ASTM D4468-85(2015)

(Test Method)Standard Test Method for Total Sulfur in Gaseous Fuels by Hydrogenolysis and Rateometric Colorimetry

Standard Test Method for Total Sulfur in Gaseous Fuels by Hydrogenolysis and<brk/> Rateometric Colorimetry

SIGNIFICANCE AND USE

4.1 This test method can be used to determine specification, or regulatory compliance to requirements, for total sulfur in gaseous fuels. In gas processing plants, sulfur can be a contaminant and must be removed before gas is introduced into gas pipelines. In petrochemical plants, sulfur is a poison for many catalysts and must be reduced to acceptable levels, usually in the range from 0.01 to 1 ppm/v. This test method may also be used as a quality-control tool for sulfur determination in finished products, such as propane, butane, ethane, and ethylene.

SCOPE

1.1 This test method covers the determination of sulfur gaseous fuels in the range from 0.001 to 20 parts per million by volume (ppm/v).

1.2 This test method may be extended to higher concentration by dilution.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 6.7, 6.8, and 7.3.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4468 − 85 (Reapproved 2015)

Standard Test Method for

Total Sulfur in Gaseous Fuels by Hydrogenolysis and

1

Rateometric Colorimetry

This standard is issued under the fixed designation D4468; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope metric reaction of H S with lead acetate. Units used are ppm/v,

2

which is equivalent to micromoles/mole.

1.1 This test method covers the determination of sulfur

gaseous fuels in the range from 0.001 to 20 parts per million by

4. Significance and Use

volume (ppm/v).

4.1 This test method can be used to determine specification,

1.2 This test method may be extended to higher concentra-

or regulatory compliance to requirements, for total sulfur in

tion by dilution.

gaseous fuels. In gas processing plants, sulfur can be a

1.3 The values stated in SI units are to be regarded as

contaminant and must be removed before gas is introduced into

standard. No other units of measurement are included in this

gas pipelines. In petrochemical plants, sulfur is a poison for

standard.

many catalysts and must be reduced to acceptable levels,

1.4 This standard may involve hazardous materials,

usually in the range from 0.01 to 1 ppm/v. This test method

operations, and equipment. This standard does not purport to

may also be used as a quality-control tool for sulfur determi-

address all of the safety concerns associated with its use. It is

nation in finished products, such as propane, butane, ethane,

the responsibility of the user of this standard to establish

and ethylene.

appropriate safety and health practices and determine the

applicability of regulatory limitations prior to use. Specific

5. Apparatus

precautionary statements are given in 6.7, 6.8, and 7.3.

5.1 Pyrolysis Furnace—A furnace that can provide an

adjustable temperature of 900 to 1300°C in a quartz or ceramic

2. Referenced Documents

tube of 5 mm or larger tube (ID) is required for pyrolysis of the

2

2.1 ASTM Standards:

sample. (See Fig. 1.) The flow system is to be a fluorocarbon

D1193 Specification for Reagent Water

or other material inert to H S and other sulfur compounds. (See

2

D1914 Practice for Conversion Units and Factors Relating to

Fig. 1.)

Sampling and Analysis of Atmospheres

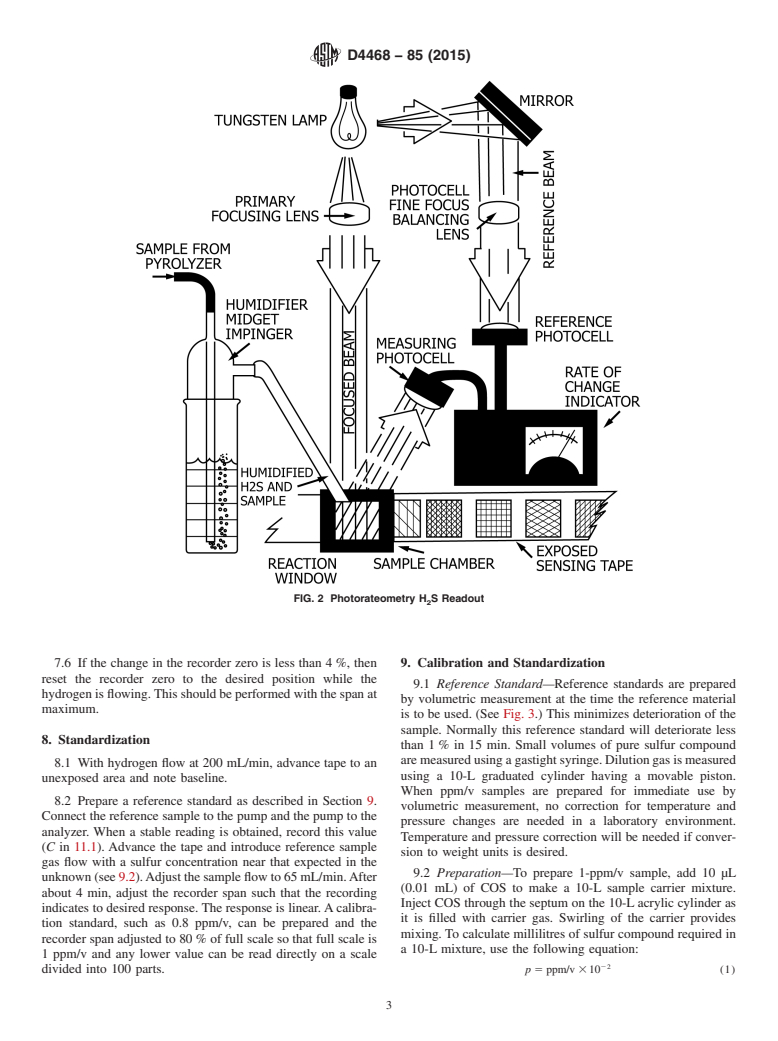

5.2 Rateometric H S Readout—Hydrogenolysis products

2

D4045 Test Method for Sulfur in Petroleum Products by

contain H S in proportion to sulfur in the sample. The H S

2 2

Hydrogenolysis and Rateometric Colorimetry

concentration is determined by measuring rate of change of

reflectance of a tape impregnated with lead acetate caused by

3. Summary of Test Method

darkening when lead sulfide is formed. Rateometric

3.1 The sample is introduced at a constant rate into a

electronics, adapted to provide first derivative output, allows

flowing hydrogen stream in a hydrogenolysis apparatus. The

sufficient sensitivity to measure to 0.001 ppm/v. (See Fig. 2.)

sample and hydrogen are pyrolyzed at a temperature of 1000°C

5.3 Recorder—A suitable chart recorder may be used for a

or above, to convert sulfur compounds to hydrogen sulfide

permanent record of analysis.

(H S). Readout is by the rateometric detection of the colori-

2

6. Reagents and Materials

1

This test method is under the jurisdiction of ASTM Committee D03 on Gaseous

6.1 Purity of Chemicals—Reagent grade unless specified

Fuels and is the direct responsibility of Subcommittee D03.05 on Determination of

otherwise.

Special Constituents of Gaseous Fuels.

Current edition approved Nov. 1, 2015. Published December 2015. Originally

6.2 Purity of Water—Unless otherwise indicated, reference

approved in 1985. Last previous edition approved in 2011 as D4468–85 (2011).

to water shall be understood to mean Type II, reagent grade

DOI: 10.1520/D4468-85R15.

2

water, conforming to Specification D1193.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.3 Sensing Tape—Lead acetate impregnated analytical

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. quality filter paper shall be used.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4468 − 85 (2015)

FIG. 1 Hydrogenolysis Flow Diagram

6.4 Acetic Acid (5 %)—Mix 1 part by volume reagent grade 7. Preparation of Apparatus

glacial acetic acid with 19 parts water to prepare 5 % acetic

7.1 Turn on the furnace and allow temperature to stabilize at

acid solution.

1000°C. If thiopheni

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4468 − 85 (Reapproved 2011) D4468 − 85 (Reapproved 2015)

Standard Test Method for

Total Sulfur in Gaseous Fuels by Hydrogenolysis and

1

Rateometric Colorimetry

This standard is issued under the fixed designation D4468; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of sulfur gaseous fuels in the range from 0.001 to 20 parts per million by volume

(ppm/v).

1.2 This test method may be extended to higher concentration by dilution.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all

of the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and

health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given

in 6.7, 6.8, and 7.3.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D1914 Practice for Conversion Units and Factors Relating to Sampling and Analysis of Atmospheres

D4045 Test Method for Sulfur in Petroleum Products by Hydrogenolysis and Rateometric Colorimetry

3. Summary of Test Method

3.1 The sample is introduced at a constant rate into a flowing hydrogen stream in a hydrogenolysis apparatus. The sample and

hydrogen are pyrolyzed at a temperature of 1000°C or above, to convert sulfur compounds to hydrogen sulfide (H S). Readout is

2

by the rateometric detection of the colorimetric reaction of H S with lead acetate. Units used are ppm/v, which is equivalent to

2

micromoles/mole.

4. Significance and Use

4.1 This test method can be used to determine specification, or regulatory compliance to requirements, for total sulfur in gaseous

fuels. In gas processing plants, sulfur can be a contaminant and must be removed before gas is introduced into gas pipelines. In

petrochemical plants, sulfur is a poison for many catalysts and must be reduced to acceptable levels, usually in the range from 0.01

to 1 ppm/v. This test method may also be used as a quality-control tool for sulfur determination in finished products, such as

propane, butane, ethane, and ethylene.

5. Apparatus

5.1 Pyrolysis Furnace—A furnace that can provide an adjustable temperature of 900 to 1300°C in a quartz or ceramic tube of

5 mm or larger tube (ID) is required for pyrolysis of the sample. (See Fig. 1.) The flow system is to be a fluorocarbon or other

material inert to H S and other sulfur compounds. (See Fig. 1.)

2

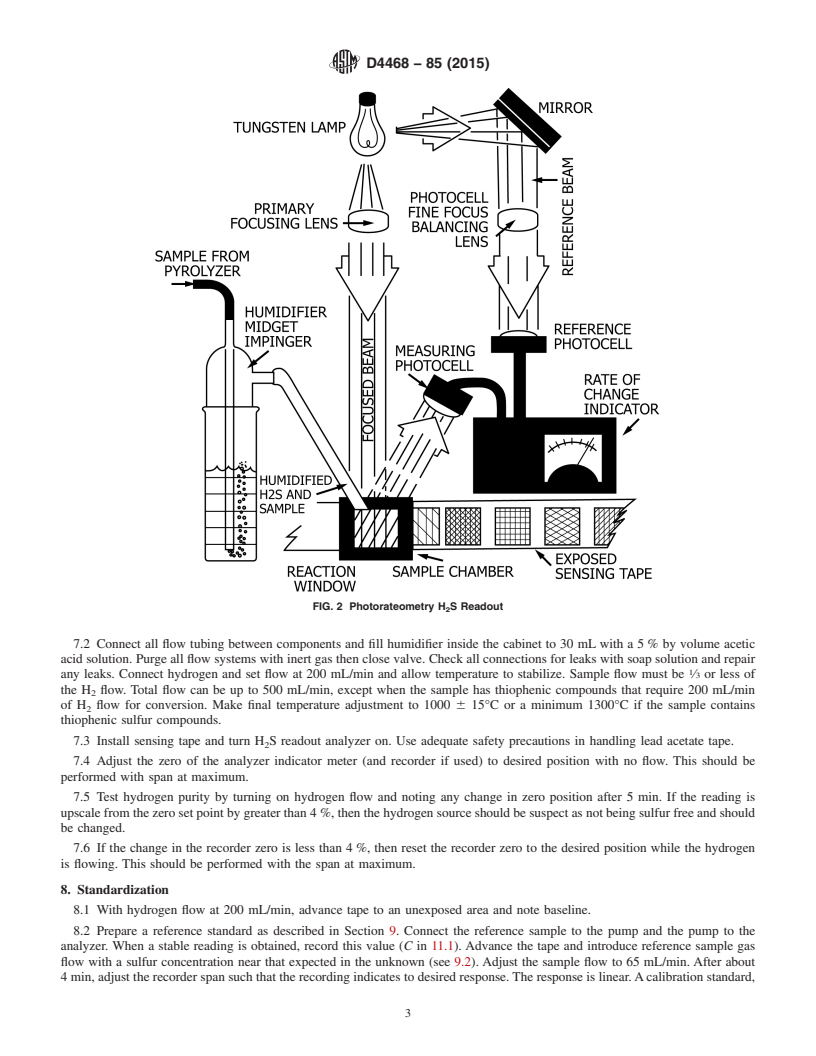

5.2 Rateometric H S Readout—Hydrogenolysis products contain H S in proportion to sulfur in the sample. The H S

2 2 2

concentration is determined by measuring rate of change of reflectance of a tape impregnated with lead acetate caused by darkening

when lead sulfide is formed. Rateometric electronics, adapted to provide first derivative output, allows sufficient sensitivity to

measure to 0.001 ppm/v. (See Fig. 2.)

1

This test method is under the jurisdiction of ASTM Committee D03 on Gaseous Fuels and is the direct responsibility of Subcommittee D03.05 on Determination of

Special Constituents of Gaseous Fuels.

Current edition approved Nov. 1, 2011Nov. 1, 2015. Published December 2011December 2015. Originally approved in 1985. Last previous edition approved in 20062011

as D4468–85 (2006).(2011). DOI: 10.1520/D4468-85R11.10.1520/D4468-85R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4468 − 85 (2015)

FIG. 1 Hydrogenolysis Flow Diagram

5.3 Recorder—A suitable chart recorder may be used for a permanent record of analysis.

6. Reagents and Materials

6.1 Purity of Chemicals—Reagent grade unless specified otherwise.

6.2 Purity of Water—Unless otherwise indicated, reference to water shall be understood to mean Type II, reagent grade water,

conforming to Specificati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.