ASTM E1267-88

(Guide)Guide for ASTM Standard Specification Quality Statements (Withdrawn 1996)

Guide for ASTM Standard Specification Quality Statements (Withdrawn 1996)

SCOPE

1.1 This guide is intended as a reference to assist ASTM technical committees and subcommittees addressing quality statements in product specifications under their jurisdiction.

1.2 It is recognized that quality provisions are not required in every standard specification. Lack of a quality provision does not indicate a deficiency in the standard.

1.3 This guide addresses the following areas and provides a check list of factors to be considered for each topic: calibration and measurement; inspection and testing; handling, storage, preservation, and shipping; nonconforming materials; and documentation.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: E 1267 – 88

Standard Guide for

ASTM Standard Specification Quality Statements

This standard is issued under the fixed designation E 1267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This guide is intended as a reference to assist ASTM 3.1 Definitions—Refer to Terminology E 456 for definition

technical committees and subcommittees addressing quality of terms other than those listed in 3.2 which are used in this

statements in product specifications under their jurisdiction. standard guide.

1.2 It is recognized that quality provisions are not required 3.2 Definitions of Terms Specific to This Standard:

in every standard specification. Lack of a quality provision 3.2.1 calibration—comparison of a measurement standard

does not indicate a deficiency in the standard. or instrument of known bias with another standard or instru-

1.3 This guide addresses the following areas and provides a ment to detect, report, and/or minimize by adjustment any

check list of factors to be considered for each topic: calibration unacceptably large bias of the item being compared.

and measurement; inspection and testing; handling, storage, 3.2.2 traceability (calibration sense)—the ability to relate

preservation, and shipping; nonconforming materials; and individual measurement results to national standards or nation-

documentation. ally accepted measurement systems through an unbroken chain

1.4 This standard may involve hazardous materials, opera- of comparisons (see MIL-STD 45662).

tions, and equipment. This standard does not purport to 3.2.3 raw material—any material intended to undergo

address all of the safety problems associated with its use. It is change when introduced into the process.

the responsibility of the user of this standard to establish 3.2.4 component—any material that is incorporated into the

appropriate safety and health practices and determine the final product without undergoing any significant change in the

applicability of regulatory limitations prior to use. Table 1 manufacturing process.

NOTE 1—Components, (for example, electrical cables, plastic connec-

2. Referenced Documents

tors), generally require control measures equivalent to those needed for

2.1 ASTM Standards:

the final product.

E 177 Practice for Use of the Terms Precision and Bias in

3.2.5 nonconformance—deviation of a material to some

ASTM Test Methods

degree from one or more of the technical requirements of a

2.2 ANSI/ASQC Standard:

standard.

M-1 Calibration Systems

2.3 Military Standards: NOTE 2—Conformance or nonconformance is an either/or determina-

tion, without regard to the degree to which a product may deviate from

MIL-I-45208 Inspection Systems Requirements

4 specified limits. An individual item may be nonconforming, and must be

MIL-Q-9858 Quality Program Requirements

treated as such, even if it comes from a lot which meets an agreed

MIL-Q-21549 Product Quality Program Requirements for

sampling plan acceptance limit.

Fleet Missile Weapon Systems Contractors

3.2.6 fitness for use—suitabilityofaproductforitsintended

MIL-STD-45662 Calibration System Requirements

use.

Military Handbook 52A (Interpretation of MIL-STD-

45662)

NOTE 3—Fitness for use is a somewhat subjective concept in which

degree of deviation from optimum becomes important, and may not relate

directly to conformance or nonconformance.

This guide is under the jurisdiction of ASTM Committee E-11 on Quality and

Statistics in ASTM Standards and is the direct responsibility of Subcommittee

4. Significance and Use

E11.10 on Quality Document Preparation.

4.1 In view of the great diversity ofASTM specifications, it

Current edition approved Nov. 1, 1988. Published January 1989.

Annual Book of ASTM Standards, Vol 14.02. is not feasible to recommend a single set of suitable quality

Available from Society for Quality Control, 310 W. Wisconsin Ave., Milwau-

statements, nor even to develop a small number of statements

kee, WI 53203.

with rules for selection. Each committee or subcommittee must

Available from Naval Publications and Forms Center, 5801 Tabor Ave.,

consider the need for quality statements for its specifications.

Philadelphia, PA 19120.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

E1267–88

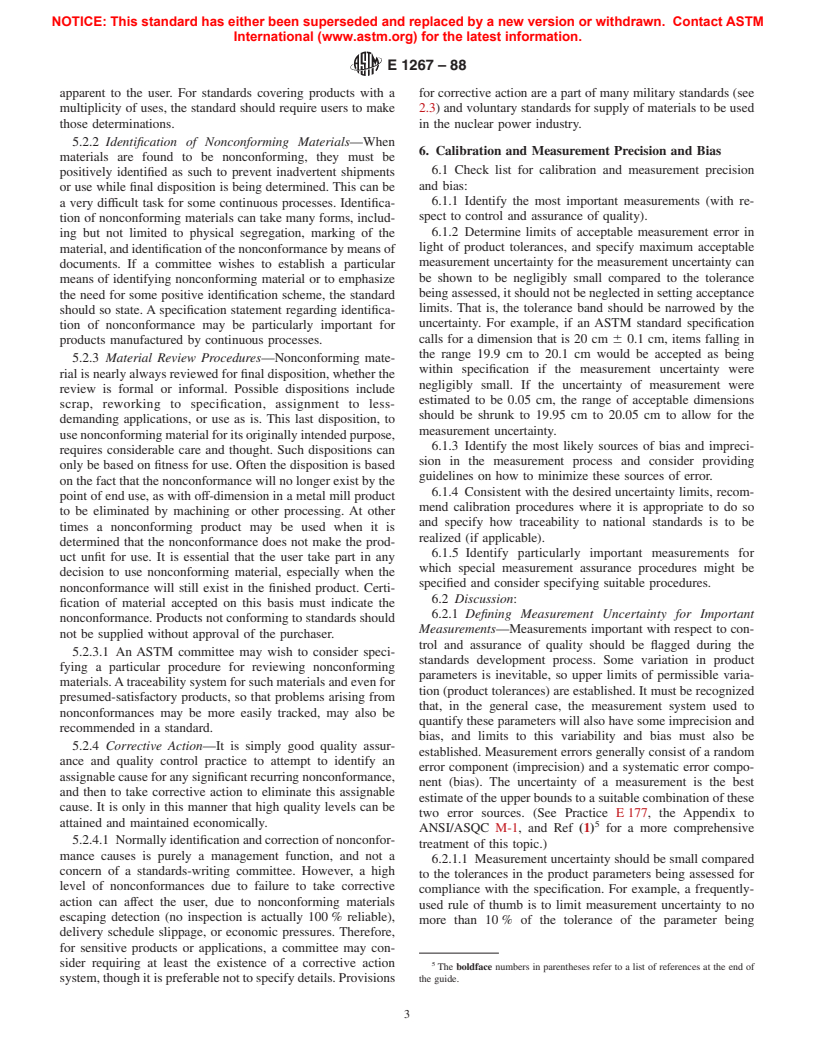

TABLE 1 Checklist to Determine the Consistency of Any ASTM Standard With E-46 Guidelines and ASTM Form and Style Manual

(Blue Book)

Note—This checklist is based on the “Standard Guide for ASTM Standard Specification Quality Statements” developed by ASTM Committee E-46. It is intended

to be used by ASTM Technical Committees and Subcommittees in addressing quality statements in product specifications under their jurisdiction. This guide calls

attention to issues that should be considered when developing specification quality statements. Reviewers of ASTM standard specifications may use this checklist to

identify whether quality statements have been considered and whether their use agrees with the principles of this guide.

Instructions—Each item of the checklist requires one of four responses. Place one checkmark after each item under the appropriate column.

(1) Not applicable;

(2) Not addressed, but should be;

(3) Addressed, but review is recommended; or

(4) Adequately addressed.

1. Calibration and Measurement Precision and Bias

(a) Limits of acceptable error quantified. __ __ __ __

(b) Recommendations to minimize bias relative to national measurement standards (“traceability to NBS”) identified. __ __ __ __

(c) Recommendations for particular instruments, standards reference materials, calibration methods, calibration points, or __ __ __ __

other factors identified.

(e) Comprehensive measurement quality assurance program specified. __ __ __ __

2. Inspection and Testing

(a) Characteristics to be inspected or tested identified. __ __ __ __

(b) Method of sampling defined. __ __ __ __

(c) Special inspection, preparation, and test procedures addressed. __ __ __ __

(d) Environmental requirements for inspection and testing addressed. __ __ __ __

(e) Equipment identified by type. __ __ __ __

(f) Required precision and calibration, personnel certification requirements identified. __ __ __ __

3. Handling

(a) Measures to maintain quality and condition of products addressed. __ __ __ __

(b) Measures to prevent mixups addressed. __ __ __ __

4. Storage and Preservation

(a) Specification or control of environmental conditions addressed. __ __ __ __

(b) Protective measures to maintain quality and conditions of materials in storage addressed. __ __ __ __

(c) If quality or fitness for use of product deteriorates over time, control measures addressed. __ __ __ __

(d) Measures to prevent mixups addressed. __ __ __ __

5. Shipping

(a) Protective measures to maintain quality and condition in shipment addressed. __ __ __ __

(b) Regulatory requirements pertaining to markings on packaging and information on shipping documents addressed. __ __ __ __

(c) Inclusion of technical documents or instructions with shipments is appropriate and measures to ensure their inclusion __ __ __ __

addressed.

(d) Measures to prevent mixups addressed. __ __ __ __

6. Nonconforming Materials

(a) Aspects of a standard where nonconformance of the material would be most serious identified. __ __ __ __

(b) Requirements for marking, segregating, or otherwise identifying nonconforming materials to prevent inadvertent use __ __ __ __

addressed.

(c) Formal material review procedures to provide for disposition of nonconforming materials, notification to users, and __ __ __ __

traceability of nonconforming items addressed.

(d) Requirements to investigate for assignable causes and institute corrective actions addressed. __ __ __ __

7. Documentation

(a) Documenting quality of supplies and/or raw materials addressed. __ __ __ __

(b) In-process quality testing, and documentation of such testing addressed. __ __ __ __

(c) Documentation of final product testing addressed. __ __ __ __

(d) Documentation of product quality to be provided to the user addressed. __ __ __ __

(e) Audit of the vendor’s facilities by the buyer or other interested party be required or encouraged addressed. __ __ __ __

This guide is intended to simplify the process by calling 5.1.4 Consider need for requirements to investigate for

attention to the considerations that should enter into develop- assignable causes and institute corrective actions.

ment of specification quality statements. 5.2 Discussions:

5.2.1 Importance of Conformance—Ideally, all products

5. Nonconforming Materials

conform to all aspects of the standards to which they are

5.1 Check List for Nonconforming Materials: manufactured. However, in all standards, some characteristics

5.1.1 Identify the aspects of a standard where nonconfor- aremoreimportantthanotherstofinalservice.Identificationof

mance of the material would be most serious. the most important characteristics by the standards-writing

5.1.2 Consider requirements for marking, segregating, or committees helps to focus manufacturing and inspection atten-

otherwise identifying nonconforming materials to prevent tion where it is most needed, and helps guide material review

inadvertent use. and user decisions regarding possible fitness for use when

5.1.3 Consider need for formal material review procedures nonconformances are found. It is particularly important to

to provide for disposition of nonconforming materials, notifi- identify latent or hidden characteristics of importance, as

cation to users, and traceability of nonconforming items, and nonconformances in such characteristics may not be readily

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

E1267–88

apparent to the user. For standards covering products with a for corrective action are a part of many military standards (see

multiplicity of uses, the standard should require users to make 2.3) and voluntary standards for supply of materials to be used

those determinations. in the nuclear power industry.

5.2.2 Identification of Nonconforming Materials—When

6. Calibration and Measurement Precision and Bias

materials are found to be nonconforming, they must be

6.1 Check list for calibration and measurement precision

positively identified as such to prevent inadvertent shipments

and bias:

or use while final disposition is being determined. This can be

6.1.1 Identify the most important measurements (with re-

a very difficult task for some continuous processes. Identifica-

spect to control and assurance of quality).

tion of nonconforming materials can take many forms, includ-

6.1.2 Determine limits of acceptable measurement error in

ing but not limited to physical segregation, marking of the

light of product tolerances, and specify maximum acceptable

material,andidentificationofthenonconformancebymeansof

measurement uncertainty for the measurement uncertainty can

documents. If a committee wishes to establish a particular

be shown to be negligibly small compared to the tolerance

means of identifying nonconforming material or to emphasize

being assessed, it should not be neglected in setting acceptance

the need for some positive identification scheme, the standard

limits. That is, the tolerance band should be narrowed by the

should so state. A specification statement regarding identifica-

uncertainty. For example, if an ASTM standard specification

tion of nonconformance may be particularly important for

calls for a dimension that is 20 cm 6 0.1 cm, items falling in

products manufactured by continuous processes.

the range 19.9 cm to 20.1 cm would be accepted as being

5.2.3 Material Review Procedures—Nonconforming mate-

within specification if the measurement uncertainty were

rial is nearly always reviewed for final disposition, whether the

negligibly small. If the uncertainty of measurement were

review is formal or informal. Possible dispositions include

estimated to be 0.05 cm, the range of acceptable dimensions

scrap, reworking to specification, assignment to less-

should be shrunk to 19.95 cm to 20.05 cm to allow for the

demanding applications, or use as is. This last disposition, to

measurement uncertainty.

usenonconformingmaterialforitsoriginallyintendedpurpose,

6.1.3 Identify the most likely sources of bias and impreci-

requires considerable care and thought. Such dispositions can

sion in the measurement process and consider providing

only be based on fitness for use. Often the disposition is based

guidelines on how to minimize these sources of error.

on the fact that the nonconformance will no longer exist by the

6.1.4 Consistent with the desired uncertainty limits, recom-

point of end use, as with off-dimension in a metal mill product

mend calibration procedures where it is appropriate to do so

to be eliminated by machining or other processing. At other

and specify how traceability to national standards is to be

times a nonconforming product may be used when it is

realized (if applicable).

determined that the nonconformance does not make the prod-

6.1.5 Identify particularly important measurements for

uct unfit for use. It is essential that the user take part in any

which special measurement assurance procedures might be

decision to use nonconforming material, especially when the

specified and consider specifying suitable procedures.

nonconformance will still exist in the finished product. Certi-

6.2 Discussion:

fication of material accepted on this basis must indicate the

6.2.1 Defining Measurement Uncertainty for Important

nonconformance. Products not conforming to standards should

Measurements—Measurements important with respect to con-

not be supplied without approval of the purchaser.

trol and assurance of quality should be flagged during the

5.2.3.1 An ASTM committee may wish to consider speci-

standards development process. Some variation in product

fying a particular procedure for reviewing nonconforming

parameters is inevitable, so upper limits of permissible varia-

materials.Atraceability system for such materials and even for

tion (product tolerances) are established. It must be recognized

presumed-satisfactory products, so that problems arising from

that, in the general case, the measurement system used to

nonconforma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.