ASTM A19-36

(Specification)Specification for Quenched-and-Tempered Carbon-Steel Axles, Shafts, and Other Forgings for Locomotives and Cars (Withdrawn 1936)

Specification for Quenched-and-Tempered Carbon-Steel Axles, Shafts, and Other Forgings for Locomotives and Cars (Withdrawn 1936)

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

•

STANDARD SPECIFICATIONS

FOR

QUENCHED-AND-TEMPERED CARBON-STEEL AXLES,

SHAFTS, AND OTHER FORGINGS FOR

1

LOCOMOTIVES AND CARS

A.S.T.M. Designation: A 19 - 36

These specifications are issued under the fixed designation A 19; the final num

ber indicates the year of original adoption as standard or, in the case of revision, the

year of last revision.

ADOPTED, 1911; REVISED, 1912, 1914, 1916, 1918, 1921, 1927, 1936.

e.

Scop

I. When used for forgings for locomotives, these specifications

cover quenched-and-tempered carbon-steel driving axles, engine and

trailing-truck axles, main and side rods, straps, crank pins and piston

rods.

MANUFACTURE

2. The steel shall be made by either or both the following proc- Process.

esses: open-hearth or electric-furnace.

.

3. A sufficient discard shall be made from each ingot to secure Discard

freedom from injurious piping and undue segregation.

4. Unless otherwise specified, for test purposes at least 20 per Prolongatlo,

ror Tests.

cent of the forgings shall be provided with prolongations or, at the

manufacturer's option, a forging may be selected.

ring.

Bo

5. (a) Unless otherwise specified by the purchaser, all axles,

shafts and similar forgings having a minimum diameter over 7 in.

shall be bored. The boring shall be done before quenching.

(b) In the case of boring, the diameter of the hole, unless other

wise specified, shall be at least 20 per cent of the minimum outside

diameter of the forging, exclusive of collars and flanges.

The procedure to be followed in quenching and tempering Heat

6.

Treatment.

shall consist in allowing the objects, immediately after forging, to

cool to a temperature below the critical range, under suitable condi-

tions to prevent injury by too rapid cooling. They shall then be

uniformly reheated to the proper temperature to refine the grain

1

Under the standardization procedure ol the Society, these specifications are under the jurilldiction

or the A.6.T.M. Committee A-1 on Steel.

(I 95)

---------------------- Page: 1 ----------------------

196 SPECIFICATIONS FOR QUENCRED-AND-TEMPERED FORGINGS

(a group thus reheated being known as a "quenching charge"), and

quenched in some medium under substantially uniform conditions for

each quenching charge. Finally, they shall be uniformly reheated to

the proper temperature for tempering or "drawing back" (a group

thus reheated being known as a "tempering charge"), and allowed to

cool uniformly.

CHEMICAL PROPERTIES AND TESTS

Chemical 7. The steel shall conform to the following requirements as to

Composition. chemical composition:

First Class by Size . . 0. 25 - 0.60 per cent

U H U

0.35- 0.60

C b S econ d •.

ar on Third " " " . . 0.35-0.65

0.35-0.70

Fourth " " " . .

I

Manganese .•. 0.40-0.70

Phosphorus .•. not over 0. 05

.. 0.05

Sulfur .•.

Ladle

8. An analysis of each melt of steel shall be made by the manu

Analyses.

facturer to determine the percentages of the elements specified in

Section 7. This analysis shall be made from a test ingot taken

during the pouring of the melt. The chemical composition thus

determined shall be reported to the purchaser or his representative,

and shall conform to the requirements specified in Section 7.

Check

9. (a) An analysis may be made by the purchaser from a forging

Analyses.

representing each melt. The chemical composition thus determined

shall conform to the requirements specified in Section 7. Drillings

for analysis may be taken from the forging or from a full-size prolonga

tion of the same, at any point midway between the center and surface

of solid forgings, and at any point midway between the inner and

outer surfaces of the wall of bored forgings; or turnings may be taken

from a test specimen.

(b) In addition to the complete analysis specified in Paragraph (a),

a phosphorus determination may be made by the purchaser from each

broken tension test specimen. The phosphorus content thus deter

mined shall conform to the requirement specified in Section 7.

PHYSICAL PROPERTIES AND TESTS

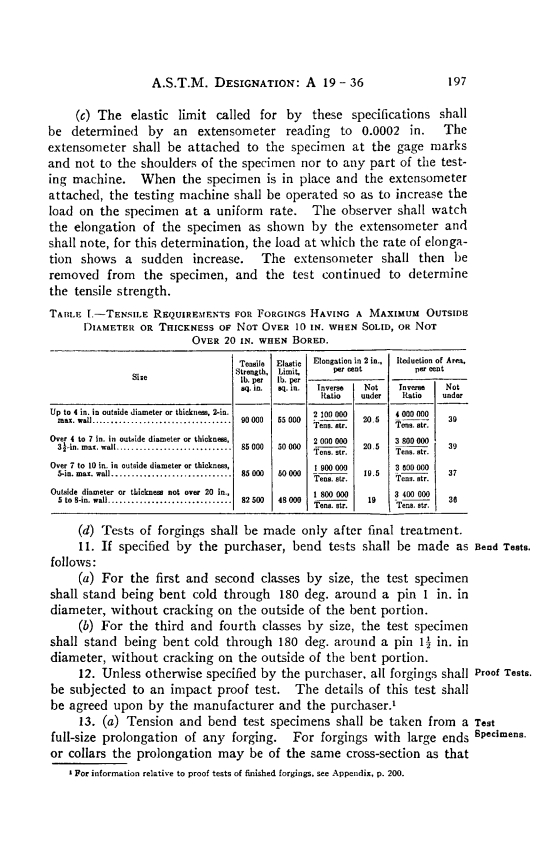

Tension

10. (a) The forgings shall conform to the minimum requirements

Teats.

as to tensile properties specified in Table I.

(b) The classification by size of the forging shall be determined

by the specified diameter or thickness which governs the size of the

prolongation from which the test specimen is taken.

---------------------- Page: 2 ----------------------

197

A.S.T.M. DESIGNATION: A 19 - 36

(c) The elastic limit called for by these specifications shall

be determined by an extensometer reading to 0.0002 in. The

extensometer shall be attached to the specimen at the gage marks

and not to the shoulders of t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.