ASTM D5680-95a

(Practice)Standard Practice for Sampling Unconsolidated Solids in Drums or Similar Containers

Standard Practice for Sampling Unconsolidated Solids in Drums or Similar Containers

SCOPE

1.1 This practice covers typical equipment and methods for collecting samples of unconsolidated solids in drums or similar containers. These methods are adapted specifically for sampling drums having a volume of 110 U.S. gal (416 L) or less. These methods are applicable to hazardous material, product, or waste. Specific sample collection and handling requirements should be described in the site-specific work plan.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5680 – 95a

Standard Practice for

Sampling Unconsolidated Solids in Drums or Similar

Containers

This standard is issued under the fixed designation D 5680; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Accident Prevention Manual for Industrial Operations,

1.1 This practice covers typical equipment and methods for

2.3 Government Documents:

collecting samples of unconsolidated solids in drums or similar

Drum Handling Practices at Hazardous Waste Sites, EPA/

containers. These methods are adapted specifically for sam-

600/2-86/013, January 1986

pling drums having a volume of 110 U.S. gal (416 L) or less.

Soil Sampling and Analysis for Volatile Compounds, EPA/

These methods are applicable to hazardous material, product,

540/4-91/001, February 1991

or waste. Specific sample collection and handling requirements

Occupational Safety and Health Guidance Manual for

should be described in the site-specific work plan.

Hazardous Waste Site Activities, National Institute for

1.2 The values stated in inch-pound units are to be regarded

Occupational Safety and Health (NIOSH), Occupational

as the standard. The values given in parentheses are for

Safety and Health Administration (OSHA), U.S. Coast

information only.

Guard (USCG), and U.S Environmental Protection

1.3 This standard does not purport to address all of the

Agency (EPA), October 1985

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 Definitions:

bility of regulatory limitations prior to use.

3.1.1 bonding—touching the sample equipment to the drum

2. Referenced Documents to form an electrically conductive path to minimize potential

electrical differences between the sampling equipment and the

2.1 ASTM Standards:

drum, reducing the buildup of static electricity.

C 702 Practice for Reducing Samples of Aggregate to

3.1.2 bung—usually a 2-in. (5.1-cm) or ⁄4-in. (1.3-cm)

Testing Size

diameter threaded plug designed specifically to close a bung

D 4547 Practice for Sampling Waste and Soils for Volatile

hole.

Organics

3.1.3 bung hole—an opening in a barrel or drum through

D 4687 Guide for General Planning of Waste Sampling

which it can be filled, emptied, or vented.

D 4700 Guide for Soil Sampling from the Vadose Zone

3.1.4 deheading—removal of the lid of a closed-head drum;

D 5088 Practice for the Decontamination of Field Equip-

usually accomplished with a drum deheader.

ment Used at Non-Radioactive Waste Sites

3.1.5 drum—implies any drum, barrel, or non-bulk con-

D 5283 Practice for Generation of Environmental Data

tainer of 5 to 110 U.S gal (19 to 416 L) capacity.

Related to Waste Management Activities: Quality Assur-

3 3.1.6 pail—a small container, usually with a capacity of 5

ance and Quality Control Planning

U.S gal. Pails typically have bungs or spouts, or the entire lid

D 5451 Practice for Sampling with a Trier Sampler

5 can be removed.

E 300 Practice for Sampling Industrial Chemicals

3.1.7 paperwork—all required site documentation, which

D 5633 Practice for Sampling With a Scoop

may include the manifests, waste profiles, material safety data

2.2 NSC Document:

sheets (MSDS), site forms, sample labels, custody seals, and

chain of custody forms.

3.1.8 unconsolidated—for solid material, the characteristic

This practice is under the jurisdiction of ASTM Committee D-34 on Waste of being uncemented or uncompacted, or both, and separated

Management and is the direct responsibility of Subcommittee D34.01 on Sampling

easily into smaller particles.

and Monitoring.

3.1.9 work plan—a plan specific to a particular site; for

Current edition approved June 15, 1995. Published August 1995. Originally

conducting activities specified in the plan.

published as D 5680 – 95. Last previous edition D 5680 – 95.

Annual Book of ASTM Standards, Vol 04.02.

Annual Book of ASTM Standards, Vol 11.04.

Available from National Safety Council, P.O. Box 558, Itasca, IL 60143-0558.

Annual Book of ASTM Standards, Vol 04.08.

Available from the Superintendent of Documents, U. S. Government Printing

Annual Book of ASTM Standards, Vol 15.05.

Office, Washington, DC 20402.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5680

4. Summary of Practice containers, shall be inspected before use to ensure that they are

clear of obvious dirt and contamination and are in good

4.1 The drum and its contents are inspected, and appropriate

working condition. Visible contamination shall be removed,

sampling equipment is selected. A clean sampling device is

and the equipment shall be decontaminated with the appropri-

then used to auger, scoop, or core into the unconsolidated solid

ate rinse materials. Decontaminated sampling equipment

material to be sampled. The sample is collected and placed in

should be protected from contamination. This may include, but

a sample container. The sampling device is then either disposed

not be limited to, storage in aluminum foil, plastic bags,

of or cleaned and decontaminated.

polytetrafluoroethylene (PTFE) film, or other means of protec-

5. Significance and Use

tion that will not impact the sample quality of intended

analysis.

5.1 This practice is intended for use in collecting samples of

7.2 Basic Pre-Sampling Practices:

unconsolidated solid materials from drums or similar contain-

ers, including those that are unstable, ruptured, or compro- 7.2.1 Review all paperwork.

mised otherwise. Special handling procedures (for example, 7.2.2 Select the sampling equipment and sample containers

remote drum opening, overpressurized drum opening, drum appropriate for the material in the drum, as detailed in the work

deheading, etc.) are described in Drum Handling Practices at plan.

Hazardous Waste Sites.

7.2.3 Enter the work zone.

7.2.4 Inspect all drums to be sampled visually. Note any

6. Interferences

abnormal conditions, including rust marks, stains, bulges, or

6.1 The condition of the materials to be sampled and the

other signs of pressurization or leaks that may require special

condition and accessibility of the drums will have a significant

handling. The work plan should define clearly the limiting

impact on the selection of sampling equipment.

condition under which special handling procedures shall be

initiated. See Drum Handling Practices at Hazardous Waste

7. Pre-Sampling

Sites for information on opening overpressurized drums and

7.1 General Principles and Precautions:

the use of remotely operated drum opening equipment.

7.1.1 Samples should be collected in accordance with an

7.2.5 Stage the drums to be sampled in a designated work

appropriate work plan (Practice D 5283 and Guide D 4687).

area if they cannot be sampled in their current location. See

This plan must include a worker health and safety section

Drum Handling Practices at Hazardous Waste Sites for further

because there are potential hazards associated with opening

information on staging turns.

drums as well as potentially hazardous contents. See Occupa-

7.2.5.1 Move the drums to upright, stable positions if

tional Safety and Health Guidance Manual for Hazardous

necessary. Sufficient space shall be left between drums to

Waste Site Activities for information on health and safety at

prevent movement hazards.

hazardous waste sites.

7.2.5.2 Number or identify uniquely all drums to be

7.1.2 Correct sampling procedures must be applied to the

sampled.

conditions as they are encountered. It is impossible to specify

7.2.6 Perform a detailed inspection of individual drums.

rigid rules describing the exact manner of sample collection

7.2.6.1 Record all relevant information from drum labels,

because of unknowns associated with each solid sampling

markings, data sheets, etc. in the field log book or on forms

situation. It is essential that the samples be collected by a

specified in the work plan.

trained and experienced sampler because of the various con-

7.2.6.2 Make sure there are no discrepancies with existing

ditions under which drummed solids must be sampled.

paperwork.

7.1.3 To be able to make probability or confidence state-

7.2.7 Slowly loosen the ring that secures the lid, or loosen

ments concerning the properties of a sampled lot, the sampling

the bung allowing any pressure or vacuum to equalize.

procedure must allow for some element of randomness in

7.2.7.1 Precautionary Notes:

selection because of the possible variations in the material. The

(1) If the drum or pail appears to be under positive or

sampler should always be on the alert for possible biases

negative pressure (that is, a slight bulge or dimple in the lid),

arising from the use of a particular sampling device or from

control the release of pressure until it has equalized. For

unexpected segregation within the material.

example, if the drum or pail is equipped with bungs, loosen the

7.1.4 All auger, trier, thief, and scoop methods may fail a

smaller bung first since doing so will make it easier to control

prime sampling requirement: that of random selection of

the release of pressure.

sample fractions. Scoops are limited to use at or near the top

(2) If the top of the drum is dished inward (dimpled), it may

surface. Augers, triers, and thiefs are normally inserted in a

“pop” when equalizing pressure, spraying the sampler with any

present pattern. Particles on the bottom or along the sides of the

material that is sitting on top of the drum.

drum may consequently never have an opportunity to be

included in a sample. Sample particles should be selected by (3) If there is evidence of a chemical reaction or sudden

pressure buildup, the sampler should leave the area immedi-

techniques that will minimize variation in measured character-

istics between the available fractions and the resulting sample ately and evaluate whether remote drum opening equipment

should be used.

(Practice C 702).

7.1.5 The sampling equipment, sample preparation equip- (4) For flammable or explosive materials, the drum and

ment, sample containers, etc. must be clean, dry, and inert to sampling equipment should be grounded if the generation of

the material being sampled. All equipment, including sample static electricity while opening or sampling the drum is a

D 5680

possibility. The drum and sampling equipment should be 7.3.3.8 Hammer and chisel.

grounded to a ground stake or to an existing ground (building 7.3.3.9 Cloths or wipes, or both.

ground, grounded water pipes, etc.). New sampling equipment 7.3.3.10 Spatula.

may have some residual static electrical charge due to the 7.3.3.11 Sample containers, lids, and liners.

materials in which they are packed and shipped. The work plan 7.3.3.12 Chain of custody forms.

should specify whether grounding is necessary. See Accident 7.3.3.13 Field log books.

Prevention Manual for Industrial Operations for information 7.3.3.14 Sample labels.

on grounding and bonding. 7.3.3.15 Sample cooler.

7.2.7.2 Drums should be opened, sampled, and closed 7.3.3.16 Ice or gel ice.

individually to minimize the risk of exposure. 7.3.3.17 Grounding cables with alligator clips and emery

7.2.7.3 Drums (or Pails) with Bungs—Loosen the large cloth.

bung slowly. Use non-sparking tools. 7.3.3.18 Portable monitoring equipment (combustible gas

7.2.7.4 Drums with Removable Lids—Loosen the ring indicator, organic vapor detectors, radiation survey meter, etc.).

slowly with a manual wrench or air impact wrench. Use 7.3.4 Equipment needed to open drums should be non-

non-sparking tools. sparking (brass or beryllium copper) and include, but not be

7.2.7.5 Pails with Removable Lids (Side-Lever Lock limited to, the following:

Ring)—Release the lever slowly. 7.3.4.1 Bung wrenches (one straight and one bent),

7.2.7.6 Pails with Removable Lids (Snap-On)—Pry the lid 7.3.4.2 Flatblade screwdriver,

loose slowly with a pail lid opener. 7.3.4.3 Breaker bar ( ⁄2 in. (1.3 cm)),

7.2.8 Manual or remote puncturing or deheading will be 7.3.4.4 Ratchet ( ⁄2 in. (1.3 cm)),

required if the drum (or pail) has a stuck bung or the lid cannot 7.3.4.5 Speed handle ( ⁄2 in. (1.3 cm)),

be removed. See Drum Handling Practices at Hazardous 7.3.4.6 Adjustable wrenches (10 and 12 in. (25 and 30 cm)),

Waste Sites for further information on manual or remote drum 7.3.4.7 Air impact wrench and sockets, and

opening. 7.3.4.8 Pail lid opener.

7.2.9 Any discrepancy discovered (such as evidence of free

8. Sample Collection

liquid) upon opening the drum should be recorded in the field

8.1 Basic Sampling Practices:

log book.

8.1.1 Bond the sampling equipment to the drum, if specified

7.3 Sampling Equipment—Selection:

in the work plan.

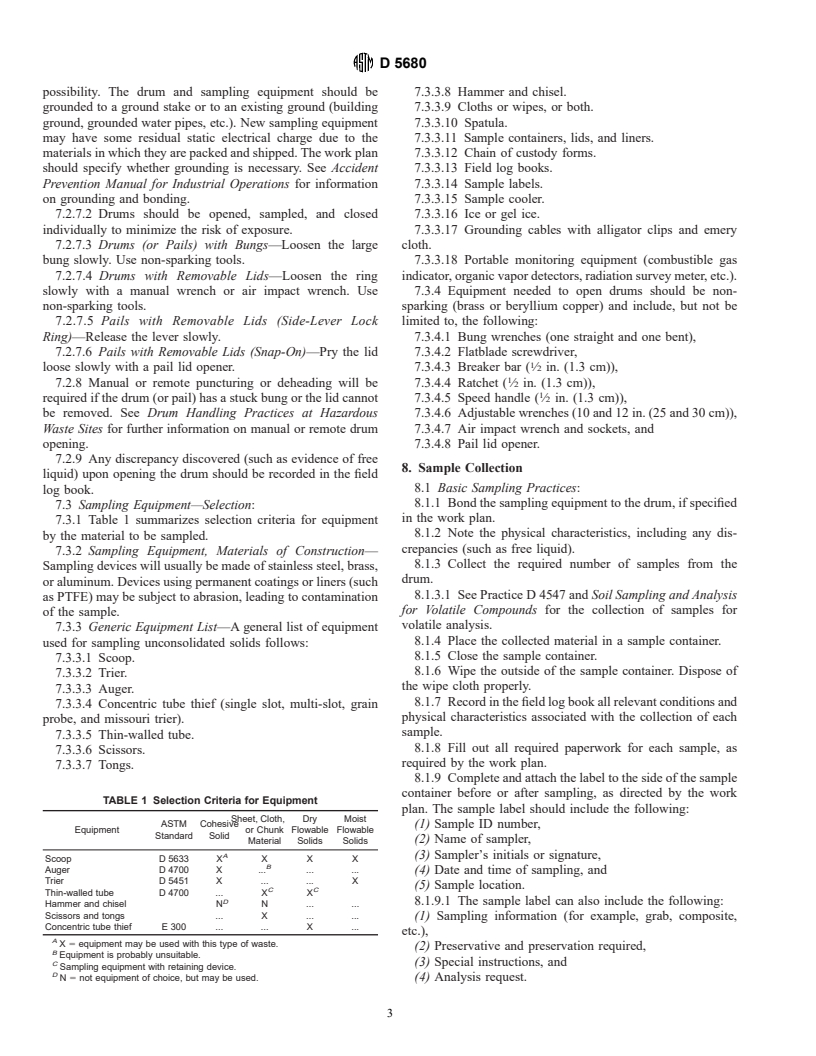

7.3.1 Table 1 summarizes selection criteria for equipment

8.1.2 Note the physical characteristics, including any dis-

by the material to be sampled.

crepancies (such as free liquid).

7.3.2 Sampling Equipment, Materials of Construction—

8.1.3 Collect the required number of samples from the

Sampling devices will usually be made of stainless steel, brass,

drum.

or aluminum. Devices using permanent coatings or liners (such

8.1.3.1 See Practice D 4547 and Soil Sampling and Analysis

as PTFE) may be subject to abrasion, leading to contamination

for Volatile Compounds for the collection of samples for

of the sample.

volatile analysis.

7.3.3 Generic Equipment List—A general list of equipment

8.1.4 Place the collected material in a sample container.

used for sampling unconsolidated solids follows:

8.1.5 Close the sample container.

7.3.3.1 Scoop.

8.1.6 Wipe the outside of the sample container. Dispose of

7.3.3.2 Trier.

the wipe cloth properly.

7.3.3.3 Auger.

8.1.7 Record in the field log book all relevant conditions and

7.3.3.4 Concentric tube thief (single slot, multi-slot, grain

physical characteristics associated with the collection of each

probe, and missouri trier).

sample.

7.3.3.5 Thin-walled tube.

8.1.8 Fill out all required paperwork for each sample, as

7.3.3.6 Scissors.

required by the work plan.

7.3.3.7 Tongs.

8.1.9 Complete and attach the label to the side of the sample

container before or after sampling, as directed by the work

TABLE 1 Selection Criteria for Equipment

plan. The sample label should include the following:

Sheet, Cloth, Dry Moist

ASTM Cohesive

(1) Sample ID number,

Equipment or Chunk Flowable Flowable

Standard Solid

(2) Name of sampler,

Material Solids Solids

A

(3) Sampler’s initials or signature,

Scoop D 5633 X XXX

B

Auger D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.