ASTM B127-98

(Specification)Standard Specification for Nickel-Copper Alloy (UNS N04400) Plate, Sheet, and Strip

Standard Specification for Nickel-Copper Alloy (UNS N04400) Plate, Sheet, and Strip

SCOPE

1.1 This specification covers rolled nickel-copper alloy (UNS N04400)* plate, sheet, and strip.

1.2 The values stated in inch-pound units are to be regarded as the standard. The other values given are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 127 – 98 Used in USDOE-NE standards

Standard Specification for

Nickel-Copper Alloy (UNS N04400) Plate, Sheet,

1

and Strip

This standard is issued under the fixed designation B 127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope MIL-STD-271 Nondestructive Testing Requirements for

2 Metals

1.1 This specification covers rolled nickel-copper alloy

(UNS N04400)* plate, sheet, and strip.

3. Terminology

1.2 The values stated in inch-pound units are to be regarded

3.1 Descriptions of Terms Specific to This Standard—The

as the standard. The other values given are for information

terms given in Table 1 shall apply.

only.

2. Referenced Documents

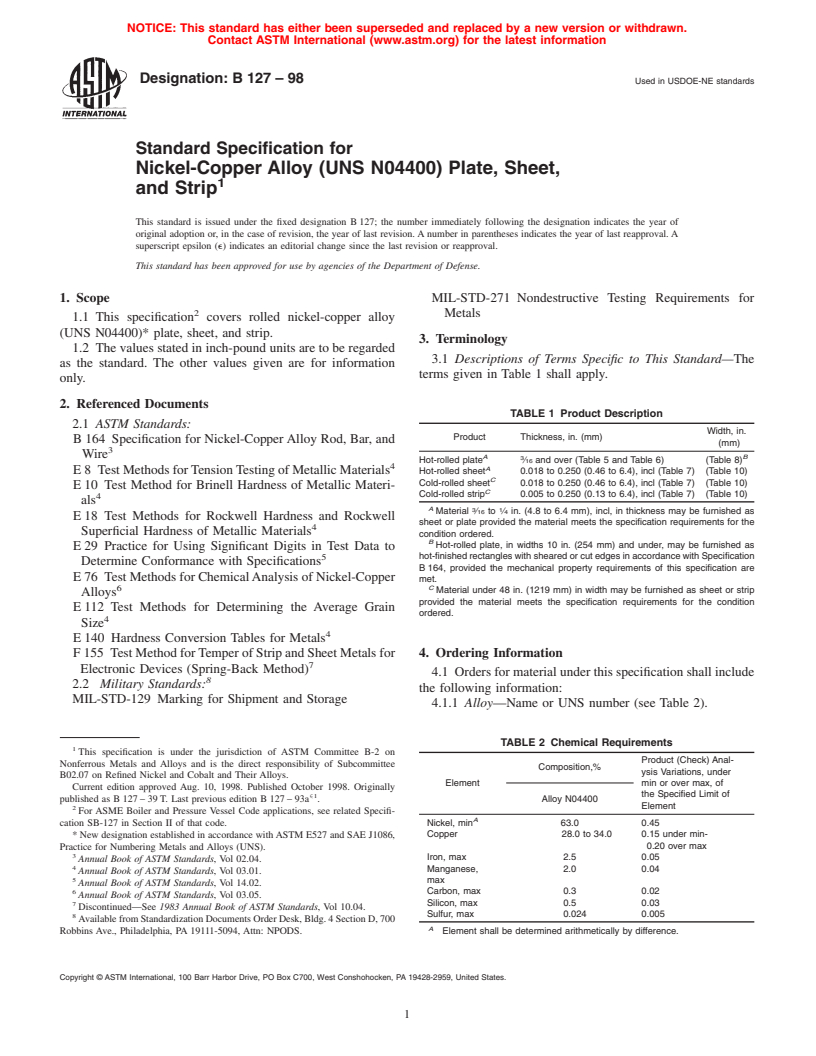

TABLE 1 Product Description

2.1 ASTM Standards:

Width, in.

Product Thickness, in. (mm)

B 164 Specification for Nickel-CopperAlloy Rod, Bar, and

(mm)

3

Wire

A B

3

Hot-rolled plate ⁄16and over (Table 5 and Table 6) (Table 8)

4

A

E 8 Test Methods forTensionTesting of Metallic Materials Hot-rolled sheet 0.018 to 0.250 (0.46 to 6.4), incl (Table 7) (Table 10)

C

Cold-rolled sheet 0.018 to 0.250 (0.46 to 6.4), incl (Table 7) (Table 10)

E 10 Test Method for Brinell Hardness of Metallic Materi-

C

Cold-rolled strip 0.005 to 0.250 (0.13 to 6.4), incl (Table 7) (Table 10)

4

als

A

3 1

Material ⁄16 to ⁄4 in. (4.8 to 6.4 mm), incl, in thickness may be furnished as

E 18 Test Methods for Rockwell Hardness and Rockwell

sheet or plate provided the material meets the specification requirements for the

4

Superficial Hardness of Metallic Materials

condition ordered.

B

Hot-rolled plate, in widths 10 in. (254 mm) and under, may be furnished as

E 29 Practice for Using Significant Digits in Test Data to

hot-finishedrectangleswithshearedorcutedgesinaccordancewithSpecification

5

Determine Conformance with Specifications

B 164, provided the mechanical property requirements of this specification are

E 76 Test Methods for ChemicalAnalysis of Nickel-Copper

met.

C

6

Material under 48 in. (1219 mm) in width may be furnished as sheet or strip

Alloys

provided the material meets the specification requirements for the condition

E 112 Test Methods for Determining the Average Grain

ordered.

4

Size

4

E 140 Hardness Conversion Tables for Metals

F 155 Test Method forTemper of Strip and Sheet Metals for 4. Ordering Information

7

Electronic Devices (Spring-Back Method)

4.1 Orders for material under this specification shall include

8

2.2 Military Standards:

the following information:

MIL-STD-129 Marking for Shipment and Storage

4.1.1 Alloy—Name or UNS number (see Table 2).

TABLE 2 Chemical Requirements

1

This specification is under the jurisdiction of ASTM Committee B-2 on

Product (Check)Anal-

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

Composition,%

ysis Variations, under

B02.07 on Refined Nickel and Cobalt and Their Alloys.

Element min or over max, of

Current edition approved Aug. 10, 1998. Published October 1998. Originally

the Specified Limit of

{1

published as B 127 – 39 T. Last previous edition B 127 – 93a . Alloy N04400

Element

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

A

cation SB-127 in Section II of that code. Nickel, min 63.0 0.45

* New designation established in accordance withASTM E527 and SAE J1086, Copper 28.0 to 34.0 0.15 under min-

0.20 over max

Practice for Numbering Metals and Alloys (UNS).

3

Iron, max 2.5 0.05

Annual Book of ASTM Standards, Vol 02.04.

4

Manganese, 2.0 0.04

Annual Book of ASTM Standards, Vol 03.01.

5

max

Annual Book of ASTM Standards, Vol 14.02.

6 Carbon, max 0.3 0.02

Annual Book of ASTM Standards, Vol 03.05.

7 Silicon, max 0.5 0.03

Discontinued—See 1983 Annual Book of ASTM Standards, Vol 10.04.

Sulfur, max 0.024 0.005

8

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

A

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. Element shall be determined arithmetically by difference.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B127–98

4.1.2 ASTM designation, including year of issue. 5.2 If a product (check) analysis is performed by the

4.1.3 Condition—See 6.1, 6.2, and Appendix X1. purchaser, the material shall conform to the product (check)

analysis variations prescribed in Table 2.

4.1.4 Finish—See Appendix X1.

4.1.5 Dimensions—Thickness, width, and length.

4.1.6 Quantity. 6. Mechanical and Other Requirements

4.1.7 Optional Requirements:

6.1 Mechanical Properties—The material

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.