ISO 3934:2021

(Main)Rubber, vulcanized and thermoplastic - Preformed gaskets used in buildings - Classification, specifications and test methods

Rubber, vulcanized and thermoplastic - Preformed gaskets used in buildings - Classification, specifications and test methods

This document specifies a system of classification of materials used in preformed gaskets for buildings. It applies to the following products: a) gaskets for use round the inside of door or window casings, i.e. weatherstripping (dynamic gaskets); b) gaskets for glazing (static gaskets); c) gaskets for use round infilling; d) gaskets for use between facade parts; e) gaskets for use between masonry walls. In addition to specifying the characteristics required for the constituent materials, some functional tests on the gaskets themselves are specified. The corresponding test procedures are given in Annexes A to E. This document applies to preformed gaskets made from vulcanized or thermoplastic rubber. It also applies to preformed gaskets made of cellular rubber designed for use at temperatures between −20 °C and +55 °C (thermal conditions category P1) and between −40 °C and +70 °C (thermal conditions category P3) (see Clause 4).

Caoutchouc vulcanisé et thermoplastique — Profilés d'étanchéité utilisés dans le bâtiment — Classification, spécifications et méthodes d'essai

General Information

Relations

Overview

ISO 3934:2021 - Rubber, vulcanized and thermoplastic - Preformed gaskets used in buildings - Classification, specifications and test methods - provides a standardized system to classify and test preformed rubber gaskets used in building envelopes. The standard covers gaskets for weatherstripping (door/window casings), glazing, infill joints, façade joints and masonry joints. It applies to vulcanized and thermoplastic rubber gaskets and to cellular rubber designed for specified thermal-condition categories.

Key topics and technical requirements

- Classification system: Gaskets are coded with criteria A–G covering type, working compression range, compression force, working temperature (thermal category), compression recovery, stress relaxation and weathering resistance.

- Environmental categories: Thermal (P1–P4), mechanical (X = static, Y = dynamic) and weathering (protected/exposed) conditions are defined to match real-world use.

- Test methods and annexes: Normative test procedures are provided in Annexes A–E:

- Annex A - Working compression range

- Annex B - Compression force

- Annex C - Compression recovery

- Annex D - Stress relaxation under specified compression

- Annex E - Variation in length

- Material performance metrics: The standard references established test methods for hardness (Shore A), compression set, tension set, low-temperature brittleness, ageing, stress relaxation and weathering. It also includes requirements for lifetime estimation (Arrhenius procedure) and tolerances on hardness.

- Conformity details: Test pieces should be taken from the actual gasket or equivalent material produced under comparable conditions; results determine the formal classification code.

Practical applications

ISO 3934:2021 is directly applicable to:

- Specifying weatherstripping and glazing gaskets for windows and doors

- Selecting gaskets for façade joints, infills, and masonry connections

- Defining performance criteria for cellular rubber gaskets used in specified temperature ranges

Using the standard helps ensure gaskets meet expected performance for sealing, durability, compression behavior and weather resistance - critical for thermal performance, air/water tightness and long-term building integrity.

Who should use this standard

- Gasket and seal manufacturers (product development, quality control)

- Architects, façade engineers and specifiers writing performance requirements

- Building product test laboratories and certification bodies

- Installers and façade contractors verifying product suitability for climate and movement conditions

Related standards (selected normative references)

ISO 37, ISO 48-4 (Shore hardness), ISO 815 (compression set), ISO 812 (low-temperature brittleness), ISO 3384-1 (stress relaxation), ISO 11346 (estimation of lifetime), ISO 1431-1 (ozone resistance), ISO 4892-2 (weathering).

Keywords: ISO 3934:2021, preformed gaskets, rubber gaskets, vulcanized rubber, thermoplastic rubber, gasket classification, building seals, test methods, compression recovery, stress relaxation, weathering resistance.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 3934

Third edition

2021-10

Rubber, vulcanized and

thermoplastic — Preformed gaskets

used in buildings — Classification,

specifications and test methods

Caoutchouc vulcanisé et thermoplastique — Profilés d'étanchéité

utilisés dans le bâtiment — Classification, spécifications et méthodes

d'essai

Reference number

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

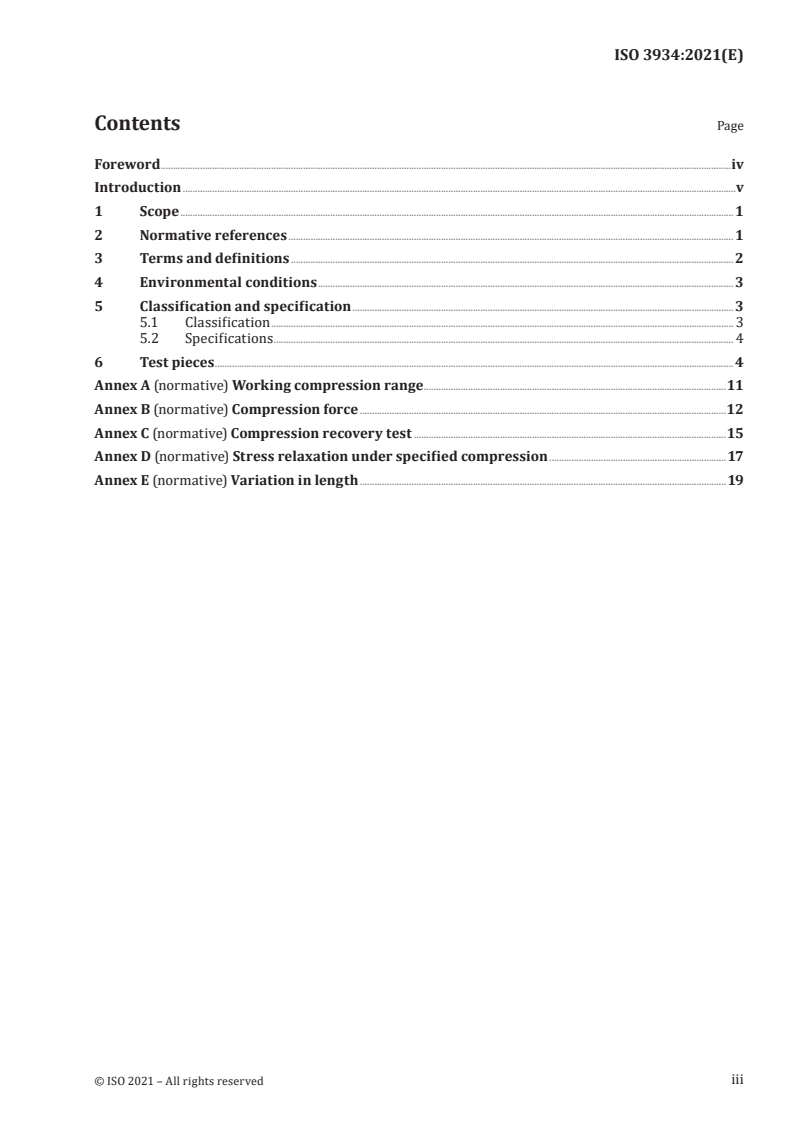

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Environmental conditions . 3

5 Classification and specification .3

5.1 Classification . 3

5.2 Specifications . 4

6 Test pieces .4

Annex A (normative) Working compression range .11

Annex B (normative) Compression force .12

Annex C (normative) Compression recovery test .15

Annex D (normative) Stress relaxation under specified compression .17

Annex E (normative) Variation in length .19

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 45, Rubber and rubber products,

Subcommittee SC 4, Products (other than hoses).

This third edition cancels and replaces the second edition (ISO 3934:2002), which has been technically

revised.

The main changes to the previous edition are as follows:

— requirements on estimation of lifetime have been added;

— hardness tolerance has increased;

— references have been updated.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

Preformed gaskets used in buildings have conditions of use which differ depending on their function

and position in the building. When preparing this document, it was felt necessary to take into account

the various conditions to which the gaskets are subjected in order to define the material specifications.

The tests take into account the static and dynamic stresses to which the gaskets are subjected.

v

INTERNATIONAL STANDARD ISO 3934:2021(E)

Rubber, vulcanized and thermoplastic — Preformed

gaskets used in buildings — Classification, specifications

and test methods

WARNING — Persons using this document should be familiar with normal laboratory practice.

This document does not purport to address all of the safety problems, if any, associated with

its use. It is the responsibility of the user of this document to establish appropriate safety and

health practices and to determine the applicability of any national regulatory conditions.

1 Scope

This document specifies a system of classification of materials used in preformed gaskets for buildings.

It applies to the following products:

a) gaskets for use round the inside of door or window casings, i.e. weatherstripping (dynamic gaskets);

b) gaskets for glazing (static gaskets);

c) gaskets for use round infilling;

d) gaskets for use between facade parts;

e) gaskets for use between masonry walls.

In addition to specifying the characteristics required for the constituent materials, some functional tests

on the gaskets themselves are specified. The corresponding test procedures are given in Annexes A to E.

This document applies to preformed gaskets made from vulcanized or thermoplastic rubber. It also

applies to preformed gaskets made of cellular rubber designed for use at temperatures between −20 °C

and +55 °C (thermal conditions category P ) and between −40 °C and +70 °C (thermal conditions

category P ) (see Clause 4).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 48-4, Rubber, vulcanized or thermoplastic — Determination of hardness — Part 4: Indentation

hardness by durometer method (Shore hardness)

ISO 105-A02, Textiles — Tests for colour fastness — Part A02: Grey scale for assessing change in colour

ISO 188:2011, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 812, Rubber, vulcanized or thermoplastic — Determination of low-temperature brittleness

ISO 815-1, Rubber, vulcanized or thermoplastic — Determination of compression set — Part 1: At ambient

or elevated temperatures

ISO 815-2, Rubber, vulcanized or thermoplastic — Determination of compression set — Part 2: At low

temperatures

ISO 1431-1, Rubber, vulcanized or thermoplastic — Resistance to ozone cracking — Part 1: Static and

dynamic strain testing

ISO 2285:2019, Rubber, vulcanized or thermoplastic — Determination of tension set under constant

elongation, and of tension set, elongation and creep under constant tensile load

ISO 3384-1:2019, Rubber, vulcanized or thermoplastic — Determination of stress relaxation in compression

— Part 1: Testing at constant temperature

ISO 4892-2, Plastics — Methods of exposure to laboratory light sources — Part 2: Xenon-arc lamps

ISO 11346, Rubber, vulcanized or thermoplastic — Estimation of life-time and maximum temperature of

use

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

compression force

force needed to compress a test piece through its working range to its minimum width (3.3)

3.2

compression recovery

ability of a gasket to recover its shape after being compressed through its working range

3.3

minimum width

lower limit of the working compression range (3.7)

Note 1 to entry: For a glazing gasket, the minimum width is the sum of the gaps between the glass and the

frame on each side of the glass. For weatherstripping, it is the gap between the door or window and the casing,

measured at the hinge side.

Note 2 to entry: It is recommended that the minimum width of weatherstripping and the minimum clearance

between glazing and frame for a glazing gasket be agreed by consultation between designer, manufacturer and

user

3.4

sample

complete batch of test material (gaskets) as supplied by the manufacturer for test purposes and from

which test pieces are cut

3.5

stress relaxation

time-dependent decrease in stress at a constant deformation

3.6

weathering resistance

resistance to combined detrimental influences of the outdoor environment (e.g. sunlight, ozone, oxygen,

humidity, temperature) on a material

3.7

working compression range

range, stated by the manufacturer, through which the gasket performs its function of being compressed

or otherwise deformed when used in any particular product

Note 1 to entry: See Annex A.

EXAMPLE For a gasket of free height (3.8) 7,5 mm, the manufacturer states a working range of 3 mm to

6 mm.

3.8

free height

height of a gasket measured without causing any significant deformation

Note 1 to entry: See Figure 1.

Figure 1 — Example of measurement of free height

4 Environmental conditions

The conditions to which gaskets may be subjected in the working environment are divided into the

following categories:

a) Thermal conditions (depending on the climate and the position in the construction)

— P : temperature of preformed gasket −20 °C to +55 °C

— P : temperature of preformed gasket –20 °C to +85 °C

— P : temperature of preformed gasket –40 °C to +70 °C

— P : temperature of preformed gasket –40 °C to +100 °C

b) Mechanical conditions

— X: static uses (see Table 1), i.e. between fixed elements

— Y: dynamic uses (see Table 1), i.e. between moving elements

c) Weathering

— R : protected from solar radiation

— R : exposed to solar radiation

5 Classification and specification

5.1 Classification

From the results of the tests carried out in accordance with this document, the classification of a

particular type of gasket shall be determined using Table 1. The numbers from Table 1, taken in the

order given, form the classification code for that gasket, viz:

— A: type of gasket

— B: working compression range

— C: compression force

— D: working temperature range

— E: compression recovery

— F: stress relaxation

— G: weathering resistance

Figure 2 gives a typical example of a classification code.

5.2 Specifications

The characteristics for the different classification criteria shall meet the requirements specified in

Tables 2 to 9.

6 Test pieces

Test pieces shall be prepared in accordance with the relevant standard test method or the relevant

annex of this document and, whenever possible, shall be cut from the gasket to be tested.

Failing this, they shall be taken from extruded ribbon (2 mm thick, 30 mm in width) or from

appropriately dimensioned test slabs prepared from the same batch of material used to produce the

gaskets being assessed and obtained under conditions that have been shown by experience to give

comparable results.

If measurements are made on test pieces not conforming to the standard referenced in Tables 2 to 9

(e.g. part of a gasket), the results can be different and the requirements to be met shall be subject to

agreement between the interested parties.

Table 1 — Classification of gaskets

Class

Code-

Characteristic

letter

0 1 2 3 4 5 6 7 8 9

X: static use

A Type of gasket

Y: dynamic use

Working compression

> 1 > 2 > 4 > 6 > 8 > 10 > 15

range (mm)

B u ≤ 1 but but but but but but but > 30

Measured in accord-

u ≤ 2 u ≤ 4 u ≤ 6 u ≤ 8 u ≤ 10 u ≤ 15 u ≤ 30

ance with Annex A

Compression force

> 50 > 100 > 700

> 10 > 20 > 200 > 500

(N/m)

but bu

...

Frequently Asked Questions

ISO 3934:2021 is a standard published by the International Organization for Standardization (ISO). Its full title is "Rubber, vulcanized and thermoplastic - Preformed gaskets used in buildings - Classification, specifications and test methods". This standard covers: This document specifies a system of classification of materials used in preformed gaskets for buildings. It applies to the following products: a) gaskets for use round the inside of door or window casings, i.e. weatherstripping (dynamic gaskets); b) gaskets for glazing (static gaskets); c) gaskets for use round infilling; d) gaskets for use between facade parts; e) gaskets for use between masonry walls. In addition to specifying the characteristics required for the constituent materials, some functional tests on the gaskets themselves are specified. The corresponding test procedures are given in Annexes A to E. This document applies to preformed gaskets made from vulcanized or thermoplastic rubber. It also applies to preformed gaskets made of cellular rubber designed for use at temperatures between −20 °C and +55 °C (thermal conditions category P1) and between −40 °C and +70 °C (thermal conditions category P3) (see Clause 4).

This document specifies a system of classification of materials used in preformed gaskets for buildings. It applies to the following products: a) gaskets for use round the inside of door or window casings, i.e. weatherstripping (dynamic gaskets); b) gaskets for glazing (static gaskets); c) gaskets for use round infilling; d) gaskets for use between facade parts; e) gaskets for use between masonry walls. In addition to specifying the characteristics required for the constituent materials, some functional tests on the gaskets themselves are specified. The corresponding test procedures are given in Annexes A to E. This document applies to preformed gaskets made from vulcanized or thermoplastic rubber. It also applies to preformed gaskets made of cellular rubber designed for use at temperatures between −20 °C and +55 °C (thermal conditions category P1) and between −40 °C and +70 °C (thermal conditions category P3) (see Clause 4).

ISO 3934:2021 is classified under the following ICS (International Classification for Standards) categories: 83.140.50 - Seals; 91.100.50 - Binders. Sealing materials. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 3934:2021 has the following relationships with other standards: It is inter standard links to ISO 3934:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 3934:2021 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Die ISO 3934:2021 legt einen umfassenden Standard für vorgeformte Dichtungen in Gebäuden fest, die aus vulkanisiertem und thermoplastischem Gummi hergestellt werden. Dieser Standard beschreibt ein System zur Klassifizierung der Materialien, die in diesen Dichtungen verwendet werden, und berücksichtigt dabei verschiedene Anwendungen. Zu den abgedeckten Produkten gehören Dichtungen für die Innenseiten von Türen und Fenstern, Dichtungen für Verglasungen, sowie Dichtungen für die Verwendung zwischen Fassadenteilen und Mauerwerk. Ein wesentlicher Stärke dieser Norm ist die präzise Definition der erforderlichen Eigenschaften der verwendeten Materialien, was den Herstellern eine klare Orientierung gibt und die Qualität der Dichtungen sichert. Darüber hinaus enthält die Norm spezifische funktionale Tests für die Dichtungen selbst, die in den Anhängen A bis E detailliert beschrieben sind. Diese Tests sind entscheidend, um sicherzustellen, dass die Dichtungen unter den gegebenen thermischen Bedingungen, die in den Kategorien P1 und P3 definiert sind, zuverlässig funktionieren. Die Relevanz der ISO 3934:2021 liegt in ihrer Fähigkeit, eine konsistente und verlässliche Grundlage für die Verwendung und den Austausch von vorgeformten Dichtungen in der Bauindustrie zu bieten. Durch die Standardisierung wird nicht nur die Qualität gesteigert, sondern auch die Sicherheit und Nachhaltigkeit von Bauprojekten gefördert. Diese Norm ist daher ein unverzichtbares Dokument für Hersteller, Architekten und Bauunternehmer, die hochwertige und langlebige Lösungen für die Abdichtung in Gebäuden suchen.

ISO 3934:2021文書は、建物で使用される成形ガスケットの分類、仕様および試験方法に関する標準であり、その範囲は非常に広く、建築資材の分野において重要な役割を果たしています。この標準は、動的ガスケットや静的ガスケット、インフィリング周囲のガスケット、ファサード部品間のガスケット、および石造壁間のガスケットといった多様な製品に適用されることが明記されています。 この標準の強みは、成分材料に求められる特性を具体的に定義している点と、それに加えガスケットそのものに対する機能試験を規定している点です。これは、ガスケットが実際の使用環境でしっかりと機能することを保証するための重要な要素です。さらに、附属書AからEにおいて、対応する試験手順が詳細に示されており、実施者が標準に基づいた評価を行う際の助けとなります。 また、ISO 3934:2021は、加硫ゴムまたは熱可塑性ゴムで作られた成形ガスケットに加え、−20°Cから+55°Cおよび−40°Cから+70°Cの温度範囲で使用されるセルラーゴム製ガスケットにも適用されるため、その適用範囲は非常に多岐にわたります。この温度条件の明確な分類は、ユーザーにとって実用的な指針となります。 したがって、ISO 3934:2021は、建物における成形ガスケットの客観的かつ標準化された評価を可能にし、品質管理や製品選定のプロセスにおいて非常に有用であるといえるでしょう。標準の定義に従うことで、業界における一貫性と信頼性が保証され、全体的な建設品質の向上に寄与します。

ISO 3934:2021 provides a comprehensive framework for the classification, specifications, and test methods pertinent to rubber, vulcanized and thermoplastic preformed gaskets used in buildings. The standard specifically addresses various applications, including weatherstripping around door and window casings, glazing gaskets, infilling gaskets, facade gaskets, and gaskets used between masonry walls. This broad scope ensures that the standard encompasses a wide range of products essential for building construction and sealing applications. One of the key strengths of ISO 3934:2021 is its detailed classification system, which allows manufacturers and users to select appropriate materials based on specific requirements. The standard not only delineates the characteristics required for the constituent materials but also incorporates functional tests that evaluate the performance of the preformed gaskets. This dual focus on material specifications and functional testing enhances the reliability of the gaskets in practical applications. Furthermore, the inclusion of test procedures detailed in Annexes A to E ensures that the assessment of gaskets is systematic and standardized, promoting consistency in performance evaluation. The standard comprehensively covers various temperature ranges with thermal conditions categories P1 and P3, accommodating a diverse range of environmental conditions that gaskets may encounter in building applications. The relevance of ISO 3934:2021 is evident in its ability to support the construction industry’s demand for high-performance gaskets that meet specific sealing requirements. By providing clear guidelines and testing frameworks, the standard not only aids manufacturers in producing compliant products but also assists architects and builders in selecting the right gaskets for their projects. In summary, ISO 3934:2021 stands out for its extensive scope, clear classifications, and robust testing methodologies. It plays a crucial role in ensuring the quality and performance of rubber, vulcanized, and thermoplastic preformed gaskets used in buildings, thereby fostering a reliable and efficient construction environment.

La norme ISO 3934:2021 offre un cadre systématique pour la classification et les spécifications des matériaux utilisés dans les joints préformés dans les bâtiments. Son champ d'application est pertinent, englobant divers produits tels que les joints pour le contour intérieur des menuiseries de portes et fenêtres, les joints pour le vitrage, ainsi que les joints utilisés entre les éléments de façade et les murs en maçonnerie. Cette exhaustivité en fait un document essentiel pour les professionnels du bâtiment et de la construction. Les forces de la norme résident dans sa capacité à définir des caractéristiques précises pour les matériaux constituants, garantissant ainsi que les joints préformés répondent à des exigences fonctionnelles élevées. En incluant des tests fonctionnels pour les joints eux-mêmes, comme spécifié dans les annexes A à E, la norme ISO 3934:2021 assure une évaluation rigoureuse de la performance des produits, ce qui renforce la confiance des utilisateurs finaux dans leur durabilité et efficacité. De plus, le document prend en compte une large gamme de conditions thermiques, en spécifiant des performances adaptées pour les joints en caoutchouc vulcanisé ou thermoplastique, ainsi que pour les joints en caoutchouc cellulaire. Cela témoigne de la pertinence de la norme dans divers environnements d'application, notamment dans des conditions extrêmes de température allant de -40 °C à +70 °C. En conclusion, la norme ISO 3934:2021 est un outil indispensable pour assurer la qualité et la conformité des joints préformés utilisés dans les bâtiments, contribuant ainsi à la sécurité et à l'efficacité énergétique des constructions modernes.

ISO 3934:2021 문서는 건축용 프리폼 개스킷의 분류, 사양 및 시험 방법에 대한 체계적인 지침을 제공하는 표준으로, 다양한 건축 응용 분야에 적합한 개스킷에 대한 사항을 다룹니다. 이 표준의 주요 범위는 문서에 명시된 다양한 목적의 개스킷 유형을 포함하며, 이는 문 또는 창틀 내부의 기밀성을 유지하는 날씨 차단용(다이나믹 개스킷), 유리 장착용(스태틱 개스킷), 내부 채움용, 외벽 부품 간의 연결용, 그리고 벽돌 사이에 사용되는 개스킷에 적용됩니다. ISO 3934:2021의 강점은 그러한 개스킷의 구성 재료에 필요한 특성을 규명할 뿐만 아니라 개스킷 자체에 대한 기능 테스트를 정의하고 있다는 점입니다. 이 문서는 채택된 시험 절차를 통해 다양한 풍화 및 기후 조건에서 개스킷의 성능을 검증하는 방법을 안내하고 있어, 건축 현장에서의 실용성을 높입니다. 부록 A부터 E까지의 시험 절차는 개스킷의 내구성과 효율성을 평가하는 데 필요한 명확한 지침을 제공하여 사용자가 신뢰할 수 있는 성능을 확보하게 합니다. 또한, ISO 3934:2021 표준은 가황 고무 및 열가소성 고무로 제작된 프리폼 개스킷에 적용되며, 세포형 고무로 제조된 개스킷 역시 저온(-20 °C)부터 고온(+70 °C) 범위에서의 사용을 고려하고 있습니다. 이러한 범위는 다양한 기후 조건에서의 사용 가능성을 확장하여, 건축 분야에서의 지속 가능성 및 첨단 성능 요구를 충족시키도록 합니다. 따라서 ISO 3934:2021은 건축용 프리폼 개스킷의 품질 보증 및 성능 기준을 명확히 하고, 이를 통해 사용자에게 신뢰성 있고 안전한 건축 제품을 제공할 수 있는 중요한 기준으로 자리 잡고 있습니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...