ASTM B144-70

(Specification)Specification for High-Leaded Tin-Bronze Sand Castings (Withdrawn 1972)

Specification for High-Leaded Tin-Bronze Sand Castings (Withdrawn 1972)

General Information

Standards Content (Sample)

£ndo

~~f~ Designation, B 144 - 70

Amencan Foundrymen's Soc,e1v

Standard Specification for

1

HIGH-LEADED TIN BRONZE SAND CASTINGS

Thi~ Stan~a_rd •~ 1~~ued under lhe fi,ed designati?n B 144: the: number i~r_nedia1c:I~ fnflmqng 1h~ dcs1gna11on md1cutc, the

~car of ongrnal adopuon or. in the ca,;e or rev1s1011, 1hc year or last rev1s1on. A number ,n parenrheSl!s indicate, the: ,car

of la~I reapprov:il. ·

1. Scope 3.3 The castings shall be of uniform qualit) .

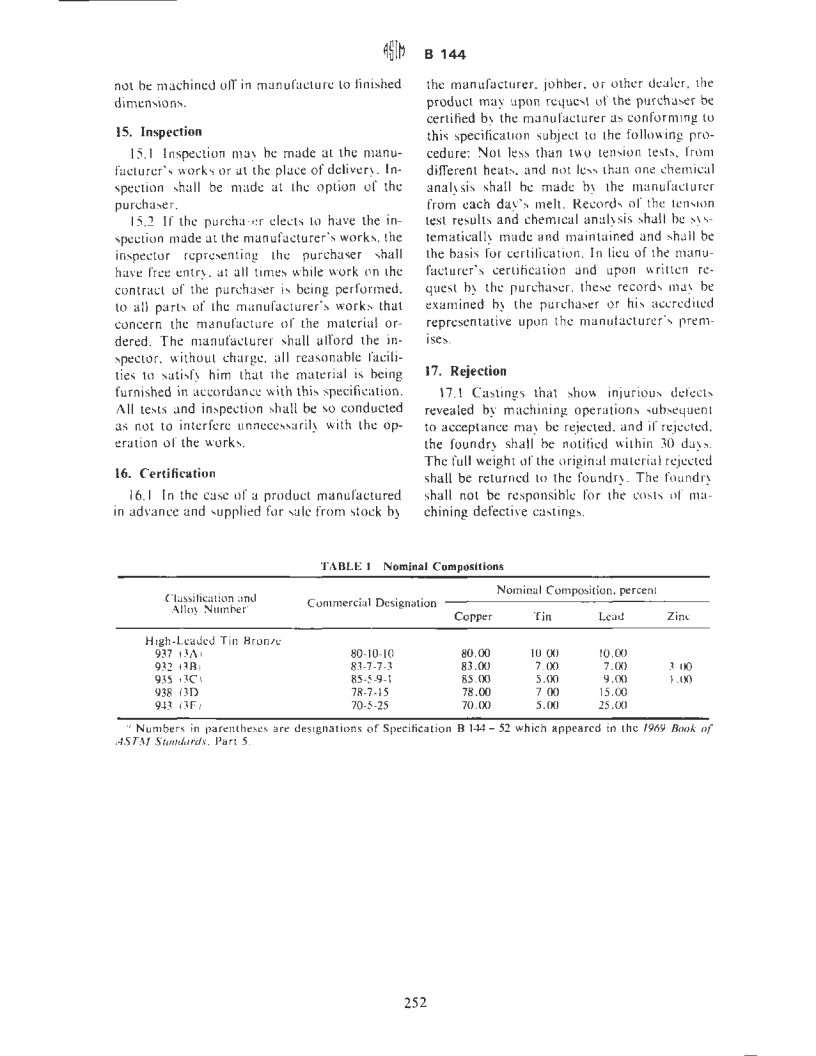

1.1 Th is specification! covers castings of

4. Chemical Composition

five allo)S having the ASTM cla ssifications.'

4. 1 The castings shall conform to the re

alloy numbers' and commercial designations,

quirements as to chemical com position pre•

and nominal composi tions shown in Table I .

scribed in Table 2.

"Jon I- Thi, ~pecitica11on covers the technical

requiremenis fo r copper-base allo~ C-dstings and is

5. Chemic2l Analysh,

nOL intended for u,e for the com:~ponding allo) s in

ingot form which a rc: ~pccified in ASTM Spccifica•

5.1 An analysis of each melt ma) be re

tion B 30. for ~oppcr- Ba.e A.Ila~, in Ingot t=orm for

quired at the option of the purchaser. If the

Sand Ca•aings.

castings are made from ingot metal in accord

l .2 The casting are intended for use for

ance with Specification B 30 or returns (back

conventional bearing~ and bushings in Lhe

stock) of known composition. and if the

cast state. Alloy 937 and 938 are frequently

foundry practice of the manuracturer is atis•

used also for castings which are called upon to

factory to the inspector. and if melting and

resist some of the mild acids such as are found

casting are witnessed by the inspector. he ma)

in mine "'aters.

waive further chemical anal) sis.

~on :! The value, ~lated 1n U.S. customarv

5.2 The sample for chemical anal)::.i,; shall

unib are to he rcgardcd a!'- the standard. Tht met•

be taken by drilling or cutting the test coupon

ric equivalents of U.S custumar) units ma} be ap

proximate. or sprue in such a manner as to be repre!--cnta

tivc of the entire cross section.

2. Ordering Information

6. Methods of Chemical Analysis

2.1 Orders for material under this spedfica

tion shall include the followi ng information:

6. 1 Analyses, when made, shall be per

2. 1.1 Allo) number (Section I).

formed in accordance with AST M Methods

2.1.2 Tests or certification required (Sec E 54, Chemical Anal~sis of Special Brasses

6

tion,; 5. 8. 10. 16). and and Bronzes.

2.1.3 Marking. if required (Section 14).

3. Manufacture

This specifica11on ,, under lh.: Jun-.diction of -\ST\1

3.1 The alloy ma~ be made by any approved

CommiLLec S.5 on Copper and Copper All,>~, .\ h,1 01

method. lf allo~ s in ingot form are used. the members ma> be found 1n the ASTM Yearboo~.

Current edition elfecti\e Feb. 17. 1970. Onem . lh h ·

alloy ingot selected shall have the same ASTM

sued 1941 . Replace:. B 144 5.?. -

" For ASME Boiler :ind Prc:.,urc: v~-.;;cl Code: apphc-a•

classification and allo) number as prescribed

11ons !>Ce related Spec1fic:11ion SB-144 in Sec1i,1n II oi that

in this specification and shall conform to the

Code:.

as prescribed in ASTM Classitica11on B 119. C:a,t Copper-Ba,c: .\ llu~,.

requirements for that alloy

which appears in the A1111110I Buu~ 11/ ASTJI Sra,,dard.1.

Specification B 30.

Part 5.

1

3.2 The castings shall be made in accordThe allO) number) .ire arb11rartl~ ,ho-.en .1nd ha, ~ n~1

olher ,ignificance.

ance with such practice as to obtain the physi

Annual Boo~ ,,( ASTM SrandordJ. Pan 5.

cal properties prescribed in this specification. •· Annual Book 11( ASTM Srundard.~. Pan .t!

250

---------------------- Page: 1 ----------------------

B 144

ance with the specified limits for requirements

7. Tensile Properties

of the properties listed in the following table,

7. I The material shall conform to the re

an observed value or a calculated value, shall

qui remcn ts as to tensi le properties prescribed

be rounded off as indicated in accordance with

in Table 3.

the rounding-off method of ASTM Recom

mended Practice E 29. for Indicating Which

8. Pressure and fracture Tests

Places of Figures Arc to Be Consider_ed Sig

8. 1 The castings made from these alloys

nificant in Specified Limiting Values.'

shall conform to such requirements as to pres

Rounded-Off Unn for

Proper!~

sure and fracture tests as may be agreed upon Observed or

Culculated Value

by the manufacturer and the purchaser and as

neare,t unit In the la~t

Chemical cornp,hition

specified in the order.

right-hand place of

figure,

nearest 1000 psi (nc:are~t

Tcn,ile strenith

9. Test Specimens

0.1 kgf /mm )

Yield strength

neare~I multiple of0.5 per9.1 It is recommended that the lest coupons

F.longation: Below 5

cent

percent

and specimens for tension le ts be prepared

nearc~t I percent

<, percent and o,cr

in accordance with ASTM Recommended

Practice B 208. for Tension Test Specimens

13. Workmanship and Finish

for Copp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.