ASTM F959-99a

(Specification)Standard Specification for Compressible-Washer-Type Direct Tension Indicators for Use with Structural Fasteners

Standard Specification for Compressible-Washer-Type Direct Tension Indicators for Use with Structural Fasteners

SCOPE

1.1 This specification covers the requirements for compressible-washer-type direct tension indicators capable of indicating the achievement of a specified minimum bolt tension in a structural bolt.

1.2 Two types of direct tension indicators in nominal diameter sizes 1/2 through 1 1/2 in. are covered:

1.2.1 Type 325—direct tension indicators for use with Specification A 325 bolts, and

1.2.2 Type 490—direct tension indicators for use with Specification A 490 bolts.

1.3 Direct tension indicators are intended for installation under either a bolt head or a hardened washer. (See Research Council on Structural Connections: Specification for Structural Joints Using ASTM A 325 or A 490 Bolts.)

1.4 The following precautionary statement pertains only to the test method portions, Section and of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 959 – 99a

Standard Specification for

Compressible-Washer-Type Direct Tension Indicators for

1

Use with Structural Fasteners

This standard is issued under the fixed designation F 959; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the requirements for

compressible-washer-type direct tension indicators capable of

indicating the achievement of a specified minimum bolt tension

in a structural bolt.

1.2 Two types of direct tension indicators in nominal

1 1

diameter sizes ⁄2 through 1 ⁄2 in., are covered:

1.2.1 Type 325—direct tension indicators for use with A 325

bolts, and

1.2.2 Type 490—direct tension indicators for use with A 490

bolts.

1.3 Direct tension indicators are intended for installation

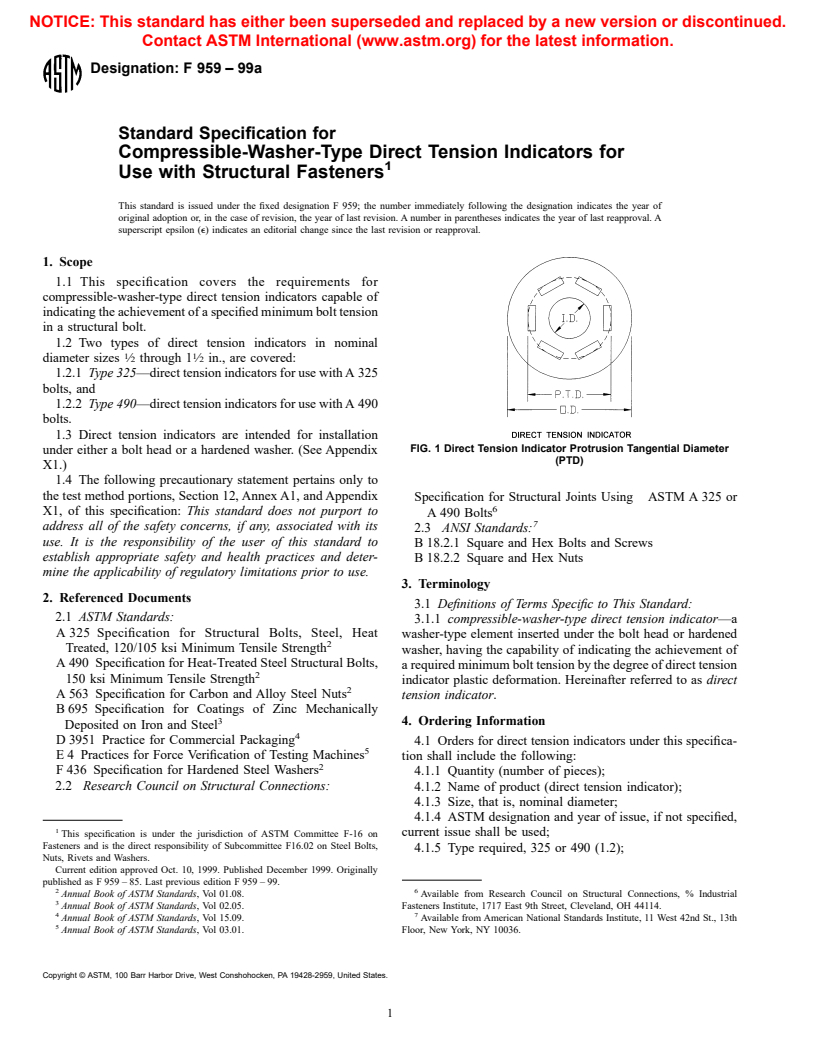

FIG. 1 Direct Tension Indicator Protrusion Tangential Diameter

under either a bolt head or a hardened washer. (See Appendix

(PTD)

X1.)

1.4 The following precautionary statement pertains only to

the test method portions, Section 12, Annex A1, and Appendix

Specification for Structural Joints Using ASTM A 325 or

6

X1, of this specification: This standard does not purport to

A 490 Bolts

7

address all of the safety concerns, if any, associated with its

2.3 ANSI Standards:

use. It is the responsibility of the user of this standard to

B 18.2.1 Square and Hex Bolts and Screws

establish appropriate safety and health practices and deter-

B 18.2.2 Square and Hex Nuts

mine the applicability of regulatory limitations prior to use.

3. Terminology

2. Referenced Documents

3.1 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards:

3.1.1 compressible-washer-type direct tension indicator—a

A 325 Specification for Structural Bolts, Steel, Heat

washer-type element inserted under the bolt head or hardened

2

Treated, 120/105 ksi Minimum Tensile Strength

washer, having the capability of indicating the achievement of

A 490 Specification for Heat-Treated Steel Structural Bolts,

a required minimum bolt tension by the degree of direct tension

2

150 ksi Minimum Tensile Strength

indicator plastic deformation. Hereinafter referred to as direct

2

A 563 Specification for Carbon and Alloy Steel Nuts

tension indicator.

B 695 Specification for Coatings of Zinc Mechanically

3

4. Ordering Information

Deposited on Iron and Steel

4

D 3951 Practice for Commercial Packaging

4.1 Orders for direct tension indicators under this specifica-

5

E 4 Practices for Force Verification of Testing Machines tion shall include the following:

2

F 436 Specification for Hardened Steel Washers

4.1.1 Quantity (number of pieces);

2.2 Research Council on Structural Connections: 4.1.2 Name of product (direct tension indicator);

4.1.3 Size, that is, nominal diameter;

4.1.4 ASTM designation and year of issue, if not specified,

1

This specification is under the jurisdiction of ASTM Committee F-16 on current issue shall be used;

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts,

4.1.5 Type required, 325 or 490 (1.2);

Nuts, Rivets and Washers.

Current edition approved Oct. 10, 1999. Published December 1999. Originally

published as F 959 – 85. Last previous edition F 959 – 99.

2 6

Annual Book of ASTM Standards, Vol 01.08. Available from Research Council on Structural Connections, % Industrial

3

Annual Book of ASTM Standards, Vol 02.05. Fasteners Institute, 1717 East 9th Street, Cleveland, OH 44114.

4 7

Annual Book of ASTM Standards, Vol 15.09. Available from American National Standards Institute, 11 West 42nd St., 13th

5

Annual Book of ASTM Standards, Vol 03.01. Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 959

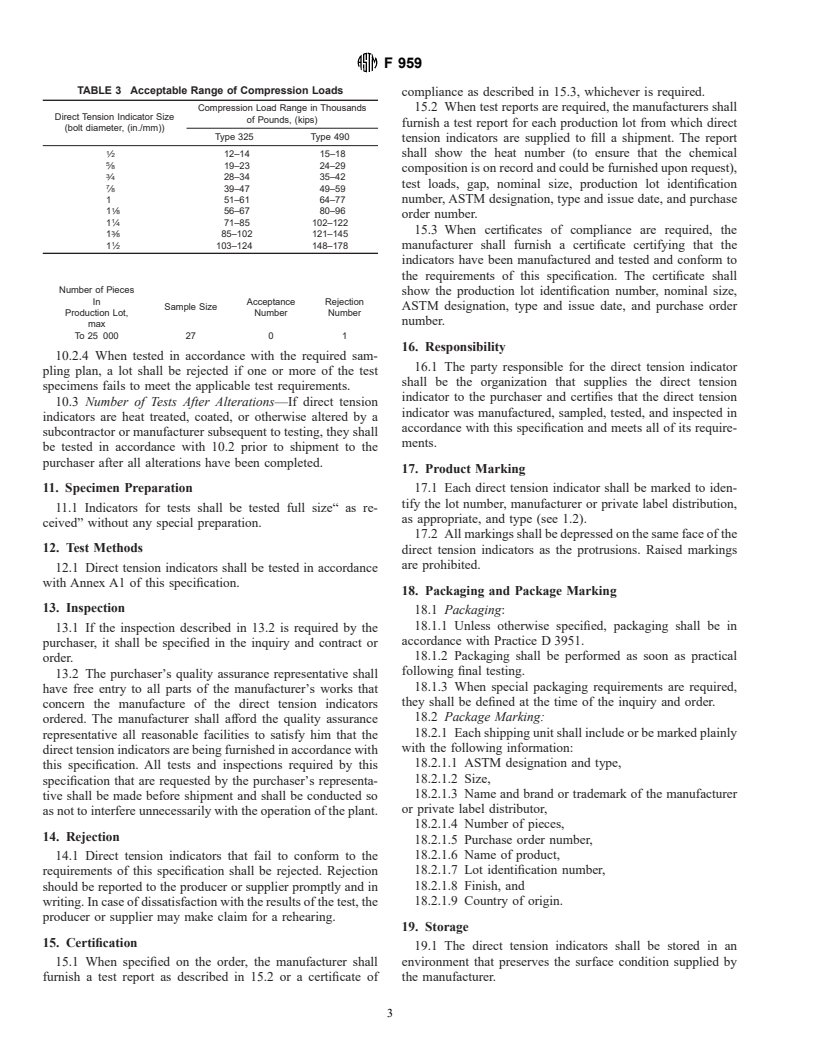

4.1.6 Coating type, if required (5.4); tested in accordance with Annex A1 of this specification. When

4.1.7 Source inspection, if required (Section 13); compressed to the gap specified in Table 2, the compression

4.1.8 Certificates of compliance or test reports, if required

load shall conform to the requirements specified in Table 3.

(Section 15), and

7.2 Bolt Tension— See Appendix X1 for field tests to ensure

4.1.9 Any special requirements.

that the desired minimum bolt tension has been achieved.

5. Materials and Manufacture

8. Dimensions

5.1 Steel used in the manufacture of direct tension indica-

8.1 The direct tension indicators shall conform to the

tors shall be produced by the basic-oxygen or electric-furnace

dimensions specified in Table 4.

process.

5.2 Design:

9. Workmanship, Finish, and Appearance

5.2.1 Direct tension indicators shall have a configuration

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.