ASTM C1778-16

(Guide)Standard Guide for Reducing the Risk of Deleterious Alkali-Aggregate Reaction in Concrete

Standard Guide for Reducing the Risk of Deleterious Alkali-Aggregate Reaction in Concrete

SIGNIFICANCE AND USE

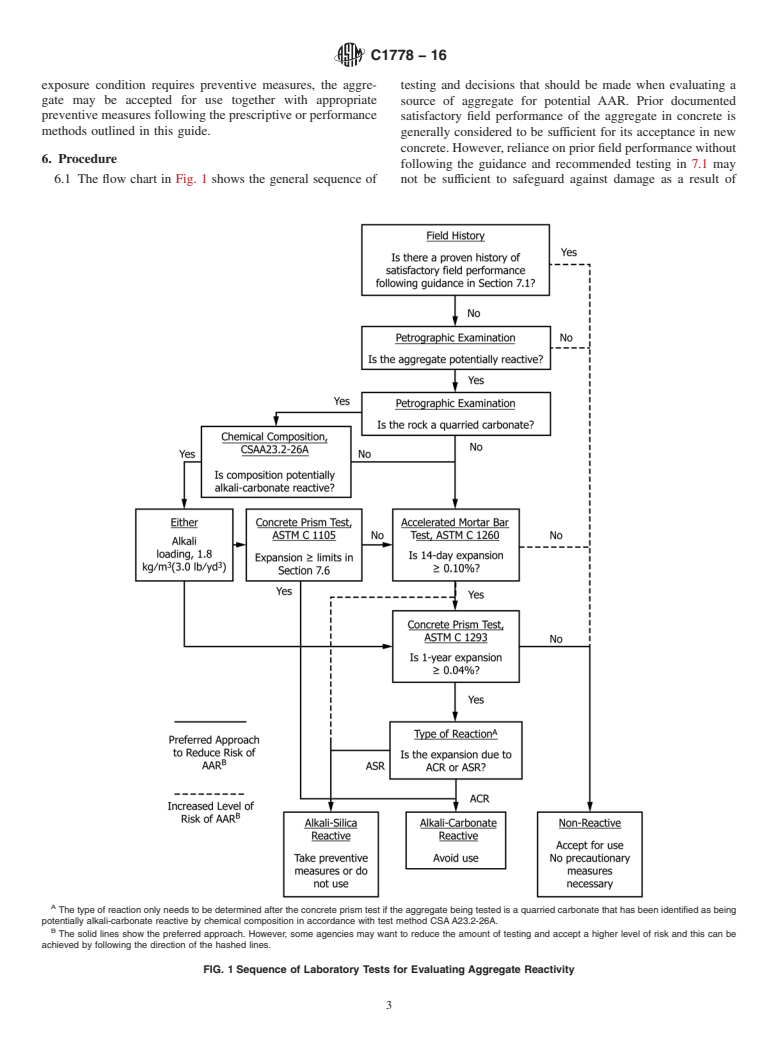

5.1 This guide provides recommendations for identifying the potential for deleterious AAR and selecting appropriate preventive measures, based on a prescriptive-based or performance approach, to minimize the risk of deleterious reaction. In regions where occurrences of AAR are rare or the aggregate sources in use have a satisfactory field performance record verified by following the guidance in this standard, it is reasonable to continue to rely on the previous field history without subjecting the aggregates to laboratory tests for AAR. In regions where AAR problems have occurred or the reactivity of aggregates is known to vary from source to source, it may be necessary to follow a testing program to determine potential reactivity and evaluate preventive measures. In this guide, the level of prevention required is a function of the reactivity of the aggregate, the nature of the exposure conditions (especially availability of moisture), the criticality of the structure, and the availability of alkali in the concrete.

5.2 Risk Evaluation—To use this guide effectively, it is necessary to define the level of risk that is acceptable, as this will determine the type and complexity of testing (Note 1). The risk of deleterious expansion occurring as a result of a failure to detect deleteriously reactive aggregates can be reduced by routine testing using petrography, or laboratory expansion tests, or both.

Note 1: The level of risk of alkali-silica reaction will depend upon the nature of the project (criticality of the structure and anticipated exposure). The determination of the level of risk is the responsibility of the individual in charge of the design, commonly a representative of the owner, and for structures designed in accordance with ACI 318, the level of acceptable risk would be determined by the licensed design professional.

5.3 For conventional structures, preventive measures determined by either performance testing or the prescriptive approach described ...

SCOPE

1.1 This guide provides guidance on how to address the potential for deleterious alkali aggregate reaction (AAR) in concrete construction. This guide addresses the process of identifying both potentially alkali-silica reactive (ASR) and alkali-carbonate reactive (ACR) aggregates through standardized testing procedures and the selection of mitigation options to minimize the risk of expansion when ASR aggregates are used in concrete construction. Mitigation methods for ASR aggregates are selected using either prescriptive or performance-based alternatives. Preventive measures for ACR aggregates are limited to avoidance of use. Because the potential for deleterious reactions depends not only on the concrete mixture but also the in-service exposure, guidance is provided on the type of structures and exposure environments where AAR may be of concern.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1778 − 16

Standard Guide for

Reducing the Risk of Deleterious Alkali-Aggregate Reaction

1

in Concrete

This standard is issued under the fixed designation C1778; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C125 Terminology Relating to Concrete and Concrete Ag-

gregates

1.1 This guide provides guidance on how to address the

C150/C150M Specification for Portland Cement

potential for deleterious alkali aggregate reaction (AAR) in

C294 Descriptive Nomenclature for Constituents of Con-

concrete construction. This guide addresses the process of

crete Aggregates

identifying both potentially alkali-silica reactive (ASR) and

C295 Guide for Petrographic Examination ofAggregates for

alkali-carbonate reactive (ACR) aggregates through standard-

Concrete

ized testing procedures and the selection of mitigation options

C311 Test Methods for Sampling and Testing Fly Ash or

to minimize the risk of expansion when ASR aggregates are

Natural Pozzolans for Use in Portland-Cement Concrete

used in concrete construction. Mitigation methods for ASR

C586 Test Method for PotentialAlkali Reactivity of Carbon-

aggregates are selected using either prescriptive or

ate Rocks as Concrete Aggregates (Rock-Cylinder

performance-based alternatives. Preventive measures for ACR

Method)

aggregates are limited to avoidance of use. Because the

C595 Specification for Blended Hydraulic Cements

potential for deleterious reactions depends not only on the

C618 Specification for Coal Fly Ash and Raw or Calcined

concrete mixture but also the in-service exposure, guidance is

Natural Pozzolan for Use in Concrete

provided on the type of structures and exposure environments

C823/C823M Practice for Examination and Sampling of

where AAR may be of concern.

Hardened Concrete in Constructions

1.2 Units—The values stated in either SI units or inch-

C856 Practice for Petrographic Examination of Hardened

pound units are to be regarded separately as standard. The

Concrete

values stated in each system may not be exact equivalents;

C989 Specification for Slag Cement for Use in Concrete and

therefore,eachsystemshallbeusedindependentlyoftheother.

Mortars

Combining values from the two systems may result in noncon-

C1105 Test Method for Length Change of Concrete Due to

formance with the standard.

Alkali-Carbonate Rock Reaction

1.3 This standard does not purport to address all of the

C1157 Performance Specification for Hydraulic Cement

safety concerns, if any, associated with its use. It is the

C1240 Specification for Silica Fume Used in Cementitious

responsibility of the user of this standard to establish appro-

Mixtures

priate safety and health practices and determine the applica-

C1260 Test Method for Potential Alkali Reactivity of Ag-

bility of regulatory limitations prior to use.

gregates (Mortar-Bar Method)

2. Referenced Documents C1293 Test Method for Determination of Length Change of

Concrete Due to Alkali-Silica Reaction

2

2.1 ASTM Standards:

C1567 Test Method for Determining the Potential Alkali-

C33/C33M Specification for Concrete Aggregates

Silica Reactivity of Combinations of Cementitious Mate-

rials and Aggregate (Accelerated Mortar-Bar Method)

1

This guide is under the jurisdiction ofASTM Committee C09 on Concrete and

3

Concrete Aggregates and is the direct responsibility of Subcommittee C09.50 on 2.2 ACI Standard:

Risk Management for Alkali Aggregate Reactions.

ACI 318 Building Code Requirements for Structural Con-

Current edition approved July 1, 2016. Published August 2016. Originally

crete and Commentary

approved in 2014. Last previous edition approved in 2014 as C1778–14. DOI:

10.1520/C1778-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

the ASTM website. Hills, MI 48333-9094, http://www.concrete.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1778 − 16

2.3 AASHTO Standard: expansion and cracking of concrete elements when exposed to

AASHTO PP 65 Standard Practice for Determining the moisture, leading to a reduction in the service life of concrete

Reactivity of Concrete Aggregates and Selecting Appro- structures.

priate Measures for Preventing Deleterious Expansion in

4.2 This guide describes approaches for identifying poten-

4

New Concrete C

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1778 − 14 C1778 − 16

Standard Guide for

Reducing the Risk of Deleterious Alkali-Aggregate Reaction

1

in Concrete

This standard is issued under the fixed designation C1778; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide provides guidance on how to address the potential for deleterious alkali aggregate reaction (AAR) in concrete

construction. This guide addresses the process of identifying both potentially alkali-silica reactive (ASR) and alkali-carbonate

reactive (ACR) aggregates through standardized testing procedures and the selection of mitigation options to minimize the risk of

expansion when ASR aggregates are used in concrete construction. Mitigation methods for ASR aggregates are selected using

either prescriptive or performance-based alternatives. Preventive measures for ACR aggregates are limited to avoidance of use.

Because the potential for deleterious reactions depends not only on the concrete mixture but also the in-service exposure, guidance

is provided on the type of structures and exposure environments where AAR may be of concern.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C33/C33M Specification for Concrete Aggregates

C125 Terminology Relating to Concrete and Concrete Aggregates

C150/C150M Specification for Portland Cement

C294 Descriptive Nomenclature for Constituents of Concrete Aggregates

C295 Guide for Petrographic Examination of Aggregates for Concrete

C311 Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete

C586 Test Method for Potential Alkali Reactivity of Carbonate Rocks as Concrete Aggregates (Rock-Cylinder Method)

C595 Specification for Blended Hydraulic Cements

C618 Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete

C823/C823M Practice for Examination and Sampling of Hardened Concrete in Constructions

C856 Practice for Petrographic Examination of Hardened Concrete

C989 Specification for Slag Cement for Use in Concrete and Mortars

C1105 Test Method for Length Change of Concrete Due to Alkali-Carbonate Rock Reaction

C1157 Performance Specification for Hydraulic Cement

C1240 Specification for Silica Fume Used in Cementitious Mixtures

C1260 Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method)

C1293 Test Method for Determination of Length Change of Concrete Due to Alkali-Silica Reaction

C1567 Test Method for Determining the Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and

Aggregate (Accelerated Mortar-Bar Method)

1

This guide is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.50 on Risk

Management for Alkali Aggregate Reactions.

Current edition approved Oct. 1, 2014July 1, 2016. Published November 2014August 2016. Originally approved in 2014. Last previous edition approved in 2014 as

C1778–14. DOI: 10.1520/C1778-14.10.1520/C1778-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1778 − 16

3

2.2 ACI Standard:

ACI 318 Building Code Requirements for Structural Concrete and Commentary

2.3 AASHTO Standard:

AASHTO PP 65 Standard Practice for Determining the Reactivity of Concrete Aggregates and Selecting Appropriate Measures

4

for Preventing Deleterious Expansion in New Concrete C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.