ISO/FDIS 23670

(Main)Space systems -- Vibration testing

Space systems -- Vibration testing

Systèmes spatiaux -- Essais de vibration

General Information

Standards Content (sample)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 23670

ISO/TC 20/SC 14

Space systems — Vibration testing

Secretariat: ANSI

Voting begins on:

20210524

Voting terminates on:

20210719

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO

ISO/FDIS 23670:2021(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. ISO 2021

---------------------- Page: 1 ----------------------

ISO/FDIS 23670:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/FDIS 23670:2021(E)

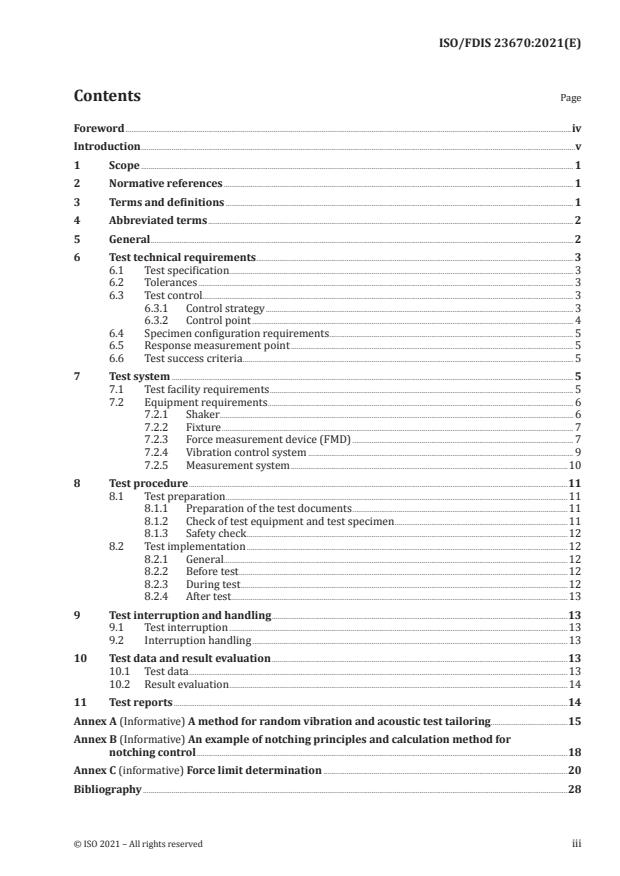

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction ..................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Abbreviated terms .............................................................................................................................................................................................. 2

5 General ............................................................................................................................................................................................................................ 2

6 Test technical requirements ..................................................................................................................................................................... 3

6.1 Test specification ................................................................................................................................................................................... 3

6.2 Tolerances ................................................................................................................................................................................................... 3

6.3 Test control ......... ........................................................................................................................................................................................ 3

6.3.1 Control strategy ................................................................................................................................................................ 3

6.3.2 Control point ....................................................................................................................................................................... 4

6.4 Specimen configuration requirements ............................................................................................................................... 5

6.5 Response measurement point ................................................................................................................................................... 5

6.6 Test success criteria ............................................................................................................................................................................ 5

7 Test system ................................................................................................................................................................................................................. 5

7.1 Test facility requirements .............................................................................................................................................................. 5

7.2 Equipment requirements ............................................................................................................................................................... 6

7.2.1 Shaker ........................................................................................................................................................................................ 6

7.2.2 Fixture ....................................................................................................................................................................................... 7

7.2.3 Force measurement device (FMD) ................................................................................................................... 7

7.2.4 Vibration control system .......................................................................................................................................... 9

7.2.5 Measurement system ................................................................................................................................................10

8 Test procedure .....................................................................................................................................................................................................11

8.1 Test preparation ..................................................................................................................................................................................11

8.1.1 Preparation of the test documents ................................................................................................................11

8.1.2 Check of test equipment and test specimen ..........................................................................................11

8.1.3 Safety check .......................................................................................................................................................................12

8.2 Test implementation .......................................................................................................................................................................12

8.2.1 General...................................................................................................................................................................................12

8.2.2 Before test ...........................................................................................................................................................................12

8.2.3 During test ..........................................................................................................................................................................12

8.2.4 After test ...................................................................... .........................................................................................................13

9 Test interruption and handling ..........................................................................................................................................................13

9.1 Test interruption ................................................................................................................................................................................13

9.2 Interruption handling ....................................................................................................................................................................13

10 Test data and result evaluation ..........................................................................................................................................................13

10.1 Test data .....................................................................................................................................................................................................13

10.2 Result evaluation ................................................................................................................................................................................14

11 Test reports .............................................................................................................................................................................................................14

Annex A (Informative) A method for random vibration and acoustic test tailoring........................................15

Annex B (Informative) An example of notching principles and calculation method for

notching control .................................................................................................................................................................................................18

Annex C (informative) Force limit determination ...............................................................................................................................20

Bibliography .............................................................................................................................................................................................................................28

© ISO 2021 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/FDIS 23670:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and nongovernmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicle,

Subcommittee SC 14, Space systems and operations.Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv © ISO 2021 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/FDIS 23670:2021(E)

Introduction

Vibration testing is one of the most important test items of space systems. The primary goals of

vibration testing are to verify the design and to detect manufacturing issues of spacecraft, subsystems

and units that could result in in-flight failures. In design, material selection, manufacture, assembly and

integration phase, the test aims on exposing defects and non-conformances existing and eliminating

potential quality problems. With regard to the launch phase, it also serves to prevent structural failure

of a space system, loosening of fasteners and connectors, failure of electronic components, leakage of

sealing elements or malfunction of mechanical system.During vibration testing, over-testing can result in unnecessary destruction of the test specimen. In

the 1990s, at the Jet Propulsion Laboratory, Mr. Terry Scharton elaborated the methodology of force

notching for qualification of satellites and spacecraft to mitigate unnecessary over-testing. Since then,

several attempts have been made to establish this methodology for a broader range of application.

This document is another attempt to transfer the methodology of force-based testing from laboratory

environment into the field of industrial application.© ISO 2021 – All rights reserved v

---------------------- Page: 5 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 23670:2021(E)

Space systems — Vibration testing

IMPORTANT — The electronic file of this document contains colours which are considered to be

useful for the correct understanding of the document. Users should therefore consider printing

this document using a colour printer.1 Scope

This document provides guidance and requirements for test providers and interested parties to

implement vibration testing.This document specifies methods, including the force limiting approach, to mitigate unnecessary over-

testing of spacecraft, subsystems and units for space application.The technical requirements in this document can be tailored to meet the actual test objectives.

2 Normative referencesThe following documents are referred to in the text in such a way that some or all of their content

constitute requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 15864:— , Space systems — General test methods for space craft, subsystems and units

ISO 19924:2017, Space systems — Acoustic testing3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at https:// www .electropedia .org/

3.1

notching

reduction of the input level or spectrum in a vibration testing to limit structural responses at resonant

frequencies according to qualification or acceptance loads to avoid over-testing.

3.2response limited vibration testing

reduction of input acceleration in a vibration testing to maintain the measured response at or below a

specified value3.3

force limited vibration testing

reduction of reaction force in a vibration testing to specified values, which are usually the interface

forces predicted for flight, plus a desired margin.1) Under preparation.

© ISO 2021 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/FDIS 23670:2021(E)

3.4

statistical DOF

number of independent variables in a statistical estimate of a probability

Note 1 to entry: The number of degrees of freedom determines the statistical accuracy of an estimate.

[SOURCE: ISO 2041:2018, 3.5.16, modified — The term has been changed from "statistical degrees of

freedom" to "statistical DOF".]4 Abbreviated terms

For the purposes of this document, the abbreviated terms described in Table 1 apply.

Table 1 — Abbreviated termsDOF degree of freedom

FEA finite element analysis

FLV force limited vibration

FLVT force limited vibration test

FMD force measurement device

FRF frequency response function

POGO propulsion generated oscillations

PSD power spectral density

RMS root mean square

TDFS two-degree of freedom system

5 General

Vibration testing is distinguished between sinusoidal vibration testing and random vibration testing.

Sinusoidal vibration testing is intended to simulate the vibration environment produce by unstable

combustion, by coupling of structural resonant frequencies (POGO), by imbalances in rotating

equipment. Sinusoidal vibration testing is also to simulate ground transportation and handling, due to

resonant responses of tires and suspension systems of the transporters.Random vibrations are generated by the launcher engines and by acoustic and aerodynamic excitation

of the launch vehicle and spacecraft fairing. During flight or ground transportation and handling, broad

band vibration environment is imposed on the spacecraft. ISO 15864 recommends either vibration or

acoustic testing, whichever is more appropriate, with the other one left optional. Generally, if acoustic

testing is performed, random vibration may be skipped. For a small compact spacecraft, acoustic testing

does not provide adequate environmental simulation, and random vibration may replace the acoustic

test. To take this decision it is important to consider:— vibration testing do not reach high frequency contents;

— whether the structure is sensitive to acoustic loads;

— whether the structure is sensitive to acoustic loads where the units are mounted.

Information for random vibration and acoustic test tailoring is provided in Annex A.

Conventional acceleration control during vibration testing may lead to the so-called over-testing

problem due to the difference of the interface impedance of the mounting structure and the shaker.

In order to overcome this problem, the force limited vibration (FLV) testing technique was developed.

In the FLV testing, in addition to the acceleration specification, the specification of the reaction force

between fixture and test specimen shall be defined. Using the FLV technique, both the acceleration

2 © ISO 2021 – All rights reserved---------------------- Page: 7 ----------------------

ISO/FDIS 23670:2021(E)

and force at the interface of test specimen and fixture are limited so that the vibration environment

characterizes the real situation more precisely.6 Test technical requirements

6.1 Test specification

The test specification shall meet the requirements of the respective launch vehicle user manual.

The test specification generally includes testing level, frequency range, test direction and test duration.

The duration of sinusoidal vibration testing is determined by the sweep rate and frequency range. The

duration of random vibration testing is expressed in seconds or minutes. The test directions usually

correspond with the three orthogonal axes, one of which is in accordance with the launch direction.

If FLVT will be applied, the test specifications shall be extended with the FLVT requirements.

When needed to re-check workmanship by dynamic mechanical environmental test for flight units that

have undergone rework and that required random vibration testing at acceptance test, the minimum

retesting shall be random vibration testing at workmanship screening level to be agreed with the

customer. However, if the most effective single axis of workmanship screening re-test for all the

reworked areas is determined, re-test excitation can be based just on that axis.6.2 Tolerances

The tolerances shall be determined based on the design standard. If not specified otherwise, the

following test level tolerances can be used.a) Sinusoidal vibration

Frequency: −2 % to +2 % (or −1 Hz to +1 Hz, whichever is greater)

Acceleration amplitude: −10 % to +10 %

b) Random vibration

Acceleration spectral density (frequency resolution better than 10 Hz)

10 Hz to 100 Hz (analysis bandwidth 10 Hz or narrower): −3 dB to +3 dB

100 Hz to 1 000 Hz (analysis bandwidth is 10 % or narrower of the central frequency): −3 dB to +3 dB

1 000 Hz to 2 000 Hz (analysis bandwidth 100 Hz or narrower): −3 dB to +3 dBStatistical DOF: not less than 100

Overall grms.: −10 % to +10 %

Test duration: −0 % to +10 %

6.3 Test control

6.3.1 Control strategy

6.3.1.1 General

The control strategy shall provide the required vibration at the required locations in or on the test

specimen. This depends on the kind of vibration to be generated and on the test specimen/shaker

interaction. Generally, a single strategy is appropriate (e.g. only acceleration input control strategy

is used). There are cases where multiple strategies are used simultaneously (e.g. acceleration input

control strategy and force limited vibration testing strategy are used simultaneously).

© ISO 2021 – All rights reserved 3---------------------- Page: 8 ----------------------

ISO/FDIS 23670:2021(E)

6.3.1.2 Acceleration input control

Acceleration input control is the basic method of vibration testing. The control accelerometers shall

be mounted on the fixture at the test specimen mounting points. Shaker motion shall be controlled

with feedback from the control accelerometer(s) to provide defined vibration levels at the fixture/ test

specimen interface.6.3.1.3 Notching

Notching is a general accepted practice in fulllevel vibration testing to avoid overtesting.

Implementation of notching shall be subject to customer approval and relevant to Launcher authority

approval. Refer to Annex B for an example of the notching calculate method. The following requirements

apply.a) The force on the main structure shall not be higher than the design value of quasi-static load plus a

desired margin.b) The vibration level shall not be less than the level of coupling analysis result for the interface

between spacecraft and launcher, unless agreed by the launcher authority.c) The response of key equipment fixed position shall not be higher than the equipment vibration

testing level.6.3.1.4 Force limited vibration testing

For force limited vibration testing, the vibration level is defined by acceleration. In addition, the

reaction force between fixture and test specimen shall be measured and limited. Dynamic force gauges

are mounted between the fixture and the test specimen. If the force achieves the limited value, the

exciter motion shall be controlled with feedback from the force gages.Force limiting is most useful for test specimens that exhibit distinct, lightly damped resonances on the

shaker. The amount of relief available from force limiting is greatest when the structural impedance

of the test specimen is equal to, or greater than that of the mounting structure in the actual mounting

situation.The force limit value shall be slightly larger than the real reaction force of the interface during launch,

plus the desired margin. Force limits value can be determined in several ways including simple and

complex TDFS Method, semi-empirical method, FEA method, quasi-static-load method, apparent

masses envelope method and design/flight loads method. A non-exhaustive list of force limit method is

specified in Annex C.6.3.1.5 Response limited vibration testing

For response limited vibration testing, the vibration level is defined by acceleration. In addition,

vibration response limits at specific points on the test specimen shall be defined. Monitoring

accelerometers shall be located at these points. The test specimen shall be excited using control point

accelerometer signals to control the exciters. The control inputs shall be automatically modified as

needed to limit responses at the monitoring accelerometers to the predefined limits. This strategy is

used to avoid damage to the specific equipment or lower level assembly.6.3.2 Control point

The control accelerometer(s) shall be mounted on the test fixture near the specimen attachment points.

For multiple-point control, an even distribution should be adopted. In case specific requirements

exist, the positions of the control points shall be determined accordingly. If more than one control

accelerometer is used, the test levels may be controlled by a control scheme either based on the

average response or on the response extremes. The control scheme shall be consistent with the test

requirement.4 © ISO 2021 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/FDIS 23670:2021(E)

6.4 Specimen configuration requirements

The specimen configuration shall be as described in ISO 15864:—, 7.13.3 and 7.14.3.

6.5 Response measurement pointThe test requirements shall specify the number, installation position and orientation, type and

measurement range of test sensors, as well as the processing modes and requirements for data

measurement. See more detailed requirements in 7.2.5.6.6 Test success criteria

It is presupposed that an accomplished test is formally compliant with the contract requirements.

For the test provider, if not specified otherwise, the following requirements shall apply.

— All vibration testing shall be applied at the right test level.— The acquisition of test specimen vibration response data shall be complete and valid.

For the specimen provider, if not specified otherwise, the following requirements shall apply.

— The intended test purposes shall be achieved.— There shall be no visual damage to the test specimen.

— The characteristic response curve (which includes the resonance frequencies and the amplification

ratio) shall be the same before and after each full level vibration testing (see 8.2.3 a)) under

consideration of the specified tolerance bands.— The test specimen performance after the test shall be specified by the customer.

7 Test system7.1 Test facility requirements

A vibration testing facility includes a vibration excitation system, a vibration control system, a

measuring system and auxiliary equipment. An example of a vibration testing facility is shown in

Figure 1.For FLVT, dynamic force gauges are mounted between the shaker/fixture and the test specimen. The

force at the interface is measured by the force gauges and is fed back to the control system to implement

response limiting.© ISO 2021 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/FDIS 23670:2021(E)

Key

1 accelerance signal conditioner 7 shaker

2 test specimen 8 data storage and processing system

3 force signal conditioner 9 data acquisition system

4 vibration controller 10 measurement system

5 power amplifier 11 accelerometer

6 force measurement device (for FLV) 12 force gauge

Figure 1 — Illustration of a force limited testing system

The test facility, including all auxiliary equipment,

— shall provide the specified vibration environments,

— shall implement the required control strategies, and

— shall meet the specified tolerances.

Measurement transducers, data recording and data reduction equipment capable of measuring,

recording, analysing, and displaying data shall be sufficient to document the test and to acquire any

additional data required.The facility shall be maintained in regular intervals and shall be checked before test campaign.

7.2 Equipment requirements7.2.1 Shaker

The requirements of the shaker are as follows.

a) The shaker test facility shall fulfil the requirements of the test concerning power, dimension,

applicable forces and moments with a margin. The test requirements shall not be limited by the

shaker performance.b) The static load capacity shall be greater than the sum of mass of the test specimen, moving part of

the shaker and the fixture. Flexible supports are necessary if this requirement cannot be met. The

6 © ISO 2021 – All rights reserved---------------------- Page: 11 ----------------------

ISO/FDIS 23670:2021(E)

natural frequency of this supporting system shall be less than the lowest test frequency, and the

allowed displacement shall be no less than the required displacement.c) The maximum displacement of shaker shall be greater than that required by the test conditions.

d) The shaker frequency range shall allow reaching the upper and lower limit frequencies specified in

the test conditions.7.2.2 Fixture

The requirements for the test fixture are as follows.

a) The fixture stiffness-and-mass ratio shall be as large as possible.

b) The fixture shall mate with the test specimen in the same way as the flight interface does, so that

the interface load distribution is similar to that in flight.c) The acceleration response of the interface between fixture and test specimen shall be uniform in

the test frequency range.d) The first natural frequency of the fixture shall be higher than the higher frequency of the vibration

testing. When this requirement cannot be met, the first natural fre...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.