ASTM D156-07a

(Test Method)Standard Test Method for Saybolt Color of Petroleum Products (Saybolt Chromometer Method)

Standard Test Method for Saybolt Color of Petroleum Products (Saybolt Chromometer Method)

SIGNIFICANCE AND USE

Determination of the color of petroleum products is used mainly for manufacturing control purposes and is an important quality characteristic since color is readily observed by the user of the product. In some cases the color may serve as an indication of the degree of refinement of the material. When the color range of a particular product is known, a variation outside the established range can indicate possible contamination with another product. However, color is not always a reliable guide to product quality and should not be used indiscriminately in product specifications.

SCOPE

1.1 This test method covers the determination of the color of refined oils such as undyed motor and aviation gasoline, jet propulsion fuels, naphthas and kerosine, and, in addition, petroleum waxes and pharmaceutical white oils.

Note 1—For determining the color of petroleum products darker than Saybolt Color − 16, see Test Method D 1500.

1.2 This test method reports results specific to this test method and recorded as, “Saybolt Color units.”

1.3 The values stated in inch-pound units or in SI units and which are not in parentheses are to be regarded as the standard. The values given in parentheses are for information only.

Note 2—Oil tubes and apparatus used in this test method have traditionally been marked in inches, (the tube is required to be etched with 1/8 in. divisions.) The Saybolt Color Numbers are aligned with inch, ½ in., ¼ in., and 1/8 in. changes in the depth of oil. These fractional inch changes do not readily correspond to SI equivalents and in view of the preponderance of apparatus already in use and marked in inches, the inch/pound unit is regarded as the standard. However the test method does use SI units of length when the length is not directly related to divisions on the oil tube and Saybolt Color Numbers. The test method uses SI units for temperature.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.^

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D156 − 07a

StandardTest Method for

Saybolt Color of Petroleum Products (Saybolt Chromometer

1

Method)

This standard is issued under the fixed designation D156; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* Waxes, Including Petrolatum

D1500Test Method forASTM Color of Petroleum Products

1.1 Thistestmethodcoversthedeterminationofthecolorof

(ASTM Color Scale)

refined oils such as undyed motor and aviation gasoline, jet

D4057Practice for Manual Sampling of Petroleum and

propulsion fuels, naphthas and kerosine, and, in addition,

Petroleum Products

petroleum waxes and pharmaceutical white oils.

NOTE 1—For determining the color of petroleum products darker than

3. Terminology

Saybolt Color−16, see Test Method D1500.

3.1 Definitions:

1.2 This test method reports results specific to this test

3.1.1 clear-and-bright, n—condition in which the sample is

method and recorded as, “Saybolt Color units.”

free of haze or cloudiness. (Also termed clean-and-bright .)

1.3 The values stated in inch-pound units or in SI units and

3.1.2 free water, n—water in excess of that soluble in the

whicharenotinparenthesesaretoberegardedasthestandard.

sample and appearing in the sample as a haze or cloudiness, as

The values given in parentheses are for information only.

droplets, or as a separated phase or layer.

NOTE 2—Oil tubes and apparatus used in this test method have 3.1.3 particulates, n—small solid or semisolid particles,

traditionallybeenmarkedininches,(thetubeisrequiredtobeetchedwith

sometimesreferredtoassiltorsediment,thatcanbesuspended

1 1

⁄8in.divisions.)TheSayboltColorNumbersarealignedwithinch, ⁄2in.,

in the sample or can settle to the bottom.

1 1

⁄4in.,and ⁄8in.changesinthedepthofoil.Thesefractionalinchchanges

3.1.4 turbidity, n—reduction of transparency of a sample

do not readily correspond to SI equivalents and in view of the prepon-

derance of apparatus already in use and marked in inches, the inch/pound

duetothepresenceofparticulatematterorwaterhaze,orboth.

unitisregardedasthestandard.HoweverthetestmethoddoesuseSIunits

3.2 Definitions of Terms Specific to This Standard:

oflengthwhenthelengthisnotdirectlyrelatedtodivisionsontheoiltube

and Saybolt Color Numbers. The test method uses SI units for tempera-

3.2.1 Saybolt color, n—an empirical definition of the color

ture.

of a clear petroleum liquid based on a scale of−16 (darkest)

1.4 This standard does not purport to address all of the

to+30 (lightest).

safety concerns, if any, associated with its use. It is the 3.2.1.1 Discussion—The number is derived by finding the

responsibility of the user of this standard to establish appro-

height of a column of the sample that, when viewed through

priate safety and health practices and determine the applica- the length of the column, visually matches the appropriate one

bility of regulatory limitations prior to use.

ofthreeglassstandardsandreferringtoTable1ofTestMethod

D156.

2. Referenced Documents

4. Summary of Test Method

2

2.1 ASTM Standards:

4.1 Theheightofacolumnofsampleisdecreasedbylevels

D938Test Method for Congealing Point of Petroleum

correspondingtocolornumbersuntilthecolorofthesampleis

unmistakably lighter than that of the standard. The color

1

number above this level is reported, regardless of whether the

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

samplewasdarker,questionable,oramatchatthehigherlevel.

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

Current edition approved Dec. 1, 2007. Published January 2008. Originally

5. Significance and Use

approved in 1923. Last previous edition approved in 2007 as D156–07. DOI:

10.1520/D0156-07A.

5.1 Determinationofthecolorofpetroleumproductsisused

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mainly for manufacturing control purposes and is an important

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

qualitycharacteristicsincecolorisreadilyobservedbytheuser

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. of the product. In some cases the color may serve as an

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D156 − 07a

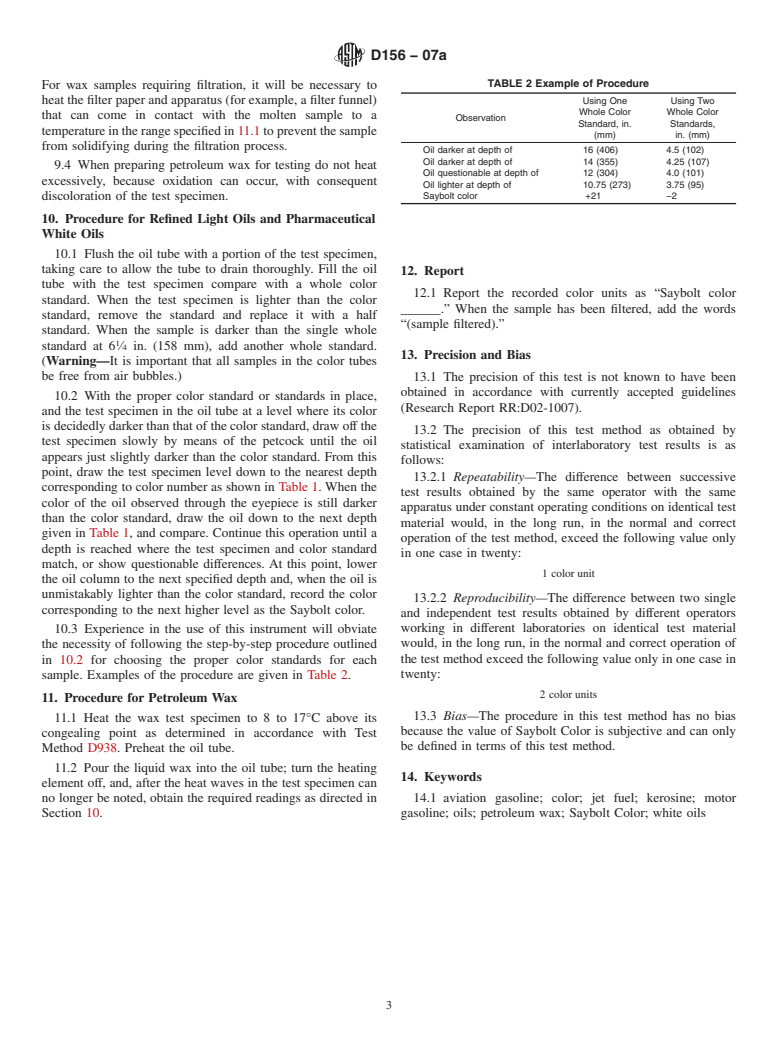

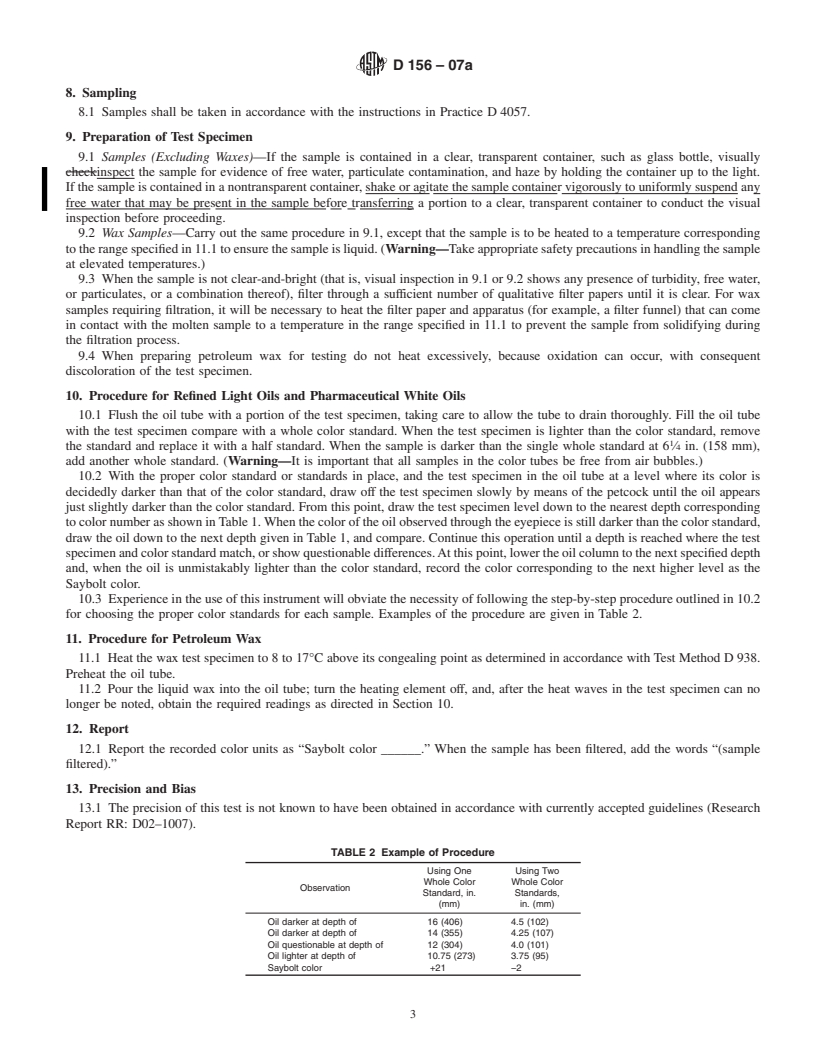

TABLE 1 Saybolt Colors Corresponding to Depths

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D156–07 Designation: D 156 – 07a

Standard Test Method for

Saybolt Color of Petroleum Products (Saybolt Chromometer

1

Method)

This standard is issued under the fixed designation D156; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method covers the determination of the color of refined oils such as undyed motor and aviation gasoline, jet

propulsion fuels, naphthas and kerosine, and, in addition, petroleum waxes and pharmaceutical white oils.

NOTE 1—For determining the color of petroleum products darker than Saybolt Color−16, see Test Method D1500.

1.2 This test method reports results specific to this test method and recorded as, “Saybolt Color units.”

1.3 Thevaluesstatedininch-poundunitsorinSIunitsandwhicharenotinparenthesesaretoberegardedasthestandard.The

values given in parentheses are for information only.

1

NOTE 2—Oil tubes and apparatus used in this test method have traditionally been marked in inches, (the tube is required to be etched with ⁄8 in.

1 1 1

divisions.) The Saybolt Color Numbers are aligned with inch, ⁄2 in., ⁄4 in., and ⁄8 in. changes in the depth of oil. These fractional inch changes do not

readily correspond to SI equivalents and in view of the preponderance of apparatus already in use and marked in inches, the inch/pound unit is regarded

as the standard. However the test method does use SI units of length when the length is not directly related to divisions on the oil tube and Saybolt Color

Numbers. The test method uses SI units for temperature.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D938 Test Method for Congealing Point of Petroleum Waxes, Including Petrolatum

D1500 Test Method for ASTM Color of Petroleum Products (ASTM Color Scale)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

3. Terminology

3.1 Definitions:

3.1.1 clear-and-bright, n—condition in which the sample is free of haze or cloudiness. (Also termed clean-and-bright .)

3.1.2 free water, n—water in excess of that soluble in the sample and appearing in the sample as a haze or cloudiness, as

droplets, or as droplets. a separated phase or layer.

3.1.3 particulates, n—small solid or semisolid particles, sometimes referred to as silt or sediment, that may or may not be

suspended in the sample. —small solid or semisolid particles, sometimes referred to as silt or sediment, that can be suspended in

the sample or can settle to the bottom.

3.1.4 turbidity, n—reduction of transparency of a sample due to the presence of particulate matter. —reduction of transparency

of a sample due to the presence of particulate matter or water haze, or both.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 Saybolt color, n—an empirical definition of the color of a clear petroleum liquid based on a scale of−16 (darkest) to+30

(lightest).

3.2.1.1 Discussion—The number is derived by finding the height of a column of the sample that, when viewed through the

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.05.0CD02.05 on Color Properties of Fuels, Petroleum Coke and Reactivity. Carbon Material.

Current edition approved July 15,Dec. 1, 2007. Published August 2007.January 2008. Originally approved in 1923. Last previous edition approved in 20022007 as

e1

D156–02 .D156–07.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 156 – 07a

lengthofthecolumn,visuallymatchestheappropriateoneofthreeglassstandards

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.