ASTM D1264-16

(Test Method)Standard Test Method for Determining the Water Washout Characteristics of Lubricating Greases

Standard Test Method for Determining the Water Washout Characteristics of Lubricating Greases

SIGNIFICANCE AND USE

4.1 This test method estimates the resistance of greases to water washout from ball bearings under conditions of the test. No correlation with field service has been established.

SCOPE

1.1 This test method covers the evaluation of the resistance of a lubricating grease to washout by water from a bearing, when tested at 38 °C and 79 °C (100 °F and 175 °F) under the prescribed laboratory conditions. It is not to be considered the equivalent of service evaluation tests. Precision and bias was determined using grease ranging from NLGI 3 to 0 grades in the research report (see Section 10).

1.2 This test method may not be suitable for some greases containing highly volatile components. This test method does not attempt to account for sample evaporation. It is the user's responsibility to determine if evaporation of the sample is a significant contributor to mass loss at the required drying temperature.

1.3 The values state in SI units are to be regarded as the standard.

1.3.1 Exception—The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.3.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1264 − 16

Standard Test Method for

Determining the Water Washout Characteristics of

1

Lubricating Greases

This standard is issued under the fixed designation D1264; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 3. Summary of Test Method

1.1 This test method covers the evaluation of the resistance

3.1 The grease is packed into a ball bearing, the bearing is

of a lubricating grease to washout by water from a bearing,

then inserted in a housing with specified clearances, and

when tested at 38 °C and 79 °C (100 °F and 175 °F) under the

rotated at 600 r⁄min 6 30 r⁄min. Water, controlled at the

prescribed laboratory conditions. It is not to be considered the

specified test temperature, impinges on the bearing housing at

equivalent of service evaluation tests. Precision and bias was

a rate of 5 mL⁄s 6 0.5 mL⁄s. The amount of grease washed

determined using grease ranging from NLGI 3 to 0 grades in

out in 60 min 6 1 min is a measure of the resistance of the

the research report (see Section 10).

grease to water washout.

1.2 This test method may not be suitable for some greases

containing highly volatile components. This test method does

4. Significance and Use

not attempt to account for sample evaporation. It is the user’s

4.1 This test method estimates the resistance of greases to

responsibility to determine if evaporation of the sample is a

water washout from ball bearings under conditions of the test.

significant contributor to mass loss at the required drying

No correlation with field service has been established.

temperature.

1.3 The values state in SI units are to be regarded as the

5. Apparatus

standard.

1.3.1 Exception—The values given in parentheses are for

5.1 Ball Bearing, ASTM test bearing size 6204 (see

2

information only.

ADJD3336.

1.4 This standard does not purport to address all of the

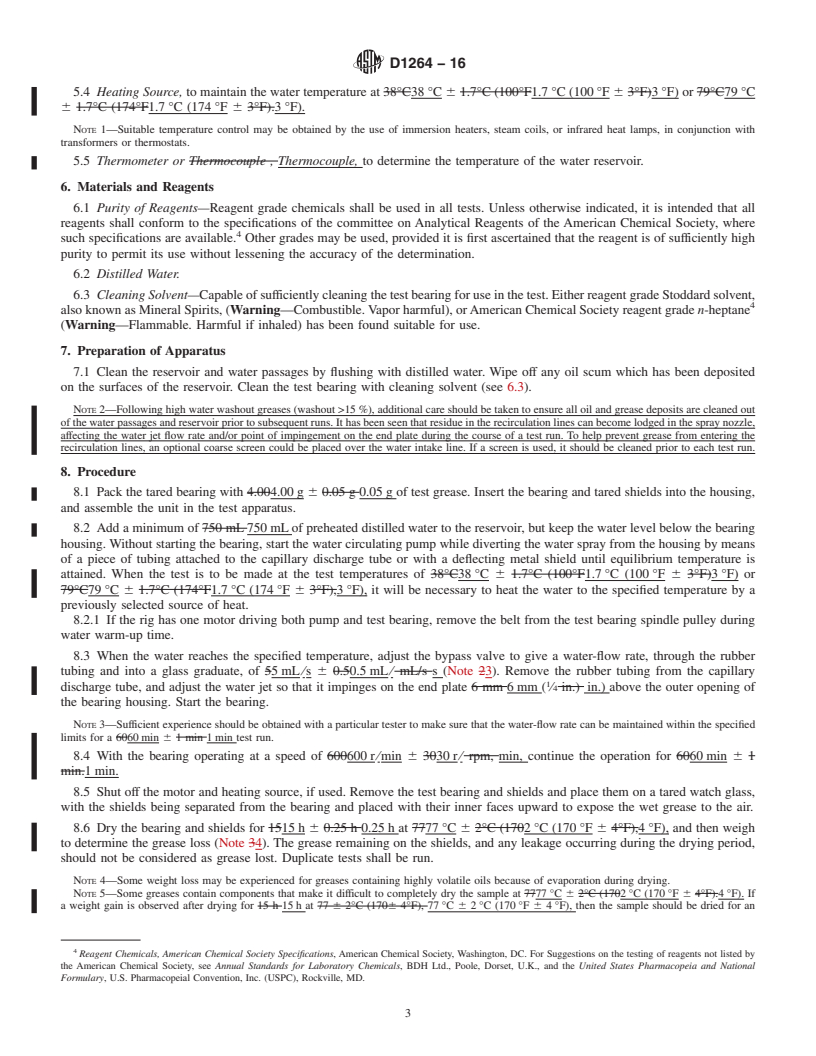

5.2 Bearing Housing and Shield with dimensions as shown

safety concerns, if any, associated with its use. It is the

in Fig. 1.

responsibility of the user this standard to establish appropriate

safety and health practices and determine the applicability of 5.3 Reservoir, Bearing-Housing Mount, Circulating Pump,

regulatory limitations prior to use. For specific warning

and Drive Motor, similar or equivalent to those shown in Fig.

statements, see 6.3.

1.

5.4 Heating Source, to maintain the water temperature at

2. Referenced Documents

38 °C 6 1.7 °C (100 °F 6 3 °F) or 79 °C 6 1.7 °C (174 °F 6

2.1 ASTM Adjuncts:

3 °F).

2

Standard Ball Bearing

NOTE 1—Suitable temperature control may be obtained by the use of

D2PP, Version 4.43, Determination of Precision and Bias

immersionheaters,steamcoils,orinfraredheatlamps,inconjunctionwith

3

Data for Use in Test Methods for Petroleum Products

transformers or thermostats.

5.5 Thermometer or Thermocouple, to determine the tem-

perature of the water reservoir.

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.G0.06 on Functional Tests - Contamination.

6. Materials and Reagents

Current edition approved April 1, 2016. Published April 2016. Originally

approved in 1953. Last previous edition approved in 2012 as D1264 – 12. DOI: 6.1 Purity of Reagents—Reagent grade chemicals shall be

10.1520/D1264-16.

used in all tests. Unless otherwise indicated, it is intended that

2

Available from ASTM International Headquarters. Order Adjunct No.

all reagents shall conform to the specifications of the commit-

ADJD3336. Original adjunct produced in 1984.

3

ADJD6300 is no longer available. tee onAnalytical Reagents of theAmerican Chemical Society,

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1264 − 16

in. mm in. mm °F °C

0.010 0.25 0.875 22.22 100 ± 3 38 ± 1.7

0.015 0.38 0.938 23.81 174 ± 3 79 ± 1.7

1

0.031 0.79 2 ⁄4 57.1

1

⁄8 3.18 6 152

5

⁄32 3.97

3

⁄16 4.76

1

⁄4 6.35

FIG. 1 Water Washout Characteristics of Lubricating Grease Apparatus

2

---------------------- Page: 2 ----------------------

D1264 − 16

4

NOTE 3—Sufficient experience should be obtained with a particular

where such specifications are available. Other grades may be

tester to make sure that the water-flow rate can be maintained within the

used, provided it is first ascertained that the reagent is of

specified limits for

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1264 − 12 D1264 − 16

Standard Test Method for

Determining the Water Washout Characteristics of

1

Lubricating Greases

This standard is issued under the fixed designation D1264; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers the evaluation of the resistance of a lubricating grease to washout by water from a bearing, when

tested at 3838 °C and 79°C (10079 °C (100 °F and 175°F)175 °F) under the prescribed laboratory conditions. It is not to be

considered the equivalent of service evaluation tests. Precision and bias was determined using grease ranging from NLGI 3 to 0

grades in the research report (see Section 10).

1.2 This test method may not be suitable for some greases containing highly volatile components. This test method does not

attempt to account for sample evaporation. It is the user’s responsibility to determine if evaporation of the sample is a significant

contributor to mass loss at the required drying temperature.

1.3 The values state in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3.1 Exception—The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see 6.3.

2. Referenced Documents

2.1 ASTM Adjuncts:

2

Standard Ball Bearing

3

D2PP, Version 4.43, Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products

3. Summary of Test Method

3.1 The grease is packed into a ball bearing, the bearing is then inserted in a housing with specified clearances, and rotated at

600600 r ⁄min 6 3030 r ⁄ rpm. min. Water, controlled at the specified test temperature, impinges on the bearing housing at a rate

of 55 mL ⁄s 6 0.50.5 mL ⁄ mL/s. s. The amount of grease washed out in 6060 min 6 1 min 1 min is a measure of the resistance

of the grease to water washout.

4. Significance and Use

4.1 This test method estimates the resistance of greases to water washout from ball bearings under conditions of the test. No

correlation with field service has been established.

5. Apparatus

2

5.1 Ball Bearing, ASTM test bearing size 6204 (see ADJD3336.

5.2 Bearing Housing and Shield with dimensions as shown in Fig. 1.

5.3 Reservoir, Bearing-Housing Mount, Circulating Pump, and Drive Motor, similar or equivalent to those shown in Fig. 1.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.G0.06 on Functional Tests - Contamination.

Current edition approved Dec. 1, 2012April 1, 2016. Published March 2013April 2016. Originally approved in 1953. Last previous edition approved in 20112012 as

D1264D1264 – 12.–11. DOI: 10.1520/D1264-12.10.1520/D1264-16.

2

Available from ASTM International Headquarters. Order Adjunct No. ADJD3336. Original adjunct produced in 1984.

3

ADJD6300 is no longer available.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1264 − 16

in. mm in. mm °F °C

0.010 0.25 0.875 22.22 100 ± 3 38 ± 1.7

0.015 0.38 0.938 23.81 174 ± 3 79 ± 1.7

1

0.031 0.79 2 ⁄4 57.1

1

⁄8 3.18 6 152

5

⁄32 3.97

3

⁄16 4.76

1

⁄4 6.35

FIG. 1 Water Washout Characteristics of Lubricating Grease Apparatus

2

---------------------- Page: 2 ----------------------

D1264 − 16

5.4 Heating Source, to maintain the water temperature at 38°C38 °C 6 1.7°C (100°F1.7 °C (100 °F 6 3°F)3 °F) or 79°C79 °C

6 1.7°C (174°F1.7 °C (174 °F 6 3°F).3 °F).

NOTE 1—Suitable temperature control may be obtained by the use of immersion heaters, steam coils, or infrared heat lamps, in conjunction with

transformers or thermostats.

5.5 Thermometer or Thermocouple , Thermocouple, to determine the temperature of the water reservoir.

6. Materials and Reagents

6.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.