ASTM F3226/F3226M-16e1

(Specification)Standard Specification for Metallic Press-Connect Fittings for Piping and Tubing Systems

Standard Specification for Metallic Press-Connect Fittings for Piping and Tubing Systems

SCOPE

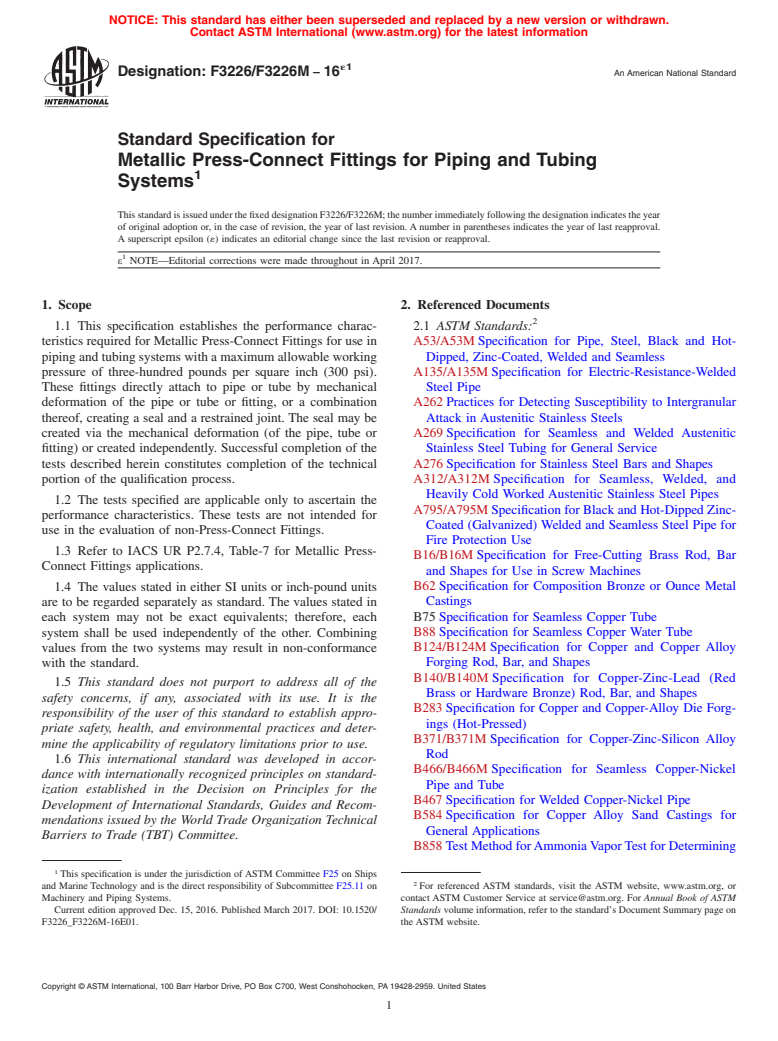

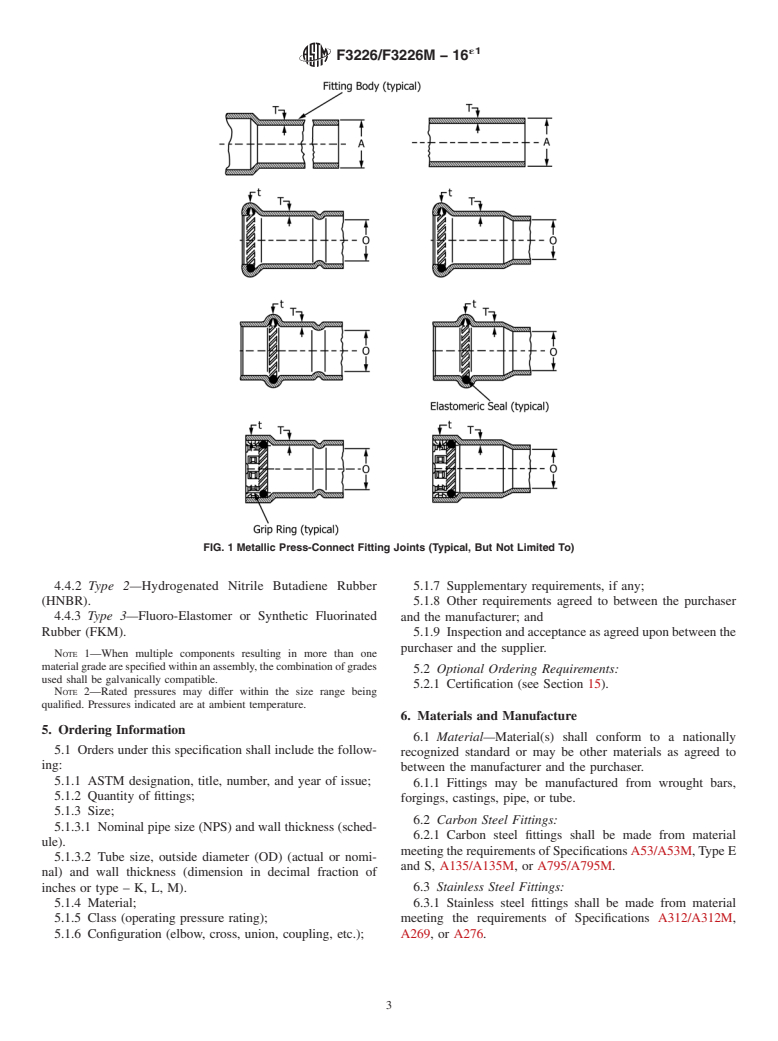

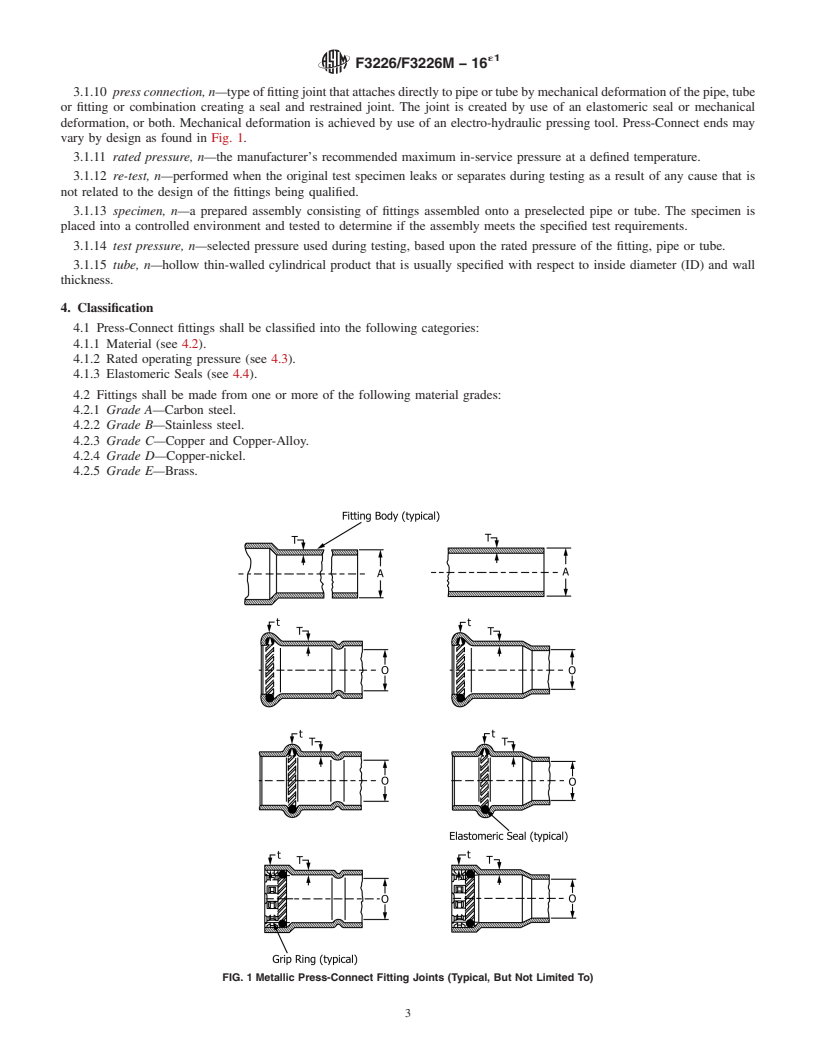

1.1 This specification establishes the performance characteristics required for Metallic Press-Connect Fittings for use in piping and tubing systems with a maximum allowable working pressure of three-hundred pounds per square inch (300 psi). These fittings directly attach to pipe or tube by mechanical deformation of the pipe or tube or fitting, or a combination thereof, creating a seal and a restrained joint. The seal may be created via the mechanical deformation (of the pipe, tube or fitting) or created independently. Successful completion of the tests described herein constitutes completion of the technical portion of the qualification process.

1.2 The tests specified are applicable only to ascertain the performance characteristics. These tests are not intended for use in the evaluation of non-Press-Connect Fittings.

1.3 Refer to IACS UR P2.7.4, Table-7 for Metallic Press-Connect Fittings applications.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F3226/F3226M −16 An American National Standard

Standard Specification for

Metallic Press-Connect Fittings for Piping and Tubing

1

Systems

ThisstandardisissuedunderthefixeddesignationF3226/F3226M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial corrections were made throughout in April 2017.

1. Scope 2. Referenced Documents

2

1.1 This specification establishes the performance charac- 2.1 ASTM Standards:

teristics required for Metallic Press-Connect Fittings for use in A53/A53MSpecification for Pipe, Steel, Black and Hot-

pipingandtubingsystemswithamaximumallowableworking Dipped, Zinc-Coated, Welded and Seamless

pressure of three-hundred pounds per square inch (300 psi). A135/A135MSpecification for Electric-Resistance-Welded

These fittings directly attach to pipe or tube by mechanical Steel Pipe

deformation of the pipe or tube or fitting, or a combination A262Practices for Detecting Susceptibility to Intergranular

thereof, creating a seal and a restrained joint. The seal may be Attack in Austenitic Stainless Steels

created via the mechanical deformation (of the pipe, tube or A269Specification for Seamless and Welded Austenitic

fitting) or created independently. Successful completion of the Stainless Steel Tubing for General Service

tests described herein constitutes completion of the technical A276Specification for Stainless Steel Bars and Shapes

portion of the qualification process. A312/A312M Specification for Seamless, Welded, and

Heavily Cold Worked Austenitic Stainless Steel Pipes

1.2 The tests specified are applicable only to ascertain the

A795/A795MSpecificationforBlackandHot-DippedZinc-

performance characteristics. These tests are not intended for

Coated (Galvanized) Welded and Seamless Steel Pipe for

use in the evaluation of non-Press-Connect Fittings.

Fire Protection Use

1.3 Refer to IACS UR P2.7.4, Table-7 for Metallic Press-

B16/B16MSpecification for Free-Cutting Brass Rod, Bar

Connect Fittings applications.

and Shapes for Use in Screw Machines

1.4 The values stated in either SI units or inch-pound units B62Specification for Composition Bronze or Ounce Metal

are to be regarded separately as standard. The values stated in Castings

B75Specification for Seamless Copper Tube

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining B88Specification for Seamless Copper Water Tube

B124/B124MSpecification for Copper and Copper Alloy

values from the two systems may result in non-conformance

with the standard. Forging Rod, Bar, and Shapes

B140/B140M Specification for Copper-Zinc-Lead (Red

1.5 This standard does not purport to address all of the

Brass or Hardware Bronze) Rod, Bar, and Shapes

safety concerns, if any, associated with its use. It is the

B283Specification for Copper and Copper-Alloy Die Forg-

responsibility of the user of this standard to establish appro-

ings (Hot-Pressed)

priate safety, health, and environmental practices and deter-

B371/B371MSpecification for Copper-Zinc-Silicon Alloy

mine the applicability of regulatory limitations prior to use.

Rod

1.6 This international standard was developed in accor-

B466/B466M Specification for Seamless Copper-Nickel

dance with internationally recognized principles on standard-

Pipe and Tube

ization established in the Decision on Principles for the

B467Specification for Welded Copper-Nickel Pipe

Development of International Standards, Guides and Recom-

B584Specification for Copper Alloy Sand Castings for

mendations issued by the World Trade Organization Technical

General Applications

Barriers to Trade (TBT) Committee.

B858TestMethodforAmmoniaVaporTestforDetermining

1

This specification is under the jurisdiction ofASTM Committee F25 on Ships

2

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Machinery and Piping Systems. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Dec. 15, 2016. Published March 2017. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F3226_F3226M-16E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F3226/F3226M − 16

Susceptibility to Stress Corrosion Cracking in Copper 3.1.6 leakage, n—theescapeoffluidorgasfromanyholein

Alloys the pressure containment wall, sufficient to drip or flow from

B967/B967MSpecification for Copper-Zinc

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F3226/F3226M − 16 F3226/F3226M − 16

Standard Specification for

Metallic Press-Connect Fittings for Piping and Tubing

1

Systems

This standard is issued under the fixed designation F3226/F3226M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial corrections were made throughout in April 2017.

1. Scope

1.1 This specification establishes the performance characteristics required for Metallic Press-Connect Fittings for use in piping

and tubing systems with a maximum allowable working pressure of three-hundred pounds per square inch (300 psi). These fittings

directly attach to pipe or tube by mechanical deformation of the pipe or tube or fitting, or a combination thereof, creating a seal

and a restrained joint. The seal may be created via the mechanical deformation (of the pipe, tube or fitting) or created

independently. Successful completion of the tests described herein constitutes completion of the technical portion of the

qualification process.

1.2 The tests specified are applicable only to ascertain the performance characteristics. These tests are not intended for use in

the evaluation of non-Press-Connect Fittings.

1.3 Refer to IACS UR P2.7.4, Table-7 for Metallic Press-Connect Fittings applications.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A53/A53M Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

A135/A135M Specification for Electric-Resistance-Welded Steel Pipe

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A269 Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

A276 Specification for Stainless Steel Bars and Shapes

A312/A312M Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

A795/A795M Specification for Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Fire

Protection Use

B16/B16M Specification for Free-Cutting Brass Rod, Bar and Shapes for Use in Screw Machines

B62 Specification for Composition Bronze or Ounce Metal Castings

B75 Specification for Seamless Copper Tube

B88 Specification for Seamless Copper Water Tube

B124/B124M Specification for Copper and Copper Alloy Forging Rod, Bar, and Shapes

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

Current edition approved Dec. 15, 2016. Published March 2017. DOI: 10.1520/F3226_F3226M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F3226/F3226M − 16

B140/B140M Specification for Copper-Zinc-Lead (Red Brass or Hardware Bronze) Rod, Bar, and Shapes

B283 Specification for Copper and Copper-Alloy Die Forgings (Hot-Pressed)

B371/B371M Specification for Copper-Zinc-Silicon Alloy Rod

B466/B466M Specification for Seamless Copper-Nickel Pipe and Tube

B467 Specification for Welded Copper-Nickel Pipe

B584 Specification for Copper Alloy Sand Castings for Ge

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.