ASTM G122-96(2008)

(Test Method)Standard Test Method for Evaluating the Effectiveness of Cleaning Agents

Standard Test Method for Evaluating the Effectiveness of Cleaning Agents

SIGNIFICANCE AND USE

The purpose of this test method is to define a procedure for evaluating the capability of cleaning agents to clean metallic coupons. Based on the outcome of the testing, suitable cleaning agents may be selected for cleaning in general and for oxygen service in particular.

The cleaning parameters can be changed and the test method can be repeated. The usual cleaning parameters include cleaning agent concentration, temperature, and time; type and strength of ultrasonic energy or agitation, if used, and others.

Note 1—Usual cleaning parameters are based on the manufacturer's recommendations.

SCOPE

1.1 This test method covers a procedure for evaluating the capability of cleaning agents and processes to remove contamination to the desired level.

1.2 The test coupons provide a relatively rough surface to which contamination can easily adhere.

1.3 The capability of a particular cleaning agent depends upon the method by which it is used and the characteristics of the article being cleaned, such as size, shape, and material. Final evaluation of the cleaning agent should include testing of actual products and production process.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Note 2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G122 − 96 (Reapproved2008)

Standard Test Method for

Evaluating the Effectiveness of Cleaning Agents

This standard is issued under the fixed designation G122; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Many systems require a high degree of cleanliness. For example, gaseous and liquid oxygen

systems must be clean, particularly of hydrocarbons, to avoid the potential hazard of a reaction and

subsequent fire or explosion. Typically, chlorinated solvents have been used to clean systems and

equipment that must be free of hydrocarbons and other contaminants. Environmental concerns dictate

that suitable replacements are needed. This test method presents a procedure that may be used to

evaluate candidate aqueous or non aqueous cleaning agents.

1. Scope E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method covers a procedure for evaluating the

E691Practice for Conducting an Interlaboratory Study to

capabilityofcleaningagentsandprocessestoremovecontami-

Determine the Precision of a Test Method

nation to the desired level.

G94Guide for Evaluating Metals for Oxygen Service

1.2 The test coupons provide a relatively rough surface to

G121Practice for Preparation of Contaminated Test Cou-

which contamination can easily adhere.

pons for the Evaluation of Cleaning Agents

1.3 The capability of a particular cleaning agent depends

2.2 ANSI Standard:

upon the method by which it is used and the characteristics of

D46.1Surface Texture (Surface Roughness, Waviness, Lay)

the article being cleaned, such as size, shape, and material.

3. Terminology

Finalevaluationofthecleaningagentshouldincludetestingof

actual products and production process.

3.1 Definitions:

3.1.1 cleaning effectiveness factor (CEF), n—the fraction of

1.4 The values stated in SI units are to be regarded as the

contaminant removed from an initially contaminated test

standard. The values given in parentheses are for information

coupon and determined by gravimetric techniques.

only.

3.1.2 residual contamination, R,n—the absolute mass of

1.5 This standard does not purport to address all of the

c

contaminant remaining after the cleaning process and ex-

safety concerns, if any, associated with its use. It is the

pressed in milligrams per square centimetre of area or option-

responsibility of the user of this standard to establish appro-

ally as milligrams per square foot.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau-

3.1.3 surface roughness, R ,n—the arithmetic average de-

A

tionary statements are given in Note 2.

viation of the surface profile from the centerline, normally

reported in micrometres.

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

D1193Specification for Reagent Water

4.1 This test method provides quantitative results as to the

ability of a specific cleaning agent/process for removing

selected contaminants from standard coupons. The coupons

This test method is under the jurisdiction of ASTM Committee G04 on

usedfortestingarepreparedinaccordancewithPracticeG121.

Compatibility and Sensitivity of Materials in Oxygen EnrichedAtmospheres and is

the direct responsibility of Subcommittee G04.01 on Test Methods. Cleaning is performed using a cleaning tank with or without

Current edition approved Sept. 1, 2008. Published October 2008. Originally

ultrasonic agitation, elevated temperature or other cleaning

approved in 1993. Last previous edition approved in 2002 as G122–96(2002).

enhancement features and depends on the manufacturer’s

DOI: 10.1520/G0122-96R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

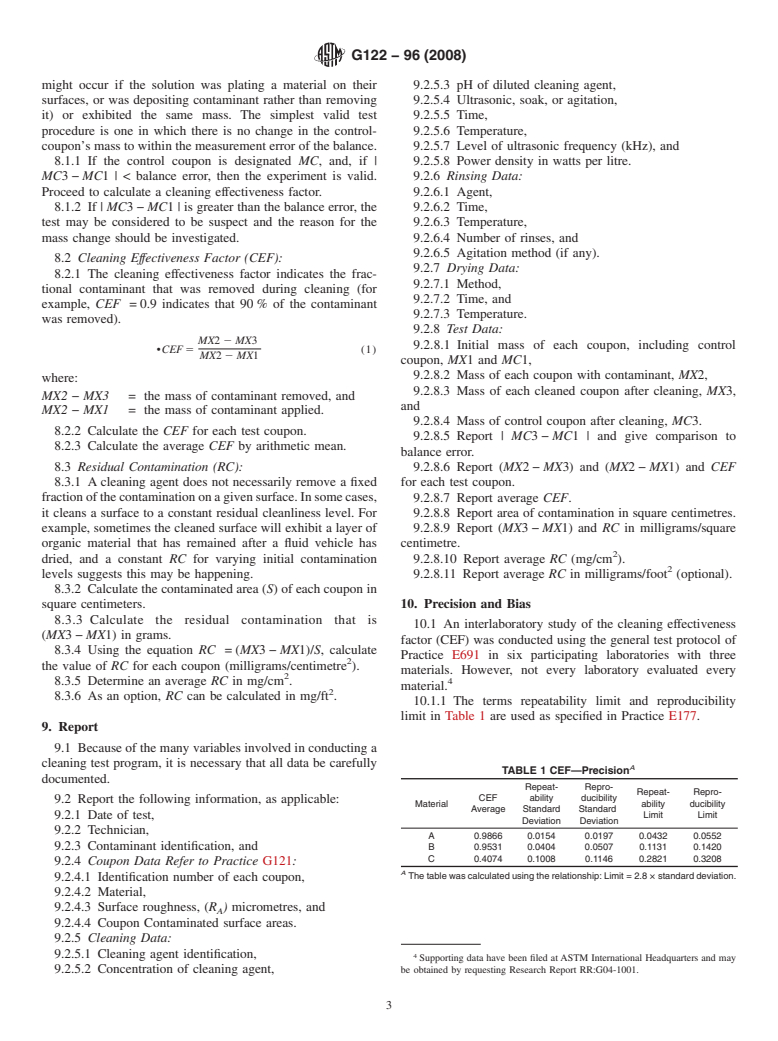

G122 − 96 (2008)

instructions. The effectiveness of the cleaning process is 7.5 Contaminate five test coupons in accordance with Prac-

representedasCEF,thecleaningeffectivenessfactor,thatisthe tice G121.

fraction of the contaminant removed as determined by gravi-

7.6 Measure the mass of all contaminated test coupons

metric techniques.Acontrol coupon is used to account for any

(recording them as MX2 as previously defined).

corrosion or material removal effects due to the cleaning

7.7 Process the control coupon in the test cleaning solution

agent/process.

separately from the contaminated test coupons.

5. Significance and Use

7.8 The contaminated test coupons can be processed in

independent beakers held in the cleaning tank or as a batch in

5.1 The purpose of this test method is to define a procedure

a single beaker.

for evaluating the capability of cleaning agents to clean

metalliccoupons.Basedontheoutcomeofthetesting,suitable

7.9 Clean the test and control coupons in the candidate

cleaningagentsmaybeselectedforcleaningingeneralandfor

cleaning agent by the manufacturer’s procedure or selected

oxygen service in particular.

procedure.

7.9.1 Prepare the cleaning agent in accordance with the

5.2 The cleaning parameters can be changed and the test

manufacturer’s recommendations.

methodcanberepeated.Theusualcleaningparametersinclude

7.9.2 Selectbeakersofsuitablesizetoaccommodatethetest

cleaning agent concentration, temperature, and time; type and

coupons and fit the beaker holder.

strength of ultrasonic energy or agitation, if used, and others.

7.9.3 Washthebeakersthoroughlywithasolutionofliquid,

NOTE 1—Usual cleaning parameters are based on the manufacturer’s

surface-active cleaning agent in hot water and rinse with type

recommendations.

II water.

7.9.4 Fill the beakers with the cleaning agent solution to a

6. Apparatus

level that will ensure the test coupons are submerged.

6.1 Materials:

7.9.5 Fill the cleaning tank to its operating level with the

6.1.1 Test Coupon, prepared in accordance with Practice

transfer fluid and preheat to desired test temperature.

G121.The mass of the coupon is approximately 30 to 45 g but

7.9.6 Place the beakers in the beaker holder in the tank so

will vary significantly for each selected material. Typical

that the liquid levels in the tank and beakers are approximately

materials used in oxygen systems are described in Guide G94.

equal.

6.1.2 Control Coupon—This is uncontaminated and is sub-

7.9.7 Allow the temperatures of the tank fluid and cleaning

jected to the identical cleaning procedure as the contaminated

agent in the beakers to equilibrate at the desired temperature.

coupons and serves to evaluate corrosion, erosion of the test

7.9.8 Suspend the test coupons and control coupon in the

coupons.

cleaning agent, using a wire hook of the same material as the

6.1.3 Cleaning Agent, prepared according to the manufac-

coupon or a compatible material. Position the coupons such

turer’s instructions. Specification D1193Type II water shall be

that they do not touch the beaker or one another.

used for preparing aqueous solutions.

7.9.9 Begin agitation or sonication in the cleaning process

6.2 Equipment: and start the timer.

6.2.1 Cleaning Tank, Avessel of sufficient size to conduct a 7.9.10 Upon completing the required cleaning time, discon-

number of evaluations simultaneously. Testing is enhanced by

tinue the agitation or sonication, and remove the coupons from

having automatic temperature and time controls. A cleaning the cleaning agent.

ta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.