ASTM A793-96(2001)

(Specification)Standard Specification for Rolled Floor Plate, Stainless Steel

Standard Specification for Rolled Floor Plate, Stainless Steel

ABSTRACT

This specification covers the standard for stainless steel floor plates for use in galley spaces, washrooms, engine rooms, and machinery spaces, and for ladder treads, gun platforms, and deck treads. Several steel grades like Type 304, 304L, 316, 316L used as floor plate material shall conform to the chemical composition requirements in carbon, manganese, phosphorus, sulfur, silicon, nitrogen, nickel, chromium, and molybdenum as determined by heat analysis. Annealing shall be the last heat treatment to which the material is subjected. The stainless steel floor plate shall be in patterns with uniform pitch from center to center, angular figures shall be arranged such that they are in angular position from a vertical or horizontal line and shall have a raised figure. Mechanical properties shall be tested by two longitudinal cold bend tests and the raised figure shall not fracture nor develop cracks or flaws on the materials. Magnetic permeability test shall also be performed on the plates and shall meet the specified magnetic permeability indicator. Floor plates of stainless steel shall be uniform in quality and condition, and free of injurious defects that may detrimentally affect the suitability for the service for which they are intended.

SCOPE

1.1 This specification covers stainless steel floor plates 1/2 in. and under for use in galley spaces, washrooms, engine rooms, and machinery spaces, and for ladder treads, gun platforms, and deck treads. For these uses, Patterns A, B, and C are considered interchangeable (see Figs. 1, 2, and 3).

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 793 – 96 (Reapproved 2001)

Standard Specification for

1

Rolled Floor Plate, Stainless Steel

This standard is issued under the fixed designation A 793; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

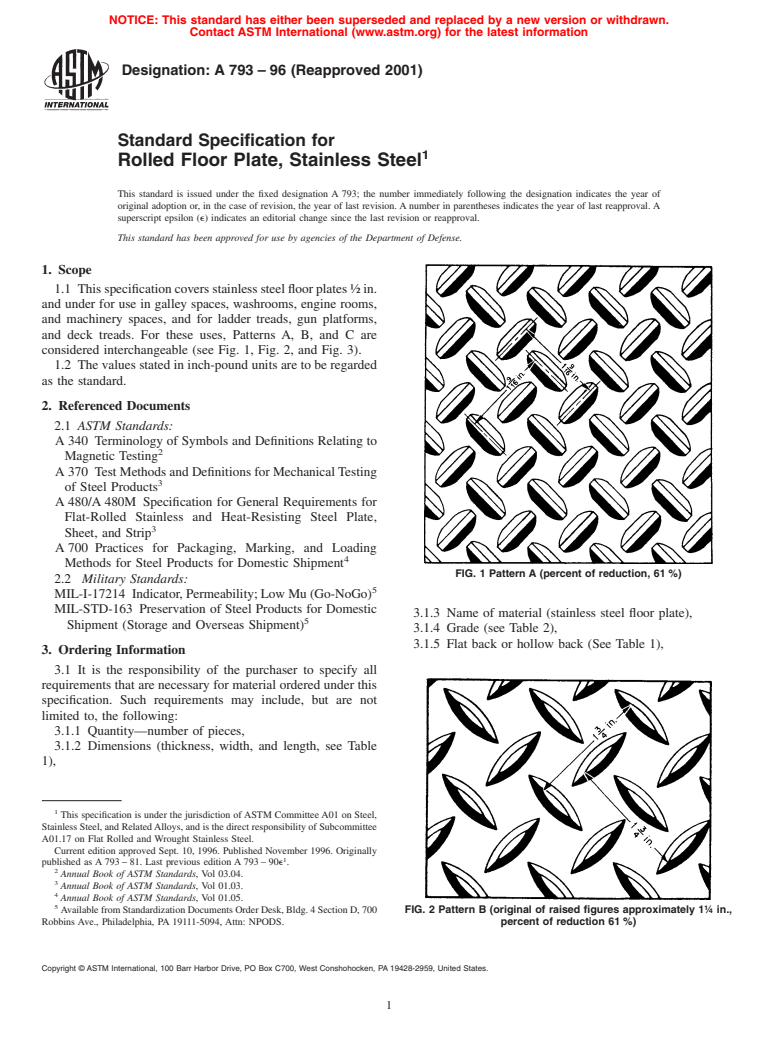

1.1 Thisspecificationcoversstainlesssteelfloorplates½in.

and under for use in galley spaces, washrooms, engine rooms,

and machinery spaces, and for ladder treads, gun platforms,

and deck treads. For these uses, Patterns A, B, and C are

considered interchangeable (see Fig. 1, Fig. 2, and Fig. 3).

1.2 The values stated in inch-pound units are to be regarded

as the standard.

2. Referenced Documents

2.1 ASTM Standards:

A340 Terminology of Symbols and Definitions Relating to

2

Magnetic Testing

A370 TestMethodsandDefinitionsforMechanicalTesting

3

of Steel Products

A480/A480M Specification for General Requirements for

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

3

Sheet, and Strip

A700 Practices for Packaging, Marking, and Loading

4

Methods for Steel Products for Domestic Shipment

FIG. 1 Pattern A (percent of reduction, 61 %)

2.2 Military Standards:

5

MIL-I-17214 Indicator,Permeability;LowMu(Go-NoGo)

MIL-STD-163 Preservation of Steel Products for Domestic

3.1.3 Name of material (stainless steel floor plate),

5

Shipment (Storage and Overseas Shipment)

3.1.4 Grade (see Table 2),

3.1.5 Flat back or hollow back (See Table 1),

3. Ordering Information

3.1 It is the responsibility of the purchaser to specify all

requirements that are necessary for material ordered under this

specification. Such requirements may include, but are not

limited to, the following:

3.1.1 Quantity—number of pieces,

3.1.2 Dimensions (thickness, width, and length, see Table

1),

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

StainlessSteel,andRelatedAlloys,andisthedirectresponsibilityofSubcommittee

A01.17 on Flat Rolled and Wrought Stainless Steel.

Current edition approved Sept. 10, 1996. Published November 1996. Originally

1

published as A793–81. Last previous edition A793–90e .

2

Annual Book of ASTM Standards, Vol 03.04.

3

Annual Book of ASTM Standards, Vol 01.03.

4

Annual Book of ASTM Standards, Vol 01.05.

5

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700 FIG. 2 Pattern B (original of raised figures approximately 1¼ in.,

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. percent of reduction 61 %)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 793 – 96 (2001)

FIG. 3 Pattern C

TABLE 1 Dimensions, Weights, and Special Characteristics of Patterns A, B, and C

Hollow Back Flat Back

Thickness of Plate at Thickness of Plate at

Weight Height of Raised Weight Height of Raised

Base of Raised Figure Base of Raised Figure,

(Approximate), Figures, min, (Approximate), Figures, min,

(Nominal), in. (mm) min, in. (mm)

2 2 A 2 2 A

lb/ft (kg/m ) in. (mm) lb/ft (kg/m ) in. (mm)

0.025 (0.64) 0.015 (0.38) 1.10 (5.37) 0.025 (0.64) . . . . . .

0.03125 (0.79) 0.02125 (0.54) 1.40 (6.84) 0.025 (0.64) . . . . . .

0.0375 (0.95) 0.027 (0.69) 1.65 (5.69) 0.025 (0.64) . . . . . .

0.05 (1.27) 0.039 (0.99) 2.30 (11.23) 0.035 (0.89) . . . . . .

0.0625 (1.59) 0.051 (1.30) 2.90 (14.16) 0.035 (0.89) . . . . . .

0.078 (1.98) 0.063 (1.60) 3.50 (17.09) 0.035 (0.89) . . . . . .

0.09375 (2.38) 0.079 (2.01) 3.938 (19.23) 0.035 (0.89) 4.875 (23.80) 0.035 (0.89)

0.109 (2.77) 0.096 (2.44) 4.59 (22.41) 0.030 (0.76) 5.50 (26.85) 0.045 (1.14)

0.125 (3.18) 0.110 (2.79) 5.25 (25.64) 0.030 (0.76) 6.125 (23.90) 0.055 (1.40)

0.140 (3.56) 0.126 (3.20) . . . . . . 6.75 (32.96) 0.055 (1.40)

0.156 (3.96) 0.141 (3.58) . . . . . . 7.375 (36.01) 0.055 (1.40)

0.172 (4.37) 0.157 (3.99) . . . . . . 8.000 (39.06) 0.055 (1.40)

0.1875 (4.76) 0.173 (4.39) . . . . . . 8.625 (42.11) 0.060 (1.52)

0.203 (5.16) 0.189 (4.80) . . . . . . 9.25 (45.16) 0.060 (1.52)

0.218 (5.54) 0.204 (5.18) . . . . . . 9.875 (48.21) 0.060 (1.52)

0.234 (5.94) 0.219 (5.56) . . . . . . 10.50 (51.27) 0.060 (1.52)

0.250 (6.35) 0.235 (5.97) . . . . . . 11.125 (54.32) 0.060 (1.52)

A

Approximate weights are shown for estimating convenience.

TABLE 2 Heat Chemical Composition, %

UNS Des-

Type C, max Mn, max P, max S, max Si, max N, max Ni Cr Mo

ignation

304 S30400 0.08 2.00 0.045 0.030 0.75 0.10 8.00–10.50 18.00–20.00 . . .

304L S30403 0.030 2.00 0.045 0.030 0.75 0.10 8.00–12.00 18.00–20.00 . . .

316 S31600 0.08 2.00 0.045 0.030 0.75 0.10 10.00–14.00 16.00–18.00

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.