ASTM D2887-99

(Test Method)Standard Test Method for Boiling Range Distribution of Petroleum Fractions by Gas Chromatography

Standard Test Method for Boiling Range Distribution of Petroleum Fractions by Gas Chromatography

SCOPE

1.1 This test method covers the determination of the boiling range distribution of petroleum products. The test method is applicable to petroleum products and fractions having a final boiling point of 538°C (1000°F) or lower at atmospheric pressure as measured by this test method. This test method is limited to samples having a boiling range greater than 55°C (100°F), and having a vapor pressure sufficiently low to permit sampling at ambient temperature.

1.2 This test method is not to be used for the analysis of gasoline samples or gasoline components. These types of samples must be analyzed by Test Method D 3710.

1.3 The values stated in SI units are to be regarded as standard. The inch-pound units given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2887 – 99 An American National Standard

Standard Test Method for

Boiling Range Distribution of Petroleum Fractions by Gas

Chromatography

This standard is issued under the fixed designation D 2887; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 355 Practice for Gas Chromatography Terms and Rela-

tionships

1.1 This test method covers the determination of the boiling

E 516 Practice for Testing Thermal Conductivity Detectors

range distribution of petroleum products. The test method is

Used in Gas Chromatography

applicable to petroleum products and fractions having a final

E 594 Practice for Testing Flame Ionization Detectors Used

boiling point of 538°C (1000°F) or lower at atmospheric

in Gas Chromatography

pressure as measured by this test method. This test method is

limited to samples having a boiling range greater than 55°C

3. Terminology

(100°F), and having a vapor pressure sufficiently low to permit

3.1 Definitions:

sampling at ambient temperature.

3.1.1 This test method makes reference to many common

1.2 This test method is not to be used for the analysis of

gas chromatographic procedures, terms, and relationships.

gasoline samples or gasoline components. These types of

Detailed definitions of these can be found in Practices E 260,

samples must be analyzed by Test Method D 3710.

E 355, and E 594.

1.3 The values stated in SI units are to be regarded as

3.2 Definitions of Terms Specific to This Standard:

standard. The inch-pound units given in parentheses are for

3.2.1 area slice—the area, resulting from the integration of

information only.

the chromatographic detector signal, within a specified reten-

1.4 This standard does not purport to address all of the

tion time interval. In area slice mode (see 6.3.2), peak detection

safety concerns, if any, associated with its use. It is the

parameters are bypassed and the detector signal integral is

responsibility of the user of this standard to establish appro-

recorded as area slices of consecutive, fixed duration time

priate safety and health practices and determine the applica-

intervals.

bility of regulatory limitations prior to use.

3.2.2 corrected area slice—an area slice corrected for base-

2. Referenced Documents line offset, by subtraction of the exactly corresponding area

slice in a previously recorded blank (non-sample) analysis.

2.1 ASTM Standards:

2 3.2.3 cumulative corrected area—the accumulated sum of

D 86 Test Method for Distillation of Petroleum Products

corrected area slices from the beginning of the analysis through

D 1160 Test Method for Distillation of Petroleum Products

2 a given retention time, ignoring any non-sample area (for

at Reduced Pressure

example, solvent).

D 2892 Test Method for Distillation of Crude Petroleum

3 3.2.4 initial boiling point (IBP)—the temperature (corre-

(15-Theoretical Plate Column)

sponding to the retention time) at which a cumulative corrected

D 3710 Test Method for Boiling Range Distribution of

3 area count equal to 0.5 % of the total sample area under the

Gasoline and Gasoline Fractions by Gas Chromatography

chromatogram is obtained.

D 4057 Practice for Manual Sampling of Petroleum and

3 3.2.5 final boiling point (FBP)—the temperature (corre-

Petroleum Products

sponding to the retention time) at which a cumulative corrected

D 4626 Practice for Calculation of Gas Chromatographic

area count equal to 99.5 % of the total sample area under the

Response Factors

chromatogram is obtained.

E 260 Practice for Packed Column Gas Chromatography

3.2.6 slice rate—the time interval used to integrate the

continuous (analog) chromatographic detector response during

This test method is under the jurisdiction of ASTM Committee D-2 on

an analysis. The slice rate is expressed in hertz (for example,

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

integrations or slices per second).

D02.04 on Hydrocarbon Analysis.

3.2.7 slice time—the time associated with the end of each

Current edition approved Dec. 10, 1999. Published February 2000. Originally

published as D 2887 – 73. Last previous edition D 2887 – 97a.

contiguous area slice. The slice time is equal to the slice

Annual Book of ASTM Standards, Vol 05.01.

number divided by the slice rate.

Annual Book of ASTM Standards, Vol 05.02.

4 3.2.8 total sample area—the cumulative corrected area,

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2887

from the initial area point to the final area point, where the graph must be capable of linear programmed temperature

chromatographic signal is considered to have returned to operation over a range sufficient to establish a retention time of

baseline after complete sample elution. at least 1 min for the IBP and to elute compounds up to a

3.3 Abbreviations: boiling temperature of 538°C (1000°F) before reaching the

3.3.1 A common abbreviation of hydrocarbon compounds is upper end of the temperature program. The programming rate

to designate the number of carbon atoms in the compound. A must be sufficiently reproducible to obtain retention time

prefix is used to indicate the carbon chain form, while a repeatability of 0.1 min (6 s) for each component in the

subscripted suffix denotes the number of carbon atoms (for calibration mixture described in 7.8.

example, normal decane = n-C ; isotetradecane = i-C ).

6.1.3 Cryogenic Column Cooling—Column starting tem-

10 14

peratures below ambient will be required if samples with IBPs

4. Summary of Test Method

of less than 93°C (200°F) are to be analyzed. This is typically

4.1 The boiling range distribution determination by distilla-

provided by adding a source of either liquid carbon dioxide or

tion is simulated by the use of gas chromatography. A nonpolar

liquid nitrogen, controlled through the oven temperature cir-

packed or open tubular (capillary) gas chromatographic col-

cuitry. Excessively low initial column temperature must be

umn is used to elute the hydrocarbon components of the sample

avoided to ensure that the stationary phase remains liquid. The

in order of increasing boiling point. The column temperature is

initial temperature of the column should be only low enough to

raised at a reproducible linear rate and the area under the

obtain a calibration curve meeting the specifications of the

chromatogram is recorded throughout the analysis. Boiling

method.

points are assigned to the time axis from a calibration curve

6.1.4 Sample Inlet System—The sample inlet system must

obtained under the same chromatographic conditions by ana-

be capable of operating continuously at a temperature equiva-

lyzing a known mixture of hydrocarbons covering the boiling

lent to the maximum column temperature employed, or provide

range expected in the sample. From these data, the boiling

for on-column injection with some means of programming the

range distribution can be obtained.

entire column, including the point of sample introduction, up to

the maximum temperature required. Connection of the column

5. Significance and Use

to the sample inlet system must be such that no temperature

5.1 The boiling range distribution of petroleum fractions

below the column temperature exists.

provides an insight into the composition of feedstocks and

6.1.5 Flow Controllers—The gas chromatograph must be

products related to petroleum refining processes. The gas

equipped with mass flow controllers capable of maintaining

chromatographic simulation of this determination can be used

carrier gas flow constant to 61 % over the full operating

to replace conventional distillation methods for control of

temperature range of the column. The inlet pressure of the

refining operations. This test method can be used for product

carrier gas supplied to the gas chromatograph must be suffi-

specification testing with the mutual agreement of interested

ciently high to compensate for the increase in column back-

parties.

pressure as the column temperature is raised. An inlet pressure

5.2 Boiling range distributions obtained by this test method

of 550 kPa (80 psig) has been found satisfactory with columns

are essentially equivalent to those obtained by true boiling

described in Table 1.

point (TBP) distillation (see Test Method D 2892). They are

6.1.6 Microsyringe—A microsyringe is needed for sample

not equivalent to results from low efficiency distillations such

introduction.

as those obtained with Test Method D 86 or D 1160.

NOTE 2—Automatic sampling devices or other sampling means, such as

6. Apparatus

indium encapsulation, can be used provided: the system can be operated

6.1 Chromatograph—The gas chromatograph used must at a temperature sufficiently high to completely vaporize hydrocarbons

with atmospheric boiling points of 538°C (1000°F), and the sampling

have the following performance characteristics:

system is connected to the chromatographic column avoiding any cold

6.1.1 Detector—Either a flame ionization or a thermal

temperature zones.

conductivity detector may be used. The detector must have

sufficient sensitivity to detect 1.0 % dodecane with a peak

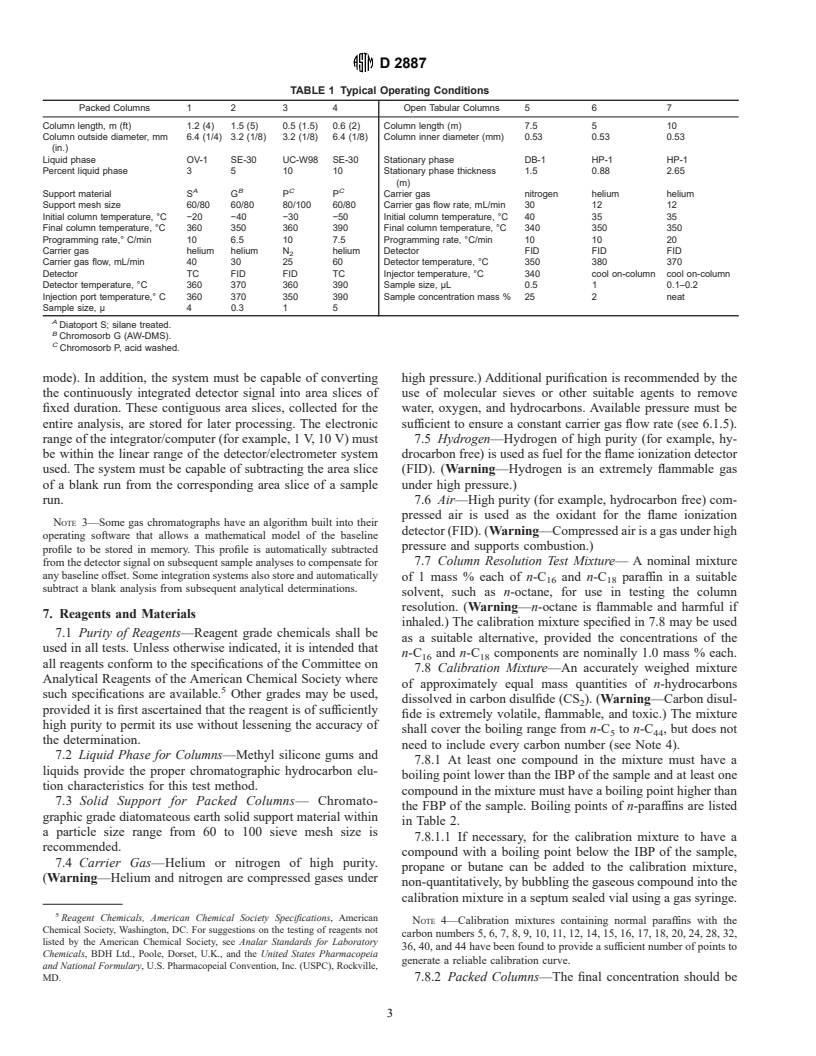

6.2 Column—Any column and conditions may be used that

height of at least 10 % of full scale on the recorder under

provide separation of typical petroleum hydrocarbons in order

conditions prescribed in this test method and without loss of

of increasing boiling point and meet the column performance

resolution as defined in 9.3.1. When operating at this sensitiv-

requirements of 9.3.1 and 9.3.3. Successfully used columns

ity level, detector stability must be such that a baseline drift of

and conditions are given in Table 1.

not more than 1 % of full scale per hour is obtained. The

6.3 Data Acquisition System:

detector must be capable of operating continuously at a

6.3.1 Recorder—A 0 to 1 mV range recording potentiom-

temperature equivalent to the maximum column temperature

eter or equivalent, with a full-scale response time of2sor less

employed. Connection of the column to the detector must be

may be used.

such that no temperature below the column temperature exists.

6.3.2 Integrator—Means must be provided for determining

the accumulated area under the chromatogram. This can be

NOTE 1—It is not desirable to operate a thermal conductivity detector at

a temperature higher than the maximum column temperature employed.

done by means of an electronic integrator or computer based

Operation at higher temperature generally contributes to higher noise

chromatography data system. The integrator/computer system

levels and greater drift and can shorten the useful life of the detector.

must have normal chromatographic software for measuring the

6.1.2 Column Temperature Programmer— The chromato- retention time and areas of eluting peaks (peak detection

D 2887

TABLE 1 Typical Operating Conditions

Packed Columns 1 2 3 4 Open Tabular Columns 5 6 7

Column length, m (ft) 1.2 (4) 1.5 (5) 0.5 (1.5) 0.6 (2) Column length (m) 7.5 5 10

Column outside diameter, mm 6.4 (1/4) 3.2 (1/8) 3.2 (1/8) 6.4 (1/8) Column inner diameter (mm) 0.53 0.53 0.53

(in.)

Liquid phase OV-1 SE-30 UC-W98 SE-30 Stationary phase DB-1 HP-1 HP-1

Percent liquid phase 3 5 10 10 Stationary phase thickness 1.5 0.88 2.65

(m)

A B C C

Support material S G P P Carrier gas nitrogen helium helium

Support mesh size 60/80 60/80 80/100 60/80 Carrier gas flow rate, mL/min 30 12 12

Initial column temperature, °C −20 −40 −30 −50 Initial column temperature, °C 40 35 35

Final column temperature, °C 360 350 360 390 Final column temperature, °C 340 350 350

Programming rate,° C/min 10 6.5 10 7.5 Programming rate, °C/min 10 10 20

Carrier gas helium helium N helium Detector FID FID FID

Carrier gas flow, mL/min 40 30 25 60 Detector temperature, °C 350 380 370

Detector TC FID FID TC Injector temperature, °C 340 cool on-column cool on-column

Detector temperature, °C 360 370 360 390 Sample size, μL 0.5 1 0.1–0.2

Injection port temperature,° C 360 370 350 390 Sample concentration mass % 25 2 neat

Sample size, μ 4 0.3 1 5

A

Diatoport S; silane treated.

B

Chromosorb G (AW-DMS).

C

Chromosorb P, acid washed.

mode). In addition, the system must be capable of converting high pressure.) Additional purification is recommended by the

the continuously integrated detector signal into area slices of use of molecular sieves or other suitable agents to remove

fixed duration. These contiguous area slices, collected for the water, oxygen, and hydrocarbons. Available pressure must be

entire analysis, are stored for later processing. The electronic sufficient to ensure a constant carrier gas flow rate (see 6.1.5).

range of the integrator/computer (for example, 1 V, 10 V) must 7.5 Hydrogen—Hydrogen of high purity (for example, hy-

be within the linear range of the detector/electrometer system drocarbon free) is used as fuel for the flame ionization detector

used. The system must be capable of subtracting the area slice (FID). (Warning—Hydrogen is an extremely flammable gas

of a blank run from the corresponding area slice of a sample under high pressure.)

run. 7.6 Air—High purity (for example, hydrocarbon free) com-

pressed air is used as the oxidant for the flame ionization

NOTE 3—Some gas chromatographs have an algorithm built into their

detector (FID). (Warning—Compressed air is a gas under high

operating software that allows a mathematical model of the baseline

pressure and supports combustion.)

profile to be stored in memory. This profile is automatically subtracted

7.7 Column Resolution Test Mixture— A nominal mixture

from the detector signal on subsequent sample analyses to compensate for

any baseline offset. Some integration systems also store and automatically

of 1 mass % each of n-C and n-C paraffin in a suitable

16 18

subtract a blank analysis from subsequent analytical determinations.

solvent, such as n-octane, for use in testing the column

resolution. (Warning—n-octane is flammable and harmful if

7. Reagents and Materials

inhaled.) The calibration mixture specified in 7.8 may be used

7.1 Purity of Reagents—Reagent grade chemicals shall be

as a suitable alternative, provided the concentrations of the

used in all tests. Unless otherwise indicated, it is intended that

n-C and n-C components are nominally 1.0 mass % each.

16 18

all reagents conform to the specifications of the Committee on

7.8 Calibration Mixture—An accurately weighed mixture

Analytical Reagents

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.