ASTM A555/A555M-97

(Specification)Standard Specification for General Requirements for Stainless Steel Wire and Wire Rods

Standard Specification for General Requirements for Stainless Steel Wire and Wire Rods

SCOPE

1.1 This specification covers general requirements that shall apply to stainless wire and wire rods. Wire rods are a semifinished product intended primarily for the manufacture of wire. Wire is intended primarily for cold forming, including coiling, stranding, weaving, heading and machining as covered under the latest revision of each of the following ASTM specifications: A313/A313M, A368, A478, A492, A493, A580/A580M and A581/A581M.

1.2 In case of conflicting requirements, the individual material specification and this general requirement specification shall prevail in the order named.

1.3 General requirements for flat products other than wire are covered in Specification A480/A480M.

1.4 General requirements for bar and billet products are covered in Specification A484/A484M.

1.5 The values stated in inch-pound units or SI (metric) units are to be regarded separately as standard; within the text and tables, the SI units are shown in brackets ([]). The values stated in each system are not exact equivalents; therefore, each system must be used independent of the other. Combining values from the two systems may result in nonconformance with the specification.

1.6 Unless the order specifies the applicable metric specification designation, the material shall be furnished in the inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: A 555/A 555M – 97

Standard Specification for

General Requirements for Stainless Steel Wire and Wire

Rods

This standard is issued under the fixed designation A 555/A 555M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope A 368 Specification for Stainless and Heat-Resisting Steel

Wire Strand

1.1 This specification covers general requirements that shall

A 370 Test Methods and Definitions for Mechanical Testing

apply to stainless wire and wire rods. Wire rods are a

of Steel Products

semifinished product intended primarily for the manufacture of

A 478 Specification for Chromium-Nickel Stainless and

wire. Wire is intended primarily for cold forming, including

Heat-Resisting Steel Weaving and Knitting Wire

coiling, stranding, weaving, heading and machining as covered

A 480/A 480M Specification for General Requirements for

under the latest revision of each of the following ASTM

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

specifications: A 313/A 313M, A 368, A 478, A 492, A 493,

Sheet, and Strip

A 580/A 580M and A 581/A 581M.

A 484/A 484M Specification for General Requirements for

1.2 In case of conflicting requirements, the individual ma-

Stainless and Heat-Resisting Bars, Billets, and Forgings

terial specification and this general requirement specification

A 492 Specification for Stainless Steel Rope Wire

shall prevail in the order named.

A 493 Specification for Stainless Steel for Cold Heading

1.3 General requirements for flat products other than wire

and Cold Forging Wire

are covered in Specification A 480/A 480M.

A 580/A 580M Specification for Stainless and Heat-

1.4 General requirements for bar and billet products are

Resisting Steel Wire

covered in Specification A 484/A 484M.

A 581/A 581M Specification for Free-Machining Stainless

1.5 The values stated in inch-pound units or SI (metric)

and Heat-Resisting Steel Wire and Wire Rods

units are to be regarded separately as standard; within the text

A 700 Practices for Packaging, Marking, and Loading

and tables, the SI units are shown in brackets ([]). The values

Methods for Steel Products for Domestic Shipment

stated in each system are not exact equivalents; therefore, each

A 751 Test Methods, Practices, and Terminology for

system must be used independent of the other. Combining

Chemical Analysis of Steel Products

values from the two systems may result in nonconformance

E 112 Test Methods for Determining Average Grain Size

with the specification.

2.2 Federal Standard:

1.6 Unless the order specifies the applicable metric specifi-

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

cation designation, the material shall be furnished in the

2.3 Military Standards:

inch-pound units.

MIL-STD-129 Marking for Shipment and Storage

2. Referenced Documents MIL-STD-163 Preservation of Steel Products for Domestic

Shipment

2.1 ASTM Standards:

2.4 Other Standard:

A 262 Practices for Detecting Susceptibility to Intergranu-

Primary Metals Bar Code Standard

lar Attack in Austenitic Stainless Steels

A 313/A 313M Specification for Stainless Steel Spring

3. Terminology

Wire

3.1 Definitions of Terms Specific to This Standard:

3.1.1 bar—wire that has been straightened and cut (see

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 01.05.

A01.17 on Flat Stainless Steel Products. Annual Book of ASTM Standards, Vol 03.01.

Current edition approved March 10, 1997. Published November 1997. Originally Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

published as A 555 – 65. Last previous edition A 555/A 555M – 94a. Robbins Ave., Philadelphia, PA 19111-5094. Attn: NPODS.

2 6

Annual Book of ASTM Standards, Vol 01.03. Automotive Industry Action Group, 26200 Lahser Road, Suite 200, Southfield,

MI 48034.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 555/A 555M

Specification A 484/A 484M). However, a straightened and cut 4.2 A variety of finishes, coatings, and lubricants are avail-

small diameter product is often called straightened and cut able. The particular type used is dependent upon the specific

wire. end use. Unless otherwise specified, the finish, coating, and

3.1.2 wire—as covered by this specification and the speci- lubricant will be furnished as required by the individual

fications itemized in 1.1, is any round or shaped cold-reduced material specification or purchase order.

product, in coils only, produced by cold-finishing coiled wire

5. Chemical Composition

rod.

3.1.3 wire rods—semifinished product intended primarily 5.1 Heat or Cast Analysis—The chemical analysis of each

heat shall be determined in accordance with the applicable

for the manufacture of wire. They are hot rolled generally to an

approximate round cross section in continuous length coils. material specification and Test Methods, Practices, and Termi-

nology A 751.

4. Materials and Manufacture

5.2 Product Analysis—When required, a product analysis

4.1 The material may be furnished in one of the conditions shall be determined in accordance with Test Methods, Prac-

detailed in the applicable material specification, that is, an- tices, and Terminology A 751. The chemical composition thus

nealed, bright annealed, cold worked, or as otherwise specified determined shall conform to the tolerances shown in Table 1.

on the purchase order. 5.3 The steel shall not contain an unspecified element for

TABLE 1 Product Analysis Tolerances

NOTE— This table specifies tolerances over the maximum limits or under the minimum limits of the chemical requirements of the applicable material

specification (see 1.1); it does not apply to heat analysis.

Tolerances over the Tolerances over the

Maximum (Upper Maximum (Upper

Upper Limit or Maximum Upper Limit or Maximum

Element Limit) or Under the Element Limit) or Under the

of Specified Range, % of Specified Range, %

Minimum (Lower Minimum (Lower

Limit) Limit)

Carbon to 0.010, incl 0.002 Cobalt over 0.05 to 0.50, incl 0.01

over 0.010 to 0.030, incl 0.005 over 0.50 to 2.00, incl 0.02

over 0.030 to 0.20, incl 0.01 over 2.00 to 5.00, incl 0.05

over 0.20 to 0.60, incl 0.02 over 5.00 to 10.00, incl 0.10

over 0.60 to 1.20, incl 0.03 over 10.00 to 15.00, incl 0.15

over 15.00 to 22.00, incl 0.20

Manganese to 1.00, incl 0.03 over 22.00 to 30.00, incl 0.25

over 1.00 to 3.00, incl 0.04 Columbium to 1.50, incl 0.05

over 3.00 to 6.00, incl 0.05 + over 1.50 to 5.00, incl 0.10

over 6.00 to 10.00, incl 0.06 tantalum over 5.00 0.15

over 10.00 to 15.00, incl 0.10

over 15.00 to 20.00, incl 0.15

Tantalum to 0.10, incl 0.02

Phosphorus to 0.040, incl 0.005

over 0.040 to 0.20, incl 0.010 Copper to 0.50, incl 0.03

over 0.50 to 1.00, incl 0.05

Sulfur to 0.040, incl 0.005 over 1.00 to 3.00, incl 0.10

over 0.040 to 0.20, incl 0.010 over 3.00 to 5.00, incl 0.15

over 0.20 to 0.50, incl 0.020 over 5.00 to 10.00, incl 0.20

Silicon to 1.00, incl 0.05 Aluminum to 0.15, incl −0.005,

over 1.00 to 3.00, incl 0.10 +0.01

over 0.15 to 0.50, incl 0.05

Chromium over 4.00 to 10.00, incl 0.10 over 0.50 to 2.00, incl 0.10

over 10.00 to 15.00, incl 0.15 over 2.00 to 5.00, incl 0.20

over 15.00 to 20.00, incl 0.20 over 5.00 to 10.00, incl 0.35

over 20.00 to 30.00, incl 0.25

Nitrogen to 0.02, incl 0.005

Nickel to 1.00, incl 0.03 over 0.02 to 0.19, incl 0.01

over 1.00 to 5.00, incl 0.07 over 0.19 to 0.25, incl 0.02

over 5.00 to 10.00, incl 0.10 over 0.25 to 0.35, incl 0.03

over 10.00 to 20.00, incl 0.15 over 0.35 to 0.45, incl 0.04

over 20.00 to 30.00, incl 0.20

over 30.00 to 40.00, incl 0.25 Tungsten to 1.00, incl 0.03

over 40.00 0.30 over 1.00 to 2.00, incl 0.05

over 2.00 to 5.00, incl 0.07

Molybdenum over 0.20 to 0.60, incl 0.03 over 5.00 to 10.00, incl 0.10

over 0.60 to 2.00, incl 0.05 over 10.00 to 20.00, incl 0.15

over 2.00 to 7.00, incl 0.10

over 7.00 to 15.00, incl 0.15 Vanadium to 0.50, incl 0.03

over 15.00 to 30.00, incl 0.20 over 0.50 to 1.50, incl 0.05

Titanium to 1.00, incl 0.05 Selenium all 0.03

over 1.00 to 3.00, incl 0.07

over 3.00 0.10

A 555/A 555M

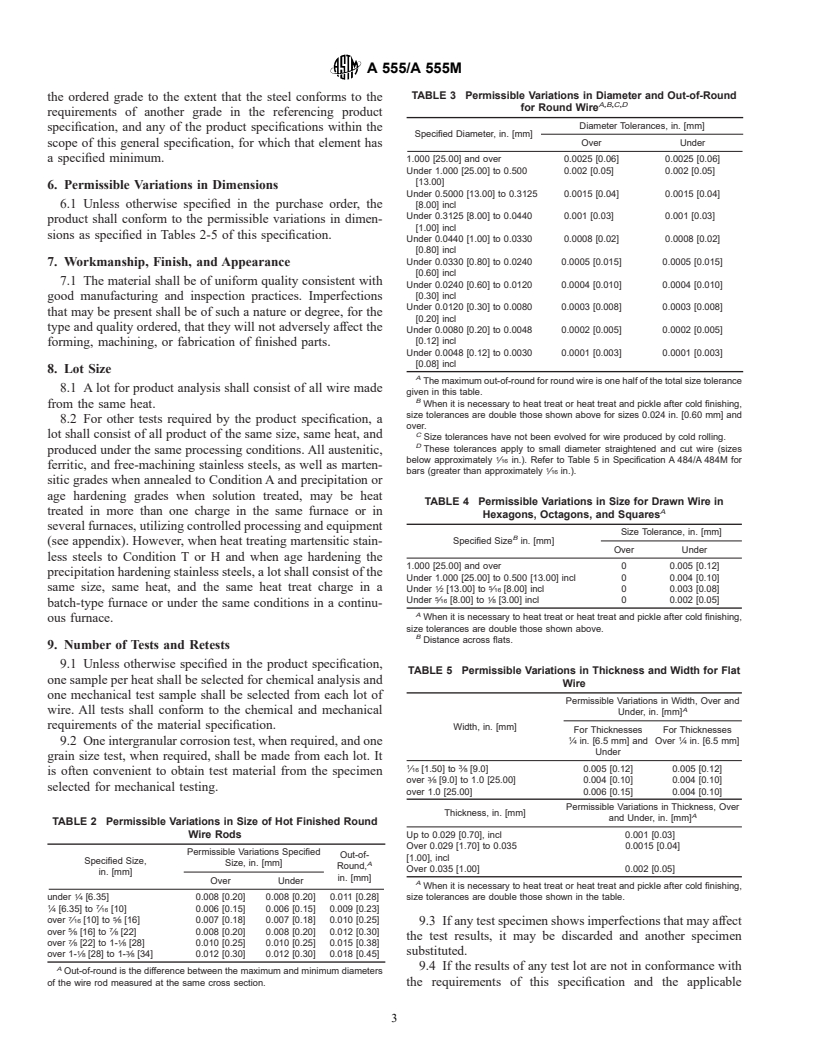

TABLE 3 Permissible Variations in Diameter and Out-of-Round

the ordered grade to the extent that the steel conforms to the

A,B,C,D

for Round Wire

requirements of another grade in the referencing product

Diameter Tolerances, in. [mm]

specification, and any of the product specifications within the

Specified Diameter, in. [mm]

scope of this general specification, for which that element has Over Under

a specified minimum. 1.000 [25.00] and over 0.0025 [0.06] 0.0025 [0.06]

Under 1.000 [25.00] to 0.500 0.002 [0.05] 0.002 [0.05]

[13.00]

6. Permissible Variations in Dimensions

Under 0.5000 [13.00] to 0.3125 0.0015 [0.04] 0.0015 [0.04]

[8.00] incl

6.1 Unless otherwise specified in the purchase order, the

Under 0.3125 [8.00] to 0.0440 0.001 [0.03] 0.001 [0.03]

product shall conform to the permissible variations in dimen-

[1.00] incl

sions as specified in Tables 2-5 of this specification.

Under 0.0440 [1.00] to 0.0330 0.0008 [0.02] 0.0008 [0.02]

[0.80] incl

Under 0.0330 [0.80] to 0.0240 0.0005 [0.015] 0.0005 [0.015]

7. Workmanship, Finish, and Appearance

[0.60] incl

7.1 The material shall be of uniform quality consistent with

Under 0.0240 [0.60] to 0.0120 0.0004 [0.010] 0.0004 [0.010]

[0.30] incl

good manufacturing and inspection practices. Imperfections

Under 0.0120 [0.30] to 0.0080 0.0003 [0.008] 0.0003 [0.008]

that may be present shall be of such a nature or degree, for the

[0.20] incl

type and quality ordered, that they will not adversely affect the

Under 0.0080 [0.20] to 0.0048 0.0002 [0.005] 0.0002 [0.005]

[0.12] incl

forming, machining, or fabrication of finished parts.

Under 0.0048 [0.12] to 0.0030 0.0001 [0.003] 0.0001 [0.003]

[0.08] incl

8. Lot Size

A

The maximum out-of-round for round wire is one half of the total size tolerance

8.1 A lot for product analysis shall consist of all wire made

given in this table.

B

When it is necessary to heat treat or heat treat and pickle after cold finishing,

from the same heat.

size tolerances are double those shown above for sizes 0.024 in. [0.60 mm] and

8.2 For other tests required by the product specification, a

over.

C

lot shall consist of all product of the same size, same heat, and

Size tolerances have not been evolved for wire produced by cold rolling.

D

These tolerances apply to small diameter straightened and cut wire (sizes

produced under the same processing conditions. All austenitic,

below approximately ⁄16 in.). Refer to Table 5 in Specification A 484/A 484M for

ferritic, and free-machining stainless steels, as well as marten-

bars (greater than approximately ⁄16 in.).

sitic grades when annealed to Condition A and precipitation or

age hardening grades when solution treated, may be heat

TABLE 4 Permissible Variations in Size for Drawn Wire in

A

treated in more than one charge in the same furnace or in

Hexagons, Octagons, and Squares

several furnaces, utilizing controlled processing and equipment

Size Tolerance, in. [mm]

B

Specified Size in. [mm]

(see appendix). However, when heat treating martensitic stain-

Over Under

less steels to Condition T or H and when age hardening the

1.000 [25.00] and over 0 0.005 [0.12]

precipitation hardening stainless steels, a lot shall consist of the

Under 1.000 [25.00] to 0.500 [13.00] incl 0 0.004 [0.10]

1 5

same size, same heat, and the same heat treat charge in a

Under ⁄2 [13.00] to ⁄16 [8.00] incl 0 0.003 [0.08]

5 1

Under ⁄16 [8.00] to ⁄8 [3.00] incl 0 0.002 [0.05]

batch-type furnace or under the same conditions in a continu-

A

When it is necessary to heat treat or heat treat and pickle after cold finishing,

ous furnace.

size tolerances are double those shown above.

B

Distance across flats.

9. Number of Tests and Retests

9.1 Unless otherwise specified in the product specification,

TABLE 5 Permissible Variations in Thickness and Width for Flat

one sample per heat shall be selected for chemical analysis and

Wire

one mechanical test sample shall be selected from each lot of

Permissible Variations in Width, Over and

A

wire. All tests shall conform to the chemical and mechanical

Under, in. [mm]

requirements of the material specification. Width, in. [mm]

For Thicknesses For Thicknesses

1 1

⁄4 in. [6.5 mm] and Over ⁄4 in. [6.5 mm]

9.2 One intergranular corrosion test, when required, and one

Under

grain size test, when required, shall be made from each lot. It

1 3

⁄16 [1.50] to ⁄8 [9.0] 0.005 [0.12] 0.005 [0.12]

is often convenient to obtain test material from the specimen

over ⁄8 [9.0] to 1.0 [25.00] 0.004 [0.10] 0.004 [0.10]

selected for mechanical testing.

over 1.0 [25.00] 0.006 [0.15] 0.004 [0.10]

Permissible Variations in Thickness, Over

Thickness, in. [mm]

A

and Under, in. [mm]

TABLE 2 Permissible Variations in Size of Hot Finished Round

Wire Rods Up to 0.029 [0.70], incl 0.001 [0.03]

Over 0.029 [1.70] to 0.035 0.0015 [0.04]

Permissible Variations Specified

Out-of-

[1.00], incl

Specified Size,

Size, in. [mm] A

Round,

Over 0.035 [1.00] 0.002 [0.05]

in. [mm]

in. [mm]

Over Under

A

When it is necessary to heat treat or heat treat and pickle after cold finishing,

under ⁄4 [6.35] 0.008 [0.20] 0.008 [0.20] 0.011 [0.28] size tolerances are double those shown in the table.

1 7

⁄4 [6.35] to ⁄16 [10] 0.006 [0.15] 0.006 [0.15] 0.009 [0.23]

7 5

over ⁄16 [10] to ⁄8 [16] 0.007 [0.18] 0.007 [0.18] 0.010 [0.25]

9.3 If any test specimen shows imperfections that may affect

5 7

over ⁄8 [16] to ⁄8 [22] 0.008 [0.20] 0.008 [0.20] 0.012 [0.30]

the test results, it may be discarded and another specimen

7 1

over ⁄8 [22] to 1- ⁄8 [28] 0.010 [0.25] 0.010 [0.25] 0.015 [0.38]

1 3 substituted.

over 1- ⁄8 [28] to 1- ⁄8 [34] 0.012 [0.30] 0.012 [0.30] 0.018 [0.45]

9.4 If the results of any test lot are not in conformance with

A

Out-of-round is the difference between the maximum and minimum diameters

of the wire rod measured at the same cross section. the requirements of this specification and the applicable

A 555/A 555M

product specification, a retest sample of two specimens may be to the producer or supplier promptly, preferably in writing. In

tested to replace each failed specimen of the original sample. If case of dissatisfaction with the results of the test, the producer

one of th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.