ISO 17862:2022

(Main)Surface chemical analysis - Secondary ion mass spectrometry - Linearity of intensity scale in single ion counting time-of-flight mass analysers

Surface chemical analysis - Secondary ion mass spectrometry - Linearity of intensity scale in single ion counting time-of-flight mass analysers

This document specifies a method for determining the maximum count rate for an acceptable limit of divergence from linearity of the intensity scale in single ion counting time-of-flight (TOF) secondary ion mass spectrometers using a test based on isotopic ratios in spectra from poly(tetrafluoroethylene) (PTFE). It also includes a method to correct for intensity nonlinearity arising from intensity lost from a microchannel plate (MCP) or scintillator and photomultiplier followed by a time-to-digital converter (TDC) detection system caused by secondary ions arriving during its dead-time. The correction can increase the intensity range for 95 % linearity by a factor of up to more than 50 so that a higher maximum count rate can be employed for those spectrometers for which the relevant correction formulae have been shown to be valid.

Analyse chimique des surfaces — Spectrométrie de masse des ions secondaires — Linéarité de l'échelle d'intensité des analyseurs de masse à temps de vol pour comptage des ions individuels

General Information

Relations

Overview

ISO 17862:2022 - "Surface chemical analysis - Secondary ion mass spectrometry - Linearity of intensity scale in single ion counting time-of-flight mass analysers" defines a standardized method to evaluate and correct intensity nonlinearity in single‑ion‑counting TOF‑SIMS instruments. The standard uses isotopic ratios measured from poly(tetrafluoroethylene) (PTFE) spectra to determine a maximum count rate for an acceptable divergence from linearity of the intensity scale. It also provides a practical dead‑time correction applicable to detection chains based on a microchannel plate (MCP) or scintillator + photomultiplier followed by a time‑to‑digital converter (TDC), potentially extending the usable intensity range (95% linearity) by a factor of more than 50 for instruments where the correction is valid.

Key technical topics and requirements

- Scope and intent: Characterize intensity linearity and define a usable maximum count‑rate for TOF‑SIMS single ion counting systems.

- Test material: Measurements are performed on PTFE tape in the “as‑received” condition using isotopic peak ratios.

- Procedure elements:

- Sample mounting and instrument setup (beam, mass analyser, energy acceptance).

- Acquisition of a set of test and analysis spectra (e.g., 16 test spectra to establish settings and 16 data spectra for analysis).

- Calculation and fitting of measured vs corrected counts and isotopic ratios to assess linear range.

- Dead‑time correction: A Poissonian dead‑time correction for MCP/TDC detection chains is provided to compensate for counts lost when multiple secondary ions arrive within the detector dead‑time τ.

- Validation and limits: The method defines validity checks for the correction and sets conservative limits where corrections are reliable. It identifies cases where nonlinearity cannot be simply corrected and a maximum acceptable count rate must be enforced.

- Quality regimen: Recommended to repeat tests after substantive detector/electronics changes (e.g., MCP replacement) or at about one‑year intervals.

Practical applications and users

- Who uses ISO 17862:2022:

- TOF‑SIMS instrument manufacturers and service engineers validating detector performance.

- Surface analysis laboratories and metrology institutes establishing quantitative SIMS capability.

- Quality control and R&D teams that require reliable quantitative depth profiling or surface composition data.

- Practical benefits:

- Establishes a verifiable maximum count rate to avoid quantitative bias from detector saturation.

- Provides an evidence‑based dead‑time correction that can dramatically expand usable dynamic range for eligible instruments.

- Helps diagnose detector faults (e.g., reduced efficiency, non‑single‑ion counting behavior) and optimize measurement settings.

Related standards

- Normative reference: ISO 13084 (Calibration of the mass scale for TOF‑SIMS).

- ISO 17862:2022 complements other surface chemical analysis standards and laboratory best practices for quantitative SIMS.

Keywords: ISO 17862:2022, TOF‑SIMS, secondary ion mass spectrometry, intensity linearity, single ion counting, MCP, TDC, dead‑time correction, PTFE, count rate.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 17862

Second edition

2022-09

Surface chemical analysis —

Secondary ion mass spectrometry —

Linearity of intensity scale in single

ion counting time-of-flight mass

analysers

Analyse chimique des surfaces — Spectrométrie de masse des ions

secondaires — Linéarité de l'échelle d'intensité des analyseurs de

masse à temps de vol pour comptage des ions individuels

Reference number

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

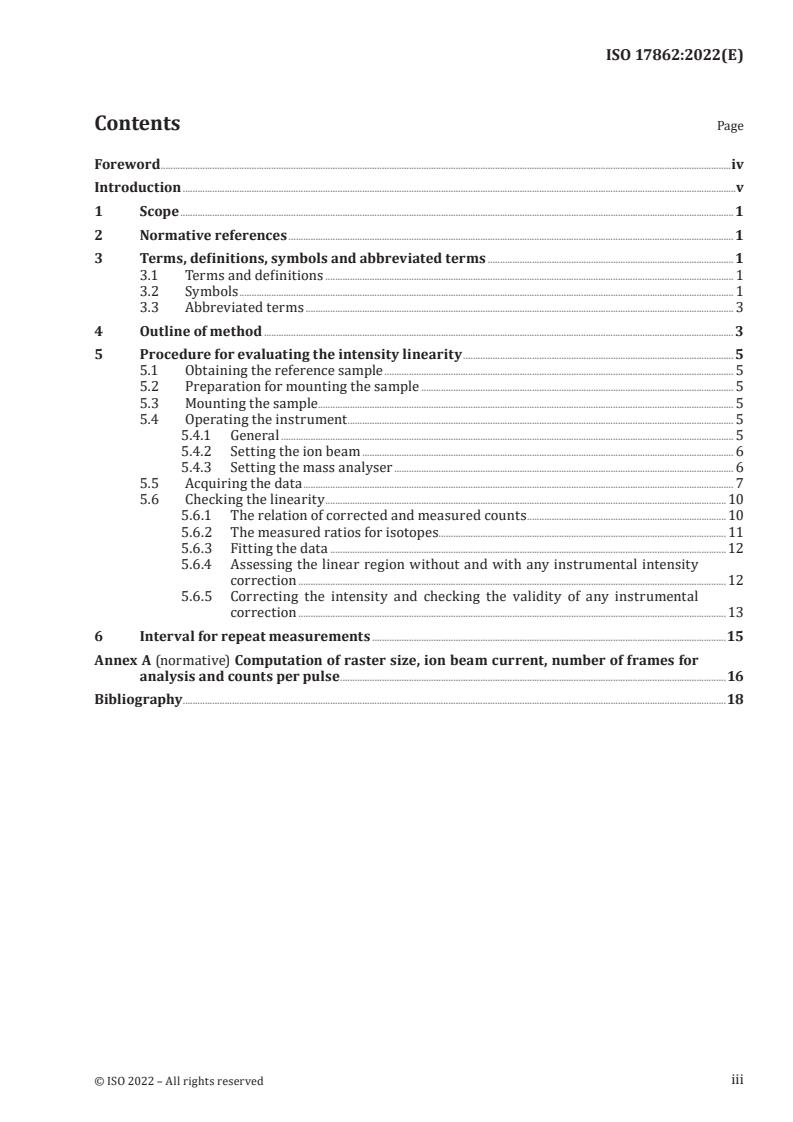

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms, definitions, symbols and abbreviated terms . 1

3.1 Terms and definitions . 1

3.2 Symbols . 1

3.3 Abbreviated terms . 3

4 Outline of method . 3

5 Procedure for evaluating the intensity linearity . 5

5.1 Obtaining the reference sample . 5

5.2 Preparation for mounting the sample . 5

5.3 Mounting the sample . 5

5.4 Operating the instrument . 5

5.4.1 General . 5

5.4.2 Setting the ion beam . 6

5.4.3 Setting the mass analyser . 6

5.5 Acquiring the data . 7

5.6 Checking the linearity . 10

5.6.1 The relation of corrected and measured counts . 10

5.6.2 The measured ratios for isotopes. 11

5.6.3 Fitting the data .12

5.6.4 Assessing the linear region without and with any instrumental intensity

correction .12

5.6.5 Correcting the intensity and checking the validity of any instrumental

correction . 13

6 Interval for repeat measurements .15

Annex A (normative) Computation of raster size, ion beam current, number of frames for

analysis and counts per pulse .16

Bibliography .18

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 201, Surface chemical analysis,

Subcommittee SC 6, Secondary ion mass spectrometry.

This second edition cancels and replaces the first edition (ISO 17862:2013), which has been technically

revised.

The main changes are as follows:

— the procedure has been simplified by removing the informative background (including Annexes B

to D);

— all figures have been fixed to adhere with ISO standards.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

For the quantitative analysis of materials using secondary ion mass spectrometry (SIMS), measurements

are made of the spectral intensities. Nonlinearity in the instrument intensity scale, unless corrected,

leads directly to errors in the relative amounts of material determined at surfaces and in-depth profiles.

In general, intensity scales are linear at very low count rates, or more correctly low counts per pulse,

but become progressively nonlinear as the count rates rise. Measurements of intensity rely on the

measurement system delivering an intensity signal fixed in proportion to the intensity being measured.

In counting systems, this proportionality is expected to be unity. If this proportionality varies with the

signal level or counting rate, the measurement system is said to be nonlinear. It is rare for nonlinearities

below 1 % to be treated as significant. The intensity scale nonlinearity can exceed 1 % for count rates

[2]

that exceed 5 % of the maximum permissible count rate . For many instruments, the nonlinearity

behaviour will not vary significantly from month-to-month, provided the detection system is correctly

set. For these instruments, the count rate can be corrected, using the relevant relationship, so that the

corrected intensity is then linear for a greatly extended fraction of the maximum obtainable count

rate. This correction to the intensity scale might or might not already be available in the instrument's

data capture or processing computer. In this document, a simple test of linearity is provided for the

intensity lost in systems in which secondary ions arrive at a detector based on a microchannel plate or

scintillator and photomultiplier followed by a time-to-digital converter. If this test is shown to be valid,

a correction is provided that, for suitable instruments, can extend the intensity scale by up to a factor

of more than 50. For some instruments, the nonlinearity cannot be predictable nor described by any

simple relationship. For these instruments, this document allows the extent of the nonlinearity to be

measured and a maximum count rate for an acceptable limit of divergence from linearity to be defined.

In some cases, adjustments to the instrumental settings can improve the situation so that the required

correction is then valid. The limit of divergence from linearity is set by the user appropriately for the

analyses to be conducted.

Although there are a number of causes of nonlinearities in TOF-SIMS instrumentation, the most

significant is intensity saturation caused by the effective dead-time of the detector system. This arises

since only one secondary ion count per primary ion pulse can be detected within a dead-time interval

τ, regardless of the actual number of secondary ions arriving at the detector. Nonlinearity can also be

aggravated by unwanted background in the spectra.

This document provides, and can only provide, a correction to the dead-time nonlinearity for a somewhat

ideal situation and not for all cases. Nevertheless, the significantly enhanced dynamic range or rate of

working can be very important. Suggestions are included to optimize the instrument to provide the

best measurement capability and to diagnose simple instrumental defects such as detector faults, e.g.

a low detector efficiency or a detector not providing single ion counting. Then, a dead-time Poissonian

correction is established to correct the measured counts within certain limits set by the analyst. This

establishes an upper value for c , the count per pulse, either before or after correction. This upper limit

M

is generally applicable to peaks where the signal is constant with both time and spatial distribution,

where there is only one peak within the dead-time interval, and where the background intensities

are negligible (these conditions are not always satisfied in practice). This is explored and explained in

detail in Reference [2]. The results from applying this document relate to a “best-case scenario” and

the linearity achievable with Formula (1) can be lower in real cases where it is not practical to use a

wide peak integration limit of ± the dead-time. More advanced dead-time correction routines should be

sought in these cases and their effectiveness can be tested using the methodology here.

This document requires technical skills that may go beyond everyday operation and should be used

when characterizing a new spectrometer so that it can be operated in an appropriate intensity range. It

should then be repeated after any substantive modification to the detection circuits, after replacement

of the microchannel plate (MCP), or at approximately 1 year intervals.

v

INTERNATIONAL STANDARD ISO 17862:2022(E)

Surface chemical analysis — Secondary ion mass

spectrometry — Linearity of intensity scale in single ion

counting time-of-flight mass analysers

1 Scope

This document specifies a method for determining the maximum count rate for an acceptable limit of

divergence from linearity of the intensity scale in single ion counting time-of-flight (TOF) secondary

ion mass spectrometers using a test based on isotopic ratios in spectra from poly(tetrafluoroethylene)

(PTFE). It also includes a method to correct for intensity nonlinearity arising from intensity lost from

a microchannel plate (MCP) or scintillator and photomultiplier followed by a time-to-digital converter

(TDC) detection system caused by secondary ions arriving during its dead-time. The correction

can increase the intensity range for 95 % linearity by a factor of up to more than 50 so that a higher

maximum count rate can be employed for those spectrometers for which the relevant correction

formulae have been shown to be valid.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 13084, Surface chemical analysis — Secondary ion mass spectrometry — Calibration of the mass scale

for a time-of-flight secondary ion mass spectrometer

3 Terms, definitions, symbols and abbreviated terms

3.1 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.2 Symbols

The term intensity is used below and elsewhere. This refers to a measurement of peak area in the

spectrum.

c measured counts per pulse intensity

M

c corrected counts per pulse intensity

P

F shorthand for F (i,j)

M M

12 + 13 12 +

F (i,j) ratio of measured intensities for the ith C F and C C F secondary ions in Table 1

M x y x-1 y

F shorthand for F (i,j)

P P

12 + 13 12 +

F (i,j) ratio of corrected intensities for the ith C F and C C F secondary ions in Table 1

P x y x-1 y

i index number for ion pair listed in Table 1

i highest primary ion current used for the saturation analysis

max

I integrated measured secondary ion intensity of a specified SIMS peak

M

I (X) integrated measured secondary ion intensity of the SIMS fragment X

M

I integrated corrected secondary ion intensity of a specified SIMS peak

P

I (X) integrated corrected secondary ion intensity of the SIMS fragment X

P

j index number for spectrum in the measurement series

k index number for setting the different primary ion currents

L shorthand for L (i,j)

P P

L (i,j) ratio of F (i,j) to the product α(i) and β(i)

P P

L shorthand for L (i,j)

M M

L (i,j) ratio of F (i,j) to the product α(i) and β(i)

M M

T

theoretical ratio of measured and corrected intensities per pulse

L

M

n number of raster frames used to generate each SIMS intensity

N total number of primary pulses used to generate the SIMS spectrum

R length of the raster side used to generate each SIMS intensity

V mass analyser desired energy acceptance, in eV

E

V mass analyser reflector voltage referred to the sample potential

R

V mass analyser reflector voltage referred to the sample potential for a secondary ion intensity to

T

fall to half the maximum intensity

12 + 13 12 +

α(i) expected isotope ratio of the ith C F and C C F secondary ions in Table 1

x y x-1 y

β(i) scaling factor to correct α(i) for the measured data, found by fitting

τ detection system dead-time

13 12

x number of C or C atoms in the characteristic PTFE secondary ion

y number of F atoms in the characteristic PTFE secondary ion

Symbols used in Annex A

A peak intensity of a selected peak (counts)

c secondary ion counts per primary ion pulse (counts)

d beam diameter (m)

e charge on the electron (C)

F pulse repetition rate or frequency (s−1)

iP pulsed ion beam current (A) (i.e. the time-averaged current with pulsing on)

I DC ion beam current (ions/s) (i.e. the current with the pulsing off)

J total ion fluence (ions/m2)

M number of pixels along a line of the raster

P total number of primary ion pulses in the acquisition time T (no units)

Q total number of incident ions

R raster size (m)

T total spectrum acquisition time (s)

w pulse width (s)

3.3 Abbreviated terms

For the purposes of this document, the following abbreviated terms apply.

MCP microchannel plate

PTFE poly(tetrafluoroethylene)

SIMS secondary ion mass spectrometry

TDC time-to-digital converter

ToF time-of-flight

4 Outline of method

The method is outlined by the flow chart shown in Figure 1. In this method, secondary ion spectra

are measured for PTFE tape analysed in the “as received” condition with no in-house cleaning and no

further sample preparation as described from 5.1 to 5.3. The analytical conditions are chosen by the

analyst as described in 5.4 to provide secondary ion intensities per pulse in the linear and nonlinear

ranges of detector ion counting. This is established using 16 test spectra for a test sample to define

the correct range of primary ion beam current settings and 16 data spectra are then measured for the

analysis sample to provide data for the linearity establishment. In order to ensure that the instrument is

operating in the best condition for linearity, considerations for setting the ion beam, the mass analyser,

the charge compensation, and the ion detection system are described from 5.5.2 to 5.5.5. PTFE is a bulk

insulator and requires charge neutralization.

The spectrometer should be operated under conditions that give the most stable performance. It

is recommended that analysts use ISO 23830 to confirm the repeatability of their instrument. The

protocol described in this document is closely aligned with that in ISO 23830 and those using ISO 23830

are already familiar with much of the procedure given here.

The acquisition of data is described in 5.5 and details of the peaks to be measured are given in Table 1.

The behaviour expected is described in 5.6 with relevant formulae. If the linearity is adequate, either

for the data directly or for the data after correction using the instrument's data capture computer,

the work is complete until, through changes to the instrument or the passage of time, a repeat of

this document is required. If the linearity is inadequate, and if the instrument follows the predicted

behaviour, a correction can be made as described in 5.6.5 which can extend the linear range by a factor

of more than 50. The work is now complete until, through changes to the instrument or the passage of

time, a repeat of this document is required.

Figure 1 — Flow chart of the work

5 Procedure for evaluating the intensity linearity

5.1 Obtaining the reference sample

For the calibration of ToF-SIMS, spectrometers obtain a new roll of PTFE tape of the type used for

domestic plumbing. Label and keep this roll with your reference samples.

NOTE The PTFE is usually in the form of a roll of tape of length 12 m, width 12 mm, and approximately

0,075 mm thick and is often sold for domestic plumbing.

5.2 Preparation for mounting the sample

Samples shall only be handled with clean, uncoated stainless steel tweezers. Any fingerprints on the

sample shall be avoided.

12 13

NOTE This document uses the intensity ratio of natural C and C isotopes to determine the linearity.

For the isotope ratio method to be successful, it is important that the isotope peaks can be measured without

any significant background from peak interferences. Since most ToF-SIMS instruments do not have sufficient

13 12

resolution to completely separate between a fragment with C and the peak interference with CH, it is

important to have no hydrogen in the reference material and a low surface energy so that hydrocarbon

contamination is minimized. PTFE has both crucial attributes and, importantly, is very easy to obtain and use.

5.3 Mounting the sample

5.3.1 To manipulate the samples, the gloves are used to hold the tweezers and not the sample. Avoid

any wiping materials, sometimes used to handle samples, as they can result in unwanted contamination

of the sample surface. Unnecessary contact of the sample with the gloves shall be avoided. Sample

mounts and other materials used to hold samples shall be cleaned regularly whenever there is a

possibility of cross-contamination of samples. The use of tapes containing silicones and other mobile

[3]

species shall be avoided .

5.3.2 Remove and discard the first 20 cm of the material from the roll obtained in 5.1 and then cut

appropriately sized samples from the subsequent material with clean scissors. As the roll is unwound,

a fresh surface of PTFE is exposed and it is this surface that is analysed. Do not clean the sample. Mount

samples on the sample holder to produce a flat, even surface using a mechanical clamping or fixing

method. Do not use adhesive tape. Ensure that the reverse side of the sample is against a conducting

surface, electrically connected to the sample holder. The PTFE shall not be placed over a hole.

NOTE 1 Common mounting systems include metal plates with holes of various sizes and metal grids. The grid

often helps if severe charging is experienced.

NOTE 2 The presence of a hole under the sample leads to poor mass resolution and repeatability in systems

that use high extraction fields such as time-of-flight and magnetic sector systems.

A repeat of this document is required in Clause

...

Frequently Asked Questions

ISO 17862:2022 is a standard published by the International Organization for Standardization (ISO). Its full title is "Surface chemical analysis - Secondary ion mass spectrometry - Linearity of intensity scale in single ion counting time-of-flight mass analysers". This standard covers: This document specifies a method for determining the maximum count rate for an acceptable limit of divergence from linearity of the intensity scale in single ion counting time-of-flight (TOF) secondary ion mass spectrometers using a test based on isotopic ratios in spectra from poly(tetrafluoroethylene) (PTFE). It also includes a method to correct for intensity nonlinearity arising from intensity lost from a microchannel plate (MCP) or scintillator and photomultiplier followed by a time-to-digital converter (TDC) detection system caused by secondary ions arriving during its dead-time. The correction can increase the intensity range for 95 % linearity by a factor of up to more than 50 so that a higher maximum count rate can be employed for those spectrometers for which the relevant correction formulae have been shown to be valid.

This document specifies a method for determining the maximum count rate for an acceptable limit of divergence from linearity of the intensity scale in single ion counting time-of-flight (TOF) secondary ion mass spectrometers using a test based on isotopic ratios in spectra from poly(tetrafluoroethylene) (PTFE). It also includes a method to correct for intensity nonlinearity arising from intensity lost from a microchannel plate (MCP) or scintillator and photomultiplier followed by a time-to-digital converter (TDC) detection system caused by secondary ions arriving during its dead-time. The correction can increase the intensity range for 95 % linearity by a factor of up to more than 50 so that a higher maximum count rate can be employed for those spectrometers for which the relevant correction formulae have been shown to be valid.

ISO 17862:2022 is classified under the following ICS (International Classification for Standards) categories: 71.040.40 - Chemical analysis. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 17862:2022 has the following relationships with other standards: It is inter standard links to ISO 17862:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 17862:2022 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...