ASTM D3762-03

(Test Method)Standard Test Method for Adhesive-Bonded Surface Durability of Aluminum (Wedge Test)

Standard Test Method for Adhesive-Bonded Surface Durability of Aluminum (Wedge Test)

SIGNIFICANCE AND USE

The test is primarily qualitative, but is very discriminating in determining variations in adherend surface preparation parameters and adhesive environmental durability. The test has found application in controlling surface preparation operations and in screening surface preparations, primer and adhesive systems for durability. In addition to determining crack growth rate and assigning a value to it, the adhesive–joint failure is evaluated and reported. For example, adhesion failure; cohesion failure; or adherend failure are noted after opening up the specimen at the conclusion of the test period.

SCOPE

1.1 This test method, simulates in a qualitative manner the forces and effects on an adhesive bond joint at metal-adhesive/primer interface. It has proven to be highly reliable in determining and predicting the environmental durability of adherend surface preparations. The method has proven to be correlatable with service performance in a manner that is much more reliable than conventional lap shear or peel tests (Note 2).

Note 1W—hile this test method is intended for use in aluminum-to-aluminum applications it may be used for determining surface durability of other metals and plastics provided consideration is given to thickness and rigidity of the adherends.

Note 2—This test method is not a quantitative fracture strength test method. To measure fracture strength see Test Method D 3433.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3762 – 03

Standard Test Method for

Adhesive-Bonded Surface Durability of Aluminum (Wedge

1

Test)

This standard is issued under the fixed designation D3762; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3433 Test Method for Fracture Strength in Cleavage of

,

2 3 Adhesives in Bonded Metal Joints

1.1 This test method simulates in a qualitative manner the

forces and effects on an adhesive bond joint at metal-adhesive/

3. Terminology

primer interface. It has proven to be highly reliable in deter-

3.1 Definitions—Many of the terms used in this test method

mining and predicting the environmental durability of adher-

are defined in Terminology D907.

end surface preparations. The method has proven to be

correlatable with service performance in a manner that is much

4. Summary of Test Method

morereliablethanconventionallapshearorpeeltests(Note2).

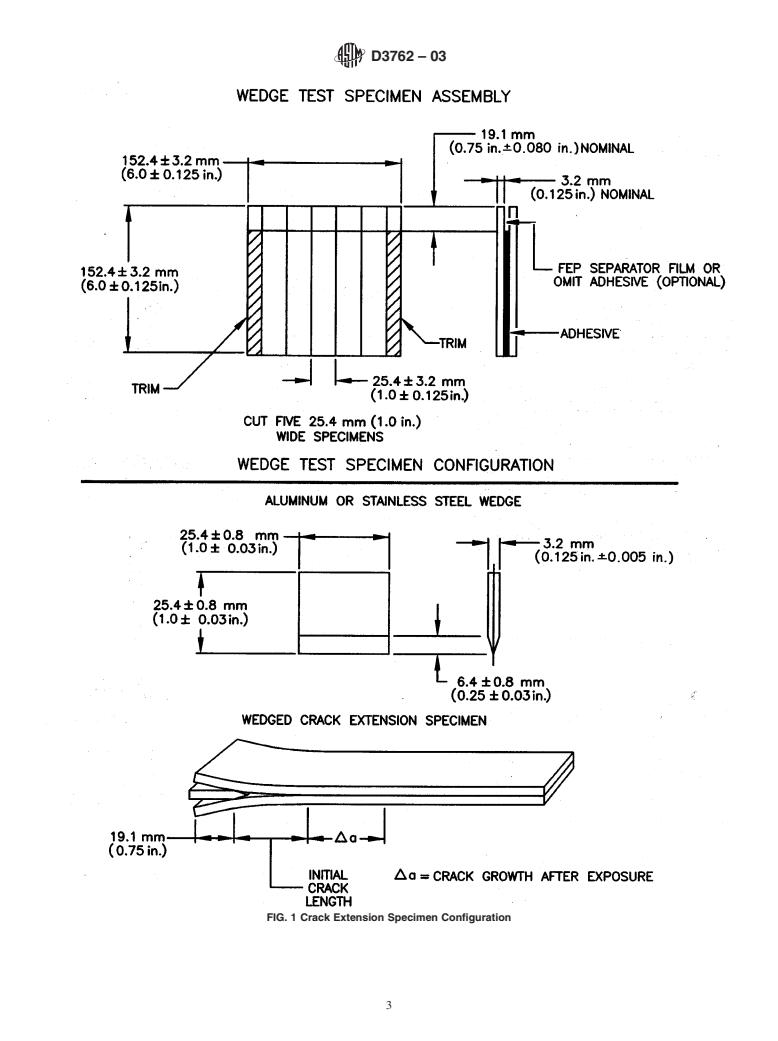

4.1 A wedge is forced into the bondline of a flat-bonded

NOTE 1—While this test method is intended for use in aluminum-to-

aluminum specimen, thereby creating a tensile stress in the

aluminum applications it may be used for determining surface durability

region of the resulting crack tip. The stressed specimen is

of other metals and plastics provided consideration is given to thickness

exposed to an aqueous environment, usually at an elevated

and rigidity of the adherends.

temperature, or to an appropriate environment relative to the

NOTE 2—This test method is not a quantitative fracture strength test

use of the bonded structure. The resulting crack growth with

method. To measure fracture strength see Test Method D3433.

time and failure modes are then evaluated. Variations in

1.2 The values stated in SI units are to be regarded as the adherend surface quality are easily observable when the

standard. The values given in parentheses are for information

specimens are forcibly, if necessary, opened at the test conclu-

only. sion.

1.3 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 5.1 The test is primarily qualitative, but is very discriminat-

priate safety and health practices and determine the applica- ing in determining variations in adherend surface preparation

bility of regulatory limitations prior to use. parameters and adhesive environmental durability.The test has

found application in controlling surface preparation operations

2. Referenced Documents

and in screening surface preparations, primer and adhesive

4

2.1 ASTM Standards: systems for durability. In addition to determining crack growth

D907 Terminology of Adhesives

rate and assigning a value to it, the adhesive–joint failure is

evaluated and reported. For example, adhesion failure; cohe-

1

sion failure; or adherend failure are noted after opening up the

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.80 on Metal

specimen at the conclusion of the test period.

Bonding Adhesives.

Current edition approved August 10, 2003. Published September 2003. Origi-

6. Apparatus

nally approved in 1979. Last previous edition approved in 1998 as D3762 – 98.

6.1 Magnifier (preferably stereo binocular), 5 to 30-power.

DOI: 10.1520/D3762-03.

2

Marceau, J. A., Moji, Y., and McMillan, J. C., “A Wedge Test for Evaluating

6.2 Marking Stylus, sharp-pointed, or triangular file.

Adhesive Bonded Surface Durability,” 21st SAMPE Symposium, Vol 21,April 6–8,

6.3 Wedges, aluminum or stainless steel.

1976.

3

Scardino,W. M., Marceau J.A., “Comparative Stressed Durability ofAdhesive

NOTE 3—Wedges are preferably of the same composition as the

Bonded Aluminum Alloy Joints” Symposium on Durability of Adhesive Bonded

adherends of the specimen being tested to reduce the possibility of

Structures, U. S.ArmyArmament Research and Development Command, Dover, N.

electrolytic corrosion. Stainless steel wedges have been found to work

J. Oct, 27–29, 1976.

4 well with many adherends and are very durable and reuseable.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.4 Scale, small, graduated in millimetres or hundredths of

Standards volume information, refer to the standard’s Document Summary page on

an inch.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D376

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.