EN 15254-5:2018

(Main)Extended application of results from fire resistance tests - Non-loadbearing walls - Part 5: Metal sandwich panel construction

Extended application of results from fire resistance tests - Non-loadbearing walls - Part 5: Metal sandwich panel construction

This document defines rules for extended applications, provides guidance, and, where appropriate, defines procedures, for variations of certain parameters and factors associated with the design of internal and external non-loadbearing walls constructed of metal sandwich panels and that have been tested in accordance with EN 1364-1, which could generate a classification in accordance with EN 13501-2.

EN 15254-5 applies for self-supporting, double skin metal faced sandwich panels having an insulating core bonded to both facings as defined in EN 14509.

Erweiterter Anwendungsbereich der Ergebnisse von Feuerwiderstandsprüfungen - Nichttragende Wände - Teil 5: Sandwichelemente in Metallbauweise

Dieses Dokument definiert Regeln für erweiterte Anwendungsbereiche, enthält Leitlinien und legt, falls erforderlich, Verfahren für Änderungen von bestimmten Parametern und Faktoren fest, die mit der Bauweise von nichttragenden Innen- und Außenwänden zusammenhängen, die aus Sandwichelementen in Metallbauweise (im Folgenden als "Sandwichelement" bezeichnet) bestehen und die nach EN 1364-1 geprüft wurden, was zu einer Klassifizierung nach EN 13501-2 führen könnte.

EN 15254-5 gilt für selbsttragende Sandwichelemente mit beidseitigen Metalldeckschichten und einem Kern aus Wärmedämmstoff, der, wie in EN 14509 definiert, mit beiden Deckschichten verklebt ist.

Application étendue des résultats d'essais de résistance au feu - Murs non porteurs - Partie 5 : Panneaux sandwiches métalliques pour la construction

Le présent document définit les règles pour les applications étendues, expose les lignes directrices et, le cas échéant, définit des procédures pour les modifications de certains paramètres et facteurs liés à la conception de murs internes et externes non porteurs en panneaux sandwiches métalliques et qui ont été soumis à essai conformément à l’EN 1364-1, pouvant générer une classification conformément à l’EN 13501-2.

L’EN 15254-5 s’applique aux panneaux sandwiches autoportants, à deux parements métalliques comportant une âme isolante liée aux deux parements métalliques tels que définis dans l’EN 14509.

Razširjena uporaba rezultatov preskusov požarne odpornosti - Nenosilne stene - 5. del: Konstrukcije iz kovinskih sendvič panelov

Ta evropski standard določa pravila za razširjeno uporabo, zagotavlja navodila in po potrebi določa postopke za odstopanja nekaterih parametrov in faktorjev, povezanih z obliko notranjih in zunanjih nenosilnih sten, zgrajenih iz kovinskih sendvič panelov, preskušenih v skladu s standardom EN 1364-1.

Standard EN 15254-5 se uporablja za samonosilne dvoslojne kovinske sendvič panele z izoliranim jedrom, vezanim na obe strani, kot je določeno v standardu EN 14509.

General Information

- Status

- Published

- Publication Date

- 24-Apr-2018

- Withdrawal Date

- 30-Oct-2018

- Technical Committee

- CEN/TC 127 - Fire safety in buildings

- Drafting Committee

- CEN/TC 127/WG 1 - Structural and separating elements

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 07-Dec-2023

- Completion Date

- 14-Apr-2025

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 13-Dec-2023

Overview

EN 15254-5:2018 - Extended application of results from fire resistance tests: Non-loadbearing walls - Part 5: Metal sandwich panel construction (CEN) defines rules, guidance and procedures for extending the applicability of a fire resistance test on metal sandwich panels. It applies to self-supporting, double-skin metal-faced sandwich panels with an insulating core bonded to both facings (as defined in EN 14509) that have been tested to EN 1364-1 and may be classified under EN 13501-2.

Key Topics

- Purpose: Predict whether variations from a tested panel or assembly still meet the required fire-resistance classification by interpolation/extrapolation of EN 1364-1 test results.

- Scope of variations considered: material changes (metal facings, coatings, adhesives, core type/composition, sheet thickness - e.g. allowed ±0.2 mm in tested thickness), and construction changes (span length, panel orientation, panel width - test results valid up to +20% increase, panel thickness, longitudinal joint construction, fixings and boundary conditions).

- Assumptions: whole-face exposure to standard furnace curve (EN 1363-1/EN 1363-2), non‑deflecting structure above/below the wall during fire exposure, post-delamination load transfer to support structure, use of EN 1993-1-2 for steel strength reduction at elevated temperatures.

- Procedure elements: establishing the field of extended application, identification of factor influences, calculation methods and additional measurements, interaction between factors, and reporting requirements.

- Supporting material: normative references (EN 1363-1, EN 1363-2, EN 1364-1, EN 1993-1-2, EN 13501-2, EN 14509, EN 15725, EN ISO 13943) and informative annexes (typical panel behaviour in fire; methods for evaluating span-length extension).

Applications

EN 15254-5 is practical for:

- Manufacturers assessing whether product variants (different cores, facings, coatings or minor dimensional changes) can use an existing fire test classification.

- Fire engineers & specifiers evaluating design options where original test configurations differ from end-use conditions.

- Test laboratories & certification bodies preparing extended application reports or advising on additional test needs.

- Building designers & façade engineers ensuring non-loadbearing sandwich walls meet fire resistance classes under EN 13501-2 when modifications to tested panels are proposed.

Using EN 15254-5 helps reduce unnecessary retesting by applying standardized rules and calculations for credible extension of test results.

Related standards

- EN 1364-1 (fire resistance tests for non-loadbearing walls)

- EN 1363-1 / EN 1363-2 (general and alternative fire test procedures)

- EN 13501-2 (fire classification from resistance tests)

- EN 14509 (self-supporting double skin metal faced insulating panels)

- EN 1993-1-2 (steel structural fire design)

- EN 15725 (extended application reports)

Frequently Asked Questions

EN 15254-5:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Extended application of results from fire resistance tests - Non-loadbearing walls - Part 5: Metal sandwich panel construction". This standard covers: This document defines rules for extended applications, provides guidance, and, where appropriate, defines procedures, for variations of certain parameters and factors associated with the design of internal and external non-loadbearing walls constructed of metal sandwich panels and that have been tested in accordance with EN 1364-1, which could generate a classification in accordance with EN 13501-2. EN 15254-5 applies for self-supporting, double skin metal faced sandwich panels having an insulating core bonded to both facings as defined in EN 14509.

This document defines rules for extended applications, provides guidance, and, where appropriate, defines procedures, for variations of certain parameters and factors associated with the design of internal and external non-loadbearing walls constructed of metal sandwich panels and that have been tested in accordance with EN 1364-1, which could generate a classification in accordance with EN 13501-2. EN 15254-5 applies for self-supporting, double skin metal faced sandwich panels having an insulating core bonded to both facings as defined in EN 14509.

EN 15254-5:2018 is classified under the following ICS (International Classification for Standards) categories: 13.220.50 - Fire-resistance of building materials and elements; 91.060.10 - Walls. Partitions. Facades. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15254-5:2018 has the following relationships with other standards: It is inter standard links to EN 15254-5:2009, prEN 15254-5. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15254-5:2018 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/117. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 15254-5:2018 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Erweiterter Anwendungsbereich der Ergebnisse von Feuerwiderstandsprüfungen - Nichttragende Wände - Teil 5: Sandwichelemente in MetallbauweiseApplication étendue des résultats des essais de résistance au feu - Murs non porteurs - Partie 5 : Panneaux sandwiches métalliques pour la constructionExtended application of results from fire resistance tests - Non-loadbearing walls - Part 5: Metal sandwich panel construction91.060.10Stene. Predelne stene. FasadeWalls. Partitions. Facades13.220.50Požarna odpornost gradbenih materialov in elementovFire-resistance of building materials and elementsICS:Ta slovenski standard je istoveten z:EN 15254-5:2018SIST EN 15254-5:2018en,fr,de01-oktober-2018SIST EN 15254-5:2018SLOVENSKI

STANDARDSIST EN 15254-5:20101DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15254-5

April

t r s z ICS

s uä t t rä w râ

{ sä r x rä s r Supersedes EN

s w t w væ wã t r r {English Version

Extended application of results from fire resistance tests æ Nonæloadbearing walls æ Part

wã Metal sandwich panel construction Application étendue des résultats d 5essais de résistance au feu æ Murs non porteurs æ Partie

w ã Panneaux sandwiches métalliques pour la construction Erweiterter Anwendungsbereich der Ergebnisse von Feuerwiderstandsprüfungen æ Nichttragende Wände æ Teil

wã Sandwichelemente in Metallbauweise This European Standard was approved by CEN on

z January

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s w t w væ wã t r s z ESIST EN 15254-5:2018

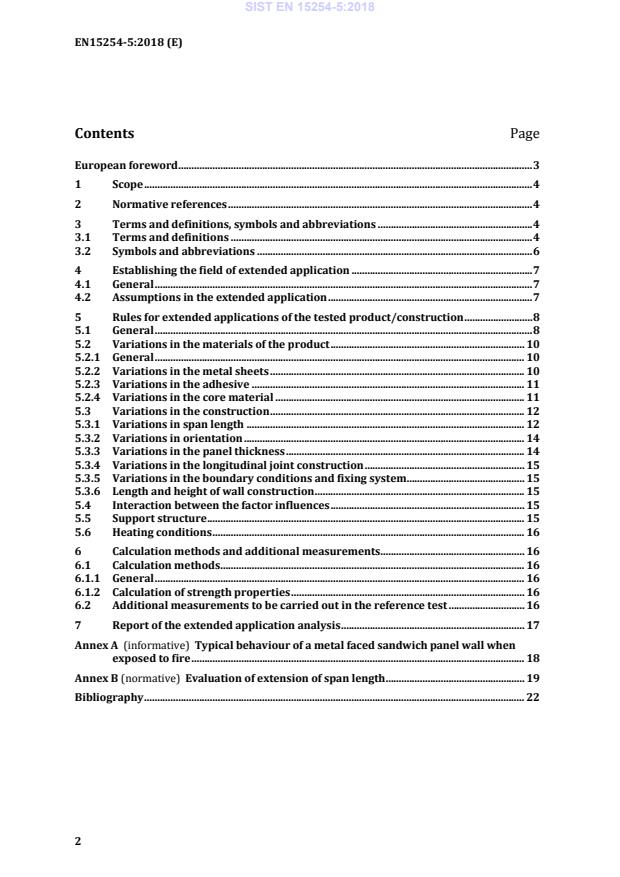

EN15254-5:2018 (E) 2 Contents Page European foreword . 3 1 Scope . 4 2 Normative references . 4 3 Terms and definitions, symbols and abbreviations . 4 3.1 Terms and definitions . 4 3.2 Symbols and abbreviations . 6 4 Establishing the field of extended application . 7 4.1 General . 7 4.2 Assumptions in the extended application . 7 5 Rules for extended applications of the tested product/construction . 8 5.1 General . 8 5.2 Variations in the materials of the product . 10 5.2.1 General . 10 5.2.2 Variations in the metal sheets . 10 5.2.3 Variations in the adhesive . 11 5.2.4 Variations in the core material . 11 5.3 Variations in the construction . 12 5.3.1 Variations in span length . 12 5.3.2 Variations in orientation . 14 5.3.3 Variations in the panel thickness . 14 5.3.4 Variations in the longitudinal joint construction . 15 5.3.5 Variations in the boundary conditions and fixing system . 15 5.3.6 Length and height of wall construction . 15 5.4 Interaction between the factor influences . 15 5.5 Support structure . 15 5.6 Heating conditions . 16 6 Calculation methods and additional measurements. 16 6.1 Calculation methods . 16 6.1.1 General . 16 6.1.2 Calculation of strength properties . 16 6.2 Additional measurements to be carried out in the reference test . 16 7 Report of the extended application analysis . 17 Annex A

(informative)

Typical behaviour of a metal faced sandwich panel wall when exposed to fire . 18 Annex B (normative)

Evaluation of extension of span length . 19 Bibliography . 22 SIST EN 15254-5:2018

EN15254-5:2018 (E) 3 European foreword This document (EN 15254-5:2018) has been prepared by Technical Committee CEN/TC 127 “Fire safety in buildings”, the secretariat of which is held by BSI. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by October 2018, and conflicting national standards shall be withdrawn at the latest by October 2018. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN shall not be held responsible for identifying any or all such patent rights. This document supersedes EN 15254-5:2009. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association. This standard is currently composed of the following parts: — EN 15254-2, Extended application of results from fire resistance tests — Non-loadbearing walls — Part 2: Masonry and Gypsum Blocks; — EN 15254-4, Extended application of results from fire resistance tests — Non-loadbearing walls — Part 4: Glazed constructions; — EN 15254-5, Extended application of results from fire resistance tests — Non-loadbearing walls — Part 5: Metal sandwich panel construction; —

EN 15254-6, Extended application of results from fire resistance tests — Non-loadbearing walls — Part 6: Curtain walling; — EN 15254-7, Extended application of results from fire resistance tests — Non-loadbearing walls — Part 7: Non-load bearing sandwich panels — Ceilings. According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 15254-5:2018

EN15254-5:2018 (E) 4 1 Scope This document defines rules for extended applications, provides guidance, and, where appropriate, defines procedures, for variations of certain parameters and factors associated with the design of internal and external non-loadbearing walls constructed of metal sandwich panels and that have been tested in accordance with EN 1364-1, which could generate a classification in accordance with EN 13501-2. EN 15254-5 applies for self-supporting, double skin metal faced sandwich panels having an insulating core bonded to both facings as defined in EN 14509. 2 Normative references The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 1363-1, Fire resistance tests — Part 1: General Requirements EN 1363-2, Fire resistance tests — Part 2: Alternative and additional procedures EN 1364-1, Fire resistance tests for non-loadbearing elements — Part 1: Walls EN 1993-1-2, Eurocode 3: Design of steel structures — Part 1-2: General rules — Structural fire design EN 13501-2, Fire classification of construction products and building elements — Part 2: Classification using data from fire resistance tests, excluding ventilation services EN 14509, Self-supporting double skin metal faced insulating panels — Factory made products - Specifications EN 15725, Extended application reports on the fire performance of construction products and building elements EN ISO 13943, Fire safety — Vocabulary (ISO 13943) 3 Terms and definitions, symbols and abbreviations 3.1 Terms and definitions For the purposes of this document, the terms and definitions given in EN 14509, EN 15725, EN 1364-1, EN 1363-1 and EN ISO 13943 the following apply. ISO and IEC maintain terminological databases for use in standardization at the following addresses: — IEC Electropedia: available at http://www.electropedia.org/ — ISO Online browsing platform: available at http://www.iso.org/obp SIST EN 15254-5:2018

EN15254-5:2018 (E) 5 3.1.1 direct field of application of test results outcome of a process (involving the application of defined rules) whereby a test result is deemed to be equally valid for variations in one or more of the product properties and/or intended end-use applications 3.1.2 extended field of application of test results outcome of a process (involving the application of defined rules that may incorporate calculation procedures) that predicts, for a variation of a product property and/or its intended end-use application(s), a test result on the basis of one or more test results to the same test standard 3.1.3 factor variation that may be applied to a parameter, e.g. a change in the core thickness 3.1.4 factor influence potential cause of a change in the fire resistance when the factor is changed, e.g. an increase in fire resistance as result of an increase of the thickness of the core 3.1.5 fastening fixing component that fastens the panels to a support structure or to the test frame 3.1.6 fixing system system consisting of fastenings and possible other means to fasten the panels to a support structure or to the test frame 3.1.7 height of assembly height of the wall in the reference test or in the end-use application for horizontally or vertically installed wall panels 3.1.8 length of assembly length of the wall in the reference test or in the end-use application for horizontally or vertically installed wall panels 3.1.9 reference test fire resistance test in accordance with EN 1363-1 and EN 1364-1, and where applicable EN 1363-2, on which the extended application is based and the results of which are used as the main source of data for the extended application 3.1.10 stitching component for fixing panels to panels in the longitudinal joint SIST EN 15254-5:2018

EN15254-5:2018 (E) 6 3.1.11 span length centre to centre distance between the supports of a panel and/or intermediate supports to which the sandwich panel is fixed 3.1.12 support structure construction onto which the panel wall is fastened in the end-use application 3.1.13 test frame frame containing the test construction for the purpose of mounting onto the furnace 3.2 Symbols and abbreviations For the purposes of this document, the following symbols and abbreviations apply. E etanchéité F load Ft,Ed the tensile load on the fasteners Fv,Ed the shear load on the fasteners Ft,Rd the design tensile load on the fastener at normal temperature Fv,Rd the design shear load on the fastener at normal temperature I isolation L span length L1 distance between midspan of two adjacent panels L2 overlap of the metal facing at the panel to panel joint PCS gross calorific potential R resistance, loadbearing capacity b width of panel c1 opening in adjacent metal sheet joints at normal room temperature on unexposed side c2 opening in adjacent metal sheet joints during the reference test on unexposed side dc depth of core fj deflection of panel to panel joint in the reference test (deflection into the furnace to be taken as positive) f1, f2 deflection of two adjacent panels at midspan in the reference test (deflection into the furnace to be taken as positive) g panel weight per square meter k yield strength factor n number of fasteners q pressure action on the panel in a fire situation

relative increase in opening of the metal sheet joint in the reference test

relative deflection of the joint compared to the adjacent panels in the reference test (to be calculated taking into account the positive and negative directions of the deflections) SIST EN 15254-5:2018

EN15254-5:2018 (E) 7 4 Establishing the field of extended application 4.1 General An extended application analysis is required when the application differs in one or more parameters from the tested one described in the test report and/or in the classification document, and which is not covered by the direct field of application of the classification document. Extended application is a prediction of the expected fire resistance of fire resistant metal faced sandwich panels. It may be based on interpolation between or extrapolation from test data. The fundamental consideration shall be that the fire resistant metal faced sandwich panels after extension would achieve the required fire performance if it were to be tested according to EN 1364-1. The extended application of test results from metal faced sandwich panels used as a non-loadbearing wall shall be based on the reference fire test results performed according to EN 1364-1 and may be complemented by one or more additional tests. The general rules in EN 15725 shall be followed. 4.2 Assumptions in the extended application The following assumptions are considered when evaluating extended applications for sandwich panels: a) the wall is required to provide fire resistance in the end-use condition; relevant classes are given in EN 13501-2; b) the wall is assumed to be exposed on the entire face of one side to the standardized heating conditions given in the EN 1363-1 fire resistance test specification or to alternative and additional procedures given in the EN 1363-2; c) the structure above and below the wall does not deflect vertically during the fire exposure period; this simulates the non-deflecting nature of the test frame which forms part of the furnace test apparatus; In reality constructions deflect and this should be taken into account by the building designer when designing the building and planning the constructional details so that no vertical loads are applied to the wall. d) after delamination of the fire-exposed facing the dead load of the sandwich panels is carried by a support structure to which the ends of the sandwich panels are attached; e) the support structure has at least the same loadbearing capacity, R, of the resistance to fire performance as the sandwich panel wall regarding integrity; f) the self weight of the facing and core is calculated from the volume and density of the materials; g) the calculation of the reduction in the strength properties of steel at elevated temperature shall be in accordance with EN 1993-1-2. SIST EN 15254-5:2018

EN15254-5:2018 (E) 8 5 Rules for extended applications of the tested product/construction 5.1 General When performing extended applications for a tested wall changes can occur either in the materials and/or in the construction. Both are dealt with in this standard. Table 1 and Table 2 list the changes which may or may not be made in an extended application assessment. The rules for the changes are given in 5.2 and 5.3. Table 1 — Material changes relevant to extended application Parameter Factors Factor influence on performance Rules Integrity E Insulation I Changes in metal facings Chemical composition of coating influence no influence a 5.2.2.1 Change from coated to non coated metal influence influence 5.2.2.1 Sheet thickness influence no influence a Allowed up to ± 0,2 mm of tested thickness. Change from one metal to another no information no information 5.2.2.2 Change in sheet geometry no information no information 5.2.2.3 Changes in adhesive Amount influence influence 5.2.3 Type influence no influence a 5.2.3 Changes in core material Type major influence major influence 5.2.4 Change in composition. major influence major influence 5.2.4.2 - 5.2.4.6 a It is understood that when a change in a factor can influence the integrity of a joint, there is a possibility that a change in the leakage of hot gases or in joint geometry can also influence the temperature rise near the joint and therefore influence the insulation rating. SIST EN 15254-5:2018

EN15254-5:2018 (E) 9 Table 2 — Constructional changes relevant to extended application Parameter Factors Factor influence on performance Rules Integrity E Insulation I Span length Decrease no influence no influence a Allowed Increase influence no influence a 5.3.1 Orientation

influence no influence a 5.3.2 Panel width Decrease no influence no influence a Test results valid Increase influence no influence a Test results valid up to + 20 % Panel thickness e.g. core thickness Decrease Increase no information major influence 5.3.3 Joint construction Type major influence major influence 5.3.4 Stiching decreased influence influence Not allowed Stiching increased influence influence 5.3.4 Sealants influence influence 5.3.4 Fixing system Type major influence no influence a 5.3.5 Amount decreased major influence no influence a 5.3.5 Amount increased influence no influence a Allowed Protection decreased major influence influence 5.3.5 Protection increased influence influence Allowed Length of assembly Vertical installation no influence no influence a 5.3.6 Horizontal installation

See span length 5.3.1 Height of assembly Vertical installation

See span length 5.3.1 Horizontal installation influence no influence a 5.3.6 Support structure Changes no information no influence a 5.5 a It is understood that when a change in a factor can influence the integrity of a joint, there is a possibility that a change in the leakage of hot gases or in joint geometry can also influence the temperature rise near the joint and therefore influence the insulation rating. SIST EN 15254-5:2018

EN15254-5:2018 (E) 10 5.2 Variations in the materials of the product 5.2.1 General Metal faced sandwich panels consist of three main materials (facing metal sheets, adhesive and core material). In the case of auto adhesively bonded panels the foamed core material also forms the adhesive layer during the foaming process. Changes in the properties of the metal sheets will not affect the fire resistance results significantly and changes can therefore be allowed. On the other hand even small changes in the core material can result in big variations in the fire resistance test results. These facts are taken into account in the following rules. 5.2.2 Variations in the metal sheets 5.2.2.1 Variations in the coatings The most essential property of the coating regarding fire resistance is the emissivity on the unexposed side. Normally the emissivity for a coated steel sheet is between 0,8 and 0,95. A change in emissivity of - 10 % for a new coating compared to the tested one is thus allowed if there is at least a 10 % margin in the insulation test result compared to the I-classification. Test results are always valid for coatings with higher emissivity values compared to the tested one. When a change in coating is made the manufacturer of the coated sheet shall provide emissivity properties for the products. A non-coated metal sheet can have an emissivity as low as 0,1. A change from a coated to a non-coated sheet is therefore not allowed. The same rule as for coatings above applies also in this case. A change in emissivity of - 10 % is allowed if the emissivities for the different sheets are known. The energy content of the coating on the exposed side is small and will not affect the fire resistance properties of the sandwich panel. Test results are valid for all coatings. If modifications in the coatings on the unexposed side are made compared to the tested one, the reaction to fire classification of the product shall be the same or better than the tested one. Test results are though valid for all colours of the same type of coating. 5.2.2.2 Variations in the metal material The following rules are valid for extended applications: a) when steel is tested the test results are valid for all grades of steel; NOTE For more information regarding

...

SIST EN 15254-5:2018은 비하중-bearing 벽체에 대한 화재 저항 테스트 결과의 연장 적용을 다루는 중요한 표준으로, 금속 샌드위치 패널 구조에 대한 명확한 규칙과 지침을 제공합니다. 이 문서는 EN 1364-1에 따라 테스트된 금속 샌드위치 패널의 설계와 관련된 특정 매개변수 및 요소의 변형에 대한 절차를 정의하며, 이러한 구조물의 화재 저항 평가에 있어 필수적인 기준을 제공합니다. 표준의 강점 중 하나는 내외부 비하중-bearing 벽체에 대한 명확한 가이드라인을 제시하여, 건축가와 엔지니어가 금속 샌드위치 패널의 사용 시 화재 성능을 예측하고 이를 기반으로 적절한 설계를 수행할 수 있도록 돕는 것입니다. 또한, 이 문서는 EN 13501-2에 따른 분류를 발생시킬 수 있는 기준을 제공하여, 건축물의 화재 안전성을 확보하는 데 기여합니다. EN 15254-5의 적용 범위는 자가 지지형, 이중 스킨 금속 외장 샌드위치 패널을 포함하여, EN 14509에 정의된 절연 코어가 두 겉면 모두에 결합된 구조를 포괄합니다. 이러한 명확한 정의는 다양한 건축 환경에서 금속 샌드위치 패널을 안전하게 사용하는 데 결정적인 역할을 하며, 효율적이고 일관된 화재 저항 평가 방법을 제공합니다. 결론적으로, SIST EN 15254-5:2018은 금속 샌드위치 패널 구조의 설계 및 사용에 있어 비할 바 없는 가이드라인을 제공하며, 화재 안전을 보장하기 위한 필수 문서로 그 실효성과 중요성을 인정받고 있습니다.

The EN 15254-5:2018 standard provides comprehensive guidelines for the extended application of fire resistance test results specifically for non-loadbearing walls using metal sandwich panel construction. This standard is significant in its scope as it addresses both internal and external walls, providing a robust framework for the classification of fire performance based on established parameters. One of the primary strengths of this standard is its detailed approach in defining the rules and procedures necessary for assessing variations in design elements of metal sandwich panels. This is particularly relevant for construction professionals seeking to ensure compliance with fire safety regulations while maximizing the performance of building materials. The standard's alignment with EN 1364-1 for fire resistance testing enhances its credibility and relevance, as it builds upon existing testing frameworks, ensuring that new applications are rooted in empirical evidence. Furthermore, the EN 15254-5:2018 standard stands out due to its specific focus on self-supporting, double skin metal-faced sandwich panels, which are increasingly used in contemporary construction projects for their insulating properties and structural efficiency. By delineating guidelines tailored to these materials, the standard facilitates a clearer understanding of how to apply fire resistance classifications under EN 13501-2, thus aiding architects, engineers, and builders in making informed design decisions that adhere to fire safety requirements. Overall, the standard serves as a crucial reference point for industry stakeholders, linking fire resistance testing outcomes with practical applications in metal sandwich panel construction, thereby enhancing both safety and compliance in building practices.

EN 15254-5:2018は、火災耐性試験の結果の拡張適用に関する重要な標準であり、特に非耐荷重壁の金属サンドイッチパネル構造に焦点を当てています。この文書は、EN 1364-1に従って試験された金属サンドイッチパネルを用いて設計された内外の非耐荷重壁に関連する特定のパラメータや要因の変動に関するルールを定義しており、火災時の安全性を向上させるためのガイダンスを提供しています。 この標準の強みは、その適用範囲の広さにあります。EN 15254-5は、自己支持型のダブルスキン金属フェイスのサンドイッチパネルに適用され、両側面に結合された断熱コアを有する構造について明確に規定しています。これにより、設計者やエンジニアは、さまざまな設計要件や使用条件に応じた適切な火災性能評価を得ることが可能です。特に、EN 13501-2に基づく分類を生成できる可能性があることは、この標準の実用性をさらに高めています。 また、EN 15254-5は、金属サンドイッチパネルの特性を考慮したため、設計の柔軟性を提供しつつ、業界標準に準拠した安全な建材の使用を促進します。このように、この文書は火災安全性に関する重要なガイダンスを提供し、建築分野における材料選定や設計の質を向上させる役割を果たしています。 火災安全基準の進展において、EN 15254-5:2018は、特に金属サンドイッチパネルの非耐荷重壁の構築に関連した専門家にとって不可欠な標準であり、今後の建設業界においてその重要性はますます高まることでしょう。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...