ASTM D5452-06

(Test Method)Standard Test Method for Particulate Contamination in Aviation Fuels by Laboratory Filtration

Standard Test Method for Particulate Contamination in Aviation Fuels by Laboratory Filtration

SIGNIFICANCE AND USE

This test method provides a gravimetric measurement of the particulate matter present in a sample of aviation turbine fuels delivered to a laboratory for evaluation. The objective is to minimize these contaminants to avoid filter plugging and other operational problems. Although tolerable levels of particulate contaminants have not yet been established for all points in fuel distribution systems, the total contaminant measurement is normally of most interest.

SCOPE

1.1 This test method covers the gravimetric determination by filtration of particulate contaminant in a sample of aviation turbine fuel delivered to a laboratory.

1.1.1 The sample is filtered through a test membrane and a control membrane using vacuum. The mass change difference identifies the contaminant level per unit volume.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 4.2, 7.3, 7.5, 11.3, and X1.7.2. Before using this standard, refer to supplier's safety labels, material safety data sheets, and technical literature.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D5452–06

Designation: 423/97

Standard Test Method for

Particulate Contamination in Aviation Fuels by Laboratory

1

Filtration

This standard is issued under the fixed designation D5452; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* Color Differences from Instrumentally Measured Color

Coordinates

1.1 This test method covers the gravimetric determination

D2276 Test Method for Particulate Contaminant in Avia-

by filtration of particulate contaminant in a sample of aviation

tion Fuel by Line Sampling

turbine fuel delivered to a laboratory.

D3828 TestMethodsforFlashPointbySmallScaleClosed

1.1.1 The sample is filtered through a test membrane and a

Cup Tester

control membrane using vacuum. The mass change difference

D4306 Practice for Aviation Fuel Sample Containers for

identifies the contaminant level per unit volume.

Tests Affected by Trace Contamination

1.2 The values stated in SI units are to be regarded as the

D4865 Guide for Generation and Dissipation of Static

standard. The values given in parentheses are for information

Electricity in Petroleum Fuel Systems

only.

D6615 Specification for Jet B Wide-Cut Aviation Turbine

1.3 This standard does not purport to address all of the

Fuel

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

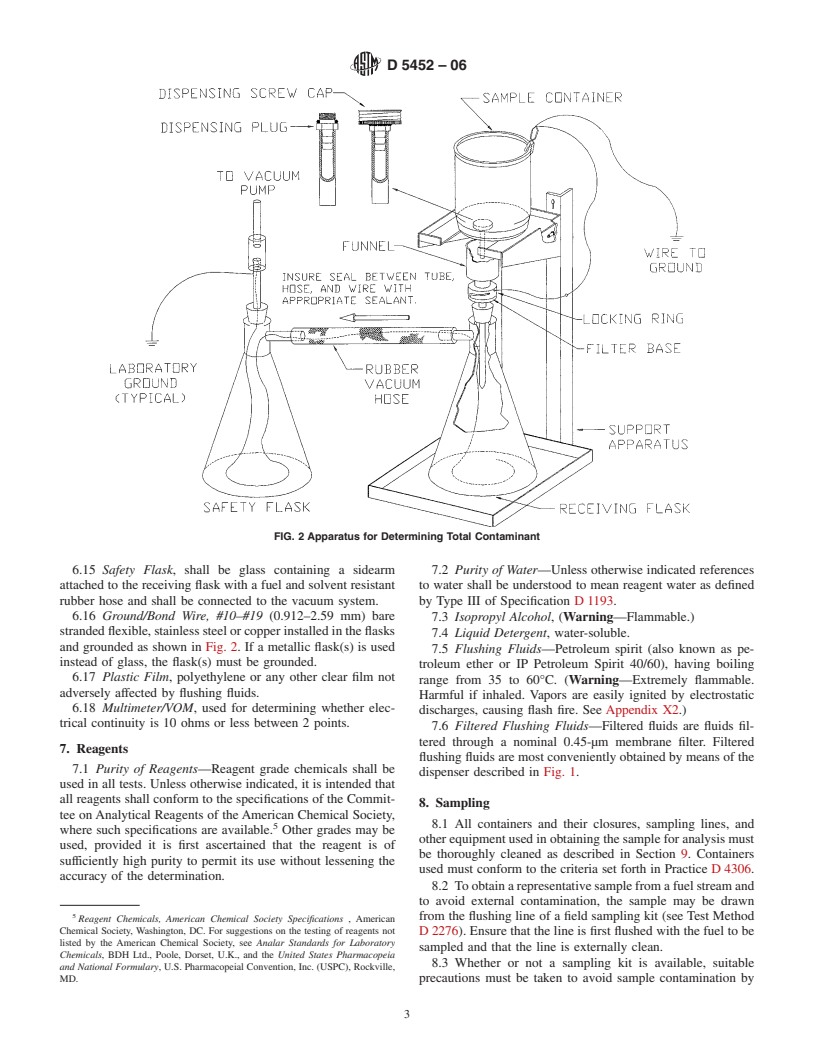

3. Terminology

priate safety and health practices and determine the applica-

3.1 Definitions:

bility of regulatory limitations prior to use. For specific hazard

3.1.1 bond, v—to connect two parts of a system electrically

statements,see4.2,7.3,7.5,11.3,andX1.7.2.Beforeusingthis

by means of a bonding wire to eliminate voltage differences.

standard, refer to supplier’s safety labels, material safety data

3.1.2 ground, vt—to connect electrically with ground

sheets, and technical literature.

(earth).

2. Referenced Documents 3.1.3 membrane filter, n—a porous article of closely con-

2

trolled pore size through which a liquid is passed to separate

2.1 ASTM Standards:

matter in suspension.

D56 TestMethodforFlashPointbyTagClosedCupTester

3

3.1.3.1 Discussion—RR:D02–1012 contains information

D93 Test Methods for Flash Point by Pensky-Martens

on membrane filters that meet the requirements therein.

Closed Cup Tester

3.1.4 particulate, adj—of or relating to minute separate

D1193 Specification for Reagent Water

particles.

D1535 Practice for Specifying Color by the Munsell Sys-

3.1.4.1 Discussion—Solids generally composed of oxides,

tem

silicates, and fuel insoluble salts.

D2244 Practice for Calculation of Color Tolerances and

3.1.5 volatile fuels—relatively wide boiling range volatile

distillate.

1

This test method is under the jurisdiction of ASTM Committee D02 on

3.1.5.1 Discussion—These are identified as Jet B in Speci-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

fication D6615 or the military grade known as JP-4.Any fuel

D02.J0.05 on Fuel Cleanliness.

or mixture having a flash point less than 38°C must be

Current edition approved Dec. 1, 2006. Published January 2007. Originally

considered volatile.

approved in 1993. Last previous edition approved in 2005 as D5452–05.

This test method has been separated from D2276 and has been modified

primarily to establish improved safety measures.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Supportingdata(includingalistofsupplierswhohaveprovideddataindicating

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM their membranes, field monitors, and field monitor castings) have been filed at

Standards volume information, refer to the standard’s Document Summary page on ASTM International Headquarters and may be obtained by requesting Research

the ASTM website. Report RR: D02–1012.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5452–06

4. Summary of Test Method

4.1 A known volume of fuel is filtered through a pre-

weighed test membrane filter and the increase in membrane

filter mass is weight determined after washing and drying.The

change in weight of a control membrane located immediately

below the test membrane filter is also determined. The objec-

tive of using a control membrane is to assess whether the fuel

itself influences the weight of a membrane. The particulate

contaminantisde

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.