ASTM F1941-00(2006)

(Specification)Standard Specification for Electrodeposited Coatings on Threaded Fasteners (Unified Inch Screw Threads (UN/UNR))

Standard Specification for Electrodeposited Coatings on Threaded Fasteners (Unified Inch Screw Threads (UN/UNR))

SCOPE

1.1 This specification covers application, performance and dimensional requirements for electrodeposited coatings on threaded fasteners with unified inch screw threads. It specifies coating thickness, supplementary chromate finishes, corrosion resistance, precautions for managing the risk of hydrogen embrittlement and hydrogen embrittlement relief for high-strength and surface-hardened fasteners. It also highlights the differences between barrel and rack plating and makes recommendations as to the applicability of each process.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

The following precautionary statement pertains to the test method portion only, Section , of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1941 – 00 (Reapproved 2006)

Standard Specification for

Electrodeposited Coatings on Threaded Fasteners (Unified

1

Inch Screw Threads (UN/UNR))

This standard is issued under the fixed designation F 1941; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This specification covers the coating of steel unified inch screw threaded fasteners by electrodepo-

sition. The properties of the coatings shall conform to theASTM standards for the individual finishes

listed.

Coating thickness values are based on the tolerances for 1A and 2A external Unified Inch Screw

Threads. The coating must not cause the basic thread size to be transgressed by either the internal or

external threads. The method of designating coated threads shall comply with ASME B1.1.

With normal methods for depositing metallic coatings from aqueous solutions, there is a risk of

delayed failure due to hydrogen embrittlement for case hardened fasteners and fasteners having a

hardness 40 HRC or above.Although this risk can be managed by selecting raw materials suitable for

the application of electrodeposited coatings and by using modern methods of surface treatment and

post heat-treatment (baking), the risk of hydrogen embrittlement cannot be completely eliminated.

Therefore, the application of a metallic coating by electrodeposition is not recommended for such

fasteners.

1. Scope 2. Referenced Documents

2

1.1 This specification covers application, performance and 2.1 ASTM Standards:

dimensional requirements for electrodeposited coatings on B117 Practice for Operating Salt Spray (Fog) Apparatus

threaded fasteners with unified inch screw threads. It specifies B 487 Test Method for Measurement of Metal and Oxide

coating thickness, supplementary chromate finishes, corrosion Coating Thickness by Microscopical Examination of a

resistance, precautions for managing the risk of hydrogen Cross Section

embrittlement and hydrogen embrittlement relief for high- B 499 Test Method for Measurement of Coating Thick-

strength and surface-hardened fasteners. It also highlights the nessesbytheMagneticMethod:NonmagneticCoatingson

differences between barrel and rack plating and makes recom- Magnetic Basis Metals

mendations as to the applicability of each process. B 504 Test Method for Measurement of Thickness of Me-

1.2 The values stated in SI units are to be regarded as the tallic Coatings by the Coulometric Method

standard. The values given in parentheses are for information B 567 Test Method for Measurement of Coating Thickness

only. by the Beta Backscatter Method

1.3 The following precautionary statement pertains to the B 568 Test Method for Measurement of Coating Thickness

test method portion only, Section 9, of this specification: This by X-Ray Spectrometry

standard does not purport to address all of the safety concerns, B 659 Guide for Measuring Thickness of Metallic and

if any, associated with its use. It is the responsibility of the user Inorganic Coatings

of this standard to establish appropriate safety and health E 376 Practice for Measuring Coating Thickness by

practices and determine the applicability of regulatory limita- Magnetic-FieldorEddy-Current(Electromagnetic)Exami-

tions prior to use. nation Methods

1

This specification is under the jurisdiction of ASTM Committee F16 on

2

Fasteners and is the direct responsibility of Subcommittee F16.03 on Coatings on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fasteners. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved June 1, 2006. Published June 2006. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1998. Last previous edition approved in 2000 as F 1941 – 00. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1941 – 00 (2006)

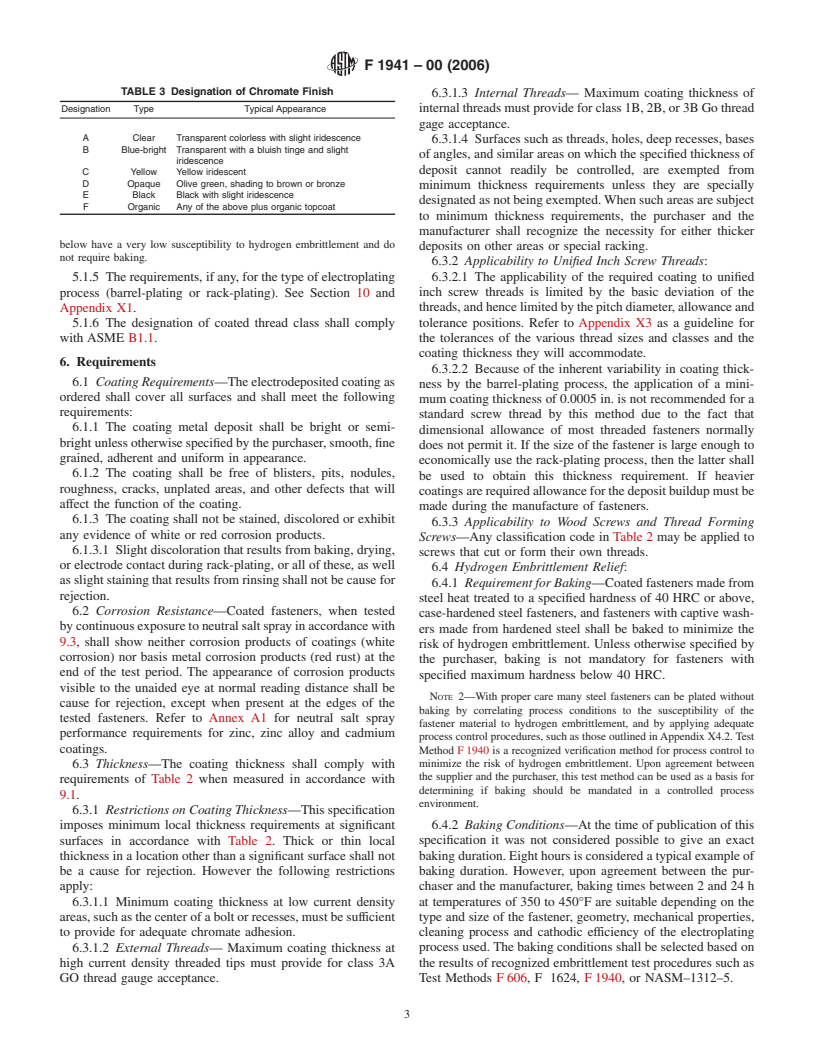

NOTE 1—Black dot (•) indicates test surface.

FIG. 1 Significant Surfaces on Externally Threaded Fasteners

F 606 Test Methods for Determining the Mechanical Prop-

erties of Externally and Internally Threaded Fasteners,

Washers, and Rivets

F 1470 GuideforFastenerSamplingforSpecifiedMechani-

cal Properties and Performance Inspection

NOTE 1—Black dot (•) indicates test surface.

F 1624 Test Method for Measurement of Hydrogen Em-

FIG. 2 Significant Surfaces on Internally Threaded Fasteners

brittlement Threshold in Steel by the Incremental Step

Loading Technique

TABLE 1 Designation of Common Coating Materials

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.