ASTM A65-87(1995)

(Specification)Standard Specification for Steel Track Spikes

Standard Specification for Steel Track Spikes

SCOPE

1.1 This specification covers steel track spikes used as fastenings between railroad rails, tie plates, and ties.

1.2 Two grades of spikes are described, Grades 1 and 2, previously known as "soft" and "high carbon" steel.

1.3 Supplementary Requirement (S1) specifying copper content is provided. It shall apply only when specified by the purchaser.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 65 – 87 (Reapproved 1995)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Steel Track Spikes

This standard is issued under the fixed designation A 65 ; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

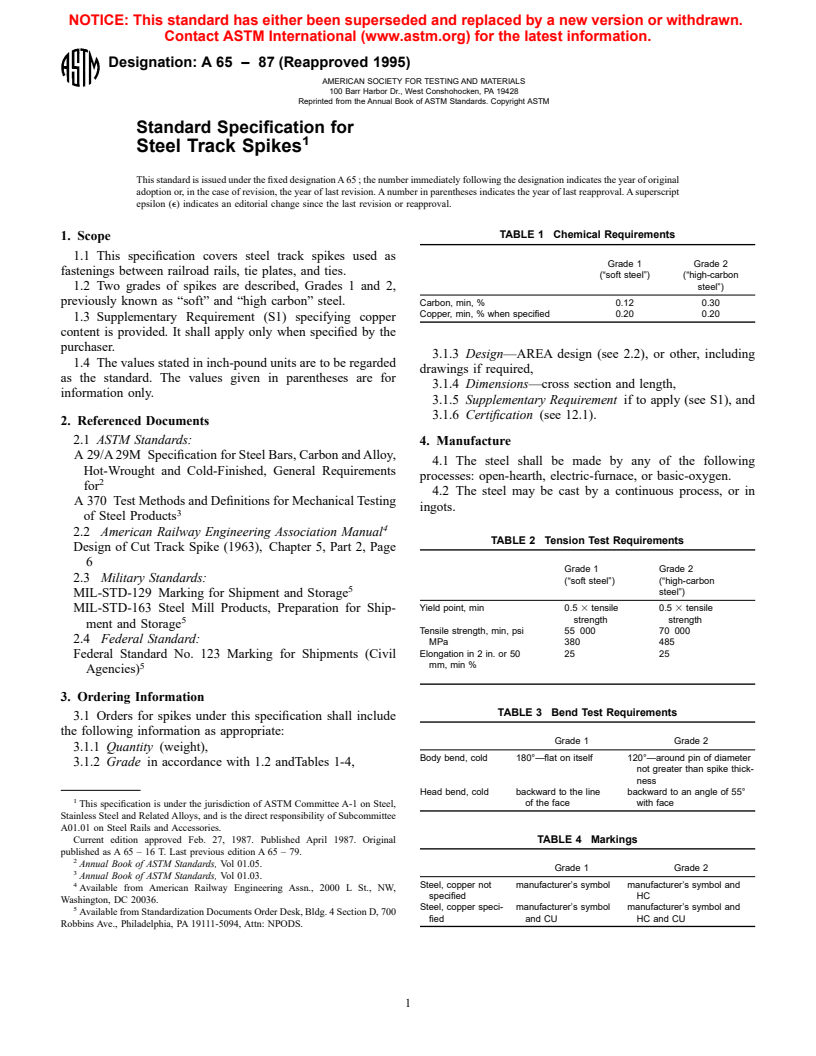

TABLE 1 Chemical Requirements

1. Scope

1.1 This specification covers steel track spikes used as

Grade 1 Grade 2

fastenings between railroad rails, tie plates, and ties.

(“soft steel”) (“high-carbon

1.2 Two grades of spikes are described, Grades 1 and 2, steel”)

previously known as “soft” and “high carbon” steel. Carbon, min, % 0.12 0.30

Copper, min, % when specified 0.20 0.20

1.3 Supplementary Requirement (S1) specifying copper

content is provided. It shall apply only when specified by the

purchaser.

3.1.3 Design—AREA design (see 2.2), or other, including

1.4 The values stated in inch-pound units are to be regarded

drawings if required,

as the standard. The values given in parentheses are for

3.1.4 Dimensions—cross section and length,

information only.

3.1.5 Supplementary Requirement if to apply (see S1), and

3.1.6 Certification (see 12.1).

2. Referenced Documents

2.1 ASTM Standards:

4. Manufacture

A 29/A 29M Specification for Steel Bars, Carbon and Alloy,

4.1 The steel shall be made by any of the following

Hot-Wrought and Cold-Finished, General Requirements

processes: open-hearth, electric-furnace, or basic-oxygen.

2

for

4.2 The steel may be cast by a continuous process, or in

A 370 Test Methods and Definitions for Mechanical Testing

ingots.

3

of Steel Products

4

2.2 American Railway Engineering Association Manual

TABLE 2 Tension Test Requirements

Design of Cut Track Spike (1963), Chapter 5, Part 2, Page

6

Grade 1 Grade 2

2.3 Military Standards:

(“soft steel”) (“high-carbon

5

steel”)

MIL-STD-129 Marking for Shipment and Storage

Yield point, min 0.5 3 tensile 0.5 3 tensile

MIL-STD-163 Steel Mill Products, Preparation for Ship-

5

strength strength

ment and Storage

Tensile strength, min, psi 55 000 70 000

2.4 Federal Standard:

MPa 380 485

Elongation in 2 in. or 50 25 25

Federal Standard No. 123 Marking for Shipments (Civil

5 mm, min %

Agencies)

3. Ordering Information

TABLE 3 Bend Test Requirements

3.1 Orders for spikes under this specification shall include

the following information as appropriate:

Grade 1 Grade 2

3.1.1 Quantity (weight),

Body bend, cold 180°—flat on itself 120°—around pin of diameter

3.1.2 Grade in accordance with 1.2 andTables 1-4,

not greater than spike thick-

ness

Head bend, cold backward to the line backward to an angle of 55°

1

of the face with face

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel and Related Alloys, and is the direct responsibility of Subcommittee

A01.01 on Steel Rails and Accessories.

TABLE 4 Markings

Current edition approved Feb. 27, 1987. Published April 1987. Original

published as A 65 – 16 T. Last previous edition A 65 – 79.

2

Annual Book of ASTM Standards, Vol 01.05.

Grade 1 Grade 2

3

Annual Book of ASTM Standards, Vol 01.03.

4 Steel, copper not manufacturer’s symbol manufacturer’s symbol and

Available from American Railway Engineering Assn., 2000 L St., NW,

specified HC

Washington, DC 20036.

Steel, copper speci- manufacturer’s symbol manufacturer’s symbol and

5

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

fied and CU HC and CU

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

1

---------------------- Page: 1 ----------------------

A65

TABLE 6 Permissible Variations in DImensions

5. Chemical or Alternative Tension Test Requirements

5.1 The manufacturer has the option to furnish spikes from

Over Under

steel conforming to the heat or cast analysis described in 5.2,

in. mm in. mm

the alternative analysis described in 5.3, or the alternative

1 1

Cross section ⁄32 0.8 ⁄64 0.4

tension test described in 5.4.

3 1

Head ⁄32 2.4 ⁄32 0.8

5.2 Heat or Cast Analysis—An analysis of each heat or cast

1 1

Length, under head to point ⁄8 3.2 ⁄8 3.2

Angle, under side of head 1° 1° 1° 1°

shall be made by the manufacturer of the steel to determine the

percentage of the elements specified in Table 1. The analysis

shall be made from a test sample taken preferably during the

9. Retests

pouring of the heat or cast. The chemical composition thus

9.1 If, during the tension or bend tests, a previously undis-

determined shall conform to the requirements of Table 1.

covered material or manufacturing flaw should be disclosed

5.3 Alternative Analysis—When the heat or c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.