ASTM D2171-07e1

(Test Method)Standard Test Method for Viscosity of Asphalts by Vacuum Capillary Viscometer

Standard Test Method for Viscosity of Asphalts by Vacuum Capillary Viscometer

SIGNIFICANCE AND USE

The viscosity at 60°C (140°F) characterizes flow behavior and may be used for specification requirements for cutbacks and asphalt binders.

SCOPE

1.1 This test method covers procedures for the determination of viscosity of asphalt binder (bitumen) by vacuum capillary viscometers at 60°C (140°F). It is applicable to materials having viscosities in the range from 0.0036 to over 20 000 Pa · s (0.036 to over 200 000 P).

Note 1—This test method is suitable for use at other temperatures, but the precision is based on determinations on asphalt binders at 60°C (140°F).

1.2 Warning—Mercury has been designated by the United States Environmental Protection Agency (EPA) and many state agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware that selling mercury, mercury-containing products, or both, into your state may be prohibited by state law.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D2171 – 07

Designation: 222/84 (89)

Standard Test Method for

1

Viscosity of Asphalts by Vacuum Capillary Viscometer

This standard is issued under the fixed designation D2171; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Table X1.1 was editorially corrected in March 2010.

This test method has been approved by the sponsoring committees and accepted by the cooperating societies in accordance with

established procedures.

1. Scope 2. Referenced Documents

2

1.1 This test method covers procedures for the determina- 2.1 ASTM Standards:

tion of viscosity of asphalt binder (bitumen) by vacuum E1 Specification for ASTM Liquid-in-Glass Thermometers

capillary viscometers at 60°C (140°F). It is applicable to E11 SpecificationforWovenWireTestSieveClothandTest

materials having viscosities in the range from 0.0036 to over Sieves

20 000 Pa · s (0.036 to over 200 000 P). E77 Test Method for Inspection and Verification of Ther-

mometers

NOTE 1—This test method is suitable for use at other temperatures, but

the precision is based on determinations on asphalt binders at 60°C

3. Terminology

(140°F).

3.1 Definitions:

1.2 Warning—Mercury has been designated by the United

3.1.1 Newtonian liquid—a liquid in which the rate of shear

States Environmental ProtectionAgency (EPA) and many state

is proportional to the shearing stress. The constant ratio of the

agencies as a hazardous material that can cause central nervous

shearing stress to the rate of shear is the viscosity of the liquid.

system,kidneyandliverdamage.Mercury,oritsvapor,maybe

If the ratio is not constant, the liquid is non-Newtonian.

hazardous to health and corrosive to materials. Caution should

3.1.2 viscosity—the ratio between the applied shear stress

be taken when handling mercury and mercury containing

and rate of shear is called the coefficient of viscosity. This

products. See the applicable product Material Safety Data

coefficient is thus a measure of the resistance to flow of the

Sheet (MSDS) for details and EPA’s website—http://

liquid. It is commonly called the viscosity of the liquid. The SI

www.epa.gov/mercury/faq.htm—for additional information.

2

unit of viscosity is 1 Pa·s(1 N·s/m ) and is called a

Users should be aware that selling mercury, mercury-

Pascal-second. The cgs unit of viscosity is 1 g/cm·s (1

containing products, or both, into your state may be prohibited

2

dyne·s/cm ) and is called a poise (P). 1 Pa·sis equivalent to

by state law.

10 P.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

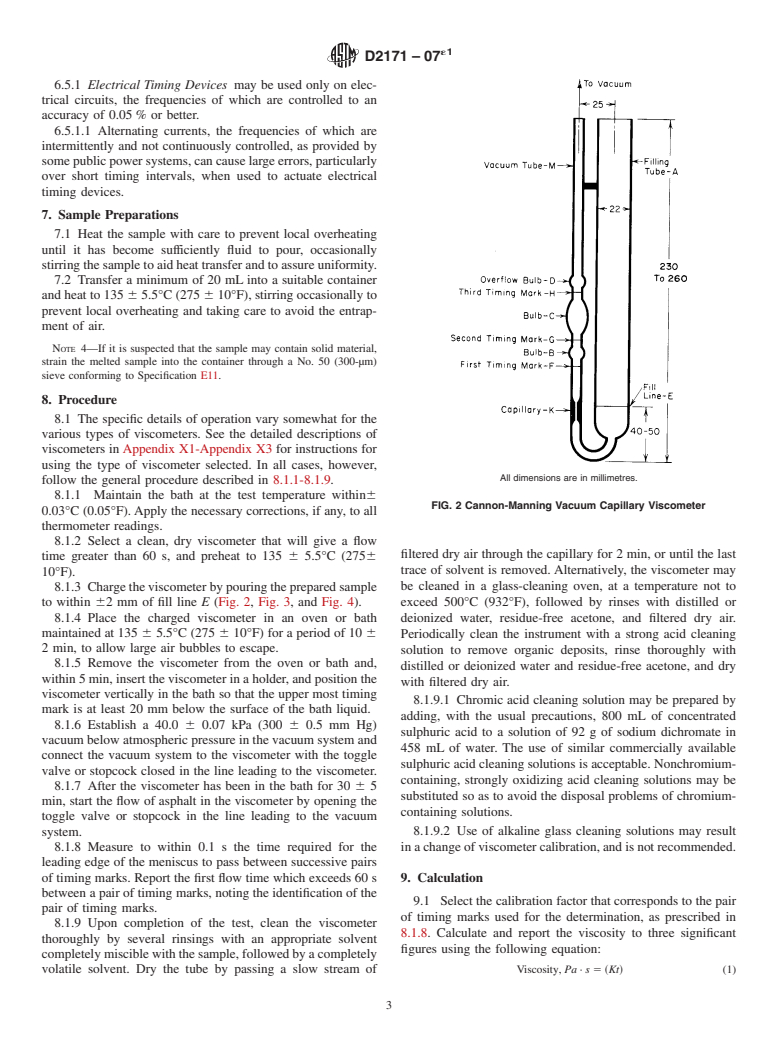

4.1 The time is measured for a fixed volume of the liquid to

priate safety and health practices and determine the applica-

be drawn up through a capillary tube by means of vacuum,

bility of regulatory limitations prior to use.

under closely controlled conditions of vacuum and tempera-

ture. The viscosity in Pascal-seconds is calculated by multi-

plying the flow time in seconds by the viscometer calibration

1

factor.

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.44 on

Rheological Tests. In the IP this test method is under the jurisdiction of the

2

Standardization Committee. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2007. Published January 2008. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1963. Last previous edition approved in 2001 as D2171 – 01. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2171-07. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

D2171 – 07

FIG. 1 Suggested Vacuum System for Vacuum Capillary Viscometers

NOTE 2—The rate of shear decreases as the liquid moves up the tube,

submergence must be determined and applied. If the thermom-

or it can also be varied by the use of different vacuum or different size

eter is completely submerged in the bath during use, the

viscometers. Thus, this method is suitable for the measurement of

pressure of the gas in the expansion chamber will be higher or

viscosities of Newtonian (simple) and non-Newtonian (complex) liquids.

lower than during standar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.