ASTM B946-11

(Test Method)Standard Test Method for Surface Finish of Powder Metallurgy (P/M) Products

Standard Test Method for Surface Finish of Powder Metallurgy (P/M) Products

SIGNIFICANCE AND USE

The surface finish of a component may be critical for certain applications, affecting properties such as wear resistance, fatigue strength, and coefficient of friction.

Surface finish may also be critical for component assembly or system performance. Dimensional fit and mating surface interaction may require certain surface finish requirements to meet performance specifications.

SCOPE

1.1 This test method covers measuring the surface finish of powder metallurgy (PM) products at all stages of manufacturing from green compact to fully hardened finished component.

1.2 This test method provides the definition and schematic of some common surface finish parameters (Ra, Rt, and Rz ISO)

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B946 − 11

StandardTest Method for

1

Surface Finish of Powder Metallurgy (PM) Products

This standard is issued under the fixed designation B946; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope surface interaction may require certain surface finish require-

ments to meet performance specifications.

1.1 This test method covers measuring the surface finish of

powder metallurgy (PM) products at all stages of manufactur-

4. Interferences

ing from green compact to fully hardened finished component.

4.1 Because many conventional PM materials contain open

1.2 This test method provides the definition and schematic

porosity at the surface, special consideration should be taken

of some common surface finish parameters (R,R, and R )

a t zISO

when measuring surface finish.

1.3 The values stated in inch-pound units are to be regarded

4.2 Theuseofaconicalpointstylusmayresultininaccurate

as standard. The values given in parentheses are mathematical

or inconsistent surface finish results because the sharper point

conversions to SI units that are provided for information only

of the stylus may drop into open porosity on the surface of the

and are not considered standard.

component.

1.4 This standard does not purport to address all of the

4.3 A chisel point stylus may be used for better accuracy

safety concerns, if any, associated with its use. It is the

and consistency.

responsibility of the user of this standard to establish appro-

priate safety and health practices and to determine the 4.4 Because the direction of pressing may cause direction-

ality in surface finish values, the direction of measurement

applicability of regulatory limitations prior to use.

should be specified and reported.

2. Referenced Documents

5. Apparatus

2

2.1 ASTM Standards:

5.1 Surface Finish Measuring Instrument.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

5.2 Stylus—Chisel point, 0.050 in. (1.27 mm) length and

3

0.0004 in. 6 30 % (0.010 mm 6 30 %) tip radius as shown in

2.2 MPIF Standard:

Fig. 1. To limit the possibility of the stylus dropping into open

MPIF Standard 58 Method for Determination of Surface

surface porosity, a chisel point stylus is recommended. If a

Finish of Powder Metallurgy Products

cone stylus is used, filtering software shall also be used to

remove the influence of open surface porosity.

3. Significance and Use

3.1 The surface finish of a component may be critical for

6. Sampling, Test Specimens, and Test Units

certain applications, affecting properties such as wear

6.1 The test surface shall be clean and free of any oil, dirt,

resistance, fatigue strength, and coefficient of friction.

debris, or foreign material.

3.2 Surface finish may also be critical for component

6.2 Sufficient surface area shall be available to permit

assembly or system performance. Dimensional fit and mating

multiple traverses by the measuring instrument.

6.3 The test surface shall be flat over a sufficient length (in

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal

accordance with instrument instructions) to allow proper

Powders and Metal Powder Products and is the direct responsibility of Subcom-

movement of the stylus.

mittee B09.05 on Structural Parts.

Current edition approved May 1, 2011. Published May 2011. Originally

7. Procedure

published 2006. Last previous edition published 2010 as B946 – 06 (2010). DOI:

10.1520/B0946-11.

7.1 ThePMpartsmanufacturerandpurchasershallagreeon

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the desired location and direction for surface finish measure-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on ment.

the ASTM website.

3

7.2 Place the surface finish instrument in a position suitable

Metal Powder Industries Federation, 105 College Rd. East, Princeton, NJ

08540-6692 U.S.A. for measuring the test sample.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B946 − 11

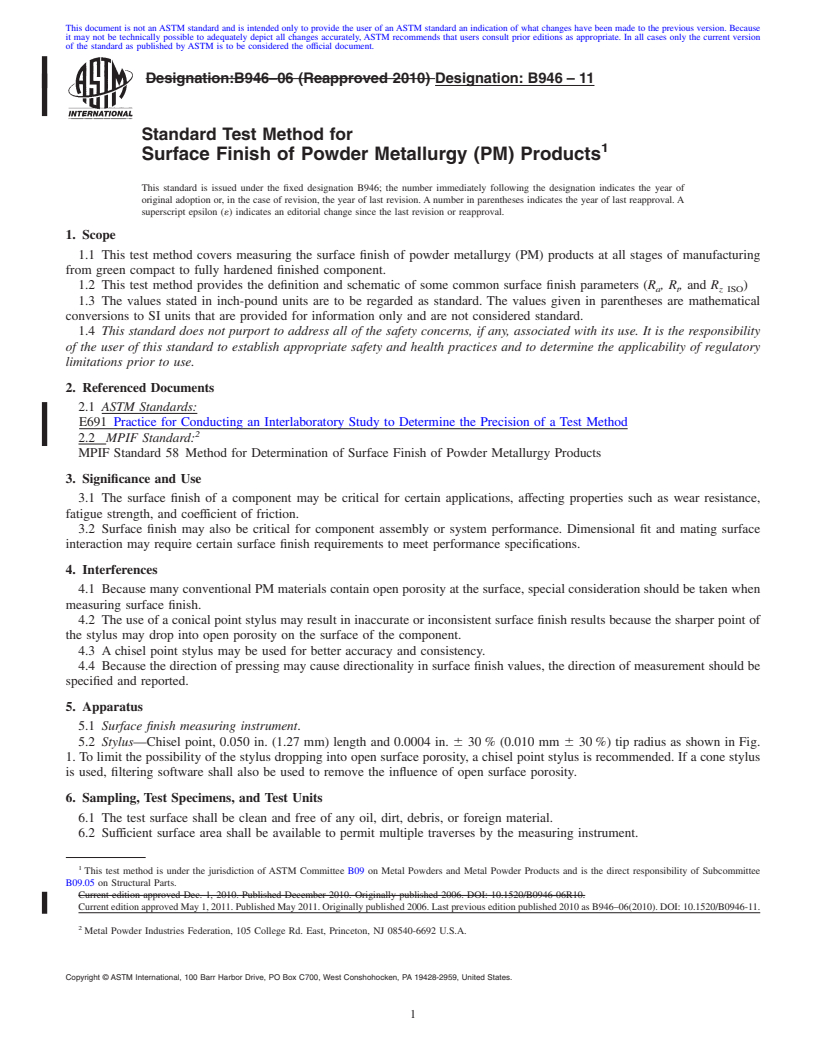

Note 3–The maximum peak-to-valley height of the filtered profile over the

evaluation length l , irrespective of the sampling lengths l .

m e

FIG. 3 R Maximum Peak-to-Valley Height

t

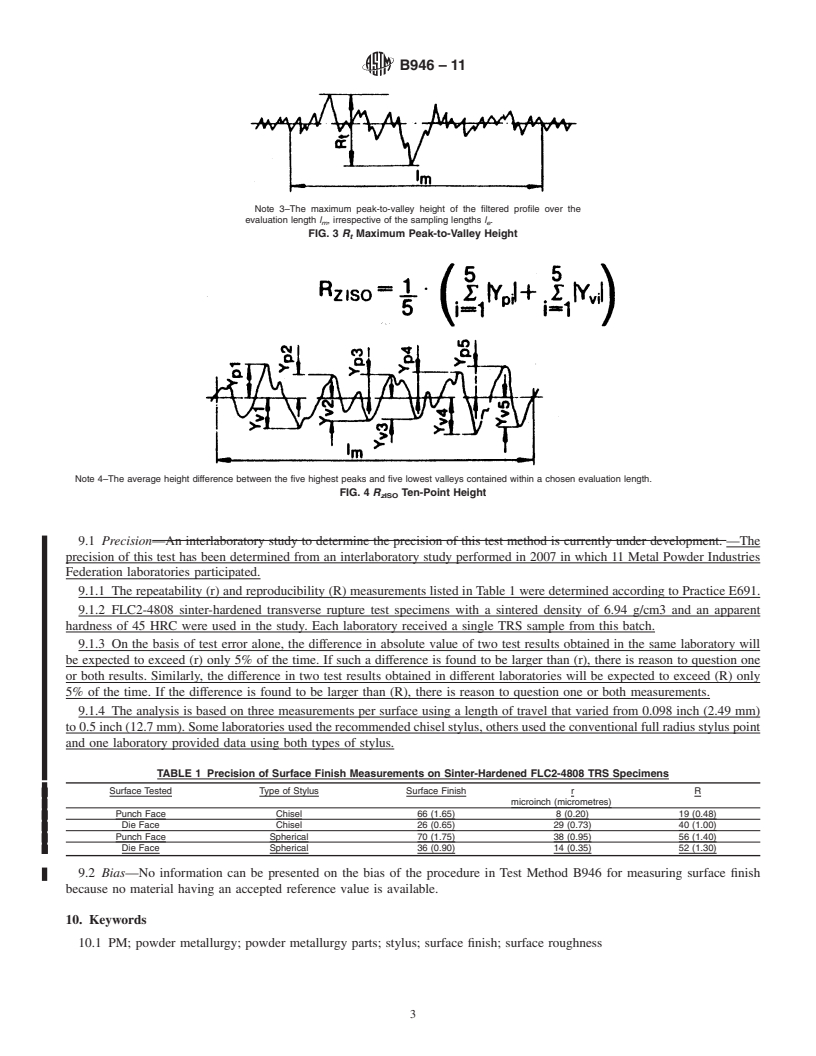

9. Precision and Bias

The Precision for this standard was developed by the Metal

Powder Industries Federation (MPIF) and is used herein with

their permission.

Note 1–The stylus is chisel shaped and has a standard radius on the edge and

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B946–06 (Reapproved 2010) Designation:B946–11

Standard Test Method for

1

Surface Finish of Powder Metallurgy (PM) Products

This standard is issued under the fixed designation B946; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers measuring the surface finish of powder metallurgy (PM) products at all stages of manufacturing

from green compact to fully hardened finished component.

1.2 This test method provides the definition and schematic of some common surface finish parameters (R ,R , and R )

a t z ISO

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2

2.2 MPIF Standard:

MPIF Standard 58 Method for Determination of Surface Finish of Powder Metallurgy Products

3. Significance and Use

3.1 The surface finish of a component may be critical for certain applications, affecting properties such as wear resistance,

fatigue strength, and coefficient of friction.

3.2 Surface finish may also be critical for component assembly or system performance. Dimensional fit and mating surface

interaction may require certain surface finish requirements to meet performance specifications.

4. Interferences

4.1 Because many conventional PM materials contain open porosity at the surface, special consideration should be taken when

measuring surface finish.

4.2 The use of a conical point stylus may result in inaccurate or inconsistent surface finish results because the sharper point of

the stylus may drop into open porosity on the surface of the component.

4.3 A chisel point stylus may be used for better accuracy and consistency.

4.4 Because the direction of pressing may cause directionality in surface finish values, the direction of measurement should be

specified and reported.

5. Apparatus

5.1 Surface finish measuring instrument.

5.2 Stylus—Chisel point, 0.050 in. (1.27 mm) length and 0.0004 in. 6 30 % (0.010 mm 6 30 %) tip radius as shown in Fig.

1. To limit the possibility of the stylus dropping into open surface porosity, a chisel point stylus is recommended. If a cone stylus

is used, filtering software shall also be used to remove the influence of open surface porosity.

6. Sampling, Test Specimens, and Test Units

6.1 The test surface shall be clean and free of any oil, dirt, debris, or foreign material.

6.2 Sufficient surface area shall be available to permit multiple traverses by the measuring instrument.

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal Powders and Metal Powder Products and is the direct responsibility of Subcommittee

B09.05 on Structural Parts.

Current edition approved Dec. 1, 2010. Published December 2010. Originally published 2006. DOI: 10.1520/B0946-06R10.

Current edition approved May 1, 2011. Published May 2011. Originally published 2006. Last previous edition published 2010 as B946–06(2010). DOI: 10.1520/B0946-11.

2

Metal Powder Industries Federation, 105 College Rd. East, Princeton, NJ 08540-6692 U.S.A.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B946–11

Note 1–The stylus is chisel shaped and has a standard radius on the edge and

is 0.050 in. (1.27 mm) wide so that it will not drop into the porosity of the P/M

surface and give a false reading by measuring the cavities.

FIG. 1 Chisel Stylus for Surface Finish Measurement

6.3 The test surface shall be flat over a sufficient length (in accordance with instrument instructions) to allow proper movement

of the stylus.

7. Procedure

7.1 The PM parts manufacturer and purchaser shall agree on the desired location and direction for surface finish measurement.

7.2 Place the surface finish instrument in a positi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.