ASTM D7453-09(2015)

(Practice)Standard Practice for Sampling of Petroleum Products for Analysis by Process Stream Analyzers and for Process Stream Analyzer System Validation

Standard Practice for Sampling of Petroleum Products for Analysis by Process Stream Analyzers and for Process Stream Analyzer System Validation

SIGNIFICANCE AND USE

5.1 Analyzer systems require representative samples of petroleum products delivered in a timely manner to (1) facilitate the control of process or blending units or (2) calculate a flow proportioned property value.

5.2 Representative samples of petroleum products are required for the determination of chemical and physical properties. These properties are used to establish the relationship between the analyzer system and the primary test method during initial and ongoing validation of the system.

5.3 Representative samples of petroleum products are tested to determine the chemical and physical properties of a batch offered for tender.

SCOPE

1.1 This practice covers the performance requirements for sample systems employed to deliver process stream samples (1) to analyzer system for analyses or (2) for analyzer validation or (3) for composite sample systems. It also outlines the selection and operation of line or batch sampling equipment intended for analyzer flow proportioned average property value system validation. Sample handling, mixing, and conditioning procedures are required to ensure that a representative sample of the liquid petroleum product is collected from the sampling source.

1.2 Applicable Fluids—This practice is applicable to single liquid phase petroleum products whose vapor pressure at sampling and sample storage conditions is less than or equal to 110 kPa (16.0 psi), and, with a D86 final boiling point less than or equal to 400 °C (752 °F).

1.2.1 Specialized sample handling may be necessary to maintain sample integrity of more volatile materials at high temperatures or extended residence time in the receiver. Such handling requirements are not within the scope of this practice. Users should consult the analytical methods to be performed on the sample for special sample storage or conditioning requirements.

1.3 Some or all of the processes outlined in this practice may be applicable to other liquids. Applying this practice to other liquids will require the consideration of additional methods and practices. It is the responsibility of the user of this standard to identify any and all applicable safety and sampling considerations and establish appropriate procedures to handle these additional considerations.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7453 − 09 (Reapproved 2015)

Standard Practice for

Sampling of Petroleum Products for Analysis by Process

Stream Analyzers and for Process Stream Analyzer System

Validation

This standard is issued under the fixed designation D7453; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The primary focus of sampling petroleum product is the timely presentation of the sample for (1)

analysis by online analyzers, (2) validation of an analyzer system and (3) collecting a composite

sample for batch physical property determination. Sediment, free water, rust, and other contaminants

found in the sample may be removed in the sample conditioning system to protect the hardware and

analytical systems. If a sample is being collected for later analysis, the sample receiver must not alter

or degrade the physical make up of the sample in any way. If a sample is being feed to an analyzer

orsampledforlatterdeterminationofwaterorparticulatecontaminationthenfilteringisnotanoption.

1. Scope 1.3 Some or all of the processes outlined in this practice

may be applicable to other liquids. Applying this practice to

1.1 This practice covers the performance requirements for

other liquids will require the consideration of additional

sample systems employed to deliver process stream samples

methods and practices. It is the responsibility of the user of this

(1) to analyzer system for analyses or (2) for analyzer

standard to identify any and all applicable safety and sampling

validation or (3) for composite sample systems. It also outlines

considerations and establish appropriate procedures to handle

theselectionandoperationoflineorbatchsamplingequipment

these additional considerations.

intendedforanalyzerflowproportionedaveragepropertyvalue

system validation. Sample handling, mixing, and conditioning 1.4 The values stated in SI units are to be regarded as the

procedures are required to ensure that a representative sample standard. The values given in parentheses are for information

of the liquid petroleum product is collected from the sampling only.

source.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.2 Applicable Fluids—This practice is applicable to single

responsibility of the user of this standard to establish appro-

liquid phase petroleum products whose vapor pressure at

priate safety and health practices and determine the applica-

sampling and sample storage conditions is less than or equal to

bility of regulatory limitations prior to use.

110 kPa (16.0 psi), and, with a D86 final boiling point less than

or equal to 400 °C (752 °F).

2. Referenced Documents

1.2.1 Specialized sample handling may be necessary to

maintain sample integrity of more volatile materials at high 2.1 ASTM Standards:

temperatures or extended residence time in the receiver. Such D3764 Practice forValidation of the Performance of Process

handling requirements are not within the scope of this practice. Stream Analyzer Systems

Usersshouldconsulttheanalyticalmethodstobeperformedon

D6122 Practice for Validation of the Performance of Multi-

the sample for special sample storage or conditioning require- variate Online, At-Line, and Laboratory Infrared Spectro-

ments.

photometer Based Analyzer Systems

D6624 Practice for Determining a Flow-Proportioned Aver-

age Property Value (FPAPV) for a Collected Batch of

1 Process Stream Material Using Stream Analyzer Data

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

mittee D02.25 on Performance Assessment and Validation of Process Stream

Analyzer Systems. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2015. Published May 2015. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2009. Last previous edition approved in 2009 as D7453 – 09. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7453-09R15. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7453 − 09 (2015)

D7278 GuideforPredictionofAnalyzerSampleSystemLag predicted PTM results with acceptable precision and bias

Times performance when compared to actual results from a primary

test method measurement system for common materials.

3. Terminology

4. Summary of Practice

3.1 Definitions:

4.1 Analyzer measurement systems require a process

3.1.1 analyzer unit response time, n—time interval between

samplethatisdeliveredinatimelymannercommensuratewith

the introduction of a step change in property characteristic at

the analyzer and process cycle time at pressure, temperature

the inlet of the analyzer unit and when the analyzer output

and flow conditions meeting system requirements, is free of

indicates a value corresponding to 99.5 % of the subsequent

contaminants, and is representative of the process stream.

change in analyzer results.

4.2 Line samples collected from the process or blender

3.1.2 automatic sampler, n—device used to repetitively

stream need to accurately reflect the composition of the

extract an grab and collect a representative sample of a batch

analyzer feed stream. This is accomplished by taking into

or process stream.

account the total analyzer system response time in order to

3.1.3 automatic sampling system, n—system consisting of a

properly validate online analyzer systems.

sample probe, sample fast cycle loop, sample supply line

4.3 This practice describes functional requirements that

stream conditioning, an automatic sampler and an associated

need to be addressed in the design and operation of automatic

controller, a flow measuring device, and sample holding,

sampling equipment.Automatic sampling equipment is used to

mixing and handling capabilities.

obtain a representative batch sample for use in validating an

3.1.4 batch, n—term referring to a volume or parcel being

analyzer system or flow proportioned average property value

transferred.

and for manufactured batch quality testing.

3.1.5 flow proportional sampler, n—sampler designed to

automatically adjust the sampling rate to be proportional to the 5. Significance and Use

flow rate of the stream.

5.1 Analyzer systems require representative samples of

3.1.6 grab, n—volume of sample extracted from a batch by

petroleum products delivered in a timely manner to (1)

a single actuation of the sample extractor.

facilitate the control of process or blending units or (2)

calculate a flow proportioned property value.

3.1.7 lag time, n—time required for material to travel from

pointAto point B in the total analyzer system (pointsAand B

5.2 Representative samples of petroleum products are re-

are user-defined).

quired for the determination of chemical and physical proper-

ties. These properties are used to establish the relationship

3.1.8 line sample, n—process material that can be safely

between the analyzer system and the primary test method

withdrawn from a sample port and associated facilities located

during initial and ongoing validation of the system.

anywhere in the total analyzer system without significantly

altering the property of interest.

5.3 Representative samples of petroleum products are tested

3.1.9 primary test method (PTM), n—ASTM or other estab- to determine the chemical and physical properties of a batch

offered for tender.

lished standard test method that produces results accepted as

the reference measure of a property.

6. Sample Delivery and Conditioning Requirements for

3.1.10 sample conditioning unit lag time, n— time required

Process Stream Analyzers

for material to flow from the sample conditioning unit inlet to

6.1 The sample will be delivered from the sample stream to

the analyzer unit inlet.

the analyzer inlet for measurement in the minimum realistic

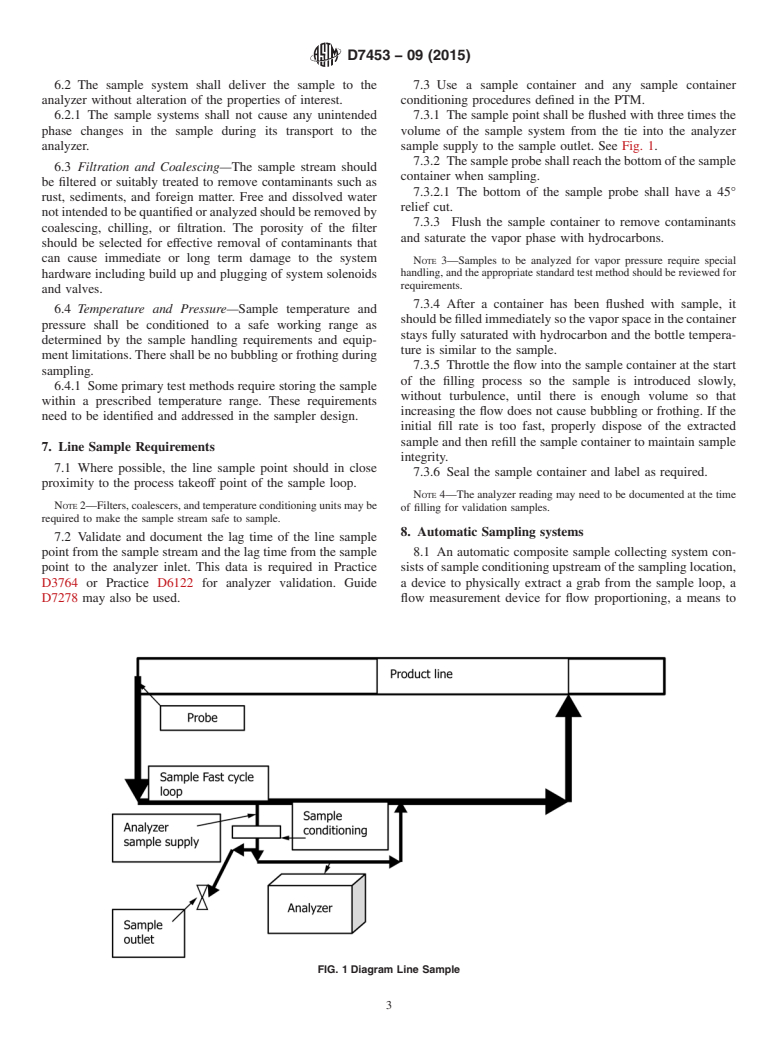

3.1.11 sample fast cycle loop, n—a system that continually

period of time possible.

and rapidly transports a representative sample of process

6.1.1 When sampling from processes that normally operate

material from the sample probe past the sample supply line and

in steady state mode, not subject to scheduled operational

returns the remaining material to the process.

variable(s) step changes that directly impact the measured

3.1.11.1 sample fast loop lag time, n—time required for

variable, the sample fast loop lag time shall be as short as

material to transport from the product takeoff point of the

practicallypossible.Itisrecommendedthatwherepossible,the

sample loop to the sample conditioning unit inlet.

sample fast loop lag time should be less than the analyzer

response time. A minimum realistic time is two minutes.

3.1.12 total analyzer system response time, n—time interval

between the when a step change in property characteristic

NOTE 1—Guide D7278 can be used for the prediction of analyzer

arrives at the sample loop inlet and when the analyzer output

sample system lag times. Refer to Practice D3764 for analyzer unit

indicates a value corresponding to 99.5 % of the subsequent response time information.

change in analyze

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7453 − 09 D7453 − 09 (Reapproved 2015)

Standard Practice for

Sampling of Petroleum Products for Analysis by Process

Stream Analyzers and for Process Stream Analyzer System

Validation

This standard is issued under the fixed designation D7453; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The primary focus of sampling petroleum product is the timely presentation of the sample for (1)

analysis by online analyzers, (2) validation of an analyzer system and (3) collecting a composite

sample for batch physical property determination. Sediment, free water, rust, and other contaminants

found in the sample may be removed in the sample conditioning system to protect the hardware and

analytical systems. If a sample is being collected for later analysis, the sample receiver must not alter

or degrade the physical make up of the sample in any way. If a sample is being feed to an analyzer

or sampled for latter determination of water or particulate contamination then filtering is not an option.

1. Scope

1.1 This practice covers the performance requirements for sample systems employed to deliver process stream samples (1) to

analyzer system for analyses or (2) for analyzer validation or (3) for composite sample systems. It also outlines the selection and

operation of line or batch sampling equipment intended for analyzer flow proportioned average property value system validation.

Sample handling, mixing, and conditioning procedures are required to ensure that a representative sample of the liquid petroleum

product is collected from the sampling source.

1.2 Applicable Fluids—This practice is applicable to single liquid phase petroleum products whose vapor pressure at sampling

and sample storage conditions is less than or equal to 110 kPa (16.0 psi), 110 kPa (16.0 psi), and, with a D86 final boiling point

less than or equal to 400°C (752°F).400 °C (752 °F).

1.2.1 Specialized sample handling may be necessary to maintain sample integrity of more volatile materials at high temperatures

or extended residence time in the receiver. Such handling requirements are not within the scope of this practice. Users should

consult the analytical methods to be performed on the sample for special sample storage or conditioning requirements.

1.3 Some or all of the processes outlined in this practice may be applicable to other liquids. Applying this practice to other

liquids will require the consideration of additional methods and practices. It is the responsibility of the user of this standard to

identify any and all applicable safety and sampling considerations and establish appropriate procedures to handle these additional

considerations.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D3764 Practice for Validation of the Performance of Process Stream Analyzer Systems

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.25 on Performance Assessment and Validation of Process Stream Analyzer Systems.

Current edition approved April 15, 2009April 1, 2015. Published May 2009May 2015. Originally approved in 2009. Last previous edition approved in 2009 as D7453 – 09.

DOI: 10.1520/D7453-09.10.1520/D7453-09R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7453 − 09 (2015)

D6122 Practice for Validation of the Performance of Multivariate Online, At-Line, and Laboratory Infrared Spectrophotometer

Based Analyzer Systems

D6624 Practice for Determining a Flow-Proportioned Average Property Value (FPAPV) for a Collected Batch of Process Stream

Material Using Stream Analyzer Data

D7278 Guide for Prediction of Analyzer Sample System Lag Times

3. Terminology

3.1 Definitions:

3.1.1 analyzer unit response time, n—time interval between the introduction of a step change in property characteristic at the

inlet of the analyzer unit and when the analyzer output indicates a value corresponding to 99.5%99.5 % of the subsequent change

in analyzer results.

3.1.2 automatic sampler, n—device used to repetitively extract an grab and collect a representative sample of a batch or process

stream.

3.1.3 automatic sampling system, n—system consisting of a sample probe, sample fast cycle loop, sample supply line stream

conditioning, an automatic sampler and an associated controller, a flow measuring device, and sample holding, mixing and

handling capabilities.

3.1.4 batch, n—term referring to a volume or parcel being transferred.

3.1.5 flow proportional sampler, n—sampler designed to automatically adjust the sampling rate to be proportional to the flow

rate of the stream.

3.1.6 grab, n—volume of sample extracted from a batch by a single actuation of the sample extractor.

3.1.7 lag time, n—time required for material to travel from point A to point B in the total analyzer system (points A and B are

user-defined).

3.1.8 line sample, n—process material that can be safely withdrawn from a sample port and associated facilities located

anywhere in the total analyzer system without significantly altering the property of interest.

3.1.9 primary test method (PTM), n—ASTM or other established standard test method that produces results accepted as the

reference measure of a property.

3.1.10 sample conditioning unit lag time, n— time required for material to flow from the sample conditioning unit inlet to the

analyzer unit inlet.

3.1.11 sample fast cycle loop, n—a system that continually and rapidly transports a representative sample of process material

from the sample probe past the sample supply line and returns the remaining material to the process.

3.1.11.1 sample fast loop lag time, n—time required for material to transport from the product takeoff point of the sample loop

to the sample conditioning unit inlet.

3.1.12 total analyzer system response time, n—time interval between the when a step change in property characteristic arrives

at the sample loop inlet and when the analyzer output indicates a value corresponding to 99.5%99.5 % of the subsequent change

in analyzer results.

3.1.12.1 Discussion—

The total analyzer system response time is the sum of the sample fast loop lag time, the sample conditioning unit lag time, and

the analyzer unit response time.

3.1.13 validation, n—statistically quantified judgment that the analyzer system or subsystem being assessed can produce

predicted PTM results with acceptable precision and bias performance when compared to actual results from a primary test method

measurement system for common materials.

4. Summary of Practice

4.1 Analyzer measurement systems require a process sample that is delivered in a timely manner commensurate with the

analyzer and process cycle time at pressure, temperature and flow conditions meeting system requirements, is free of contaminants,

and is representative of the process stream.

4.2 Line samples collected from the process or blender stream need to accurately reflect the composition of the analyzer feed

stream. This is accomplished by taking into account the total analyzer system response time in order to properly validate online

analyzer systems.

4.3 This practice describes functional requirements that need to be addressed in the design and operation of automatic sampling

equipment. Automatic sampling equipment is used to obtain a representative batch sample for use in validating an analyzer system

or flow proportioned average property value and for manufactured batch quality testing.

D7453 − 09 (2015)

5. Significance and Use

5.1 Analyzer systems require representative samples of petroleum products delivered in a timely manner to (1) facilitate the

control of process or blending units or (2) calculate a flow proportioned property value.

5.2 Representative samples of petroleum products are required for the determination of chemical and physical properties. These

properties are used to establish the relationship between the analyzer system and the primary test method during initial and ongoing

validation of the system.

5.3 Representative samples of petroleum products are tested to determine the chemical and physical properties of a batch offered

for tender.

6. Sample Delivery and Conditioning Requirements for Process Stream Analyzers

6.1 The sample will be delivered from the sample stream to the analyzer inlet for measurement in the minimum realistic period

of time possible.

6.1.1 When sampling from processes t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.