ASTM D5197-97

(Test Method)Standard Test Method for Determination of Formaldehyde and Other Carbonyl Compounds in Air (Active Sampler Methodology)

Standard Test Method for Determination of Formaldehyde and Other Carbonyl Compounds in Air (Active Sampler Methodology)

SCOPE

1.1 This test method covers a procedure for the determination of formaldehyde (HCHO) and other aldehydes in air. This test method is specific for formaldehyde but, with modification, fourteen other aldehydes can be detected.

1.2 This test method involves drawing air through a cartridge containing silica gel coated with 2,4-dinitrophenylhydrazine (DNPH) reagent. Aldehydes and ketones readily form a stable derivative with the DNPH reagent. The DNPH derivative is analyzed for aldehydes and ketones utilizing high performance liquid chromatography (HPLC). The sampling procedure is a modification of U.S. EPA Method TO-11 (see 2.2).

1.3 This test method is based on the specific reaction of carbonyl compounds (aldehydes and ketones) with DNPH in the presence of an acid to form stable derivatives according to the reaction shown in Fig. 1, (where: both and are alkyl or aromatic groups (ketones), or both, or either or is a hydrogen atom (aldehydes)). The determination of formaldehyde, as a DNPH derivative, is similar to that of U.S. EPA Method TO-11 in that it utilizes HPLC. The detection limits have been extended to other aldehydes and ketones that can be determined as outlined in Section 13. This test method is suitable for determination of formaldehyde in the concentration range of high ppb to low ppm (v/v).

1.4 The sampling method gives a time-weighted average (TWA) sample. It can be used for long-term (1 to 24 h) or short-term (5 to 60 min) sampling of indoor air for formaldehyde.

1.5 The sampling flow rate, as described in this test method is presently limited to about 1.5 L/min. This limitation is principally due to the high pressure drop (>8 kPa at 1.0 L/min) across the DNPH-coated silica gel cartridges. This procedure is not compatible with pumps used in personal sampling equipment, that are inadequate for this application.

1.6 This test method instructs the user to purchase Sep-PAK chromatographic grade silica gel cartridges and apply acidified DNPH in situ to each cartridge, if the user desires to prepare his own cartridges. The silica gel in the Sep-PAK cartridge have a particle size of 55 to 105 [mu]m. Pre-coated DNPH silica gel cartridges are also available, if the user desires to purchase them.

1.7 The values stated in SI units are to be regarded as the standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5197 – 97

Standard Test Method for

Determination of Formaldehyde and Other Carbonyl

Compounds in Air (Active Sampler Methodology)

This standard is issued under the fixed designation D 5197; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope graphic grade silica gel cartridges by the application of

acidified DNPH to each cartridge.

1.1 This test method covers a procedure for the determina-

1.6 The sampling flow rate, as described in this test method,

tion of formaldehyde (HCHO) and other carbonyl compounds

has been validated for sampling rates up to 1.5 L/min. This

(aldehydes and ketones) in air. This test method is most specific

flow rate limitation is principally due to the high pressure drop

for formaldehyde but, with modification, at least 13 other

(>8 kPa at 1.0 L/min) across the user prepared silica gel

carbonyl compounds can be detected and quantified.

cartridges which have a particle size of 55 to 105 μm. These

1.2 This test method involves drawing air through a car-

cartridges are not generally compatible with battery-powered

tridge containing silica gel coated with 2,4-

pumps used in personal sampling equipment (for example,

dinitrophenylhydrazine (DNPH) reagent. Carbonyl compounds

those used by industrial hygienists.

readily form stable derivatives with the DNPH reagent. The

1.7 Alternatively, pre-coated DNPH silica gel cartridges are

DNPH derivatives are analyzed for parent aldehydes and

also available and may be substituted provided they can be

ketones utilizing high performance liquid chromatography

demonstrated to perform equivalently. Some of these use

(HPLC). The sampling procedure is a modification of U.S.

silica gel of a larger particle size that results in a lower pressure

EPA Method TO-11 (see 2.2).

drop across the cartridge. These low pressure drop cartridges

1.3 This test method is based on the specific reaction of

may be more suitable for sampling air using battery-powered

carbonyl compounds with DNPH in the presence of an acid to

personal sampling pumps.

form stable derivatives according to the reaction shown in Fig.

1.8 The values stated in SI units are to be regarded as the

1, (where: both R and R are alkyl or aromatic groups

standard.

(ketones), or both, or either R or R is a hydrogen atom

1.9 This standard does not purport to address all of the

(aldehydes)). The determination of formaldehyde, as a DNPH

safety concerns, if any, associated with its use. It is the

derivative, is similar to that of U.S. EPA Method TO-11 in that

responsibility of the user of this standard to establish appro-

it utilizes HPLC with UV detection as the analytical finish. The

priate safety and health practices and determine the applica-

detection limits have been extended to other carbonyl com-

bility of regulatory limitations prior to use.

pounds that can be determined as outlined in Section 13. This

test method is suitable for determination of formaldehyde and

2. Referenced Documents

other carbonyl compounds in the concentration range from

2.1 ASTM Standards:

approximately 10 ppb to 1 ppm (v/v).

D 1193 Specification for Reagent Water

1.4 The sampling method gives a time-weighted average

D 1356 Terminology Relating to Sampling and Analysis of

(TWA) sample. It can be used for long-term (1 to 24 h) or

Atmospheres

short-term (5 to 60 min) sampling of air for formaldehyde.

D 3195 Practice for Rotameter Calibration

1.5 This test method instructs the user on how to prepare

D 3631 Test Methods for Measuring Surface Atmospheric

sampling cartridges from commercially available chromato-

Pressure

1 2

This test method is under the jurisdiction of ASTM Committee D-22 on The cartridge used in the development and performance evaluation of this test

Sampling and Analysis of Atmospheres and is the direct responsibility of Subcom- method was the Sep-Pak Plus Silica cartridge. The sole source of supply of the

mittee D22.05 on Indoor Air. cartridge known to the committee at this time is Waters Associates, 34 Maple Street,

Current edition approved March 10, 1997. Published May 1997. Originally Milford, MA 01757. If you are aware of alternative suppliers, please provide this

published as D 5197 – 91. Last previous edition D 5197 – 92. information to ASTM Headquarters. Your comments will receive careful consider-

ation at a meeting of the responsible technical committee, which you may attend.

Tejada, S. B., “Evaluation of Silica Gel Cartridges Coated in situ with Acidified

2,4-Dinitrophenylhydrazine for Sampling Aldehydes and Ketones in Air,” Interna-

tional Journal of Environmental Analytical Chemistry, Vol 26, 1986, pp. 167–185.

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 11.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5197

4.2 After sampling, the sample cartridges are individually

capped and placed in individual bottles or other sealable

containers. Sample identifying tags or labels are attached and

the individual sample containers are then placed in a friction-

top can or other suitable sealable secondary container with a

pouch of charcoal for transport to the laboratory for analysis.

The cartridges are placed in cold storage until analysis.

Alternatively, the cartridges may be desorbed, diluted to a

known volume, and refrigerated until analysis.

NOTE 1—A heat-sealable foil-lined plastic pouch of the type included

with some commercial pre-coated DNPH cartridges may be used for

storing a DNPH-coated cartridge after sampling, if appropriate.

4.3 The DNPH-formaldehyde derivative is determined us-

ing isocratic reverse phase HPLC, equipped with an ultraviolet

(UV) absorption detector operated at 360 nm.

FIG. 1 Reaction of Carbonyl Compounds

4.4 A blank cartridge is likewise desorbed and analyzed in

D 3686 Practice for Sampling Atmospheres to Collect Or- accordance with 4.3.

ganic Compound Vapors (Activated Charcoal Tube Ad-

4.5 Formaldehyde and other carbonyl compounds in the

sorption Method)

sample are identified and quantified by comparison of their

E 177 Practice for Use of the Terms Precision and Bias in

retention times and peak heights or peak areas with those of

ASTM Test Methods

standard solutions.

E 682 Practice for Liquid Chromatography Terms and Re-

lationships

5. Significance and Use

2.2 EPA Methods:

5.1 This test method provides an analytical procedure for

Method TO-11, EPA-600/4-89-017, Compendium of Meth-

measuring formaldehyde and other carbonyl compounds in

ods for the Determination of Toxic Organic Compounds in

indoor or outdoor air.

Ambient Air, U.S. Environmental Protection Agency,

Research Triangle Park, NC, June 1988 (PB90-116 989/

6. Interferences

AS)

EPA-600/4-77-027a, Quality Assurance Handbook for Air

6.1 The solid sorbent sampling procedure is specific for

Pollution Measurement Systems, Volume II—Ambient sampling and analysis of formaldehyde. Interferences in this

Air Specific Methods, U.S. Environmental Protection

test method are certain isomeric aldehydes or ketones that may

Agency, Research Triangle Park, NC, July 1979 be unresolved by the HPLC system when analyzing for other

EPA-600/4-83-027, Technical Assistance Document for

aldehydes and ketones. Organic compounds that have the same

Sampling and Analysis of Toxic Organic Compounds in retention time and significant absorbance at 360 nm as the

Ambient Air, U.S. Environmental Protection Agency,

DNPH derivative of formaldehyde will interfere. Such inter-

Research Triangle Park, NC, June 1983 (PB90-187 014/ ferences can often be overcome by altering the separation

AS)

conditions (for example, using alternative HPLC columns or

mobile phase compositions).

3. Terminology

6.2 Formaldehyde contamination of the DNPH reagent is a

3.1 Definitions:

frequently encountered problem. The DNPH must be purified

3.1.1 For definitions of terms used in this test method, refer

by multiple recrystallizations in UV-grade acetonitrile. Recrys-

to Terminology D 1356 and Practice E 682.

tallization is accomplished, at 40 to 60°C, by slow evaporation

3.2 Definitions of Terms Specific to This Standard:

of the solvent to maximize crystal size. The purified DNPH

3.2.1 All other pertinent abbreviations and symbols are

crystals are stored under UV-grade acetonitrile until use.

defined when first cited in this test method.

Impurity levels of carbonyl compounds in the DNPH are

determined prior to use by HPLC and should be less than 0.15

4. Summary of Test Method

μg per cartridge.

4.1 A known volume of indoor air is drawn through a

6.3 Exposure of the DNPH-coated sampling cartridges to

prepacked silica gel cartridge coated with acidified DNPH, at a

direct sunlight may produce artifacts and should be avoided.

sampling rate of 0.5 to 1.2 L/min for an appropriate period of

6.4 Ozone at high concentrations has been shown to inter-

time. Both sampling rate and time are dependent upon carbonyl

fere negatively by reacting with both the DNPH and its

concentrations in the test atmosphere.

Annual Book of ASTM Standards, Vol 14.02.

7 9

Annual Book of ASTM Standards, Vol 14.01. Grosjean, D., “Ambient Levels of Formaldehyde, Acetaldehyde, and Formic

Available from the U.S. Department of Commerce, National Technical Infor- Acid in Southern California: Results of a One-Year Base-Line Study,” Environmen-

mation Service, 5285 Port Royal Rd., Springfield, VA 22161. tal Science & Technology, Vol 25, 1991, pp. 710–715.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5197

carbonyl derivatives (hydrazones) in the cartridge. The extent pre-coated DNPH cartridges.

of interference depends on the temporal variations of both the 6.5 This test method is not intended to be used for accurate

ozone and the carbonyl compounds and the duration of quantitation of acrolein in air. Inaccurate results for acrolein

sampling. Significant negative interference from ozone was may result from the formation of multiple derivative peaks, the

observed even at concentrations of formaldehyde and ozone instability of the peak ratios, or interferences from acetone and

11 12

typical of clean ambient air (2 and 40 ppbv, respectively). acetaldehyde, or combination thereof.

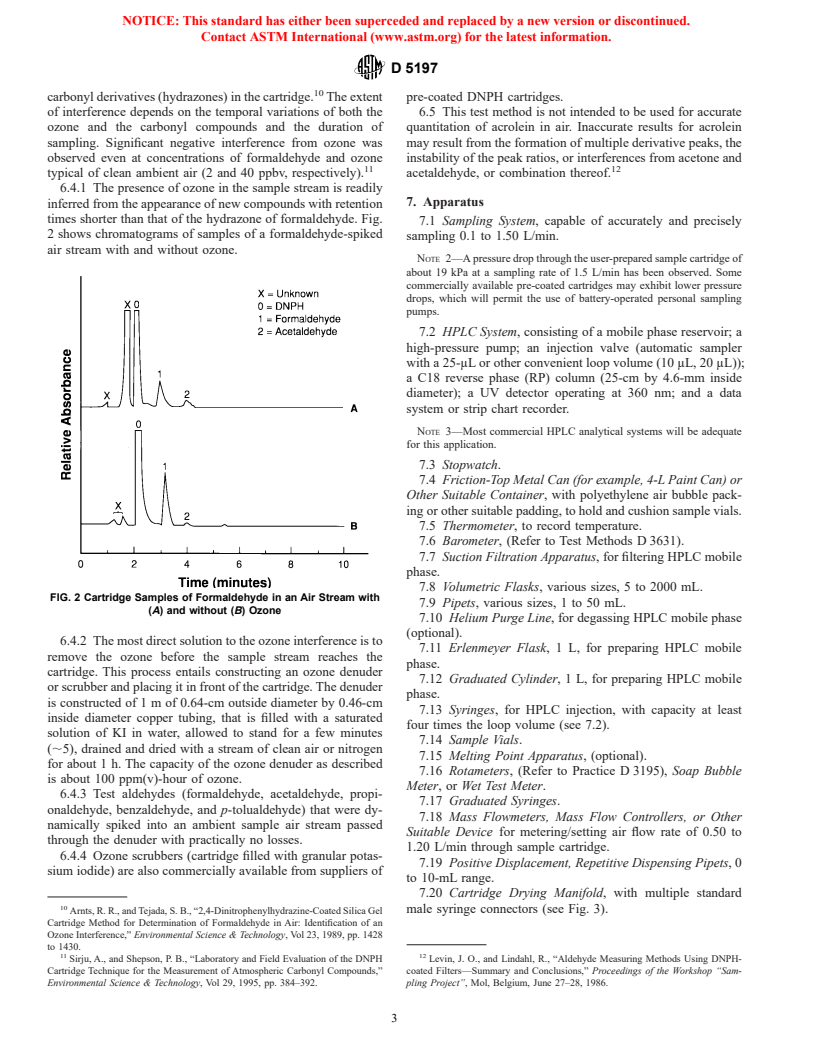

6.4.1 The presence of ozone in the sample stream is readily

7. Apparatus

inferred from the appearance of new compounds with retention

times shorter than that of the hydrazone of formaldehyde. Fig.

7.1 Sampling System, capable of accurately and precisely

2 shows chromatograms of samples of a formaldehyde-spiked

sampling 0.1 to 1.50 L/min.

air stream with and without ozone.

NOTE 2—A pressure drop through the user-prepared sample cartridge of

about 19 kPa at a sampling rate of 1.5 L/min has been observed. Some

commercially available pre-coated cartridges may exhibit lower pressure

drops, which will permit the use of battery-operated personal sampling

pumps.

7.2 HPLC System, consisting of a mobile phase reservoir; a

high-pressure pump; an injection valve (automatic sampler

with a 25-μL or other convenient loop volume (10 μL, 20 μL));

a C18 reverse phase (RP) column (25-cm by 4.6-mm inside

diameter); a UV detector operating at 360 nm; and a data

system or strip chart recorder.

NOTE 3—Most commercial HPLC analytical systems will be adequate

for this application.

7.3 Stopwatch.

7.4 Friction-Top Metal Can (for example, 4-L Paint Can) or

Other Suitable Container, with polyethylene air bubble pack-

ing or other suitable padding, to hold and cushion sample vials.

7.5 Thermometer, to record temperature.

7.6 Barometer, (Refer to Test Methods D 3631).

7.7 Suction Filtration Apparatus, for filtering HPLC mobile

phase.

7.8 Volumetric Flasks, various sizes, 5 to 2000 mL.

FIG. 2 Cartridge Samples of Formaldehyde in an Air Stream with

7.9 Pipets, various sizes, 1 to 50 mL.

(A) and without (B) Ozone

7.10 Helium Purge Line, for degassing HPLC mobile phase

(optional).

6.4.2 The most direct solution to the ozone interference is to

7.11 Erlenmeyer Flask, 1 L, for preparing HPLC mobile

remove the ozone before the sample stream reaches the

phase.

cartridge. This process entails constructing an ozone denuder

7.12 Graduated Cylinder, 1 L, for preparing HPLC mobile

or scrubber and placing it in front of the cartridge. The denuder

phase.

is constructed of1mof 0.64-cm outside diameter by 0.46-cm

7.13 Syringes, for HPLC injection, with capacity at least

inside diameter copper tubing, that is filled with a saturated

four times the loop volume (see 7.2).

solution of KI in water, allowed to stand for a few minutes

7.14 Sample Vials.

(;5), drained and dried with a stream of clean air or nitrogen

7.15 Melting Point Apparatus, (optional).

for about 1 h. The capacity of the ozone denuder as described

7.16 Rotameters, (Refer to Practice D 3195), Soap Bubble

is about 100 ppm(v)-hour of ozone.

Meter,or Wet Test Meter.

6.4.3 Test aldehydes (formaldehyde, acetaldehyde, propi-

7.17 Graduated Syringes.

onaldehyde, benzaldehyde, and p-tolualdehyde) that were dy-

7.18 Mass Flowmeters, Mass Flow Controllers, or Other

namically spiked into an ambient sample air stream passed

Suitable Device for metering/setting air flow rate of 0.50 to

through the denuder with practically no losses.

1.20 L/min through sample cartridge.

6.4.4 Ozone scrubbers (cartridge filled with granular potas-

7.19 Positive Displacement, Repetitive Dispensing Pipets,0

sium iodide) are also commercially available from suppliers of

to 10-mL range.

7.20 Cartridge Drying Manifold, with multiple standard

male syringe connectors (see Fig. 3).

Arnts, R. R., and Tejada, S. B., “2,4-Dinitrophenylhydrazine-Coated Silica Gel

Cartridge Method for Determination of Formaldehyde in Air: Identification of an

Ozone Interference,” Environmental Science & Technology, Vol 23, 1989, pp. 1428

to 1430.

11 12

Sirju, A., and Shepson, P. B., “Laboratory and Field Evaluation of the DNPH Levin, J. O., and Lindahl, R., “Aldehyde Measuring Methods Using DNPH-

Cartridge Technique for the Measurement of Atmospheric Carbonyl Compounds,” coated Filters—Summary and Conclusions,” Proceedings of the Workshop “Sam-

Environmental Science & Technology, Vol 29, 1995, pp. 384–392. pling Project”, Mol, Belgium, June 27–28, 1986.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.