resin with additives such as colorants, fillers or plasticizers; nor do they include reprocessed or reground resin or any fabricated articles. The methods and properties included are those required to identify the various types of resins. Additional procedures are provided in the Appendix for further characterization of the resins.

1.2 The values stated in SI units as detailed in are to be regarded as the standard, and the practices of are incorporated herein.

1.3 The following precautionary caveat pertains only to the Specimen Preparation section, Section 9, and the Test Methods section, Section 10, of this specification: This specification does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Notes 3 and 9 for specific cautionary statements.

Note 1—Information in this specification is technically equivalent to related information in ISO 12086-1 and ISO 12086-2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4894 −07(Reapproved 2012)

Standard Specification for

Polytetrafluoroethylene (PTFE) Granular Molding and Ram

1

Extrusion Materials

This standard is issued under the fixed designation D4894; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers granular resins and test meth- 2.1 ASTM Standards:

ods for polytetrafluoroethylene (PTFE) that have never been D618Practice for Conditioning Plastics for Testing

preformed or molded and are normally processed by methods D638Test Method for Tensile Properties of Plastics

similar to those used in powder metallurgy or ceramics, or by D792Test Methods for Density and Specific Gravity (Rela-

special extrusion processes. These PTFE resins are homopoly- tive Density) of Plastics by Displacement

mers of tetrafluoroethylene, or, in some cases, modified ho- D883Terminology Relating to Plastics

mopolymerscontainingnotmorethanonepercentbyweightof D1895Test Methods forApparent Density, Bulk Factor, and

other fluoromonomers. The usual methods of processing ther- Pourability of Plastic Materials

moplastics generally are not applicable to these materials D3295Specification for PTFE Tubing, Miniature Beading

because of their viscoelastic properties at processing tempera- and Spiral Cut Tubing

tures.Thematerialsincludedhereindonotincludemixturesof D3892Practice for Packaging/Packing of Plastics

PTFE resin with additives such as colorants, fillers or plasti- D4441Specification for Aqueous Dispersions of Polytetra-

cizers;nordotheyincludereprocessedorregroundresinorany fluoroethylene

fabricated articles. The methods and properties included are D4591Test Method for Determining Temperatures and

those required to identify the various types of resins. Addi- Heats of Transitions of Fluoropolymers by Differential

tional procedures are provided in the Appendix for further Scanning Calorimetry

characterization of the resins. D4745Classification System and Basis for Specification for

FilledPolytetrafluoroethlyene(PTFE)MoldingandExtru-

1.2 The values stated in SI units as detailed in IEEE/ASTM

sion Materials Using ASTM Methods

SI-10 are to be regarded as the standard, and the practices of

D4895 Specification for Polytetrafluoroethylene (PTFE)

IEEE/ASTM SI-10 are incorporated herein.

Resin Produced From Dispersion

1.3 The following precautionary caveat pertains only to the

E11Specification forWovenWireTest Sieve Cloth andTest

SpecimenPreparationsection,Section9,andtheTestMethods

Sieves

section, Section 10, of this specification: This specification

E177Practice for Use of the Terms Precision and Bias in

does not purport to address all of the safety concerns, if any,

ASTM Test Methods

associated with its use. It is the responsibility of the user of this

IEEE/ASTM SI-10Standard for Use of the International

standard to establish appropriate safety and health practices

System of Units (SI): The Modern Metric System

3

and determine the applicability of regulatory limitations prior

2.2 ISO Standards:

to use. See Notes 3 and 9 for specific cautionary statements.

ISO 12086-1 Plastics—Fluoropolymer Dispersions and

Moulding and Extrusion Materials—Part 1: Designation

NOTE 1—Information in this specification is technically equivalent to

related information in ISO12086-1 and ISO12086-2.

System and Basis for Specification

1 2

This specification is under the jurisdiction of ASTM Committee D20 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Materials. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2012. Published June 2012. Originally the ASTM website.

3

approved in 1989. Last previous edition approved in 2007 as D4894-07. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D4894-07R12. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

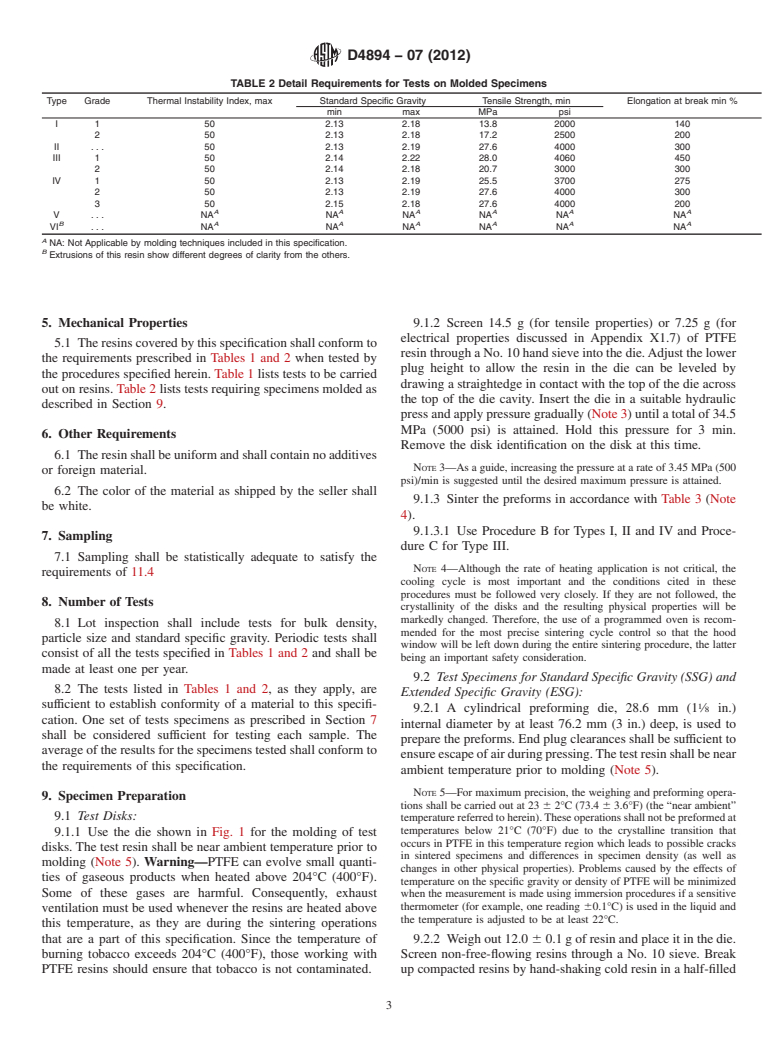

D4894−07 (2012)

A

TABLE 1 Detail Requirements for Tests on Resins

Type Grade Bulk Density, g/L Particle Size, Average Diameter, µm Water Content, max, % Melting Peak Temperature

Initial °C Second °C

A

I 1 700 ± 100 500 ± 150 0.04 327±10

A

2 675±50 375±75 0.04 327±10

A

II . . . . . . <100 0.04 327±10

A

III 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.