ASTM B65-28

(Specification)Specification for Lead Yellow Brass Sand Castings for General Purposes (Withdrawn 1937)

Specification for Lead Yellow Brass Sand Castings for General Purposes (Withdrawn 1937)

General Information

Standards Content (Sample)

STANDARD SP1'~CIFICATIONS

FOR

YELLOW BRASS SAND CASTINGS

FOR GENERAL PURPOSESl

:A.S.T.M. Designation; B 65 -28

These specifications are issued under the fixed designation B 6S; the final

number iDdicates the year of original adoption ns standard or, in the case of revision,

the year of last revision.

Isst1BD AS TJ?NTATIVB, 1927; AnoPTno, 1928.

Scapo.

1. These specifications cover castings made from one of the many

yellow brasses commonly used for a wide variety of castings.

MANUFACTURE

Proces&. 2. (a) The alloy may be made by any approved method.

(b) The castings shall be of uniform quality.

CHEMICAL PROPERTIES AND 'fBSTS

Chemical

3. {a) The alloy shall conform to tl1e following requirements as

Compositiau.

to chemical composition:

MAXIMll .

Copper,percent . 63.S 62.0 67.0

Tin, per cent . . , , . . . . . . . . . . . . . . . . . . none none I. 0

Lead, per cent. . . 2.5 J.5 J,S

Zinc, per cent. . . . . . . . . . . . . . . . . 34. 0 remainder remainder

Iron, per cent. . none 0. 75

Nickel, pC1' cent. . . . . . . . . . none o. 25

l'hosphorus, per cent. . . . . . . . . . . . . . . none o. OJ

Aluminum, per cent. • . . . . . . . . . . . . . . none o. 3

Sulfur, p~r cent . . . . , . none o. OS

Antimony, per cent. . . . . none o. 15

Total other impurities, per cent . . . . . none 0.15

(b) Where "none" is specified it shall be construecl to refer to

none as detennined on a. 10-g. sample.

Cb11111lc• I

4. (a) An analysis of each melt may be ronde n.t the option of

Anal)'IOI.

the purch!lSer and at his own expense.

1 Untler lho atantlanii&alloa procedure or tbe Sac:IGty, these spci;lfications are under the iuristlio.

ton of th~ A.s:r.M. Committee n.s on Copper and Copper Aloys, CMt nnd Wrought.

(682)

---------------------- Page: 1 ----------------------

A.S.T.M. DESIGNATION: B 65 - 28 683

(b) The sample for chemical analysis shall be taken from cuttings

from the test bars.

PHYSICAL PROPERTIES AND TESTS

.5. (a) Where desired by the purchaser and so specified in the Physi.cal

contract or purchase order, the alloy shall conform to the following !~~~~:e

minimum requirements as to tensile properties:

Tensile strength, lb. per sq. in . 20 000

Elongation in 2 in., per cent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • 15

(b) Where physical requirements are not specified in the con

tract or purchase order, a fracture of the test specimens shall be made

and the fractured surface shall indicate the soundness and uniformity

of the metal upon examination with the naked eye. If the test bars

Radius nof less k----------·-- 2.;f "-------»! ,. -

thanJ<.1 Parallel Sect/on I Nofe:-TheoaqeL@nqfh,

,-----.-}j ! .------ Para'//e/ Secf/on, and

I ti ,,, o.}i • i l J s;;;!f Z!ii:r::

J to f/f the Holders of

k------------ 2 "-------o>I the Tesf!nq Machine

' Gaqe Lengfh ' in such a Way fhaf the

for ElonqaHor7 Load shall be axial.

after Frcrclure

FIG. !.-Tension Test Specimen.

do not indicate a uniform soundness and quality of metal, the castings

may be rejected.

6. (a) The tension test specimen shall be machined from coupons Tension Test

to the dimensions shown in Fig. 1. The ends shall be of a form to fit Specimens.

the holders of the testing machine in such a way that the load shall

be axial.

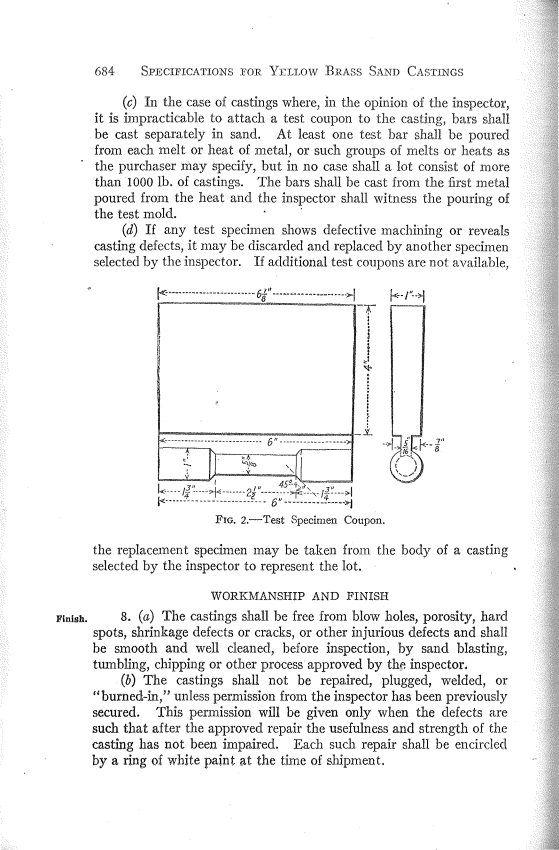

(b) The coupon attached to the casting shall be in accordance

with the dimensions shown in Fig. 2. The fin gate along the side

5

shall be not less than in. in thickness at any point along its length.

1 6

7. (a) Each casting weighing 250 lb. or more shall have, if prac- Number of

ticable, at least one test coupon attached. The responsibility of fur- Tests.

nishing sufficient test specimens shall rest with the manufacturer. 1

(b) In the case of castings weighing less than 250 lb. each, at

least one test coupon shall, if practicable, be attached to one or more

castings from each melt or heat or from such groups of melts or heats

as the purchaser may specify, but in no case shall a lot consist ofmore

than 1000 lb of castings. - -

---------------------- Page: 2 ----------------------

684 SPECIFICATIONS :FOR YELLOW BRASS SAND CASTINGS

(c) In the case of castings where, in the opinion of the inspector,

it is impracticable to attach a test coupon to the casting, bars shall

be cast separately in sand. At least one test bar shall be poured

from each melt or heat of metal, or such groups of melts or heats as

the purchaser n1ay specify, but in no case shall a lot consist of more

than 1000 lb. of castings. The bars shall be cast from the first metal

poured from the heat and the inspector shall witness the pouring of

the test mold. ·

(d) If any test specimen shows defective machining or reveals

casting defects, it may be discarded and replaced by another specimen

selected by the inspector. If additional test coupons are not available,

[<

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.