IEC TR 62368-2:2019

(Main)Audio/video, information and communication technology equipment - Part 2: Explanatory information related to IEC 62368-1:2018

Audio/video, information and communication technology equipment - Part 2: Explanatory information related to IEC 62368-1:2018

IEC TR 62368-2:2019 provides explanatory information related to IEC 62368-1. Only those subclauses considered to need further background reference information or explanation of their content to benefit the reader are included. Therefore, not all numbered subclauses are cited. Unless otherwise noted, all references are to clauses, subclauses, annexes, figures or tables located in IEC 62368-1:2018. This third edition updates the second edition of IEC 62368-2 published in 2014 to take into account changes made to IEC 62368-1:2014 as identified in the Foreword of IEC 62368-1:2018. This Technical Report is informative only. In case of a conflict between IEC 62368-1 and IEC TR 62368-2, the requirements in IEC 62368-1 prevail over this Technical Report.

Key words: Audio/Video, Safeguards, Information, Communication

Équipements des technologies de l'audio/vidéo, de l'information et de la communication - Partie 2 : Précisions relatives à l'IEC 62368-1:2018

L'IEC TR 62368-2:2019 fournit des explications au sujet de l'IEC 62368-1. Ne sont inclus que les paragraphes qui nécessitent des informations complémentaires ou des explications pouvant bénéficier au lecteur. Par conséquent, certains numéros de paragraphes ne sont pas cités. Sauf indication contraire, toutes les références à des articles, paragraphes, annexes, figures ou tableaux renvoient à l'IEC 62368-1:2018 Cette troisième édition actualise la deuxième édition de l'IEC 62368-2 publiée en 2014 et intègre les modifications faites dans l'IEC 62368-1:2014 telles qu'indiquées dans l'Avant-propos de l'IEC 62368-1:2018. Le présent Rapport technique est un document informatif. En cas de conflits entre l'IEC 62368-1 et l'IEC TR 62368-2, les exigences de l'IEC 62368-1 prévalent sur le présent Rapport technique.

Mots-clés: Audio/Vidéo, Protection, Information, Communication

General Information

- Status

- Published

- Publication Date

- 06-May-2019

- Technical Committee

- TC 108 - Safety of electronic equipment within the field of audio/video, information technology and communication technology

- Drafting Committee

- WG HBSDT - TC 108/WG HBSDT

- Current Stage

- PPUB - Publication issued

- Start Date

- 07-May-2019

- Completion Date

- 26-Apr-2019

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC TR 62368-2:2019 is an informative Technical Report published by the IEC that provides explanatory information and background guidance for the safety standard IEC 62368-1:2018. It is the third edition, updating the 2014 TR to reflect changes in the 2018 edition of IEC 62368-1. IEC TR 62368-2 does not add requirements; where a conflict exists, the mandatory requirements in IEC 62368-1 prevail. The report targets Audio/Video, Information and Communication Technology (AV/ICT) equipment and explains the intent and application of selected clauses to help users implement the hazard-based approach in IEC 62368-1.

Key Topics and Technical Guidance

The Technical Report focuses on subclauses that benefit from additional background or explanation and includes informative material on:

- Hazard-based safety engineering (HBSE) concepts and risk-reduction principles (illustrations and flowcharts).

- Electrically-caused injury: explanations of shock, touch-current, insulation, clearances and protective bonding.

- Electrically-caused fire: prevention, ignition likelihood reduction, and fire spread control; material flammability considerations.

- Hazardous substances: assessment and control measures for chemical risks.

- Mechanical hazards: safeguards against moving parts, structural strength and impact tests.

- Thermal burn and radiation risks: evaluation of hot surfaces, heating elements, optical and UV radiation.

- Test methods and examples: normal/abnormal/single-fault tests, test generators, and practical measurement guidance.

- Annex guidance: detailed informative annexes covering examples of equipment in scope, component considerations, battery protection, clearances/creepage measurement, fire resistance tests, mechanical strength tests, and instructions/markings.

Practical Applications - Who Uses This Standard

IEC TR 62368-2 is useful for:

- Product safety engineers and designers of audio/video and ICT equipment seeking interpretive guidance for IEC 62368-1.

- Test laboratories and compliance teams using the TR to understand test intent and examples.

- Regulatory authorities and certification bodies reviewing manufacturer documentation.

- Technical writers and training organizations preparing user instructions and safety documentation.

- Manufacturers implementing safeguards (electrical, thermal, mechanical, fire and chemical) and selecting appropriate test criteria.

Related Standards (if applicable)

- IEC 62368-1:2018 - normative standard for AV/ICT safety (requirements take precedence).

- References in the TR include other IEC/ISO guidance (e.g., IEC/TS 60479-1 on effects of current) and national/regional implementation documents where applicable.

Keywords: IEC TR 62368-2, IEC 62368-1, Audio/Video, Information and Communication Technology, safeguards, product safety, electrical safety, fire safety, battery protection.

IEC TR 62368-2:2019 RLV - Audio/video, information and communication technology equipment - Part 2: Explanatory information related to IEC 62368-1:2018 Released:5/7/2019 Isbn:9782832269169

IEC TR 62368-2:2019 - Audio/video, information and communication technology equipment - Part 2: Explanatory information related to IEC 62368-1:2018

Frequently Asked Questions

IEC TR 62368-2:2019 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Audio/video, information and communication technology equipment - Part 2: Explanatory information related to IEC 62368-1:2018". This standard covers: IEC TR 62368-2:2019 provides explanatory information related to IEC 62368-1. Only those subclauses considered to need further background reference information or explanation of their content to benefit the reader are included. Therefore, not all numbered subclauses are cited. Unless otherwise noted, all references are to clauses, subclauses, annexes, figures or tables located in IEC 62368-1:2018. This third edition updates the second edition of IEC 62368-2 published in 2014 to take into account changes made to IEC 62368-1:2014 as identified in the Foreword of IEC 62368-1:2018. This Technical Report is informative only. In case of a conflict between IEC 62368-1 and IEC TR 62368-2, the requirements in IEC 62368-1 prevail over this Technical Report. Key words: Audio/Video, Safeguards, Information, Communication

IEC TR 62368-2:2019 provides explanatory information related to IEC 62368-1. Only those subclauses considered to need further background reference information or explanation of their content to benefit the reader are included. Therefore, not all numbered subclauses are cited. Unless otherwise noted, all references are to clauses, subclauses, annexes, figures or tables located in IEC 62368-1:2018. This third edition updates the second edition of IEC 62368-2 published in 2014 to take into account changes made to IEC 62368-1:2014 as identified in the Foreword of IEC 62368-1:2018. This Technical Report is informative only. In case of a conflict between IEC 62368-1 and IEC TR 62368-2, the requirements in IEC 62368-1 prevail over this Technical Report. Key words: Audio/Video, Safeguards, Information, Communication

IEC TR 62368-2:2019 is classified under the following ICS (International Classification for Standards) categories: 33.160.01 - Audio, video and audiovisual systems in general; 35.020 - Information technology (IT) in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62368-2:2019 has the following relationships with other standards: It is inter standard links to IEC TR 62368-2:2015, IEC TR 62368-2:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase IEC TR 62368-2:2019 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of IEC standards.

Standards Content (Sample)

IEC TR 62368-2 ®

Edition 3.0 2019-05

REDLINE VERSION

TECHNICAL

REPORT

colour

inside

Audio/video, information and communication technology equipment –

Part 2: Explanatory information related to IEC 62368-1:20142018

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TR 62368-2 ®

Edition 3.0 2019-05

REDLINE VERSION

TECHNICAL

REPORT

colour

inside

Audio/video, information and communication technology equipment –

Part 2: Explanatory information related to IEC 62368-1: 20142018

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 33.160.01; 35.020 ISBN 978-2-8322-6916-9

– 2 – IEC TR 62368-2:2019 RLV © IEC 2019

CONTENTS

FOREWORD . 6

INTRODUCTION . 9

0 Principles of this product safety standard . 10

1 Scope . 12

2 Normative references . 13

3 Terms, definitions and abbreviations . 13

4 General requirements . 16

5 Electrically-caused injury . 23

6 Electrically-caused fire . 73

7 Injury caused by hazardous substances. 108

8 Mechanically-caused injury . 112

9 Thermal burn injury. 120

10 Radiation . 129

Annex A Examples of equipment within the scope of this standard . 136

Annex B Normal operating condition tests, abnormal operating condition tests .

and single fault condition tests . 137

Annex C UV Radiation . 140

Annex D Test generators . 140

Annex E Test conditions for equipment containing audio amplifiers . 140

Annex F Equipment markings, instructions, and instructional safeguards . 141

Annex G Components . 142

Annex H Criteria for telephone ringing signals . 150

Annex J Insulated winding wires for use without interleaved insulation . 152

Annex K Safety interlocks . 152

Annex L Disconnect devices . 152

Annex M Equipment containing batteries and their protection circuits . 153

Annex O Measurement of creepage distances and clearances . 162

Annex P Safeguards against conductive objects . 162

Annex Q Circuits intended for interconnection with building wiring . 163

Annex R Limited short-circuit test . 164

Annex S Tests for resistance to heat and fire . 164

Annex T Mechanical strength tests . 166

Annex U Mechanical strength of CRTs and protection against the effects of

implosion . 167

Annex V Determination of accessible parts . 167

Annex X Alternative method for determing clearances for insulation in circuits

connected to an AC mains not exceeding 420 V peak (300 V RMS) . 168

Annex Y Construction requirements for outdoor enclosures . 168

Annex A (informative) Background information related to the use of SPDs . 171

Annex B (informative) Background information related to measurement of discharges

– Determining the R-C discharge time constant for X- and Y-capacitors . 185

Annex C (informative) Background information related to resistance to candle flame

ignition . 196

Bibliography . 197

Figure 1 – Risk reduction as given in ISO/IEC Guide 51. 11

Figure 2 – HBSE Process Chart . 12

Figure 3 – Protective bonding conductor as part of a safeguard . 15

Figure 4 – Safeguards for protecting an ordinary person . 19

Figure 5 – Safeguards for protecting an instructed person . 20

Figure 6 – Safeguards for protecting a skilled person . 20

Figure 7 – Flow chart showing the intent of the glass requirements . 22

Figure 8 – Conventional time/current zones of effects of AC currents (15 Hz to 100 Hz)

on persons for a current path corresponding to left hand to feet (see IEC/TS 60479-

1:2005, Figure 20) . 25

Figure 9 – Conventional time/current zones of effects of DC currents on persons for a

longitudinal upward current path (see IEC/TS 60479-1:2005, Figure 22) . 26

Figure 10 – Illustration that limits depend on both voltage and current . 27

Figure 11 – Illustration of working voltage . 41

Figure 12 – Illustration of transient voltages on paired conductor external circuits . 43

Figure 13 – Illustration of transient voltages on coaxial-cable external circuits . 44

Figure 14 – Basic and reinforced insulation in Table 15 14 of IEC 62368-1:20142018;

ratio reinforced to basic . 46

Figure 15 – Reinforced clearances according to Rule 1, Rule 2, and Table 15 14 . 48

Figure 16 – Example illustrating accessible internal wiring . 56

Figure 17 – Waveform on insulation without surge suppressors and no breakdown . 59

Figure 18 – Waveforms on insulation during breakdown without surge suppressors . 59

Figure 19 – Waveforms on insulation with surge suppressors in operation . 60

Figure 20 – Waveform on short-circuited surge suppressor and insulation . 60

Figure 21 – Example for an ES2 source . 62

Figure 22 – Example for an ES3 source . 62

Figure 23 – Overview of protective conductors . 64

Figure 24 – Example of a typical touch current measuring network . 67

Figure 25 – Touch current from a floating circuit . 69

Figure 26 – Touch current from an earthed circuit . 70

Figure 27 – Summation of touch currents in a PABX . 70

Figure 28 – Possible safeguards against electrically-caused fire . 78

Figure 29 – Fire clause flow chart . 81

Figure 30 – Prevent ignition flow chart . 86

Figure 31 – Control fire spread summary . 88

Figure 32 – Control fire spread PS2 . 89

Figure 33 – Control fire spread PS3 . 90

Figure 34 – Fire cone application to a large component . 99

Figure 35 – Flowchart demonstrating the hierarchy of hazard management . 111

Figure 36 – Model for chemical injury . 112

Figure 37 – Direction of forces to be applied . 117

Figure 38 – Model for a burn injury . 120

– 4 – IEC TR 62368-2:2019 RLV © IEC 2019

Figure 39 – Model for safeguards against thermal burn injury . 122

Figure 40 – Model for absence of a thermal hazard . 123

Figure 41 – Model for presence of a thermal hazard with a physical safeguard in place . 123

Figure 42 – Model for presence of a thermal hazard with behavioural safeguard

in place . 123

Figure 43 – Flowchart for evaluation of Image projectors (beamers) . 131

Figure 44 – Graphical representation of L ,T . 133

Aeq

Figure 45 – Overview of operating modes . 139

Figure 46 – Voltage-current characteristics (Typical data) . 143

Figure 47 – Example of IC current limiter circuit . 148

Figure 48 – Current limit curves . 151

Figure 49 – Example of a dummy battery circuit . 161

Figure 50 – Example of a circuit with two power sources. 164

Figure A.1 – Installation has poor earthing and bonding; equipment damaged

(from ITU-T K.66) . 172

Figure A.2 – Installation has poor earthing and bonding; using main earth bar for

protection against lightning strike (from ITU-T K.66) . 172

Figure A.3 – Installation with poor earthing and bonding, using a varistor and a GDT

for protection against a lightning strike . 173

Figure A.4 – Installation with poor earthing and bonding; equipment damaged (TV set) . 173

Figure A.5 – Safeguards . 174

Figure A.6 – Discharge stages . 178

Figure A.7 – Holdover . 179

Figure A.8 – Discharge . 180

Figure A.9 – Characteristics . 182

Figure A.10 – Follow on current pictures . 183

Figure B.1 – Typical EMC filter schematic . 185

Figure B.2 – 100 MΩ oscilloscope probes . 187

Figure B.3 – Combinations of EUT resistance and capacitance for 1-s time constant . 189

Figure B.4 – 240 V mains followed by capacitor discharge . 190

Figure B.5 – Time constant measurement schematic . 191

Figure B.6 – Worst-case measured time constant values for 100 MΩ and 10 MΩ probes . 195

Table 1 – General summary of required safeguards . 20

Table 2 – Time/current zones for AC 15 Hz to 100 Hz for hand to feet pathway (see

IEC/TS 60479-1:2005, Table 11) . 26

Table 3 – Time/current zones for DC for hand to feet pathway (see IEC/TS 60479-

1:2005, Table 13). 27

Table 4 – Limit values of accessible capacitance (threshold of pain) . 30

Table 5 – Total body resistances R for a current path hand to hand, DC, for large

T

surface areas of contact in dry condition . 33

Table 6 – Insulation requirements for external circuits . 43

Table 7 – Voltage drop across clearance and solid insulation in series . 50

Table 8 – Examples of application of various safeguards . 80

Table 9 – Basic safeguards against fire under normal operating conditions and

abnormal operating conditions . 82

Table 10 – Supplementary safeguards against fire under single fault conditions . 83

Table 11 – Method 1: Reduce the likelihood of ignition . 85

Table 12 – Method 2: Control fire spread . 94

Table 13 – Fire barrier and fire enclosure flammability requirements . 101

Table 14 – Summary – Fire enclosure and fire barrier material requirements . 105

Table 15 – Control of chemical hazards . 110

Table 16 – Overview of requirements for dose-based systems . 135

Table 17 – Safety of batteries and their cells – requirements (expanded information on

documents and scope) . 155

Table B.1 – 100- MΩ oscilloscope probes . 187

Table B.2 – Capacitor discharge . 188

Table B.3 – Maximum T values for combinations of R and C for

measured EUT EUT

T of 1 s . 194

EUT

– 6 – IEC TR 62368-2:2019 RLV © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

AUDIO/VIDEO, INFORMATION AND

COMMUNICATION TECHNOLOGY EQUIPMENT –

Part 2: Explanatory information related to IEC 62368-1:20142018

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example, "state of the art".

IEC 62368-2, which is a Technical Report, has been prepared by IEC technical committee

TC 108: Safety of electronic equipment within the field of audio/video, information technology

and communication technology.

This third edition updates the second edition of IEC 62368-2 published in 2014 to take into

account changes made to IEC 62368-1:2014 as identified in the Foreword of

IEC 62368-1:2018.

This Technical Report is informative only. In case of a conflict between IEC 62368-1 and IEC

TR 62368-2, the requirements in IEC 62368-1 prevail over this Technical Report.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

108/708/DTR 108/711/RVDTR

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

In this document, the following print types are used:

– notes/explanatory matter: in smaller roman type;

– tables and figures that are included in the rationale have linked fields (shaded in grey if

“field shading” is active);

– terms that are defined in IEC 62368-1: in bold type.

In this document, where the term (HBSDT) is used, it stands for Hazard Based Standard

Development Team, which is the Working Group of IEC TC 108 responsible for the

development and maintenance of IEC 62368-1.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 62368 series can be found, under the general title Audio/video,

information and communication technology equipment, on the IEC website.

In this document, only those subclauses from IEC 62368-1 considered to need further

background reference information or explanation to benefit the reader in applying the relevant

requirements are included. Therefore, not all numbered subclauses are cited. Unless

otherwise noted, all references are to clauses, subclauses, annexes, figures or tables located

in IEC 62368-1:2018.

The entries in the document may have one or two of the following subheadings in addition to

the Rationale statement:

Source – where the source is known and is a document that is accessible to the general

public, a reference is provided.

Purpose – where there is a need and when it may prove helpful to the understanding of the

Rationale, we have added a Purpose statement.

– 8 – IEC TR 62368-2:2019 RLV © IEC 2019

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

IEC 62368-1 is based on the principles of hazard-based safety engineering, which is a

different way of developing and specifying safety considerations than that of the current

practice. While this document is different from traditional IEC safety documents in its

approach and while it is believed that IEC 62368-1 provides a number of advantages, its

introduction and evolution are not intended to result in significant changes to the existing

safety philosophy that led to the development of the safety requirements contained in

IEC 60065 and IEC 60950-1. The predominant reason behind the creation of IEC 62368-1 is

to simplify the problems created by the merging of the technologies of ITE and CE. The

techniques used are novel, so a learning process is required and experience is needed in its

application. Consequently, the committee recommends that this edition of the document be

considered as an alternative to IEC 60065 or IEC 60950-1 at least over the recommended

transition period.

– 10 – IEC TR 62368-2:2019 RLV © IEC 2019

AUDIO/VIDEO, INFORMATION AND

COMMUNICATION TECHNOLOGY EQUIPMENT –

Part 2: Explanatory information related to IEC 62368-1:20142018

0 Principles of this product safety standard

Clause 0 is informational and provides a rationale for the normative clauses

of the document.

0.5.1 General

ISO/IEC Guide 51:2014, 6.3.5 states:

“When reducing risks the order of priority shall be as follows:

a) inherently safe design;

b) guards and protective devices;

c) information for end users.

Inherently safe design measures are the first and most important step in

the risk reduction process. This is because protective measures inherent to

the characteristics of the product or system are likely to remain effective,

whereas experience has shown that even well-designed guards and

protective devices can fail or be violated and information for use might not

be followed.

Guards and protective devices shall be used whenever an inherently safe

design measure does not reasonably make it possible either to remove

hazards or to sufficiently reduce risks. Complementary protective measures

involving additional equipment (for example, emergency stop equipment)

might have to be implemented.

The end user has a role to play in the risk reduction procedure by

complying with the information provided by the designer/supplier. However,

information for use shall not be a substitute for the correct application of

inherently safe design measures, guards or complementary protective

measures.”

In general, this principle is used in IEC 62368-1. The table below shows a

comparison between the hierarchy required in ISO/IEC Guide 51 and the

hierarchy used in IEC 62368-1:20142018:

ISO/IEC Guide 51 IEC 62368-1

a) inherently safe design 1. inherently safe design by limiting all energy

hazards to class 1

b) guards and protective devices 2. equipment safeguards

3. installation safeguards

4. personal safeguards

c) information for end users 5. behavioral safeguards

6. instructional safeguards

Risk assessment has been considered as part of the development of

IEC 62368-1 as indicated in the following from ISO/IEC Guide 51 (Figure 1)

in this document. See also the Hazard Based Safety Engineering (HBSE)

Process Flow (Figure 2) in this document that also provides additional

details for the above comparison.

Figure 1 – Risk reduction as given in ISO/IEC Guide 51

– 12 – IEC TR 62368-2:2019 RLV © IEC 2019

Figure 2 – HBSE Process Chart

0.5.7 Equipment safeguards during skilled person service conditions

Purpose: To explain the intent of requirements for providing safeguards against

involuntary reaction.

Rationale: By definition, a skilled person has the education and experience to identify

all class 3 energy sources to which he may be exposed. However, while

servicing one class 3 energy source in one location, a skilled person may

be exposed to another class 3 energy source in a different location.

In such a situation, either of two events is possible. First, something may

cause an involuntary reaction of the skilled person with the consequences

of contact with the class 3 energy source in the different location. Second,

the space in which the skilled person is located may be small and

cramped, and inadvertent contact with a class 3 energy source in the

different location may be likely.

In such situations, this document may require an equipment safeguard

solely for the protection of a skilled person while performing servicing

activity.

___________

1 Scope

Purpose: To identify the purpose and applicability of this document and the

exclusions from the scope.

Rationale: The scope excludes requirements for functional safety. Functional safety is

addressed in IEC 61508-1. Because the scope includes computers that

may control safety systems, functional safety requirements would

necessarily include requirements for computer processes and software.

The requirements provided in IEC 60950-23 could be modified and added

to IEC 62368 as another –X document. However, because of the hazard-

based nature of IEC 62368-1, the requirements from IEC 60950-23 have

been incorporated into the body of IEC 62368-1 and made more generic.

The intent of the addition of the IEC 60950-23 requirements is to maintain

the overall intent of the technical requirements from IEC 60950-23,

incorporate them into IEC 62368-1 following the overall format of

IEC 62368-1 and simplify and facilitate the application of these

requirements.

Robots traditionally are covered under the scopes of ISO documents,

typically maintained by ISO TC 299. ISO TC 299 has working groups for

personal care robots and service robots, and produces for example,

ISO 13482, Robots and robotic devices – Safety requirements for personal

care robots.

___________

2 Normative references

The list of normative references is a list of all documents that have a

normative reference to it in the body of the document. As such, referenced

documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments)

applies.

Recently, there were some issues with test houses that wanted to use the

latest edition as soon as it was published. As this creates serious problems

for manufacturers, since they have no chance to prepare, it was felt that a

reasonable transition period should be taken into account. This is in line

with earlier decisions taken by the SMB that allow transition periods to be

mentioned in the foreword of the documents. Therefore IEC TC 108

decided to indicate this in the introduction of the normative references

clause, to instruct test houses to take into account any transition period,

effective date or date of withdrawal established for the document.

These documents are referenced, in whole, in part, or as alternative

requirements to the requirements contained in this document. Their use is

specified, where necessary, for the application of the requirements of this

document. The fact that a standard is mentioned in the list does not mean

that compliance with the document or parts of it are required.

___________

3 Terms, definitions and abbreviations

Rationale is provided for definitions that deviate from IEV definitions or

from pilot standard Basic or Group Safety publication definitions.

3.3.2.1 electrical enclosure

Source: IEC 60050-195:1998, 195-06-13

Purpose: To support the concept of safeguards as used in this document.

Rationale: The IEV definition is modified to use the term “safeguard” in place of the

word “protection”. The word “safeguard” identifies a physical “thing”

whereas the word “protection” identifies the act of protecting. This

document sets forth requirements for use of physical safeguards and

requirements for those safeguards. The safeguards provide “protection”

against injury from the equipment.

– 14 – IEC TR 62368-2:2019 RLV © IEC 2019

3.3.5.1 basic insulation

Source: IEC 60050-195:1998, 195-06-06

Purpose: To support the concept of safeguards as used in this document.

Rationale: The IEV definition is modified to use the term “safeguard” in place of the

word “protection”. The word “safeguard” identifies a physical “thing”

whereas the word “protection” identifies the act of protecting. This

document sets forth requirements for use of physical safeguards and

requirements for those safeguards. The safeguards provide “protection”

against injury from the equipment.

3.3.5.2 double insulation

Source: IEC 60050-195:1998, 195-06-08

Purpose: To support the concept of safeguards as used in this document.

Rationale: See 3.3.5.1, basic insulation.

3.3.5.56 solid insulation

Source: IEC 60664-1:2007, 3.4 IEC 60050-212:2015, 212-11-02

Purpose: To support the concept that safeguards are interposed between an energy

source and a body part.

Rationale: IEC 60664-1 defines insulation as material interposed between two

conductive parts. The IEC 60664-1 definition is modified by adding that

insulation is also “between a conductive part and a body part.” For safety

purposes, solid insulation is not only used between conductors, but is also

used between a conductor and a body part. For example, a Class II

equipment employs solid insulation in this manner.

3.3.5.67 supplementary insulation

Source: IEC 60050-195:1998, 195-06-07

Purpose: To support the concept of safeguards as used in this document.

Rationale: See 3.3.5.1, basic insulation.

3.3.6.79 restricted access area

Source: IEC 60050-195:1998, 195-04-04

Purpose: To use the concept of “instructed persons” and “skilled persons” as used

in this document.

Rationale: The IEV definition is modified to use the terms “instructed persons” and

“skilled persons” rather than “electrically instructed persons” and

“electrically skilled persons.”

3.3.7.87 reasonably foreseeable misuse

Source: ISO/IEC Guide 51:2014, 3.147

Rationale: Misuse depends on personal objectives, personal perception of the

equipment, and the possible use of the equipment (in a manner not

intended by the manufacturer) to accomplish those personal objectives.

Equipment within the scope of this document ranges from small handheld

equipment to large, permanently installed equipment. There is no

commonality among the equipment for readily predicting human behaviour

leading to misuse of the equipment and resultant injury. Where a possible

reasonably foreseeable misuse that may lead to an injury is not covered

by the requirements of the document, manufacturers are encouraged to

consider reasonably foreseeable misuse of equipment and provide

safeguards, as applicable, to prevent injury in the event of such misuse.

(Not all reasonably foreseeable misuse of equipment results in injury or

potential for injury.)

3.3.8.1 instructed person

Source: IEC 60050-826:2004, 826-18-02

Rationale: The IEV definition is modified to use the terms “energy sources”, “skilled

person”, and “precautionary safeguard”. The definition is made stronger

by using the term “instructed” rather than “advised”.

3.3.8.3 skilled person

Source: IEC 60050-826:2004, 826-18-01

Rationale: The IEV definition is modified to use the phrase “to reduce the likelihood

of”. IEC 62368-1 does, in general, tends not use the word “hazard”.

3.3.11.9 protective bonding conductor

Rationale: The protective bonding conductor, is not a complete safeguard, but a

component part of the earthing system safeguard. The protective

bonding conductor provides a fault current pathway from a part (insulated

from ES3 by basic insulation only) to the equipment protective earthing

terminal, see Figure 3 in this document.

Figure 3 – Protective bonding conductor as part of a safeguard

The parts required to be earthed via a protective bonding conductor are

those that have only basic insulation between the parts and ES3, and are

connected to accessible parts.

Only the fault current pathway is required to be a protective bonding

conductor. Other earthing connections of accessible conductive parts

can be by means of a functional earth conductor to the equipment PE

terminal or to a protective bonding conductor.

3.3.14.43 prospective touch voltage

Source: IEC 60050-195:1998, 195-05-09

– 16 – IEC TR 62368-2:2019 RLV © IEC 2019

Purpose: To properly identify electric shock energy source voltages.

Rationale: The IEV definition is modified to delete “animal”. The word “person” is also

deleted as all of the requirements in the document are with respect to

persons.

3.3.14.98 working voltage

Source: IEC 60664-1:2007, 3.5

Purpose: To distinguish between RMS. working voltage and the peak of the

working voltage.

Rationale: The IEC 60664-1 definition is modified to delete “RMS”. IEC 62368-1 uses

both RMS. working voltage and peak of the working voltage; each term

is defined.

3.3.15.2 class II construction

Source: IEC 60335-1:2010, 3.3.11

Purpose: Although the term is not used in the document, for completeness, it was

decided to retain this definition.

Rationale: The word “appliance” is changed to “equipment”.

____________

4 General requirements

Purpose: To explain how to investigate and determine whether or not safety is

involved.

Rationale: In order to establish whether or not safety is involved, the circuits and

construction are investigated to determine whether the consequences of

possible fault conditions would lead to an injury. Safety is involved if, as a

result of a single fault condition, the consequences of the fault lead to a

risk of injury.

If a fault condition should lead to a risk of injury, the part, material, or

device whose fault was simulated may comprise a safeguard.

Rationale is provided for questions regarding the omission of some

traditional requirements appearing in other safety documents. Rationale is

also provided for further explanation of new concepts and requirements in

this document.

Reasonable foreseeable misuse

Rationale: Apart from Annex M, this document does not specifically mention

foreseeable misuse or abnormal operating conditions. Nevertheless, the

requirements of the document cover many kinds of foreseeable misuse,

such as covering of ventilation openings, paper jams, stalled motors, etc.

functional insulation

Rationale: This document does not include requirements for functional insulation. By

its nature, functional insulation does not provide a safeguard function

against electric shock or electrically-caused fire and therefore may be

faulted. Obviously, not all functional insulations are faulted as this would

be prohibitively time-consuming. Sites for functional insulation faults

should be based upon physical examination of the equipment, and upon the

electrical schematic.

Note that basic insulation and reinforced insulation may also serve as

functional insulation, in which case the insulation is not faulted.

functional components

Rationale: This document does not include requirements for functional components.

By their nature, individual functional components do not provide a

safeguard function against electric shock, electrically-caused fire, thermal

injury, etc., and therefore may be candidates for fault testing. Obviously,

not all functional components are faulted as this would be prohibitively

time-consuming. Candidate components for fault testing should be based

upon physical examination of the equipment, upon the electrical schematic

diagrams, and whether a fault of that component might result in conditions

for electric shock, conditions for ignition and propagation of fire, conditions

for thermal injury, etc.

As with all single fault condition testing (Clause B.4), upon faulting of a

functional component, there shall not be any safety consequence (for

example, a benign consequence), or a basic safeguard, supplementary

safeguard , or reinforced safeguard shall remain effective.

In some cases, a pair of functional components may comprise a safeguard.

If the fault of one of the components in the pair is mitigated by the second

component, then the pair is designated as a double safeguard. For

example, if two diodes are employed in series to protect a battery from

reverse charge, then the pair comprises a double safeguard and the

components should be limited to the manufacturer and part number actually

tested. A second example is that of an X-capacitor and discharge resistor.

If the discharge resistor should fail open, then the X-capacitor will not be

discharged. Therefore, the X-capacitor value is not to exceed the ES2 limits

specified for a charged capacitor. Again, the two components com

...

IEC TR 62368-2 ®

Edition 3.0 2019-05

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

colour

inside

Audio/video, information and communication technology equipment –

Part 2: Explanatory information related to IEC 62368-1:2018

Équipements des technologies de l'audio/vidéo, de l'information

et de la communication –

Partie 2: Précisions relatives à l'IEC 62368-1:2018

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and once 67 000 electrotechnical terminology entries in English and

a month by email. French extracted from the Terms and Definitions clause of IEC

publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or need CISPR.

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Le premier dictionnaire d'électrotechnologie en ligne au monde,

webstore.iec.ch/advsearchform avec plus de 22 000 articles terminologiques en anglais et en

La recherche avancée permet de trouver des publications IEC français, ainsi que les termes équivalents dans 16 langues

en utilisant différents critères (numéro de référence, texte, additionnelles. Egalement appelé Vocabulaire

comité d’études,…). Elle donne aussi des informations sur les Electrotechnique International (IEV) en ligne.

projets et les publications remplacées ou retirées.

Glossaire IEC - std.iec.ch/glossary

IEC Just Published - webstore.iec.ch/justpublished 67 000 entrées terminologiques électrotechniques, en anglais

Restez informé sur les nouvelles publications IEC. Just et en français, extraites des articles Termes et Définitions des

Published détaille les nouvelles publications parues. publications IEC parues depuis 2002. Plus certaines entrées

Disponible en ligne et une fois par mois par email. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

Electropedia - www.electropedia.org

IEC TR 62368-2 ®

Edition 3.0 2019-05

TECHNICAL

REPORT

RAPPORT

TECHNIQUE

colour

inside

Audio/video, information and communication technology equipment –

Part 2: Explanatory information related to IEC 62368-1:2018

Équipements des technologies de l'audio/vidéo, de l'information

et de la communication –

Partie 2: Précisions relatives à l'IEC 62368-1:2018

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 33.160.01; 35.020 ISBN 978-2-8322-6716-5

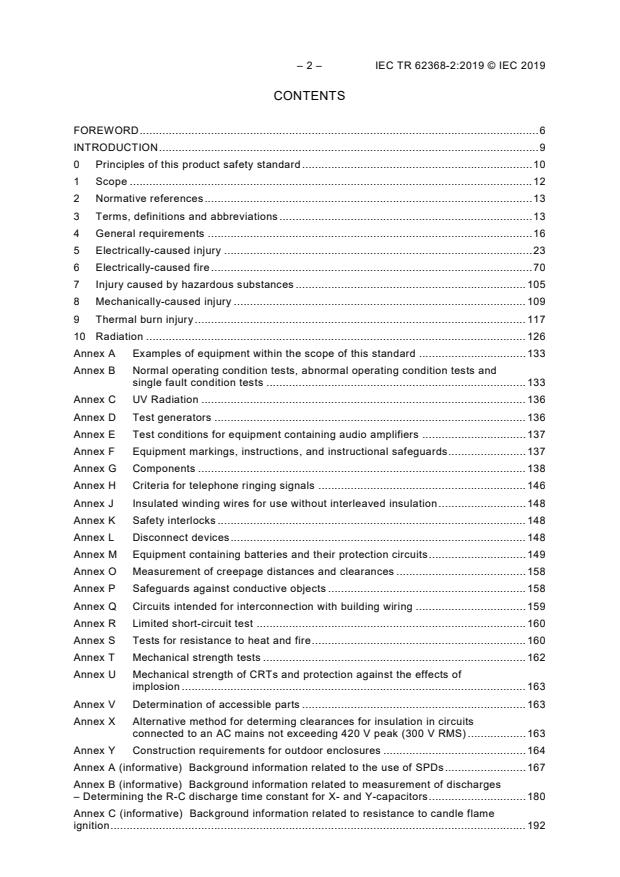

– 2 – IEC TR 62368-2:2019 © IEC 2019

CONTENTS

FOREWORD . 6

INTRODUCTION . 9

0 Principles of this product safety standard . 10

1 Scope . 12

2 Normative references . 13

3 Terms, definitions and abbreviations . 13

4 General requirements . 16

5 Electrically-caused injury . 23

6 Electrically-caused fire . 70

7 Injury caused by hazardous substances . 105

8 Mechanically-caused injury . 109

9 Thermal burn injury . 117

10 Radiation . 126

Annex A Examples of equipment within the scope of this standard . 133

Annex B Normal operating condition tests, abnormal operating condition tests and

single fault condition tests . 133

Annex C UV Radiation . 136

Annex D Test generators . 136

Annex E Test conditions for equipment containing audio amplifiers . 137

Annex F Equipment markings, instructions, and instructional safeguards . 137

Annex G Components . 138

Annex H Criteria for telephone ringing signals . 146

Annex J Insulated winding wires for use without interleaved insulation . 148

Annex K Safety interlocks . 148

Annex L Disconnect devices . 148

Annex M Equipment containing batteries and their protection circuits . 149

Annex O Measurement of creepage distances and clearances . 158

Annex P Safeguards against conductive objects . 158

Annex Q Circuits intended for interconnection with building wiring . 159

Annex R Limited short-circuit test . 160

Annex S Tests for resistance to heat and fire . 160

Annex T Mechanical strength tests . 162

Annex U Mechanical strength of CRTs and protection against the effects of

implosion . 163

Annex V Determination of accessible parts . 163

Annex X Alternative method for determing clearances for insulation in circuits

connected to an AC mains not exceeding 420 V peak (300 V RMS) . 163

Annex Y Construction requirements for outdoor enclosures . 164

Annex A (informative) Background information related to the use of SPDs . 167

Annex B (informative) Background information related to measurement of discharges

– Determining the R-C discharge time constant for X- and Y-capacitors . 180

Annex C (informative) Background information related to resistance to candle flame

ignition . 192

Bibliography . 193

Figure 1 – Risk reduction as given in ISO/IEC Guide 51. 11

Figure 2 – HBSE Process Chart . 12

Figure 3 – Protective bonding conductor as part of a safeguard . 15

Figure 4 – Safeguards for protecting an ordinary person . 19

Figure 5 – Safeguards for protecting an instructed person . 19

Figure 6 – Safeguards for protecting a skilled person . 20

Figure 7 – Flow chart showing the intent of the glass requirements . 22

Figure 8 – Conventional time/current zones of effects of AC currents (15 Hz to 100 Hz)

on persons for a current path corresponding to left hand to feet (see IEC/TS 60479-

1:2005, Figure 20) . 25

Figure 9 – Conventional time/current zones of effects of DC currents on persons for a

longitudinal upward current path (see IEC/TS 60479-1:2005, Figure 22) . 26

Figure 10 – Illustration that limits depend on both voltage and current . 27

Figure 11 – Illustration of working voltage . 39

Figure 12 – Illustration of transient voltages on paired conductor external circuits . 41

Figure 13 – Illustration of transient voltages on coaxial-cable external circuits . 42

Figure 14 – Basic and reinforced insulation in Table 14 of IEC 62368-1:2018; ratio

reinforced to basic . 43

Figure 15 – Reinforced clearances according to Rule 1, Rule 2, and Table 14 . 45

Figure 16 – Example illustrating accessible internal wiring . 53

Figure 17 – Waveform on insulation without surge suppressors and no breakdown . 56

Figure 18 – Waveforms on insulation during breakdown without surge suppressors . 57

Figure 19 – Waveforms on insulation with surge suppressors in operation . 57

Figure 20 – Waveform on short-circuited surge suppressor and insulation . 57

Figure 21 – Example for an ES2 source . 59

Figure 22 – Example for an ES3 source . 59

Figure 23 – Overview of protective conductors . 61

Figure 24 – Example of a typical touch current measuring network . 64

Figure 25 – Touch current from a floating circuit . 66

Figure 26 – Touch current from an earthed circuit . 67

Figure 27 – Summation of touch currents in a PABX . 67

Figure 28 – Possible safeguards against electrically-caused fire . 75

Figure 29 – Fire clause flow chart . 78

Figure 30 – Prevent ignition flow chart . 83

Figure 31 – Control fire spread summary . 85

Figure 32 – Control fire spread PS2 . 86

Figure 33 – Control fire spread PS3 . 87

Figure 34 – Fire cone application to a large component . 96

Figure 35 – Flowchart demonstrating the hierarchy of hazard management . 108

Figure 36 – Model for chemical injury . 109

Figure 37 – Direction of forces to be applied . 114

Figure 38 – Model for a burn injury . 117

– 4 – IEC TR 62368-2:2019 © IEC 2019

Figure 39 – Model for safeguards against thermal burn injury . 119

Figure 40 – Model for absence of a thermal hazard . 120

Figure 41 – Model for presence of a thermal hazard with a physical safeguard in place . 120

Figure 42 – Model for presence of a thermal hazard with behavioural safeguard

in place . 120

Figure 43 – Flowchart for evaluation of Image projectors (beamers) . 128

Figure 44 – Graphical representation of L ,T . 130

Aeq

Figure 45 – Overview of operating modes . 135

Figure 46 – Voltage-current characteristics (Typical data) . 140

Figure 47 – Example of IC current limiter circuit . 144

Figure 48 – Current limit curves . 147

Figure 49 – Example of a dummy battery circuit . 157

Figure 50 – Example of a circuit with two power sources. 160

Figure A.1 – Installation has poor earthing and bonding; equipment damaged

(from ITU-T K.66) . 168

Figure A.2 – Installation has poor earthing and bonding; using main earth bar for

protection against lightning strike (from ITU-T K.66) . 168

Figure A.3 – Installation with poor earthing and bonding, using a varistor and a GDT

for protection against a lightning strike . 169

Figure A.4 – Installation with poor earthing and bonding; equipment damaged (TV set) . 169

Figure A.5 – Safeguards . 170

Figure A.6 – Discharge stages . 174

Figure A.7 – Holdover . 175

Figure A.8 – Discharge . 176

Figure A.9 – Characteristics . 177

Figure A.10 – Follow on current pictures . 178

Figure B.1 – Typical EMC filter schematic . 180

Figure B.2 – 100 MΩ oscilloscope probes . 182

Figure B.3 – Combinations of EUT resistance and capacitance for 1-s time constant . 184

Figure B.4 – 240 V mains followed by capacitor discharge . 186

Figure B.5 – Time constant measurement schematic . 187

Figure B.6 – Worst-case measured time constant values for 100 MΩ and 10 MΩ probes . 191

Table 1 – General summary of required safeguards . 20

Table 2 – Time/current zones for AC 15 Hz to 100 Hz for hand to feet pathway (see

IEC/TS 60479-1:2005, Table 11) . 26

Table 3 – Time/current zones for DC for hand to feet pathway (see IEC/TS 60479-

1:2005, Table 13). 27

Table 4 – Limit values of accessible capacitance (threshold of pain) . 30

Table 5 – Total body resistances R for a current path hand to hand, DC, for large

T

surface areas of contact in dry condition . 32

Table 6 – Insulation requirements for external circuits . 42

Table 7 – Voltage drop across clearance and solid insulation in series . 47

Table 8 – Examples of application of various safeguards . 77

Table 9 – Basic safeguards against fire under normal operating conditions and

abnormal operating conditions . 79

Table 10 – Supplementary safeguards against fire under single fault conditions . 80

Table 11 – Method 1: Reduce the likelihood of ignition . 82

Table 12 – Method 2: Control fire spread . 91

Table 13 – Fire barrier and fire enclosure flammability requirements . 98

Table 14 – Summary – Fire enclosure and fire barrier material requirements . 102

Table 15 – Control of chemical hazards . 107

Table 16 – Overview of requirements for dose-based systems . 132

Table 17 – Safety of batteries and their cells – requirements (expanded information on

documents and scope) . 151

Table B.1 – 100- MΩ oscilloscope probes . 182

Table B.2 – Capacitor discharge . 183

Table B.3 – Maximum T values for combinations of R and C for

measured EUT EUT

T of 1 s . 190

EUT

– 6 – IEC TR 62368-2:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

AUDIO/VIDEO, INFORMATION AND

COMMUNICATION TECHNOLOGY EQUIPMENT –

Part 2: Explanatory information related to IEC 62368-1:2018

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example, "state of the art".

IEC 62368-2, which is a Technical Report, has been prepared by IEC technical committee

TC 108: Safety of electronic equipment within the field of audio/video, information technology

and communication technology.

This third edition updates the second edition of IEC 62368-2 published in 2014 to take into

account changes made to IEC 62368-1:2014 as identified in the Foreword of

IEC 62368-1:2018.

This Technical Report is informative only. In case of a conflict between IEC 62368-1 and IEC

TR 62368-2, the requirements in IEC 62368-1 prevail over this Technical Report.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

108/708/DTR 108/711/RVDTR

Full information on the voting for the approval of this technical report can be found in the

report on voting indicated in the above table.

In this document, the following print types are used:

– notes/explanatory matter: in smaller roman type;

– tables and figures that are included in the rationale have linked fields (shaded in grey if

“field shading” is active);

– terms that are defined in IEC 62368-1: in bold type.

In this document, where the term (HBSDT) is used, it stands for Hazard Based Standard

Development Team, which is the Working Group of IEC TC 108 responsible for the

development and maintenance of IEC 62368-1.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 62368 series can be found, under the general title Audio/video,

information and communication technology equipment, on the IEC website.

In this document, only those subclauses from IEC 62368-1 considered to need further

background reference information or explanation to benefit the reader in applying the relevant

requirements are included. Therefore, not all numbered subclauses are cited. Unless

otherwise noted, all references are to clauses, subclauses, annexes, figures or tables located

in IEC 62368-1:2018.

The entries in the document may have one or two of the following subheadings in addition to

the Rationale statement:

Source – where the source is known and is a document that is accessible to the general

public, a reference is provided.

Purpose – where there is a need and when it may prove helpful to the understanding of the

Rationale, we have added a Purpose statement.

– 8 – IEC TR 62368-2:2019 © IEC 2019

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

IEC 62368-1 is based on the principles of hazard-based safety engineering, which is a

different way of developing and specifying safety considerations than that of the current

practice. While this document is different from traditional IEC safety documents in its

approach and while it is believed that IEC 62368-1 provides a number of advantages, its

introduction and evolution are not intended to result in significant changes to the existing

safety philosophy that led to the development of the safety requirements contained in

IEC 60065 and IEC 60950-1. The predominant reason behind the creation of IEC 62368-1 is

to simplify the problems created by the merging of the technologies of ITE and CE. The

techniques used are novel, so a learning process is required and experience is needed in its

application. Consequently, the committee recommends that this edition of the document be

considered as an alternative to IEC 60065 or IEC 60950-1 at least over the recommended

transition period.

– 10 – IEC TR 62368-2:2019 © IEC 2019

AUDIO/VIDEO, INFORMATION AND

COMMUNICATION TECHNOLOGY EQUIPMENT –

Part 2: Explanatory information related to IEC 62368-1:2018

0 Principles of this product safety standard

Clause 0 is informational and provides a rationale for the normative clauses

of the document.

0.5.1 General

ISO/IEC Guide 51:2014, 6.3.5 states:

“When reducing risks the order of priority shall be as follows:

a) inherently safe design;

b) guards and protective devices;

c) information for end users.

Inherently safe design measures are the first and most important step in

the risk reduction process. This is because protective measures inherent to

the characteristics of the product or system are likely to remain effective,

whereas experience has shown that even well-designed guards and

protective devices can fail or be violated and information for use might not

be followed.

Guards and protective devices shall be used whenever an inherently safe

design measure does not reasonably make it possible either to remove

hazards or to sufficiently reduce risks. Complementary protective measures

involving additional equipment (for example, emergency stop equipment)

might have to be implemented.

The end user has a role to play in the risk reduction procedure by

complying with the information provided by the designer/supplier. However,

information for use shall not be a substitute for the correct application of

inherently safe design measures, guards or complementary protective

measures.”

In general, this principle is used in IEC 62368-1. The table below shows a

comparison between the hierarchy required in ISO/IEC Guide 51 and the

hierarchy used in IEC 62368-1:2018:

ISO/IEC Guide 51 IEC 62368-1

a) inherently safe design 1. inherently safe design by limiting all energy

hazards to class 1

b) guards and protective devices 2. equipment safeguards

3. installation safeguards

4. personal safeguards

c) information for end users 5. behavioral safeguards

6. instructional safeguards

Risk assessment has been considered as part of the development of

IEC 62368-1 as indicated in the following from ISO/IEC Guide 51 (Figure 1)

in this document. See also the Hazard Based Safety Engineering (HBSE)

Process Flow (Figure 2) in this document that also provides additional

details for the above comparison.

Figure 1 – Risk reduction as given in ISO/IEC Guide 51

– 12 – IEC TR 62368-2:2019 © IEC 2019

Figure 2 – HBSE Process Chart

0.5.7 Equipment safeguards during skilled person service conditions

Purpose: To explain the intent of requirements for providing safeguards against

involuntary reaction.

Rationale: By definition, a skilled person has the education and experience to identify

all class 3 energy sources to which he may be exposed. However, while

servicing one class 3 energy source in one location, a skilled person may

be exposed to another class 3 energy source in a different location.

In such a situation, either of two events is possible. First, something may

cause an involuntary reaction of the skilled person with the consequences

of contact with the class 3 energy source in the different location. Second,

the space in which the skilled person is located may be small and

cramped, and inadvertent contact with a class 3 energy source in the

different location may be likely.

In such situations, this document may require an equipment safeguard

solely for the protection of a skilled person while performing servicing

activity.

___________

1 Scope

Purpose: To identify the purpose and applicability of this document and the

exclusions from the scope.

Rationale: The scope excludes requirements for functional safety. Functional safety is

addressed in IEC 61508-1. Because the scope includes computers that

may control safety systems, functional safety requirements would

necessarily include requirements for computer processes and software.

The requirements provided in IEC 60950-23 could be modified and added

to IEC 62368 as another –X document. However, because of the hazard-

based nature of IEC 62368-1, the requirements from IEC 60950-23 have

been incorporated into the body of IEC 62368-1 and made more generic.

The intent of the addition of the IEC 60950-23 requirements is to maintain

the overall intent of the technical requirements from IEC 60950-23,

incorporate them into IEC 62368-1 following the overall format of

IEC 62368-1 and simplify and facilitate the application of these

requirements.

Robots traditionally are covered under the scopes of ISO documents,

typically maintained by ISO TC 299. ISO TC 299 has working groups for

personal care robots and service robots, and produces for example,

ISO 13482, Robots and robotic devices – Safety requirements for personal

care robots.

___________

2 Normative references

The list of normative references is a list of all documents that have a

normative reference to it in the body of the document. As such, referenced

documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments)

applies.

Recently, there were some issues with test houses that wanted to use the

latest edition as soon as it was published. As this creates serious problems

for manufacturers, since they have no chance to prepare, it was felt that a

reasonable transition period should be taken into account. This is in line

with earlier decisions taken by the SMB that allow transition periods to be

mentioned in the foreword of the documents. Therefore IEC TC 108

decided to indicate this in the introduction of the normative references

clause, to instruct test houses to take into account any transition period,

effective date or date of withdrawal established for the document.

These documents are referenced, in whole, in part, or as alternative

requirements to the requirements contained in this document. Their use is

specified, where necessary, for the application of the requirements of this

document. The fact that a standard is mentioned in the list does not mean

that compliance with the document or parts of it are required.

___________

3 Terms, definitions and abbreviations

Rationale is provided for definitions that deviate from IEV definitions or

from Basic or Group Safety publication definitions.

3.3.2.1 electrical enclosure

Source: IEC 60050-195:1998, 195-06-13

Purpose: To support the concept of safeguards as used in this document.

Rationale: The IEV definition is modified to use the term “safeguard” in place of the

word “protection”. The word “safeguard” identifies a physical “thing”

whereas the word “protection” identifies the act of protecting. This

document sets forth requirements for use of physical safeguards and

requirements for those safeguards. The safeguards provide “protection”

against injury from the equipment.

– 14 – IEC TR 62368-2:2019 © IEC 2019

3.3.5.1 basic insulation

Source: IEC 60050-195:1998, 195-06-06

Purpose: To support the concept of safeguards as used in this document.

Rationale: The IEV definition is modified to use the term “safeguard” in place of the

word “protection”. The word “safeguard” identifies a physical “thing”

whereas the word “protection” identifies the act of protecting. This

document sets forth requirements for use of physical safeguards and

requirements for those safeguards. The safeguards provide “protection”

against injury from the equipment.

3.3.5.2 double insulation

Source: IEC 60050-195:1998, 195-06-08

Purpose: To support the concept of safeguards as used in this document.

Rationale: See 3.3.5.1, basic insulation.

3.3.5.6 solid insulation

Source: IEC 60050-212:2015, 212-11-02

3.3.5.7 supplementary insulation

Source: IEC 60050-195:1998, 195-06-07

Purpose: To support the concept of safeguards as used in this document.

Rationale: See 3.3.5.1, basic insulation.

3.3.6.9 restricted access area

Source: IEC 60050-195:1998, 195-04-04

Purpose: To use the concept of “instructed persons” and “skilled persons” as used

in this document.

Rationale: The IEV definition is modified to use the terms “instructed persons” and

“skilled persons” rather than “electrically instructed persons” and

“electrically skilled persons.”

3.3.7.7 reasonably foreseeable misuse

Source: ISO/IEC Guide 51:2014, 3.7

Rationale: Misuse depends on personal objectives, personal perception of the

equipment, and the possible use of the equipment (in a manner not

intended by the manufacturer) to accomplish those personal objectives.

Equipment within the scope of this document ranges from small handheld

equipment to large, permanently installed equipment. There is no

commonality among the equipment for readily predicting human behaviour

leading to misuse of the equipment and resultant injury. Where a possible

reasonably foreseeable misuse that may lead to an injury is not covered