ISO 23794

(Main)Rubber, vulcanized or thermoplastic — Abrasion testing — Guidance

Rubber, vulcanized or thermoplastic — Abrasion testing — Guidance

This document provides guidance on the determination of the abrasion resistance of vulcanized and thermoplastic rubbers. It covers both solid and loose abrasives. The guidelines given are intended to assist in the selection of an appropriate test method and appropriate test conditions for evaluating a material and assessing its suitability for a product subject to abrasion. Factors influencing the correlation between laboratory abrasion testing and product performance are considered, but, for example this document is not concerned with wear tests developed for specific finished rubber products, for example, trailer tests for tyres.

Caoutchouc, vulcanisé ou thermoplastique — Essais d’abrasion — Lignes directrices

Le présent document fournit des lignes directrices relatives à la détermination de la résistance à l'abrasion des caoutchoucs vulcanisés et thermoplastiques. Il inclut des abrasifs à l'état solide ou en poudre. Les lignes directrices fournies sont destinées à faciliter le choix d’une méthode d'essai et des conditions d’essai appropriées pour évaluer un matériau et établir son aptitude à l'emploi pour un produit soumis à une abrasion. Les facteurs ayant une influence sur la corrélation entre des essais d'abrasion en laboratoire et la performance du produit sont pris en compte, mais, par exemple le présent document ne traite pas des essais d'usure mis au point pour des produits finis particuliers en caoutchouc, par exemple essais sur remorque pour les pneumatiques.

General Information

Relations

Buy Standard

Standards Content (Sample)

ISO 23794:2022(E)

Style Definition: Heading 1: Indent: Left: 0 pt, First

line: 0 pt, Tab stops: Not at 21.6 pt

ISO/TC 45/SC 2

Style Definition: Heading 2: Font: Bold, Tab stops: Not

at 18 pt

Secretariat: JISC

Style Definition: Heading 3: Font: Bold

Date: 2022-11-17xx

Style Definition: Heading 4: Font: Bold

Style Definition: Heading 5: Font: Bold

Rubber, vulcanized or thermoplastic — Abrasion testing — Guidance

Style Definition: Heading 6: Font: Bold

Caoutchouc vulcanisé ou thermoplastique — Essais d'abrasion — Lignes directrices

Style Definition: ANNEX

Style Definition: AMEND Terms Heading: Font: Bold

Style Definition: AMEND Heading 1 Unnumbered:

Font: Bold

Formatted: Italian (Italy)

---------------------- Page: 1 ----------------------

ISO 23794:2022(E)

© ISO 2022

Formatted: Pattern: Clear

Formatted: Pattern: Clear

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this

publication may be reproduced or utilized otherwise in any form or by any means, electronic or mechanical,

including photocopying, or posting on the internet or an intranet, without prior written permission. Permission

can be requested from either ISO at the address below or ISO’s member body in the country of the requester.

ISO copyright officeCP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: + 41 22 749 01 11

E-mail: copyright@iso.org

Website: www.iso.orgwww.iso.org

Published in Switzerland

ii © ISO 2022 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 23794:2022(E)

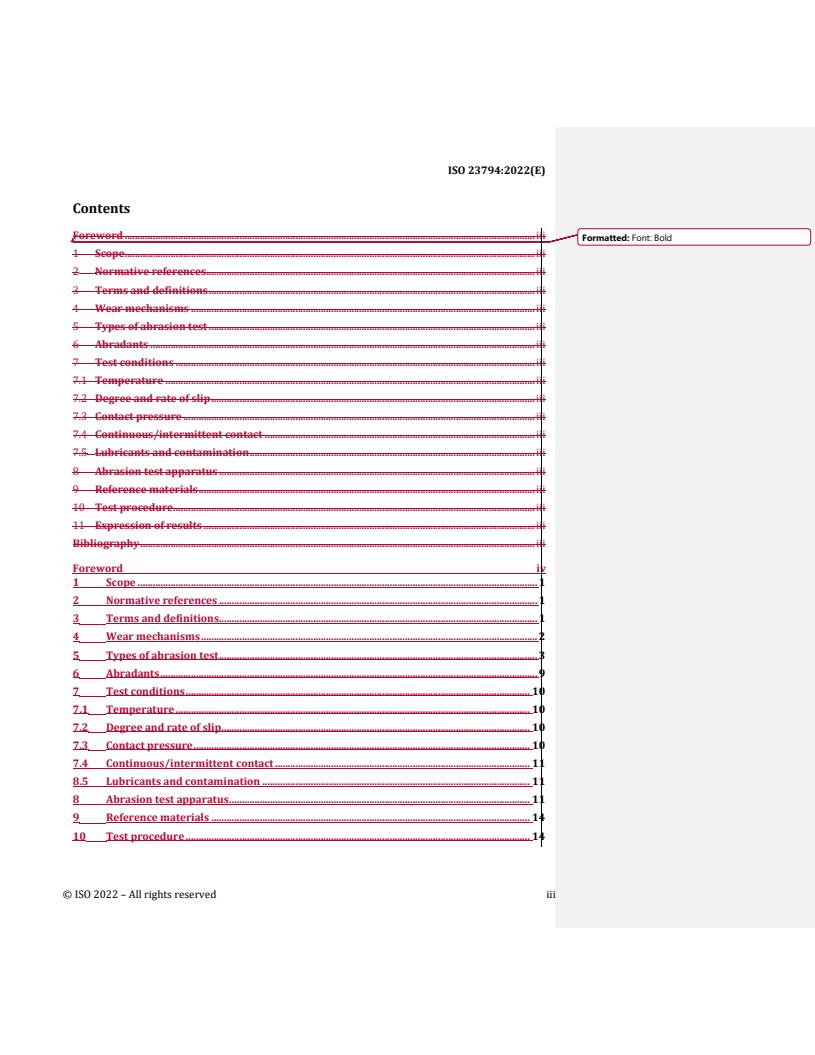

Contents

Foreword ................................................................................................................................................................. iii

Formatted: Font: Bold1 Scope................................................................................................................................................................. iii

2 Normative references ................................................................................................................................. iii

3 Terms and definitions ................................................................................................................................ iii

4 Wear mechanisms ....................................................................................................................................... iii

5 Types of abrasion test ................................................................................................................................ iii

6 Abradants ....................................................................................................................................................... iii

7 Test conditions ............................................................................................................................................. iii

7.1 Temperature ................................................................................................................................................. iii

7.2 Degree and rate of slip ............................................................................................................................... iii

7.3 Contact pressure .......................................................................................................................................... iii

7.4 Continuous/intermittent contact .......................................................................................................... iii

7.5 Lubricants and contamination ................................................................................................................ iii

8 Abrasion test apparatus ............................................................................................................................ iii

9 Reference materials .................................................................................................................................... iii

10 Test procedure .............................................................................................................................................. iii

11 Expression of results .................................................................................................................................. iii

Bibliography ........................................................................................................................................................... iii

Foreword iv1 Scope ............................................................................................................................................................. 1

2 Normative references ............................................................................................................................. 1

3 Terms and definitions ............................................................................................................................. 1

4 Wear mechanisms .................................................................................................................................... 2

5 Types of abrasion test ............................................................................................................................. 3

6 Abradants .................................................................................................................................................... 9

7 Test conditions ....................................................................................................................................... 10

7.1 Temperature ........................................................................................................................................... 10

7.2 Degree and rate of slip ......................................................................................................................... 10

7.3 Contact pressure .................................................................................................................................... 10

7.4 Continuous/intermittent contact .................................................................................................... 11

8.5 Lubricants and contamination ......................................................................................................... 11

8 Abrasion test apparatus ...................................................................................................................... 11

9 Reference materials ............................................................................................................................. 14

10 Test procedure ....................................................................................................................................... 14

© ISO 2022 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO 23794:2022(E)

10 Expression of results ............................................................................................................................ 15

Bibliography ......................................................................................................................................................... 17

Formatted: Normal, Adjust space between Latin andAsian text, Adjust space between Asian text and

numbers, Tab stops: Not at 22 pt + 467.5 pt

iv © ISO 2022 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 23794:2022(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national

standards bodies (ISO member bodies). The work of preparing International Standards is normally

carried out through ISO technical committees. Each member body interested in a subject for which a

technical committee has been established has the right to be represented on that committee.

International organizations, governmental and non-governmental, in liaison with ISO, also take part

in the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for

the different types of ISO documents should be noted. This document was drafted in accordance with

the editorial rules of the ISO/IEC Directives, Part 2 (seewww.iso.org/directiveswww.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject

of patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details

of any patent rights identified during the development of the document will be in the Introduction

and/or on the ISO list of patent declarations received (seewww.iso.org/patentswww.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.htmlwww.iso.org/iso/foreword.html.This document was prepared by Technical Committee ISO/TC 45, Rubber and rubber products,

Subcommittee SC 2, Testing and analysis.This fourth edition cancels and replaces the third edition (ISO 23794:2015), which has been

Formatted: Pattern: Cleartechnically revised.

Formatted: Pattern: Clear

Formatted: Pattern: Clear

The main changes are as follows:

— some terms (abradant and abrasion paternpattern) have been added in Clause 3;

Formatted: Pattern: Clear

— Figures 1 to 9 have been transferred from Clause 10 to Clause 5;

Formatted: Pattern: Clear

Formatted: Pattern: Clear

— some captions for the figures have been changed to proper description;

Formatted: Pattern: Clear

— in Clause 8, the order of the description has been changed;

Formatted: Pattern: Clear

— in addition, the text has been editorially revised to improve clarity.

© ISO 2022 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 23794:2022(E)

Any feedback or questions on this document should be directed to the user’s national standards body.

A complete listing of these bodies can be found atwww.iso.org/members.htmlwww.iso.org/members.html.

vi © ISO 2022 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 23794:2022(E)

Rubber, vulcanized or thermoplastic — Abrasion testing —

Guidance

WARNING 1 — Persons using this document should be familiar with normal laboratory practice. This

document does not purport to address all of the safety problems, if any, associated with its use. It is

the responsibility of the user to establish appropriate safety and health practices and to determine

the applicability of any other restrictions.WARNING 2 — Certain procedures specified in this document can involve the use or generation of

substances, or the generation of waste, that can constitute a local environmental hazard. Reference

should be made to appropriate documentation on safe handling and disposal after use.

1 ScopeThis document provides guidance on the determination of the abrasion resistance of vulcanized and

thermoplastic rubbers. It covers both solid and loose abrasives.The guidelines given are intended to assist in the selection of an appropriate test method and

appropriate test conditions for evaluating a material and assessing its suitability for a product subject

to abrasion. Factors influencing the correlation between laboratory abrasion testing and product

performance are considered, but, for example this document is not concerned with wear tests

developed for specific finished rubber products, for example, trailer tests for tyres.

2 Normative referencesThere are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obphttps://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/https://www.electropedia.org/

3.1abrasion

loss of material from a surface due to frictional forces

[[1]]

[SOURCE: ISO 1382:2020, , 3.1]

Formatted: Pattern: Clear

Formatted: Pattern: Clear

3.2

Formatted: Pattern: Clear

abrasion resistance

resistance to wear resulting from mechanical action upon a surface

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Note 1 to entry: Abrasion resistance is expressed by the abrasion resistance index.

© ISO 2022 – All rights reserved 1---------------------- Page: 7 ----------------------

ISO 23794:2022(E)

[[1]]

[SOURCE: ISO 1382:2020, , 3.2]

Formatted: Pattern: Clear

Formatted: Pattern: Clear

3.3

Formatted: Pattern: Clear

abrasion resistance index

ratio of the loss in volume of a standard rubber to the loss in volume of a test rubber, measured under

Formatted: Pattern: Clearthe same specified conditions and expressed as a percentage

Formatted: Pattern: Clear

Note 1 to entry: ISO 4649 contains a method for the determination of abrasion resistance (3.2) using a rotating

Formatted: Pattern: Cleardrum device.

Formatted: Pattern: Clear

[[1]]

[SOURCE: ISO 1382:2020, , 3.3] Formatted: Pattern: Clear

Formatted: Pattern: Clear

3.4

Formatted: Pattern: Clear

relative volume loss

loss in volume of a test rubber due to abrasion by a specified abradant which causes a reference

Formatted: Pattern: Clearrubber to lose a defined mass under the same conditions

Formatted: Pattern: Clear

Formatted: Pattern: Clear

3.5

abradant

material or means used for grinding, rasping rubber to cause abrasion

3.6

abrasion pattern

patterns on a surface formed by friction

4 Wear mechanisms

The mechanisms by which wear of rubber occurs when it is in moving contact with another material

are complex, but the principal factors involved are cutting and abrasion. It is possible to categorize

wear mechanisms in various ways and commonly distinction is made between:— abrasive wear,

— fatigue wear, and

— adhesive wear.

Additionally, wear by roll formation is sometimes considered as a separate mechanism.

Abrasive wear is caused by sharp asperities cutting the rubber.Fatigue wear is caused by particles of rubber being detached as a result of dynamic stressing on a

localized scale.Adhesive wear is the transfer of rubber to another surface as a result of adhesive forces between the

two surfaces.Wear by roll formation is where there is progressive tearing of a layer of rubber which forms a roll.

There can also be corrosive wear due to direct chemical attack on the surface.The term erosive wear is sometimes used for the action of particles in a liquid stream.

In any particular wear situation, more than one mechanism is usually involved, but one can be

predominate. Abrasive wear requires hard, sharp cutting edges, and high friction. Fatigue wear

2 © ISO 2022 – All rights reserved---------------------- Page: 8 ----------------------

ISO 23794:2022(E)

occurs with smooth or rough but blunt surfaces and does not need high friction. Adhesive wear is

much less common, but can occur on smooth surfaces. Roll formation requires high friction and

relatively poor tear strength. Roll formation results in a characteristic abrasion pattern of ridges and

grooves at right angles to the direction of movement.Abrasive wear or roll formation results in much more rapid wear than fatigue processes. The

mechanism and hence the rate of wear can change, perhaps quite suddenly, with the conditions, such

as contact pressure, speed, and temperature. In any practical circumstances, the mechanisms can be

complex and critically dependent on the conditions. Consequently, the critical factor as regards

testing is that the test conditions should essentially reproduce the service conditions if a good

correlation is to be obtained. Even a comparison between two rubbers can be invalid if the dominant

mechanism is different in testing and in service. The range of conditions encountered in applications

such as tyres is so complex, that they cannot be matched by a single test.It follows that there cannot be a universal standard abrasion test method for rubber, and the test

method and test conditions have to be chosen to suit the end application. Also, great care has to be

taken if the test is intended to provide a significant degree of acceleration.5 Types of abrasion test

Many abrasion testing machines have been devised and standardized at national level for use with

rubber. The majority of rubber tests involve a relatively sharp abradant and were devised for use

with tyre tread materials.Abrasion tests can be divided into two main types: those using a loose abradant and those using a

solid abradant.A loose abrasive powder can be used rather in the manner of a shot-blasting machine as a logical way

of simulating the action of sand or similar abradants impinging on the rubber in service. A loose

abradant can also be used between two sliding surfaces. Conveyor belts or tank linings are examples

of products subject to abrasion by loose materials. A car tyre is an example of the situation where

there is a combination of abrasion against a solid rough abradant, the road, and abrasion against a

free-flowing abradant in the form of grit particles. This situation can also occur in testing as a result

of the generation of wear debris from a solid abradant.Solid abradants can consist of almost anything, but the most common are: abrasive wheels (vitreous

or resilient), abrasive papers or cloths, and metal “knives”. The majority of wear situations involve

the rubber moving in contact with another solid material.Distinctions can be made on the basis of the geometry by which the test piece and abradant are

rubbed together. Many geometries are possible, and some common configurations are shown in

Figure 1 to Figure 9:Formatted: Pattern: Clear

Figure 1: The test piece reciprocates linearly against a sheet of abradant (or alternatively a strip of Formatted: Pattern: Clear

abradant can be moved past a stationary test piece).Formatted: Pattern: Clear

Figure 2: The abradant is a rotating disc with the test piece held against it (or vice versa).

Formatted: Pattern: ClearFigure 3: Both abradant and test piece are in the form of a wheel, either of which can be the driven

Formatted: Pattern: Clearmember.

Figure 4: The rotating disc test piece is driving, or driven by, the abradant wheel(s). The relative

Formatted: Pattern: Clearposition of test piece and abradant is as the figure and vice versa.

Figure 5: Both the test piece and the abradant are rotating.

Formatted: Pattern: Clear

© ISO 2022 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO 23794:2022(E)

Figure 6: The test piece is held against a rotating drum and traverses the drum. The test piece may

Formatted: Pattern: Clearcan also be rotated.

Figure 7: The test piece revolves in contact with metal knives.

Formatted: Pattern: Clear

Figure 8: Test pieces are tumbled together with abrasive particles inside a hollow rotating drum.

Formatted: Pattern: ClearFigure 9: Single metal knife is held against a rotating tube test piece.

Formatted: Pattern: Clear

If the abrasion is unidirectional, abrasion patterns will develop which can markedly affect abrasion

loss.23794_ed4fig1.EPS

Key

1 test piece

2 abradant

F load

Formatted: Font: Italic

Figure 1 — Test piece reciprocating linearly against a sheet of abradant

23794_ed4fig2.EPS

4 © ISO 2022 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 23794:2022(E)

Key

1 test piece

2 abradant

F load

Formatted: Font: Italic

Figure 2 — Test piece held against a rotating disc of abradant

23794_ed4fig3.EPS

Key

1 test piece

© ISO 2022 – All rights reserved 5

---------------------- Page: 11 ----------------------

ISO 23794:2022(E)

2 abradant

F load

Formatted: Font: Italic

Figure 3 — Test piece and abradant in the form of wheels either of which could can be driven

23794_ed4fig4.EPSKey

1 test piece

2 abradant

F load

Formatted: Font: Italic

NOTE The relative position of test piece and abradant is as the figure and vice versa.

Figure 4 — Rotating disc test piece driving, or driven by, the abradant wheel(s).)

23794_ed4fig5.EPS6 © ISO 2022 – All rights reserved

---------------------- Page: 12 ----------------------

ISO 23794:2022(E)

Key

1 test piece

2 abradant

F load

Formatted: Font: Italic

Figure 5 — Rotating test piece held against a rotating abradant disc

23794_ed4fig6.EPS

Key

1 test piece

2 abradant

F load

Formatted: Font: Italic

NOTE The test piece may can also be rotated.

Figure 6 — The testTest piece is held against a rotating drum and traverses the drum.

23794_ed4fig7.EPS© ISO 2022 – All rights reserved 7

---------------------- Page: 13 ----------------------

ISO 23794:2022(E)

Key

1 test piece

2 abradant

F load

Formatted: Font: Italic

Figure 7 — Knife-type abradant held against test piece in the form of a rotating disc

23794_ed4fig8.EPSKey

1 test piece

2 abradant

3 rotating drum (mill)

Figure 8 — Test pieces and abradants inside a rotating drum

23794_ed4fig9.EPS

8 © ISO 2022 – All rights reserved

---------------------- Page: 14 ----------------------

ISO 23794:2022(E)

Key

1 test piece

2 abradant

F load

Formatted: Font: Italic

Figure 9 — Knife-type abradant held against a rotating cylindrical tube test piece

6 AbradantsAbradants can be classified into the following types:

— abrasive wheels;

— abrasive papers and cloths attached to discs;

— metal knives;

— smooth surfaces;

— loose abradants.

The abrasive wheel is probably the most convenient abradant because of its low cost and mechanical

stability, and also, by simple refacing, a consistent surface can be maintained. Wheels are

characterized by the nature of the abrading particles, their size and sharpness, the structure of the

wheel, and the manner in which the abrasive is bonded (either resilient or vitreous). It follows that a

very wide range of abrasive properties is possible.Abrasive papers and cloths are inexpensive and easy to use, but deteriorate in cutting power rather

quickly. They are characterized by the nature of the abrading particles and their size and sharpness.

Metal “knives” can have various geometries, including the form of a mesh and a raised pattern on a

wheel. The main characteristic is the sharpness (radius) of the edges in contact with the rubber, and

there can be some difficulty maintaining a reproducible sharpness.© ISO 2022 – All rights reserved 9

---------------------- Page: 15 ----------------------

ISO 23794:2022(E)

Smooth surfaces are characterized by their degree of smoothness and the material, which defines the

level of friction.Loose abradants are commonly particles of the same material as is used to form abrasive wheels or

papers, and are characterized by their size and sharpness.The choice of abradant should be made primarily to give the best correlation with service conditions,

but it is also necessary for the abradant to be available in a convenient form and for its production to

be reproducible.As a consequence of these considerations, abrasive wheels and papers or cloths predominate where

cutting by sharp asperities is to be simulated. It is still necessary to select an appropriate asperity

size and sharpness. Materials such as textiles and metal plates are more appropriate for other

applications. Smoother materials generally abrade relatively slowly and, if conditions are

accelerated, give rise to an excessive temperature rise at the sliding surfaces. Because of these

difficulties, abrasive wheels and papers are frequently used for convenience in situations where they

are inappropriate for assessment of in-service performance.7 Test conditions

7.1 Temperature

Although temperature has a large effect on wear rate and is one of the important factors in obtaining

correlation between laboratory and service conditions, it is extremely difficult to control the

temperature during testing. Abrasion tests are normally carried out at standard laboratory

temperature. However, it is the temperature of the contact surfaces which is of importance rather

than the ambient temperature, and the surface temperature reached is dependent on several

experimental factors as outlined in 7.2 to 7.5.Formatted: Pattern: Clear

7.2 Degree and rate of slip

With any geometry involving a fixed abradant, there is relative movement or slip between the

abradant and the test piece, and the degree of slip is a critical factor in determining the wear rate. In

Figure 1 and Figure 6, there is 100 % slip, and the rate of slip is the same as the rate of movement

Formatted: Pattern: Clearbetween abradant and test piece, whereas in Figure 3, the degree of slip can be varied by changing

Formatted: Pattern: Clearthe angle between the wheels. In Figure 2, Figure 4, Figure 5 and Figure 7, the rate of slip will depend

Formatted: Pattern: Clearon the distance of the test piece from the centreline. In Figure 9, the degree of slip is 100 % but the

rate of slip varies across the test piece. In all cases, the rate will depend on the speed of the driven

Formatted: Pattern: Clearmember. An increase in the rate of slip will also increase the amount of heat generated and hence the

Formatted: Pattern: Cleartemperature.

Formatted: Pattern: Clear

7.3 Contact pressure

Formatted: Pattern: Clear

The contact pressure between the test piece and abradant is another critical factor in determining

Formatted: Pattern: Clearthe wear rate. Under some conditions, the wear rate is approximately proportional to the pressure,

but abrupt changes will occur if, with changing pressure, the abrasion mechanism changes. Such a

change can be because of a large rise in temperature.Rather than consider contact pressure and degree of slip separately, it has been proposed that the

power consumed in moving the rubber over the abradant should be used as a measure of the severity

of an abrasion test. The power used will depend on the friction between the surfaces and will

determine the rate of temperature rise.10 © ISO 2022 – All rights reserved

---------------------- Page: 16 ----------------------

ISO 23794:2022(E)

7.4 Continuous/intermittent contact

An important difference between the types of apparatus shown in, for example, Figure 1 and Figure 4

Formatted: Pattern: Clearis that, in the first case, the test piece is continuously and totally in contact with the abradant and

Formatted: Pattern: Clearthere is no chance of the heat generated at the contact surfaces being dissipated.

7.5 Lubricants and contaminationAny change in the nature of the contact surfaces will affect the rate of wear, and this includes changes

in the abradant and the test piece as the wear process proceeds. Additionally, there can be deliberate

addition of another material between the contact surfaces, accidental contamination, debris from the

abradant, and debris from the test piece.Introduction of a particulate material between the contact surfaces can be made to simulate service

conditions, such as a car tyre running on a dusty road. Similarly, a lubricant such as water can be

introduced. Relatively few types of apparatus are capable of operating under these conditions.

It is common practice to remove wear debris by continuously brushing the test piece or by the use of

air jets. In the latter case, care has to be taken to ensure that the air supply is not contaminated with

oil or water from the compressor. Clogging or smearing of the abradant is a common problem with

abrasive wheels and papers, and its occurrence will invalidate the test. It is normally caused by a high

temperature at the contact surfaces and, although the problem can sometimes be reduced by

introducing a powder between the surfaces, it should be treated as an indication that the test

conditions are not suitable. If high temperatures are experienced in service, a test method in which

new abradant is continually used should be chosen.If correlation between laboratory tests and service conditions is required, the test conditions should

be chosen extremely carefully to match those found in the application concerned.8 Abrasion test apparatus

A large number of abrasion testers have been developed, and the following list is not exhaustive, but

covers those of greatest significance in the rubber and plastics industries (the main features of each

are presented in Table 1).Formatted: Pattern: Clear

— Akron: Wheel-on-wheel geometry, notable for the ability to vary the degree of slip by changing

the relative angle of the wheels.[2]

NOTE 1 An example of the use of this method can be found in BS 903-A9 .

Formatted: Pattern: Clear

Formatted: Pattern: Clear

— Blade abrader: Single knife blade under a constant normal load is in contact with the flat surface

of a rotating cylindrical tube test piece. Formatted: Pattern: ClearFormatted: Pattern: Clear

1) 1

— DuPont (Grasselli) : : Pair of small, flat-faced moulded test pieces on a rotating abrasive paper

disc.1) [24]

— Laboratory Abrasion Tester 100 (LAT 100) (System Dr Grosch ): Sophisticated computer-

Formatted: Pattern: Clear...

INTERNATIONAL ISO

STANDARD 23794

Fourth edition

Rubber, vulcanized or

thermoplastic — Abrasion testing —

Guidance

Caoutchouc vulcanisé ou thermoplastique — Essais d'abrasion —

Lignes directrices

PROOF/ÉPREUVE

Reference number

ISO 23794:2022(E)

© ISO 2022

---------------------- Page: 1 ----------------------

ISO 23794:2022(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

PROOF/ÉPREUVE © ISO 2022 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 23794:2022(E)

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ..................................................................................................................................................................................... 1

3 Terms and definitions .................................................................................................................................................................................... 1

4 Wear mechanisms ..............................................................................................................................................................................................2

5 Types of abrasion test .....................................................................................................................................................................................3

6 Abradants .................................................................................................................................................................................................................... 8

7 Test conditions .......................................................................................................................................................................................................9

7.1 Temperature ............................................................................................................................................................................................. 9

7.2 Degree and rate of slip ..................................................................................................................................................................... 9

7.3 Contact pressure ................................................................................................................................................................................... 9

7.4 Continuous/intermittent contact ........................................................................................................................................... 9

7.5 Lubricants and contamination ................................................................................................................................................. 9

8 Abrasion test apparatus ............................................................................................................................................................................10

9 Reference materials ......................................................................................................................................................................................12

10 Test procedure ....................................................................................................................................................................................................12

11 Expression of results ....................................................................................................................................................................................13

Bibliography .............................................................................................................................................................................................................................15

iii© ISO 2022 – All rights reserved PROOF/ÉPREUVE

---------------------- Page: 3 ----------------------

ISO 23794:2022(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.This document was prepared by Technical Committee ISO/TC 45, Rubber and rubber products,

Subcommittee SC 2, Testing and analysis.This fourth edition cancels and replaces the third edition (ISO 23794:2015), which has been technically

revised.The main changes are as follows:

— some terms (abradant and abrasion pattern) have been added in Clause 3;

— Figures 1 to 9 have been transferred from Clause 10 to Clause 5;

— some captions for the figures have been changed to proper description;

— in Clause 8, the order of the description has been changed;

— in addition, the text has been editorially revised to improve clarity.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.PROOF/ÉPREUVE © ISO 2022 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 23794:2022(E)

Rubber, vulcanized or thermoplastic — Abrasion testing —

Guidance

WARNING 1 — Persons using this document should be familiar with normal laboratory practice.

This document does not purport to address all of the safety problems, if any, associated with its

use. It is the responsibility of the user to establish appropriate safety and health practices and to

determine the applicability of any other restrictions.WARNING 2 — Certain procedures specified in this document can involve the use or generation

of substances, or the generation of waste, that can constitute a local environmental hazard.

Reference should be made to appropriate documentation on safe handling and disposal after

use.1 Scope

This document provides guidance on the determination of the abrasion resistance of vulcanized and

thermoplastic rubbers. It covers both solid and loose abrasives.The guidelines given are intended to assist in the selection of an appropriate test method and appropriate

test conditions for evaluating a material and assessing its suitability for a product subject to abrasion.

Factors influencing the correlation between laboratory abrasion testing and product performance are

considered, but, for example this document is not concerned with wear tests developed for specific

finished rubber products, for example, trailer tests for tyres.2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at https:// www .electropedia .org/

3.1

abrasion

loss of material from a surface due to frictional forces

[1]

[SOURCE: ISO 1382:2020 , 3.1]

3.2

abrasion resistance

resistance to wear resulting from mechanical action upon a surface

Note 1 to entry: Abrasion resistance is expressed by the abrasion resistance index.

[1][SOURCE: ISO 1382:2020 , 3.2]

© ISO 2022 – All rights reserved PROOF/ÉPREUVE

---------------------- Page: 5 ----------------------

ISO 23794:2022(E)

3.3

abrasion resistance index

ratio of the loss in volume of a standard rubber to the loss in volume of a test rubber, measured under

the same specified conditions and expressed as a percentageNote 1 to entry: ISO 4649 contains a method for the determination of abrasion resistance (3.2) using a rotating

drum device.[1]

[SOURCE: ISO 1382:2020 , 3.3]

3.4

relative volume loss

loss in volume of a test rubber due to abrasion by a specified abradant which causes a reference rubber

to lose a defined mass under the same conditions3.5

abradant

material or means used for grinding, rasping rubber to cause abrasion

3.6

abrasion pattern

patterns on a surface formed by friction

4 Wear mechanisms

The mechanisms by which wear of rubber occurs when it is in moving contact with another material

are complex, but the principal factors involved are cutting and abrasion. It is possible to categorize

wear mechanisms in various ways and commonly distinction is made between— abrasive wear,

— fatigue wear, and

— adhesive wear.

Additionally, wear by roll formation is sometimes considered as a separate mechanism.

Abrasive wear is caused by sharp asperities cutting the rubber.Fatigue wear is caused by particles of rubber being detached as a result of dynamic stressing on a

localized scale.Adhesive wear is the transfer of rubber to another surface as a result of adhesive forces between the

two surfaces.Wear by roll formation is where there is progressive tearing of a layer of rubber which forms a roll.

There can also be corrosive wear due to direct chemical attack on the surface.The term erosive wear is sometimes used for the action of particles in a liquid stream.

In any particular wear situation, more than one mechanism is usually involved, but one can be

predominate. Abrasive wear requires hard, sharp cutting edges, and high friction. Fatigue wear occurs

with smooth or rough but blunt surfaces and does not need high friction. Adhesive wear is much less

common, but can occur on smooth surfaces. Roll formation requires high friction and relatively poor

tear strength. Roll formation results in a characteristic abrasion pattern of ridges and grooves at right

angles to the direction of movement.Abrasive wear or roll formation results in much more rapid wear than fatigue processes. The

mechanism and hence the rate of wear can change, perhaps quite suddenly, with the conditions, such

as contact pressure, speed, and temperature. In any practical circumstances, the mechanisms can be

complex and critically dependent on the conditions. Consequently, the critical factor as regards testing

PROOF/ÉPREUVE © ISO 2022 – All rights reserved---------------------- Page: 6 ----------------------

ISO 23794:2022(E)

is that the test conditions should essentially reproduce the service conditions if a good correlation is

to be obtained. Even a comparison between two rubbers can be invalid if the dominant mechanism is

different in testing and in service. The range of conditions encountered in applications such as tyres is

so complex, that they cannot be matched by a single test.It follows that there cannot be a universal standard abrasion test method for rubber, and the test

method and test conditions have to be chosen to suit the end application. Also, great care has to be

taken if the test is intended to provide a significant degree of acceleration.5 Types of abrasion test

Many abrasion testing machines have been devised and standardized at national level for use with

rubber. The majority of rubber tests involve a relatively sharp abradant and were devised for use with

tyre tread materials.Abrasion tests can be divided into two main types: those using a loose abradant and those using a solid

abradant.A loose abrasive powder can be used rather in the manner of a shot-blasting machine as a logical

way of simulating the action of sand or similar abradants impinging on the rubber in service. A loose

abradant can also be used between two sliding surfaces. Conveyor belts or tank linings are examples of

products subject to abrasion by loose materials. A car tyre is an example of the situation where there

is a combination of abrasion against a solid rough abradant, the road, and abrasion against a free-

flowing abradant in the form of grit particles. This situation can also occur in testing as a result of the

generation of wear debris from a solid abradant.Solid abradants can consist of almost anything, but the most common are: abrasive wheels (vitreous

or resilient), abrasive papers or cloths, and metal “knives”. The majority of wear situations involve the

rubber moving in contact with another solid material.Distinctions can be made on the basis of the geometry by which the test piece and abradant are rubbed

together. Many geometries are possible, and some common configurations are shown in Figure 1 to

Figure 9:Figure 1: The test piece reciprocates linearly against a sheet of abradant (or alternatively a strip of

abradant can be moved past a stationary test piece).Figure 2: The abradant is a rotating disc with the test piece held against it (or vice versa).

Figure 3: Both abradant and test piece are in the form of a wheel, either of which can be the driven

member.Figure 4: The rotating disc test piece is driving, or driven by, the abradant wheel(s). The relative position

of test piece and abradant is as the figure and vice versa.Figure 5: Both the test piece and the abradant are rotating.

Figure 6: The test piece is held against a rotating drum and traverses the drum. The test piece may can

also be rotated.Figure 7: The test piece revolves in contact with metal knives.

Figure 8: Test pieces are tumbled together with abrasive particles inside a hollow rotating drum.

Figure 9: Single metal knife is held against a rotating tube test piece.If the abrasion is unidirectional, abrasion patterns will develop which can markedly affect abrasion

loss.© ISO 2022 – All rights reserved PROOF/ÉPREUVE

---------------------- Page: 7 ----------------------

ISO 23794:2022(E)

Key

1 test piece

2 abradant

F load

Figure 1 — Test piece reciprocating linearly against a sheet of abradant

Key

1 test piece

2 abradant

F load

Figure 2 — Test piece held against a rotating disc of abradant

PROOF/ÉPREUVE © ISO 2022 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 23794:2022(E)

Key

1 test piece

2 abradant

F load

Figure 3 — Test piece and abradant in the form of wheels either of which can be driven

Key1 test piece

2 abradant

F load

NOTE The relative position of test piece and abradant is as the figure and vice versa.

Figure 4 — Rotating disc test piece driving, or driven by, the abradant wheel(s)© ISO 2022 – All rights reserved PROOF/ÉPREUVE

---------------------- Page: 9 ----------------------

ISO 23794:2022(E)

Key

1 test piece

2 abradant

F load

Figure 5 — Rotating test piece held against a rotating abradant disc

Key

1 test piece

2 abradant

F load

NOTE The test piece can also be rotated.

Figure 6 — Test piece held against a rotating drum and traverses the drum

PROOF/ÉPREUVE © ISO 2022 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 23794:2022(E)

Key

1 test piece

2 abradant

F load

Figure 7 — Knife-type abradant held against test piece in the form of a rotating disc

Key1 test piece

2 abradant

3 rotating drum (mill)

Figure 8 — Test pieces and abradants inside a rotating drum

© ISO 2022 – All rights reserved PROOF/ÉPREUVE

---------------------- Page: 11 ----------------------

ISO 23794:2022(E)

Key

1 test piece

2 abradant

F load

Figure 9 — Knife-type abradant held against a rotating cylindrical tube test piece

6 AbradantsAbradants can be classified into the following types:

— abrasive wheels;

— abrasive papers and cloths attached to discs;

— metal knives;

— smooth surfaces;

— loose abradants.

The abrasive wheel is probably the most convenient abradant because of its low cost and mechanical

stability, and also, by simple refacing, a consistent surface can be maintained. Wheels are characterized

by the nature of the abrading particles, their size and sharpness, the structure of the wheel, and the

manner in which the abrasive is bonded (either resilient or vitreous). It follows that a very wide range

of abrasive properties is possible.Abrasive papers and cloths are inexpensive and easy to use, but deteriorate in cutting power rather

quickly. They are characterized by the nature of the abrading particles and their size and sharpness.

Metal “knives” can have various geometries, including the form of a mesh and a raised pattern on a

wheel. The main characteristic is the sharpness (radius) of the edges in contact with the rubber, and

there can be some difficulty maintaining a reproducible sharpness.Smooth surfaces are characterized by their degree of smoothness and the material, which defines the

level of friction.Loose abradants are commonly particles of the same material as is used to form abrasive wheels or

papers, and are characterized by their size and sharpness.PROOF/ÉPREUVE © ISO 2022 – All rights reserved

---------------------- Page: 12 ----------------------

ISO 23794:2022(E)

The choice of abradant should be made primarily to give the best correlation with service conditions,

but it is also necessary for the abradant to be available in a convenient form and for its production to be

reproducible.As a consequence of these considerations, abrasive wheels and papers or cloths predominate where

cutting by sharp asperities is to be simulated. It is still necessary to select an appropriate asperity size

and sharpness. Materials such as textiles and metal plates are more appropriate for other applications.

Smoother materials generally abrade relatively slowly and, if conditions are accelerated, give rise to an

excessive temperature rise at the sliding surfaces. Because of these difficulties, abrasive wheels and

papers are frequently used for convenience in situations...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.