ASTM D2670-95(2016)

(Test Method)Standard Test Method for Measuring Wear Properties of Fluid Lubricants (Falex Pin and Vee Block Method)

Standard Test Method for Measuring Wear Properties of Fluid Lubricants (Falex Pin and Vee Block Method)

SIGNIFICANCE AND USE

5.1 This test method may be used to determine wear obtained with fluid lubricants under the prescribed test conditions. The user of this test method should determine to his or her own satisfaction whether results of this test procedure correlate with field performance or other bench test machines. If the test conditions are changed, wear values may change and relative ratings of fluids may be different.

SCOPE

1.1 This test method covers a procedure for making a preliminary evaluation of the wear properties of fluid lubricants by means of the Falex Pin and Vee Block Lubricant Test Machine.

Note 1: Certain fluid lubricants may require different test parameters depending upon their performance characteristics.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2670 − 95 (Reapproved 2016)

Standard Test Method for

Measuring Wear Properties of Fluid Lubricants (Falex Pin

1

and Vee Block Method)

This standard is issued under the fixed designation D2670; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.1.2 direct load, n—theloadthatisappliedlinearly,bisect-

ing the angle of the vee block corrected to either the 800lbf or

1.1 This test method covers a procedure for making a

3000lbf gauge reference.

preliminaryevaluationofthewearpropertiesoffluidlubricants

3.1.2.1 Discussion—This load is equivalent to the true load

by means of the Falex Pin and Vee Block Lubricant Test

times the cos 42°.

Machine.

3.1.3 true load, n—the sum of the applied forces normal to

NOTE 1—Certain fluid lubricants may require different test parameters

the tangents of contact between the faces of one vee block and

depending upon their performance characteristics.

the journal pin corrected to the 4500lbf gauge reference line.

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

3.1.4 wear teeth, n—a measurement of wear, which in this

as the standard. The values given in parentheses are for

test, is based on the number of ratchet wheel teeth advanced

information only.

during the test while maintaining load.

1.3 This standard does not purport to address all of the

3.1.4.1 Discussion—The number of teeth is directly related

safety concerns, if any, associated with its use. It is the

to the total wear (inches).

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use.

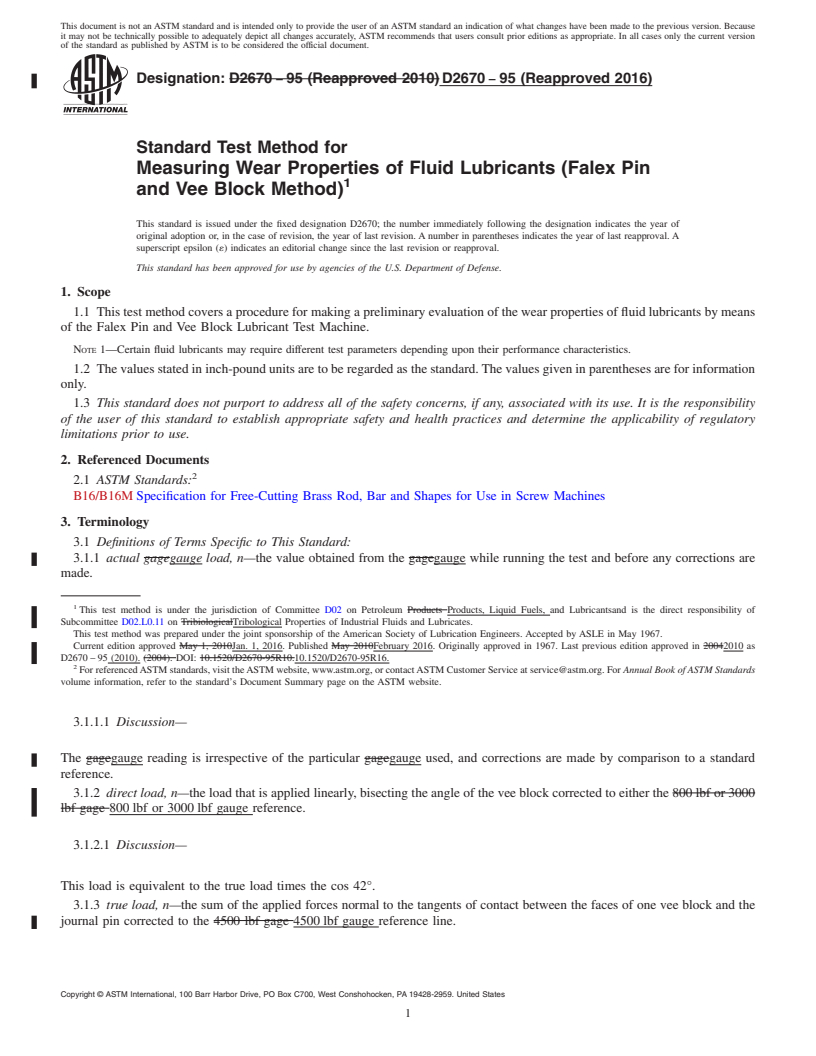

4.1 The test consists of running a rotating steel journal

againsttwostationarysteelV-blocksimmersedinthelubricant

2. Referenced Documents

sample. Load is applied to the V-blocks and maintained by a

2

2.1 ASTM Standards:

ratchet mechanism. Wear is determined and recorded as the

B16/B16MSpecification for Free-Cutting Brass Rod, Bar

numberofteethoftheratchetmechanismadvancedtomaintain

and Shapes for Use in Screw Machines

load constant during the prescribed testing time.

3. Terminology

5. Significance and Use

3.1 Definitions of Terms Specific to This Standard:

5.1 This test method may be used to determine wear

3.1.1 actual gauge load, n—the value obtained from the

obtained with fluid lubricants under the prescribed test condi-

gauge while running the test and before any corrections are

tions. The user of this test method should determine to his or

made.

her own satisfaction whether results of this test procedure

3.1.1.1 Discussion—Thegaugereadingisirrespectiveofthe

correlate with field performance or other bench test machines.

particulargaugeused,andcorrectionsaremadebycomparison

Ifthetestconditionsarechanged,wearvaluesmaychangeand

to a standard reference.

relative ratings of fluids may be different.

1

This test method is under the jurisdiction of Committee D02 on Petroleum

6. Apparatus

Products, Liquid Fuels, and Lubricantsand is the direct responsibility of Subcom-

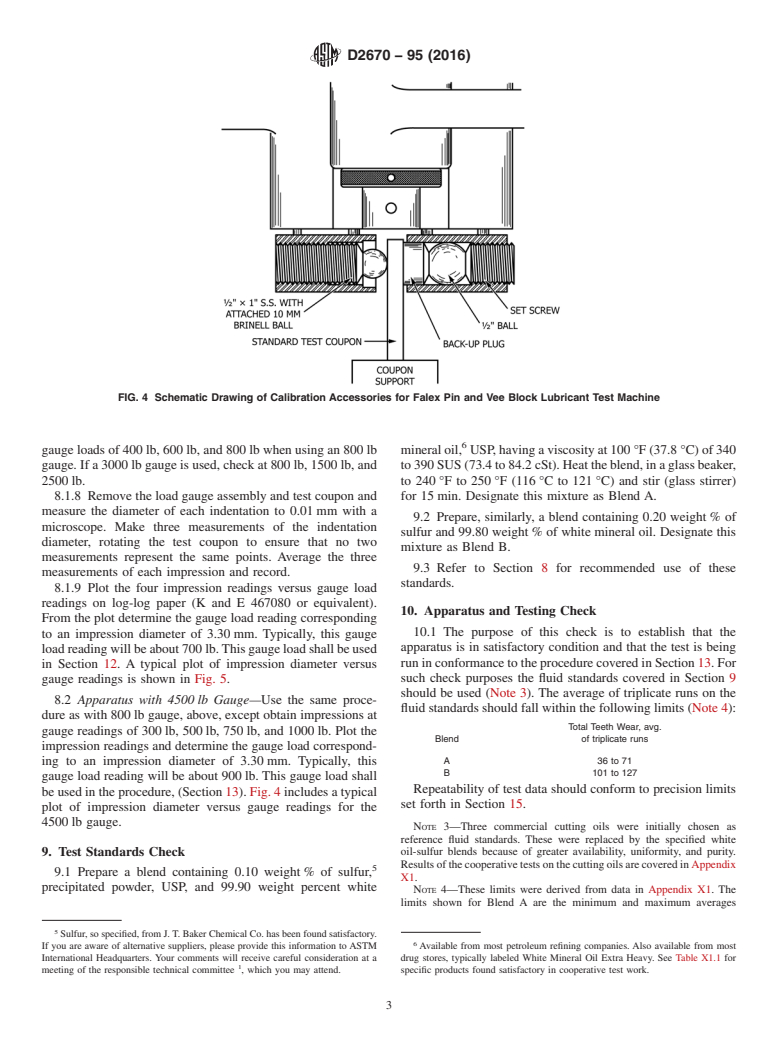

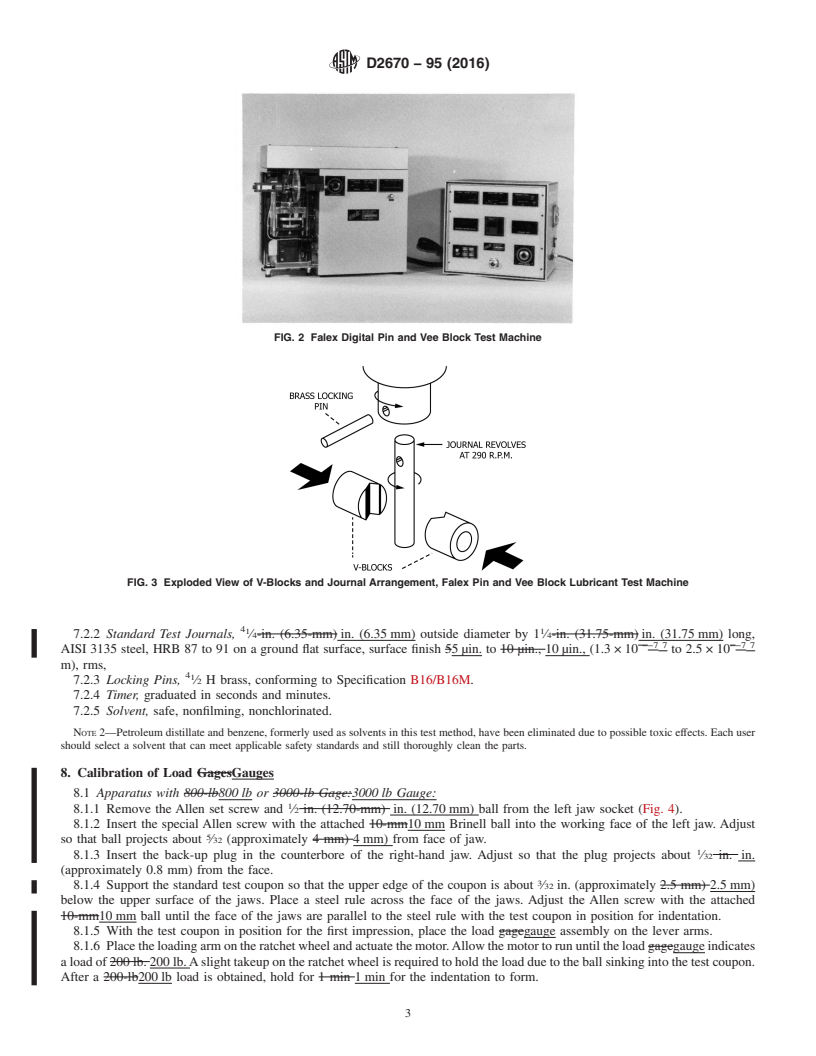

6.1 Falex Pin and Vee Block Lubricant Test Machine,

mittee D02.L0.11 on Tribological Properties of Industrial Fluids and Lubricates.

3

This test method was prepared under the joint sponsorship of the American

illustrated in Figs. 1-3.

Society of Lubrication Engineers. Accepted by ASLE in May 1967.

Current edition approved Jan. 1, 2016. Published February 2016. Originally

approved in 1967. Last previous edition approved in 2010 as D2670–95 (2010).

3

DOI: 10.1520/D2670-95R16. The Falex Pin and Vee Block Test Machine available from Falex Corp., 1020

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Airpark Dr., Sugar Grove, IL60554 has been found satisfactory for this purpose.A

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM new model of this machine has been available since 1983. Certain operating

Standards volume information, refer to the standard’s Document Summary page on procedures are different for this new model. Consult the instruction manual of

the ASTM website. machine for this information.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2670 − 95 (2016)

7. Reagents and Materials

7.1 Required for Calibration of Load Gauge:

4

7.1.1 Allen Screw, with attached 10mm Brinell ball.

4

7.1.2 Back-Up Plug.

4

7.1.3 Standard Test Coupon, soft, annealed copper, HB 37

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2670 − 95 (Reapproved 2010) D2670 − 95 (Reapproved 2016)

Standard Test Method for

Measuring Wear Properties of Fluid Lubricants (Falex Pin

1

and Vee Block Method)

This standard is issued under the fixed designation D2670; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers a procedure for making a preliminary evaluation of the wear properties of fluid lubricants by means

of the Falex Pin and Vee Block Lubricant Test Machine.

NOTE 1—Certain fluid lubricants may require different test parameters depending upon their performance characteristics.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B16/B16M Specification for Free-Cutting Brass Rod, Bar and Shapes for Use in Screw Machines

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 actual gagegauge load, n—the value obtained from the gagegauge while running the test and before any corrections are

made.

1

This test method is under the jurisdiction of Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.L0.11 on TribiologicalTribological Properties of Industrial Fluids and Lubricates.

This test method was prepared under the joint sponsorship of the American Society of Lubrication Engineers. Accepted by ASLE in May 1967.

Current edition approved May 1, 2010Jan. 1, 2016. Published May 2010February 2016. Originally approved in 1967. Last previous edition approved in 20042010 as

D2670 – 95 (2010). (2004). DOI: 10.1520/D2670-95R10.10.1520/D2670-95R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

The gagegauge reading is irrespective of the particular gagegauge used, and corrections are made by comparison to a standard

reference.

3.1.2 direct load, n—the load that is applied linearly, bisecting the angle of the vee block corrected to either the 800 lbf or 3000

lbf gage 800 lbf or 3000 lbf gauge reference.

3.1.2.1 Discussion—

This load is equivalent to the true load times the cos 42°.

3.1.3 true load, n—the sum of the applied forces normal to the tangents of contact between the faces of one vee block and the

journal pin corrected to the 4500 lbf gage 4500 lbf gauge reference line.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2670 − 95 (2016)

3.1.4 wear teeth, n—a measurement of wear, which in this test, is based on the number of ratchet wheel teeth advanced during

the test while maintaining load.

3.1.4.1 Discussion—

The number of teeth is directly related to the total wear (inches).

4. Summary of Test Method

4.1 The test consists of running a rotating steel journal against two stationary steel V-blocks immersed in the lubricant sample.

Load is applied to the V-blocks and maintained by a ratchet mechanism. Wear is determined and recorded as the number of teeth

of the ratchet mechanism advanced to maintain load constant during the prescribed testing time.

5. Significance and Use

5.1 This test method may be used to determine wear obtained with fluid lubricants under the prescribed test conditions. The user

of this test method should determine to his or her own satisfaction whether results of this test procedure correlate with field

performance or other bench test machines. If the test conditions are changed, wear values may change and relative ratings of fluids

may be different.

6. Apparatus

3

6.1 Falex Pin and Vee Block Lubricant Test Machine, illustrated in Figs. 1-3.

7. Reagents and Materials

7.1 Required for C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.