ASTM B890-98

(Test Method)Standard Test Method for Determination of Metallic Constituents of Tungsten Alloys and Tungsten Hardmetals by X-Ray Fluorescence Spectrometry

Standard Test Method for Determination of Metallic Constituents of Tungsten Alloys and Tungsten Hardmetals by X-Ray Fluorescence Spectrometry

SCOPE

1.1 This test method describes a procedure for the determination of the concentration, generally reported as mass percent, of the metallic constituents of tungsten-based alloys and hardmetals utilizing wavelength dispersive X-ray fluorescence spectrometry (XRF). This test method incorporates the preparation of standards using reagent grade metallic oxides, lithium-borate compounds, and fusion techniques. This test method details techniques for preparing representative specimens of both powder and sintered tungsten-based material. This test method is accurate for a wide range of compositions, and can be used for acceptance of material to grade specifications.

1.2 This test method is applicable to mixtures of tungsten or tungsten carbide with additions of refractory metal carbides and binder metals. Table 1 lists the most common elemental constituents and their concentration range. Note that many of these occur as metallic carbides.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: B 890 – 98

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determination of Metallic Constituents of Tungsten Alloys

and Tungsten Hardmetals by X-Ray Fluorescence

1

Spectrometry

This standard is issued under the fixed designation B 890; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

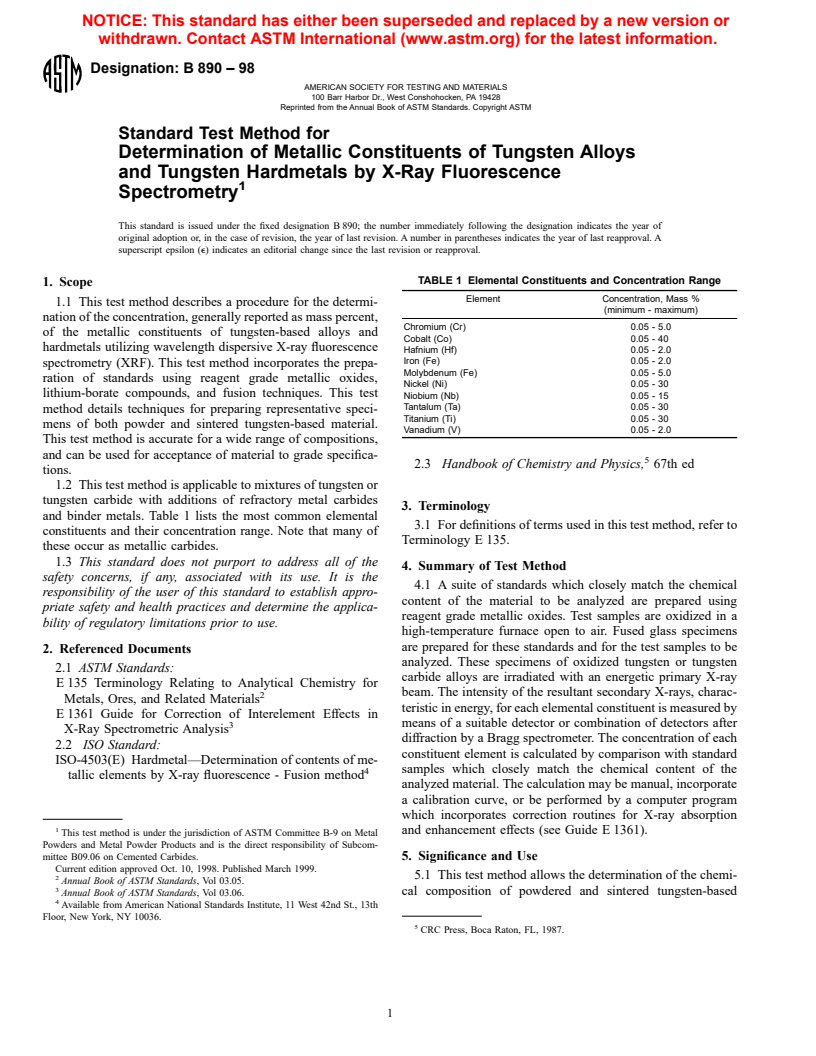

TABLE 1 Elemental Constituents and Concentration Range

1. Scope

Element Concentration, Mass %

1.1 This test method describes a procedure for the determi-

(minimum - maximum)

nation of the concentration, generally reported as mass percent,

Chromium (Cr) 0.05 - 5.0

of the metallic constituents of tungsten-based alloys and

Cobalt (Co) 0.05 - 40

hardmetals utilizing wavelength dispersive X-ray fluorescence

Hafnium (Hf) 0.05 - 2.0

Iron (Fe) 0.05 - 2.0

spectrometry (XRF). This test method incorporates the prepa-

Molybdenum (Fe) 0.05 - 5.0

ration of standards using reagent grade metallic oxides,

Nickel (Ni) 0.05 - 30

lithium-borate compounds, and fusion techniques. This test

Niobium (Nb) 0.05 - 15

Tantalum (Ta) 0.05 - 30

method details techniques for preparing representative speci-

Titanium (Ti) 0.05 - 30

mens of both powder and sintered tungsten-based material.

Vanadium (V) 0.05 - 2.0

This test method is accurate for a wide range of compositions,

and can be used for acceptance of material to grade specifica-

5

2.3 Handbook of Chemistry and Physics, 67th ed

tions.

1.2 This test method is applicable to mixtures of tungsten or

tungsten carbide with additions of refractory metal carbides

3. Terminology

and binder metals. Table 1 lists the most common elemental

3.1 For definitions of terms used in this test method, refer to

constituents and their concentration range. Note that many of

Terminology E 135.

these occur as metallic carbides.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 A suite of standards which closely match the chemical

responsibility of the user of this standard to establish appro-

content of the material to be analyzed are prepared using

priate safety and health practices and determine the applica-

reagent grade metallic oxides. Test samples are oxidized in a

bility of regulatory limitations prior to use.

high-temperature furnace open to air. Fused glass specimens

are prepared for these standards and for the test samples to be

2. Referenced Documents

analyzed. These specimens of oxidized tungsten or tungsten

2.1 ASTM Standards:

carbide alloys are irradiated with an energetic primary X-ray

E 135 Terminology Relating to Analytical Chemistry for

beam. The intensity of the resultant secondary X-rays, charac-

2

Metals, Ores, and Related Materials

teristic in energy, for each elemental constituent is measured by

E 1361 Guide for Correction of Interelement Effects in

means of a suitable detector or combination of detectors after

3

X-Ray Spectrometric Analysis

diffraction by a Bragg spectrometer. The concentration of each

2.2 ISO Standard:

constituent element is calculated by comparison with standard

ISO-4503(E) Hardmetal—Determination of contents of me-

samples which closely match the chemical content of the

4

tallic elements by X-ray fluorescence - Fusion method

analyzed material. The calculation may be manual, incorporate

a calibration curve, or be performed by a computer program

which incorporates correction routines for X-ray absorption

1

and enhancement effects (see Guide E 1361).

This test method is under the jurisdiction of ASTM Committee B-9 on Metal

Powders and Metal Powder Products and is the direct responsibility of Subcom-

mittee B09.06 on Cemented Carbides. 5. Significance and Use

Current edition approved Oct. 10, 1998. Published March 1999.

5.1 This test method allows the determination of the chemi-

2

Annual Book of ASTM Standards, Vol 03.05.

3

cal composition of powdered and sintered tungsten-based

Annual Book of ASTM Standards, Vol 03.06.

4

Available from American National Standards Institute, 11 West 42nd St., 13th

Floor, New York, NY 10036.

5

CRC Press, Boca Raton, FL, 1987.

1

---------------------- Page: 1 ----------------------

NOTICE:¬This¬standard¬has¬either¬been¬superseded¬and¬replaced¬by¬a¬new¬version¬or

discontinued.¬Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

B 890

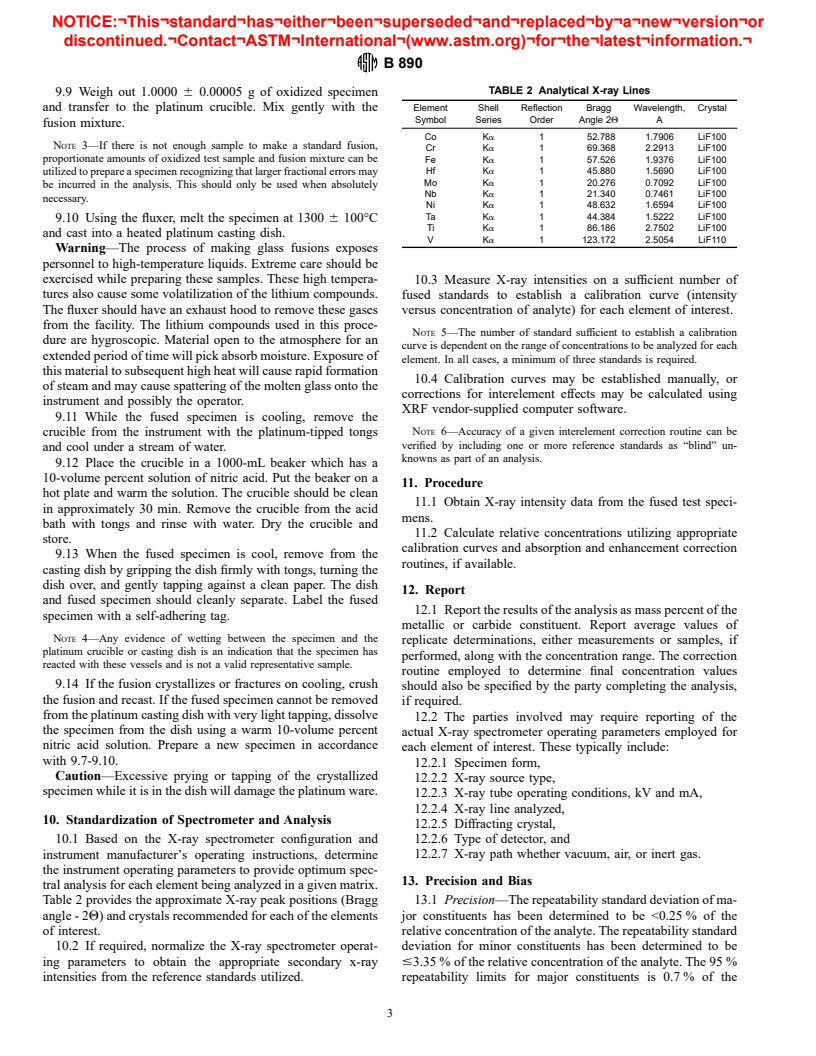

6

hardmetals. This test method is not applicable to material such specifications are available. Other grades may be used,

which will not oxidize readily at high t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.