ASTM C1409-98(2003)

(Guide)Standard Guide for Measuring and Estimating Quantities of Insulated Piping and Components

Standard Guide for Measuring and Estimating Quantities of Insulated Piping and Components

SCOPE

1.1 This guide defines the components of an insulated piping system to be measured or counted to determine quantities and pricing for unit price contracts or extra work.

1.2 Pricing may be done through unit pricing for each item by pipe size, type of insulation system, insulating thickness, double or multilayer insulation, type of weatherproofing or jacketing, and pressure rating (if necessary) or through component (fitting) factor or multipliers.

1.2.1 Component (fitting) factors or multipliers, which are multipliers times the straight length of piping as shown in Table 1, determine relative prices for each component not within the scope of this guide. These factors or multipliers are to be determined by the insulating contractor relative to the given situation and insulation system specification.

1.2.2 It is suggested that only one type of pricing be used on a project.

1.2.3 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1409–98 (Reapproved 2003)

Standard Guide for

Measuring and Estimating Quantities of Insulated Piping

and Components

This standard is issued under the fixed designation C 1409; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Acommittee ofASTM International initiated this guide to improve industry-wide understanding of

thecomponentsinaninsulatedpipingsystemthataffecttheinstalledcostofinsulatingthesystem.The

method of measurement standard used as a bias for this guide is the National Commercial and

Industrial Standards.

ASTM International defines a guide as a series of options or instructions that does not recommend

a specific course of action. A guide only suggests a course of action. Its purpose is to offer guidance

based on a consensus of viewpoints, but not to establish a fixed procedure. A guide is intended to

increase the awareness of the user to available techniques in a given subject area and to provide

information from which subsequent evaluation and standardization can be derived.

It is the intention that this guide will help gain wider acceptance and understanding of the concepts

in the MICA standard.

1. Scope 2. Summary of Guide

1.1 This guide defines the components of an insulated 2.1 This guide lists examples of components of piping

piping system to be measured or counted to determine quan- systems which effect insulation cost. From this list, compo-

tities and pricing for unit price contracts or extra work. nents to be counted are selected by the involved parties.

1.2 Pricing may be done through unit pricing for each item

3. Significance and Use

by pipe size, type of insulation system, insulation thickness,

3.1 This guide establishes procedures to help parties in-

double or multilayer insulation, type of weatherproofing or

jacketing, and pressure rating (if necessary) or through com- volved in unit price piping insulation contracts reach agree-

ment as to what components will be counted for pricing

ponent (fitting) factor or multipliers.

1.2.1 Component (fitting) factors or multipliers, which are purposes.

multipliers times the straight length of piping as shown in

4. Procedure

Table 1, determine relative prices for each component not

4.1 For a unit price-type contract, establish unit prices for

within the scope of this guide. These factors or multipliers are

straight run piping. These unit prices should include pipe size,

to be determined by the insulating contractor relative to the

type of insulation system, insulation thickness, double or

given situation and insulation system specification.

multilayer insulation, and type of weatherproofing or jacketing

1.2.2 It is suggested that only one type of pricing be used on

such as shown in the example in Table 1.

a project.

4.2 Determine the quantity of straight run pipe insulation by

1.2.3 The values stated in inch-pound units are to be

straight pipe measurement from centerline to centerline and

regarded as the standard.

include lengths of all in-line components. This method is

defined as “measured through” (see Fig. X3.1).

This guide is under the jurisdiction of ASTM Committee C16 on Thermal

4.3 Count the quantities of piping components. The piping

Insulation and is the direct responsibility of Subcommittee C16.40 on Insulation

components (fittings) to be counted may be modified by those

Systems.

listed in Table 2. The components should be categorized by

Current edition approved April 10, 2003. Published July 2003. Originally

approved in 1998. Last previous edition approved in 1998 as C 1409 – 98.

pipe size, type of insulation system, insulation thickness, and

Further information is available from the Midwest Insulation ContractorsAssn.

(MICA), 2017 S. 139th Circle, Omaha, NE.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1409–98 (2003)

TABLE 1 Piping Unit Price Schedule, Hot Insulation, 0.016-in. Thick Aluminum Jacketing, Cost per Linear Foot (All Materials and Labor

Necessary for a Complete Installation)

1 1 1 1 A,B A,B A,B

1 ⁄2 22 ⁄2 33 ⁄2 43 ⁄2 DL 4DL 4DL

2 and under

2 ⁄2

3 ⁄2

Over 30 and

Equipment

A

DL = Double layer.

B

In some insulation systems, double-layer insulation may occur at smaller thickness.

pressure rating, if necessary.Table 2 may be used as a checklist 6. Industry Examples

to assist in the categorization.

6.1 Examples of how components are categorized and made

4.4 The method of pricing (unit price per component or

part of a unit price contract are shown in Appendix X1 and

fitting factors) for each category will be determined by the

Appendix X2. These examples provide a range of possibilities.

terms of a request for quotation or commercial contract.

6.2 Examples of unit pricing by component are shown in

However, users of this guide must be aware that selection of

Appendix X3. One of these schedules, fitting factors, or

elements to be counted, categories, and method of measuring

multipliers will be required for each component.

pipe, have a direct bearing on the final total price. Knowledge

6.3 The method of measurement and how straight pipe

of this fact is critical to the selection of the most qualified

equivalent factors are categorized are shown in Fig. X3.1. Fig.

installer.

X3.1 is basically the MICA standard and depicts the “Center-

4.5 For a unit price contract, each component shall have its

lineMeasureThrough”methodofdeterminingtotalquantityof

own table categorized by pipe size, type of insulation system,

straight run pipe.

insulation thickness, and pressure rating, if necessary.

7. Keywords

5. Piping Components

7.1 extra work; factors; fittings; insulated pipe; measure

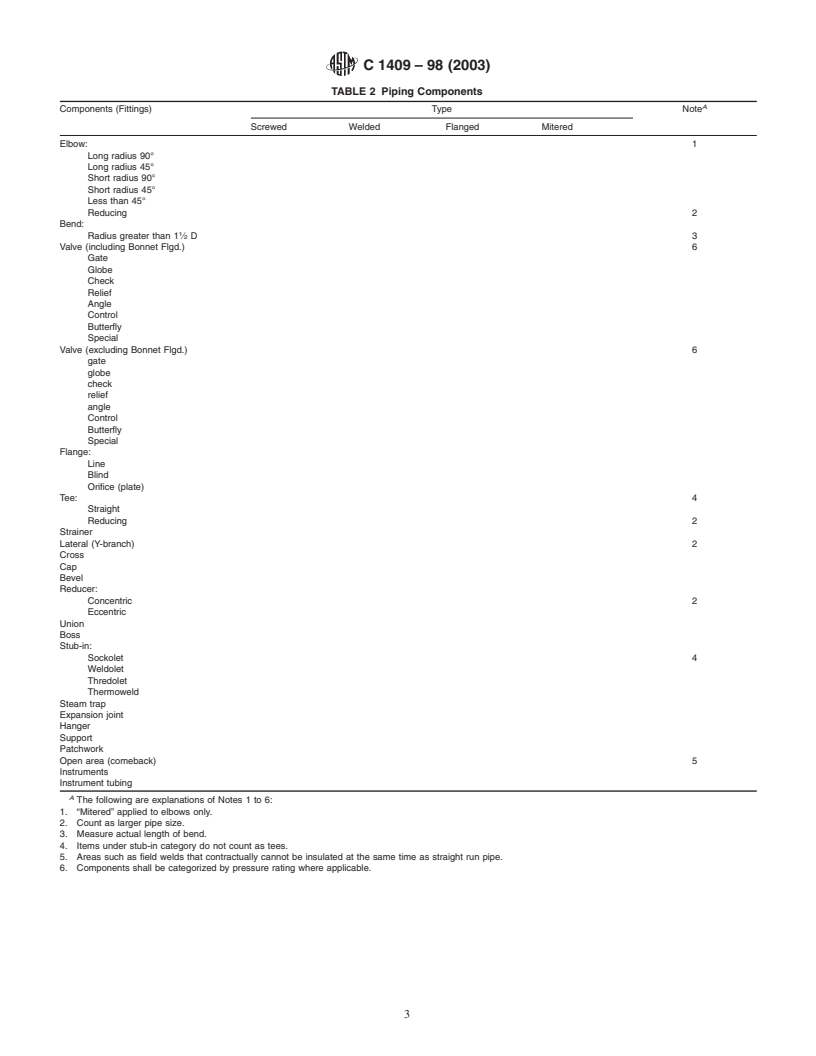

5.1 Table 2 lists a sample of components which effect the

quantities; piping components; unit prices

cost of insulation on a piping system. The “Note” column is

used when additional information is required to explain a

component as it generally applies to the insulation industry.

5.2 Table2maybeusedasachecklistwhenchoosingwhich

components will be counted and when determining difficulty

factors. However, for inclusion in contract or request for quote

documents, a summary similar to Appendix X1 may be used.

C1409–98 (2003)

TABLE 2 Piping Components

A

Components (Fittings) Type Note

Screwed Welded Flanged Mitered

Elbow: 1

Long radius 90°

Long radius 45°

Short radius 90°

Short radius 45°

Less than 45°

Reducing 2

Bend:

Radius greater than 1 ⁄2 D 3

Valve (including Bonnet Flgd.) 6

Gate

Globe

Check

Relief

Angle

Control

Butterfly

Special

Valve (excluding Bonnet Flgd.) 6

gate

globe

check

relief

angle

Control

Butterfly

Special

Flange:

Line

Blind

Orifice (plate)

Tee: 4

Straight

Reducing 2

Strainer

Lateral (Y-branch) 2

Cross

Cap

Bevel

Reducer:

Concentric 2

Eccentric

Union

Boss

Stub-in:

Sockolet 4

Weldolet

Thredolet

Thermoweld

Steam trap

Expansion joint

Hanger

Support

Patchwork

Open area (comeback) 5

Instruments

Instrument tubing

A

The following

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.