ASTM E1067/E1067M-11

(Practice)Standard Practice for Acoustic Emission Examination of Fiberglass Reinforced Plastic Resin (FRP) Tanks/Vessels

Standard Practice for Acoustic Emission Examination of Fiberglass Reinforced Plastic Resin (FRP) Tanks/Vessels

SIGNIFICANCE AND USE

The AE examination method detects damage in FRP equipment. The damage mechanisms that are detected in FRP are as follows: resin cracking, fiber debonding, fiber pullout, fiber breakage, delamination, and bond failure in assembled joints (for example, nozzles, manways, etc.). Flaws in unstressed areas and flaws that are structurally insignificant will not generate AE.

This practice is convenient for on-line use under operating stress to determine structural integrity of in-service equipment usually with minimal process disruption.

Indications located with AE should be examined by other techniques; for example, visual, ultrasound, dye penetrant, etc., and may be repaired and tested as appropriate. Repair procedure recommendations are outside the scope of this practice.

SCOPE

1.1 This practice covers acoustic emission (AE) examination or monitoring of fiberglass-reinforced plastic (FRP) tanks-vessels (equipment) under pressure or vacuum to determine structural integrity.

1.2 This practice is limited to tanks-vessels designed to operate at an internal pressure no greater than 1.73 MPa absolute [250 psia] above the static pressure due to the internal contents. It is also applicable for tanks-vessels designed for vacuum service with differential pressure levels between 0 and 0.10 MPa [0 and 14.5 psi].

1.3 This practice is limited to tanks-vessels with glass contents greater than 15 % by weight.

1.4 This practice applies to examinations of new and in-service equipment.

1.5 Units—The values stated in either SI units or inch-pound units are to be regarded as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (For more specific safety precautionary information see 8.1.)

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1067/E1067M − 11

Standard Practice for

Acoustic Emission Examination of Fiberglass Reinforced

1

Plastic Resin (FRP) Tanks/Vessels

ThisstandardisissuedunderthefixeddesignationE1067/E1067M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D5436Specification for Cast Poly(Methyl Methacrylate)

Plastic Rods, Tubes, and Shapes

1.1 This practice covers acoustic emission (AE) examina-

E543Specification forAgencies Performing Nondestructive

tionormonitoringoffiberglass-reinforcedplastic(FRP)tanks-

Testing

vessels (equipment) under pressure or vacuum to determine

E650Guide for Mounting Piezoelectric Acoustic Emission

structural integrity.

Sensors

1.2 This practice is limited to tanks-vessels designed to

E750Practice for Characterizing Acoustic Emission Instru-

operate at an internal pressure no greater than 1.73 MPa

mentation

absolute[250psia]abovethestaticpressureduetotheinternal

E1316Terminology for Nondestructive Examinations

contents. It is also applicable for tanks-vessels designed for

E2075Practice for Verifying the Consistency of AE-Sensor

vacuum service with differential pressure levels between 0 and

Response Using an Acrylic Rod

0.10 MPa [0 and 14.5 psi].

E2374Guide for Acoustic Emission System Performance

1.3 This practice is limited to tanks-vessels with glass Verification

contents greater than 15% by weight.

2.2 ANSI/ASNT Standards:

SNT-TC-1A Recommended Practice for Nondestructive

1.4 This practice applies to examinations of new and in-

3

Testing Personnel Qualification and Certification

service equipment.

ANSI/ASNT CP-189Standard for Qualification and Certifi-

1.5 Units—The values stated in either SI units or inch-

3

cation of Nondestructive Testing Personnel

poundunitsaretoberegardedasstandard.Thevaluesstatedin

2.3 AIA Standard:

each system may not be exact equivalents; therefore, each

NAS-410Certification and Qualification of Nondestructive

system shall be used independently of the other. Combining

4

Personnel (Quality Assurance Committee)

values from the two systems may result in non-conformance

with the standard.

3. Terminology

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.1 Complete definitions of terms related to plastics and

acoustic emission will be found in Terminology D883 and

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- E1316.

bility of regulatory limitations prior to use. (For more specific

3.2 Definitions of Terms Specific to This Standard:

safety precautionary information see 8.1.)

3.2.1 FRP—fiberglass reinforced plastic, a glass-fiber poly-

mer composite with certain mechanical properties superior to

2. Referenced Documents

those of the base resin.

2

2.1 ASTM Standards:

3.2.2 operating pressure—the pressure at the top of a vessel

D883Terminology Relating to Plastics

at which it normally operates. It shall not exceed the design

pressure and it is usually kept at a suitable level below the

setting of the pressure-relieving devices to prevent their

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

frequent opening.

structive Testing and is the direct responsibility of Subcommittee E07.04 on

Acoustic Emission Method.

CurrenteditionapprovedJuly1,2011.PublishedJuly2011.Originallyapproved

in 1985. Last previous edition approved in 2007 as E1067-07. DOI: 10.1520/

3

E1067-11. AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

Standards volume information, refer to the standard’s Document Summary page on WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1067/E1067M − 11

3.2.3 pressure, design—the pressure used in design to de- ANSI/ASNT-CP-189, SNT-TC-1A, NAS-410, or a similar

termine the required minimum thicknesses and minimum document and certified by the employer or certifying agency,

mechanical properties. as applicable. The practice or standard used and its applicable

revision shall be identified in the contractual agreement b

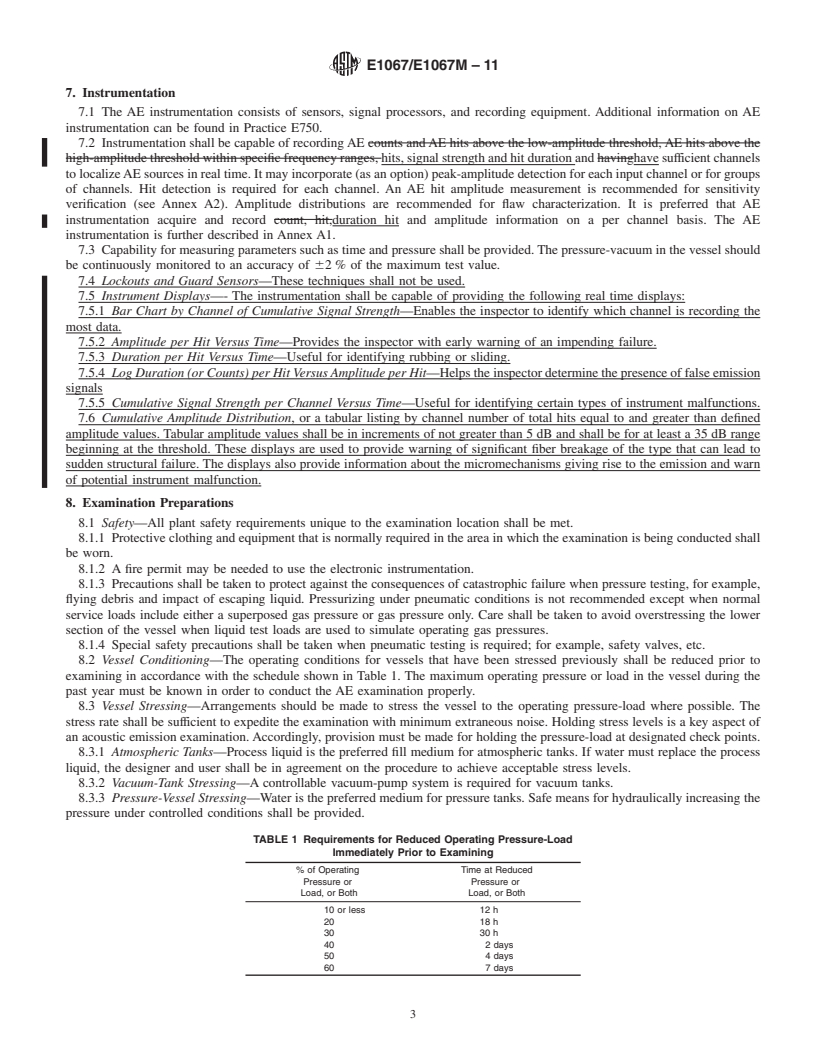

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1067–07 Designation:E1067/E1067M–11

Standard Practice for

Acoustic Emission Examination of Fiberglass Reinforced

1

Plastic Resin (FRP) Tanks/Vessels

ThisstandardisissuedunderthefixeddesignationE1067/E1067M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers acoustic emission (AE) examination or monitoring of fiberglass-reinforced plastic (FRP) tanks-vessels

(equipment) under pressure or vacuum to determine structural integrity.

1.2 This practice is limited to tanks-vessels designed to operate at an internal pressure no greater than 0.441.73 MPa absolute

(65psia)[250psia]abovethestaticpressureduetotheinternalcontents.Itisalsoapplicablefortanks-vesselsdesignedforvacuum

service with differential pressure levels between 0 and 0.060.10 MPa (0[0 and 9 psi). 14.5 psi].

1.3 This practice is limited to tanks-vessels with glass contents greater than 15% by weight.

1.4 This practice applies to examinations of new and in-service equipment.

1.5The values stated in SI units are to be regarded as standard. The inch-pound units in parentheses may be approximate.

1.5 Units—The values stated in either SI units or inch-pound units are to be regarded as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. (For more specific safety precautionary information see 8.1.)

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D5436 Specification for Cast Poly(Methyl Methacrylate) Plastic Rods, Tubes, and Shapes

E543 Specification for Agencies Performing Nondestructive Testing

E650 Guide for Mounting Piezoelectric Acoustic Emission Sensors

E750 Practice for Characterizing Acoustic Emission Instrumentation

E1316 Terminology for Nondestructive Examinations

E2075 Practice for Verifying the Consistency of AE-Sensor Response Using an Acrylic Rod

E2374 Guide for Acoustic Emission System Performance Verification

2.2 ANSI/ASNT Standards:

3

SNT-TC-1A Recommended Practice for Nondestructive Testing Personnel Qualification and Certification

3

ANSI/ASNT CP-189 Standard for Qualification and Certification of Nondestructive Testing Personnel

2.3 AIA Standard:

4

NAS-410 Certification and Qualification of Nondestructive Personnel (Quality Assurance Committee)

3. Terminology

3.1 Complete definitions of terms related to plastics and acoustic emission will be found in Terminology D883 and E1316.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 count value N —an evaluation criterion based on the total number of AE counts. (See A2.4 of Annex A2.)

c

1

ThispracticeisunderthejurisdictionofASTMCommitteeE07onNondestructiveTestingandisthedirectresponsibilityofSubcommitteeE07.04onAcousticEmission

Method.

Current edition approved Feb. 15, 2007. Published March 2007. Originally approved in 1985. Last previous edition approved in 2001 as E1067-01. DOI:

10.1520/E1067-07.

Current edition approved July 1, 2011. Published July 2011. Originally approved in 1985. Last previous edition approved in 2007 as E1067-07. DOI: 10.1520/E1067-11.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

4

Available from Aerospace Industries Association of America, Inc. (AIA), 1000 Wilson Blvd., Suite 1700, Arlington, VA 22209-3928, http://www.aia-aerospace.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1067/E1067M–11

3.2.2FRP—fiberglassreinforcedplastic,aglass-fiberpolymercomposi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.