ISO/AWI TR 20896-2

(Main)Dentistry — Digital impression devices — Part 2: Methods for assessing accuracy for implanted devices

Dentistry — Digital impression devices — Part 2: Methods for assessing accuracy for implanted devices

This document describes methods of acquiring and analysing data from which the accuracy of a numerical model of the geometry of the mucosa and implant bodies in the jaw of a patient can be assessed.

Médecine bucco-dentaire — Dispositifs d'empreinte numérique — Partie 2: Méthodes d'évaluation de l'exactitude de dispositifs implantés

Le présent document décrit des méthodes de collecte et d’analyse des données à partir desquelles l’exactitude d'un modèle numérique de la géométrie de la muqueuse et des implants dentaires dans la mâchoire d'un patient peut être évaluée.

General Information

Buy Standard

Standards Content (Sample)

FINAL

TECHNICAL ISO/DTR

DRAFT

REPORT 20896-2

ISO/TC 106/SC 9

Dentistry — Digital impression

Secretariat: JISC

devices —

Voting begins on:

2022-09-28

Part 2:

Voting terminates on:

Methods for assessing accuracy for

2022-12-21

implanted devices

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/DTR 20896-2:2022(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. © ISO 2022

---------------------- Page: 1 ----------------------

ISO/DTR 20896-2:2022(E)

FINAL

TECHNICAL ISO/DTR

DRAFT

REPORT 20896-2

ISO/TC 106/SC 9

Dentistry — Digital impression

Secretariat: JISC

devices —

Voting begins on:

Part 2:

Voting terminates on:

Methods for assessing accuracy for

implanted devices

COPYRIGHT PROTECTED DOCUMENT

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.RECIPIENTS OF THIS DRAFT ARE INVITED TO

ISO copyright office

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

CP 401 • Ch. de Blandonnet 8

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

CH-1214 Vernier, Geneva

DOCUMENTATION.

Phone: +41 22 749 01 11

IN ADDITION TO THEIR EVALUATION AS

Reference number

Email: copyright@iso.org

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/DTR 20896-2:2022(E)

Website: www.iso.org

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

Published in Switzerland

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

© ISO 2022 – All rights reserved

NATIONAL REGULATIONS. © ISO 2022

---------------------- Page: 2 ----------------------

ISO/DTR 20896-2:2022(E)

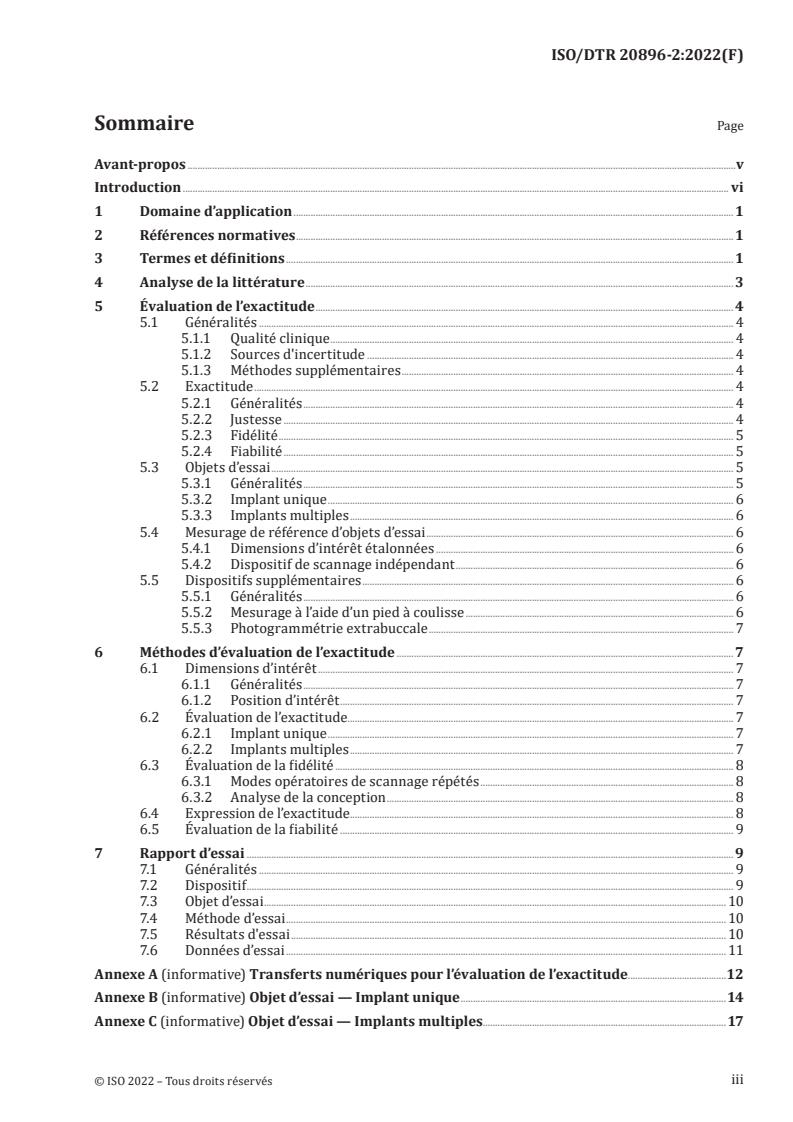

Contents Page

Foreword ..........................................................................................................................................................................................................................................v

Introduction .............................................................................................................................................................................................................................. vi

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ..................................................................................................................................................................................... 1

3 Terms and definitions .................................................................................................................................................................................... 1

4 Literature review ................................................................................................................................................................................................ 3

5 Assessment of accuracy ................................................................................................................................................................................ 3

5.1 General ........................................................................................................................................................................................................... 3

5.1.1 Clinical quality ..................................................................................................................................................................... 3

5.1.2 Sources of uncertainty .................................................................................................................................................. 4

5.1.3 Auxiliary methods ............................................................................................................................................................ 4

5.2 Accuracy ....................................................................................................................................................................................................... 4

5.2.1 General ........................................................................................................................................................................................ 4

5.2.2 Trueness ..................................................................................................................................................................................... 4

5.2.3 Precision .................................................................................................................................................................................... 5

5.2.4 External reliability ........................................................................................................................................................... 5

5.3 Test objects ................................................................................................................................................................................................ 5

5.3.1 General ........................................................................................................................................................................................ 5

5.3.2 Single implant........................................................................................................................................................................ 5

5.3.3 Multiple implants ............................................................................................................................................................... 5

5.4 Reference measurement of test objects ........................................................................................................................... 6

5.4.1 Calibrated measures of interest ........................................................................................................................... 6

5.4.2 Independent scanning device.................................................................................................................................. 6

5.5 Auxiliary devices .................................................................................................................................................................................. 6

5.5.1 General ........................................................................................................................................................................................ 6

5.5.2 Calliper measurement ................................................................................................................................................... 6

5.5.3 Extra-oral photogrammetry .................................................................................................................................... 6

6 Accuracy assessment methods .............................................................................................................................................................7

6.1 Measures of interest .......................................................................................................................................................................... 7

6.1.1 General ........................................................................................................................................................................................ 7

6.1.2 Position of interest............................................................................................................................................................ 7

6.2 A ssessment of trueness .................................................................................................................................................................. 7

6.2.1 Single implant........................................................................................................................................................................ 7

6.2.2 Multiple implants ............................................................................................................................................................... 7

6.3 Assessment of precision ................................................................................................................................................................. 8

6.3.1 Repeated scanning procedures ............................................................................................................................. 8

6.3.2 Design analysis .................................................................................................................................................................... 8

6.4 Expression of accuracy.................................................................................................................................................................... 8

6.5 A ssessment of reliability ............................................................................................................................................................... 8

7 Test report .................................................................................................................................................................................................................. 9

7.1 General ........................................................................................................................................................................................................... 9

7.2 Device ............................................................................................................................................................................................................. 9

7.3 Test object ................................................................................................................................................................................................... 9

7.4 Test method ............................................................................................................................................................................................ 10

7.5 Test results .............................................................................................................................................................................................. 10

7.6 Test data .................................................................................................................................................................................................... 10

Annex A (Informative) Scan body for accuracy assessment ....................................................................................................11

Annex B (informative) Test object — Single implant ......................................................................................................................13

Annex C (informative) Test object — Multiple implants .............................................................................................................16

Annex D (informative) Guidance on evaluating precision and external reliability .......................................18

iii© ISO 2022 – All rights reserved

---------------------- Page: 3 ----------------------

ISO/DTR 20896-2:2022(E)

Bibliography .............................................................................................................................................................................................................................22

© ISO 2022 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DTR 20896-2:2022(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.This document was prepared by Technical Committee ISO/TC 106, Dentistry, Subcommittee SC 9, Dental

CAD/CAM systems, in collaboration with the European Committee for Standardization (CEN) Technical

Committee CEN/TC 55, Dentistry, in accordance with the Agreement on technical cooperation between

ISO and CEN (Vienna Agreement).A list of all parts in the ISO 20896 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.© ISO 2022 – All rights reserved

---------------------- Page: 5 ----------------------

ISO/DTR 20896-2:2022(E)

Introduction

Dental CAD/CAM systems that produce indirect dental restorations require a 3-dimensional digitized

description, often called a digital impression, of the patient's dentition as a starting point for the design

and fabrication of inlays, crowns, bridges and larger prosthetic or orthodontic appliances. The device

that acquires and digitizes the 3-dimensional metrology data must be sufficiently accurate to enable

the manufacture of a clinically acceptable restoration.This document describes possible test methods for evaluating the accuracy of digital impression

devices designed for direct oral scanning of implant bodies, intended as support for prosthetic

appliances to replace a patient's dentition, in order to obtain a digital impression. It is a complement to

ISO 20896-1, which assesses the accuracy of digital impression devices from which a digital impression

of a patient’s dentition can be created. A companion standard, ISO 12836, provides test methods for

assessing the accuracy of fixed devices for digitizing physical impressions or models/casts made from

such impressions. Separate standards were deemed necessary after it became apparent that two of the

test objects described in ISO 12836 were unsuited for successful interpretation of data acquired with a

digital impression device.Assessment of the accuracy of digital impression devices for a full-arch test object as described in Part

1 or similar tests has revealed that intra-oral, digital impression devices are intrinsically limited in

accuracy to taking impressions of just a few teeth. Furthermore, experience and experiments with

these devices to create a digital impression after the placement of single implants, indicate that a scan

body fitted to the implant body allows an accuracy in position and orientation at least as good as for a

tooth preparation. Implants are however also an indicated treatment for fully or partially edentulous

patients. For such indications, several implant bodies are placed in the upper or lower jaw. Scanning

technology is developing rapidly, to overcome inaccuracies that occur when scanning an edentulous

patient. One hindrance to the development of a relevant method of assessing accuracy for this clinical

case is the lack of a mechanically stable material that can adequately represent mucosal tissue in a test

object.This document reviews the theory and techniques employed to exploit scan bodies to overcome the

challenges of scanning edentulous mucosal tissue by optical methods.© ISO 2022 – All rights reserved

---------------------- Page: 6 ----------------------

TECHNICAL REPORT ISO/DTR 20896-2:2022(E)

Dentistry — Digital impression devices —

Part 2:

Methods for assessing accuracy for implanted devices

1 Scope

This document describes methods of acquiring and analysing data from which the accuracy of

a numerical model of the geometry of the mucosa and implant bodies in the jaw of a patient can be

assessed.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1942, Dentistry — VocabularyISO 3534-1, Statistics — Vocabulary and symbols — Part 1: General statistical terms and terms used in

probabilityISO 5725-1, Accuracy (trueness and precision) of measurement methods and results — Part 1: General

principles and definitionsISO 16443:2014, Dentistry — Vocabulary for dental implants systems and related procedure

ISO 18739, Dentistry — Vocabulary of process chain for CAD/CAM systemsISO 20896-1, Dentistry — Digital impression devices — Part 1: Methods for assessing accuracy

ISO/IEC Guide 98-3:2008, Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in

me a s ur ement (GUM: 1995)ISO/IEC Guide 99, International vocabulary of metrology — Basic and general concepts and associated

terms (VIM)3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 1942, ISO 3534-1, ISO 5725-1,

ISO 16443, ISO 18739, ISO 20896-1, ISO/IEC Guide 98-3, ISO/IEC Guide 99 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at https:// www .electropedia .org/

3.1

digital impression data

set of numerical coordinates providing a three-dimensional representation of the surfaces of teeth and

surrounding tissue acquired directly from the patient by a digital impression device and presented in a

format suited to a computer-aided dental design and manufacturing (CAD/CAM) process

Note 1 to entry: A digital impression data set can be supplemented by data on surface colour.

© ISO 2022 – All rights reserved---------------------- Page: 7 ----------------------

ISO/DTR 20896-2:2022(E)

Note 2 to entry: A set of digital impression data are distinct from a virtual model as defined in ISO 18739. A

virtual model is produced by design or similar software.3.2

external reliability

confidence interval for an estimated dimension after eliminating gross errors (3.3) in the data as

detected by the digitizing system's softwareNote 1 to entry: External reliability is evaluated by propagation of uncertainties as estimated from the redundancy

(3.7) in an accepted data set, as described in Annex D.3.3

gross error

error in an observation arising from partial failure or incorrect calibration of a measurement device,

incorrect pattern recognition or data interpretation and leading to unacceptable error of measurement

in the digital impressionNote 1 to entry: Detection and elimination of gross errors is an essential function of the registration software for

a digital impression device.3.4

intra-oral calibration appliance

extended scan body (3.9) that is scanned together with the mucosa, residual dentition and other scan

bodies and provides internal calibration of digital impression data (3.1)3.5

position of interest

coordinates of a feature on an implant body that define the placement of the implant body

Note 1 to entry: The feature can be defined by the symmetry of the implant body, for example, its axis. It lies on a

surface of the body that is accessible when placed in a jaw.3.6

range image

two-dimensional array of data on the distances from the scanning device to the surfaces being scanned

Note 1 to entry: The array indices define direction with respect to the axis of the scanning device for which the

distance applies.3.7

redundancy

difference between the number of observations judged to be validly measured and the number of

parameters that need to be estimated to calibrate and describe movement of the scanning device and to

produce digital impression data (3.1)Note 1 to entry: The software of a digitizing device may exploit redundancy to perform an assessment of raw

data in order to detect gross errors (3.3) by statistical testing (see Annex D).3.8

reference impression data

set of three-dimensional coordinates acquired by a digital impression device or a combination of

scanning device and digitizing device that represent the surfaces to a better precision than that of the

device being assessed3.9

scan body

implant impression post with a numerically defined geometric shape from which the position and

orientation of an implant body can be determined in a scanning procedure© ISO 2022 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DTR 20896-2:2022(E)

4 Literature review

Intra-oral scanning builds on 170 years of development in photogrammetry. It belongs to the branch

[4]known as close-range photogrammetry and where it represents very close-range. In the confines of

the mouth, a scanning device requires miniature components with their attendant need for continual

re-calibration in the face of considerable image distortion.Articles relevant to assessing accuracy in scanning in the oral cavity to produce digital impression data

for existing dentition or an edentulous jaw were searched by the keywords: “intra-oral scanning” and

“accuracy”. Of an initial list totalling 158 articles from the period 2013 to June 2020, sub-lists for those

concentrating on scanning an edentulous jaw (29 articles) and those scanning a full arch with full or

partial dentition (59 articles) were chosen for review. Figure 1 shows the number of articles by year of

publication. Many studies compare digitizing devices from several manufacturers.Key

edentulous

full-arch

other

Figure 1 — Refereed articles with search keywords “intra-oral scanning” and “accuracy”

The diversity of methods and variety of statistics employed show that consensus on appropriate

methods of benchmarking digital impression devices would benefit both device manufacturers, their

customers and, in some jurisdictions, regulatory authorities.5 Assessment of ac curacy

5.1 General

5.1.1 Clinical quality

Since digital impression data are the input to the process of designing and manufacturing, a dental

prosthetic appliance, its accuracy, within clinically acceptable tolerances, is a quality factor to be

controlled. When a prosthesis is placed on two or more prepared teeth, a clinical requirement on

uncertainty in separation of critical features is that it be less than approximately 100 µm. When

placing a prosthetic appliance on two or more implant abutments, the requirement on accuracy is more

stringent.© ISO 2022 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DTR 20896-2:2022(E)

5.1.2 Sources of uncertainty

Digital impression devices that rely solely on numerical registration methods to combine a large

number of small range images of three-dimensional surfaces into a large model are subject to

uncertainties. These arise from the registration of overlapping range images where the uncertainty

depends on the number of data elements in the overlap. The uncertainty increases as it is propagated

across a scanned region, leading to large uncertainties in relative positions and orientations derived for

features at the extreme ends of a scanning pattern. For full-arch scanning, the accuracy has been shown

to be unacceptably poor, but techniques are evolving to improve accuracy. It is therefore desirable that

standard methods for comparing techniques and instrumentation be available by providing measures

of interest by which accuracy can be assessed.5.1.3 Auxiliary methods

Some solutions for reducing uncertainties employ auxiliary methods of measurement or calibration.

These can be both intra- and extra-oral. The auxiliary data are utilized either directly in the registration

of range images or employed in a separate numerical algorithm to correct for distortion in the digital

impression data. In order to be utilized directly, the results or data from auxiliary measurements are

available prior to taking the digital impression data.5.2 Accuracy

5.2.1 General

Accuracy is a general concept that includes both trueness and precision or reliability. Operational

procedures for estimating trueness, precision and reliability are presented as means for assessing

accuracy.5.2.2 Trueness

For digital impression data, the operations by which trueness is assessed can be of two types:

a) Direct comparison with independent, calibrated measurements of particular measures of interest:

these measures are distances or angles relative to a reference plane which itself is defined by the

dentition, as in Annex A or by one or more auxiliary devices.b) Estimation of a goodness-of-fit statistic derived from overall comparison with reference impression

data: this method of assessment frequently disguises serious discrepancies that are of limited

spatial extent. Assessments employing this methodology can require the digital impression data to

fit reference impression data at a clinically relevant, limited, contiguous subset of points at or near

one extreme of the scanning pattern, for example, a scan body, and then determine the quality of fit

of a similar feature (e.g. a second scan body) near the opposite extreme.Goodness-of-fit statistics expressed in the units of the measures of interest give the user a clearer

basis for comparison than those expressed as in relative terms; i.e. as percentages.

Clinically, trueness is ultimately determined when a prosthetic appliance, which has been designed and

manufactured from the digital impression data, is placed in the patient’s mouth. Quality management

[2]procedures and systems can build up data records that, on review, allow assessment of trueness of

the digital impressions upon which prosthesis design and manufacturing are based.

© ISO 2022 – All rights reserved---------------------- Page: 10 ----------------------

ISO/DTR 20896-2:2022(E)

5.2.3 Precision

By precision is meant that repeated measurements with the digital impression device agree to within a

nominated tolerance regardless of operator, provided the scanning is performed within the guidelines

supplied with the device. Assessments of precision are of two types:a) Repeated measurements of measures of interest and evaluation of statistics that describe

variability, as described in Part 1, This is a Type A evaluation of uncertainty.The precision of this determination is expressed as standard uncertainty σ. When the precision

in a value is derived from the standard deviation S of n repeated measurements, the standard

uncertainty is:σ = S/√n

b) Deduction from knowledge of the design and mode of operation of the scanning device and the

algorithms employed to extract a digital impression from raw data. This is a Type B evaluation of

uncertainty.5.2.4 External reliability

Determination of reliability (see Annex D) assesses the precision of given digital impression data derived

from a single scanning procedure. It provides a measure of the contribution of errors in observations

to uncertainties in the digital impression data. The determination of reliability exploits the excess over

the minimum necessary number of measurements, or redundancy, in the data acquired in the course of

a single scanning procedure, and employs it eithera) within the scanning and registration algorithm to indicate when adequate data have been acquired

to achieve a given precision, orb) in post-analysis to detect and eliminate gross errors arising from unpredictable sources and then

to estimate the residual uncertainties.5.3 Test objects

...

ISO/TC 106/SC 9 N 229

Date: 2022-03-30

ISO/TR 20896--2:2022(E)

ISO TC 106/SC 9/WG 3

Secretariat: JISC

Dentistry — Digital impression devices — Part 2: Methods for assessing the accuracy of scanning

for implanted devicesFirst edition

Date: 2022-09-13

---------------------- Page: 1 ----------------------

ISO/TR 20896-2:2022(E)

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of

this publication may be reproduced or utilized otherwise in any form or by any means, electronic or

mechanical, including photocopying, or posting on the internet or an intranet, without prior written

permission. Permission can be requested from either ISO at the address below or ISO’sISO's member body

in the country of the requester.ISO Copyright Office

CP 401 • CH. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: + 41 22 749 01 11

Email: copyright@iso.org copyright@iso.org

Website: www.iso.orgwww.iso.org

Published in Switzerland.

ii © ISO 2022 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TR 20896-2:2022(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national

standards bodies (ISO member bodies). The work of preparing International Standards is normally

carried out through ISO technical committees. Each member body interested in a subject for which a

technical committee has been established has the right to be represented on that committee.

International organizations, governmental and non-governmental, in liaison with ISO, also take part in

the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.This document was prepared by Technical Committee ISO/TC 106, Dentistry, Subcommittee SC 9, Dental

CAD/CAM systems., in collaboration with the European Committee for Standardization (CEN) Technical

Committee CEN/TC 55, Dentistry, in accordance with the Agreement on technical cooperation between

ISO and CEN (Vienna Agreement).A list of all parts in the ISO 20896 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.© ISO 2022 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TR 20896-2:2022(E)

Introduction

Dental CAD/CAM systems that produce indirect dental restorations require a 3-dimensional digitized

description, often called a digital impression, of the patient's dentition as a starting point for the design

and fabrication of inlays, crowns, bridges and larger prosthetic or orthodontic appliances. The device

that acquires and digitizes the 3-dimensional metrology data must be sufficiently accurate to enable the

manufacture of a clinically acceptable restoration.This document describes possible test methods for evaluating the accuracy of digital impression devices

designed for direct oral scanning of implant bodies, intended as support for prosthetic appliances to

replace a patient's dentition, in order to obtain a digital impression. It is a complement to Part 1 (ISO

20896-1), which is a standard for assessingassesses the accuracy of digital impression devices from

which a digital impression of a patient’s dentition can be created. A companion standard, ISO 12836,

provides test methods for assessing the accuracy of fixed devices for digitizing physical impressions or

models/casts made from such impressions. Separate standards were deemed necessary after it became

apparent that two of the test objects described in ISO 12836 were unsuited for successful interpretation

of data acquired with a digital impression device.Assessment of the accuracy of digital impression devices for a full-arch test object as described in Part 1

or similar tests has revealed that intra-oral, digital impression devices are intrinsically limited in

accuracy to taking impressions of just a few teeth. Furthermore, experience and experiments with these

devices to create a digital impression after the placement of single implants, indicate that a scan body

fitted to the implant body allows an accuracy in position and orientation at least as good as for a tooth

preparation. Implants are however also an indicated treatment for fully or partially edentulous patients.

For such indications, several implant bodies are placed in the upper or lower jaw. Scanning technology

is developing rapidly, to overcome inaccuracies that occur when scanning an edentulous patient. One

hindrance to the development of a relevant method of assessing accuracy for this clinical case is the lack

of a mechanically stable material that can adequately represent mucosal tissue in a test object.

This document reviews the theory and techniques employed to exploit scan bodies to overcome the

challenges of scanning edentulous mucosal tissue by optical methods.iv © ISO 2022 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TR 20896-2:2022(E)

Dentistry — Digital impression devices — Part 2: Methods for

assessing the accuracy of scanning for implanted devices

1 Scope

This document describes methods of acquiring and analysing data from which the accuracy of a

numerical model of the geometry of the mucosa and implant bodies in the jaw of a patient can be

assessed.[1]

NOTE 1 ISO 20896-1 specifies test methods for the assessment of accuracy of digitizing devices used

intra-orally on patients with complete or almost complete dentition.[2]

NOTE 2 ISO 12836 specifies the test methods for the assessment of accuracy of digitizing devices

used in a dental laboratory.32 Normative references

There are no normative references in this document.

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1942, Dentistry — VocabularyISO 3534-1, Statistics — Vocabulary and symbols — Part 1: General statistical terms and terms used in

probabilityISO 5725-1, Accuracy (trueness and precision) of measurement methods and results — Part 1: General

principles and definitionsISO 16443:2014, Dentistry — Vocabulary for dental implants systems and related procedure

ISO 18739, Dentistry — Vocabulary of process chain for CAD/CAM systemsISO 20896-1, Dentistry — Digital impression devices — Part 1: Methods for assessing accuracy

ISO/IEC Guide 98-3:2008, Uncertainty of measurement — Part 3: Guide to the expression of uncertainty

in measurement (GUM:1995)ISO/IEC Guide 99, International vocabulary of metrology — Basic and general concepts and associated

terms (VIM)43 Terms and definitions

[3] [4]

For the purposes of this document, the terms and definitions given in ISO 1942 ,, ISO 3534-1 ,, ISO

[5] [6] [7] [1] [8] [9]5725-1 ,, ISO 16443 ,, ISO 18739 ,, ISO 20896-1 ,, ISO/IEC Guide 98-3 ,, ISO/IEC Guide 99 and

the following apply.© ISO 2022 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO/TR 20896-2:2022(E)

ISO and IEC maintain terminologicalterminology databases for use in standardization at the following

addresses:— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

digital impression data

set of numerical coordinates providing a three-dimensional representation of the surfaces of teeth and

surrounding tissue acquired directly from the patient by a digital impression device and presented in a

format suited to a computer-aided dental design and manufacturing (CAD/CAM) process

Note 1 to entry: A digital impression data set can be supplemented by data on surface colour.

Note 2 to entry: A set of digital impression data isare distinct from a virtual model as defined in ISO 18739. A

virtual model is produced by design or similar software.3.2

external reliability

confidence interval for an estimated dimension after eliminating gross errors (3.3) in the data as

detected by the digitizing system's softwareNote 1 to entry: External reliability is evaluated by propagation of uncertainties as estimated from the redundancy

(3.7) in an accepted data set, as described in Annex D.3.3

gross error

error in an observation arising from partial failure or incorrect calibration of a measurement device,

incorrect pattern recognition or data interpretation and leading to unacceptable error of measurement

in the digital impressionNote 1 to entry: Detection and elimination of gross errors is an essential function of the registration software for a

digital impression device.3.4

intra-oral calibration appliance

extended scan body (3.9) that is scanned together with the mucosa, residual dentition and other scan

bodies and provides internal calibration of digital impression data. (3.1)3.5

position of interest

coordinates of a feature on an implant body that define the placement of the implant body

Note 1 to entry: The feature can be defined by the symmetry of the implant body, for example, its axis. It lies on a

surface of the body that is accessible when placed in a jaw.3.6

range image

two-dimensional array of data on the distances from the scanning device to the surfaces being scanned

Note 1 to entry: The array indices define direction with respect to the axis of the scanning device for which the

distance applies.3.7

redundancy

2 © ISO 2022 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/TR 20896-2:2022(E)

difference between the number of observations judged to be validly measured and the number of

parameters that need to be estimated to calibrate and describe movement of the scanning device and to

produce digital impression data (3.1)Note 1 to entry: The software of a digitizing device may exploit redundancy to perform an assessment of raw data

in order to detect gross errors (3.3) by statistical testing. (see Annex D)).3.8

reference impression data

set of three-dimensional coordinates acquired by a digital impression device or a combination of

scanning device and digitizing device that represent the surfaces to a better precision than that of the

device being assessed3.9

scan body

implant impression post with a numerically defined geometric shape from which the position and

orientation of an implant body can be determined in a scanning procedure54 Literature review

Intra-oral scanning builds on 170 years of development in photogrammetry. It belongs to the branch

[12] [4]known as close-range photogrammetry and where it represents very close-range .. In the confines

of the mouth, a scanning device requires miniature components with their attendant need for continual

re-calibration in the face of considerable image distortion.Articles relevant to assessing accuracy in scanning in the oral cavity to produce digital impression data

for existing dentition or an edentulous jaw were searched by the key wordskeywords: “intra-oral

scanning” and “accuracy”. Of an initial list totalling 158 articles from the period 2013 to June 2020, sub-

lists for those concentrating on scanning an edentulous jaw (29 articles) and those scanning a full arch

with full or partial dentition (59 articles) were chosen for review. Figure 1 shows the number of articles

by year of publication. Many studies compare digitizing devices from several manufacturers.

Intra-oral scanning ; accuracy2020 2019 2018 2017 2016 2015 2014 2013

Edentulous Full-arch Other

© ISO 2022 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO/TR 20896-2:2022(E)

Key

edentulous

full-arch

other

Figure 1 – — Refereed articles with search key wordskeywords “intra-oral scanning” and

“accuracy”The diversity of methods and variety of statistics employed show that consensus on appropriate

methods of benchmarking digital impression devices would benefit both device manufacturers, their

customers and, in some jurisdictions, regulatory authorities.65 Assessment of accuracy

6.15.1 General

6.1.15.1.1 Clinical quality

Since digital impression data are the input to the process of designing and manufacturing, a dental

prosthetic appliance, its accuracy, within clinically acceptable tolerances, is a quality factor to be

controlled. When a prosthesis is placed on two or more prepared teeth, a clinical requirement on

uncertainty in separation of critical features is that it be less than approximately 100 µm. When placing

a prosthetic appliance on two or more implant abutments, the requirement on accuracy is more

stringent.6.1.25.1.2 Sources of uncertainty

Digital impression devices that rely solely on numerical registration methods to combine a large

number of small range images of three-dimensional surfaces into a large model are subject to

uncertainties. These arise from the registration of overlapping range images where the uncertainty

depends on the number of data elements in the overlap. The uncertainty increases as it is propagated

across a scanned region, leading to large uncertainties in relative positions and orientations derived for

features at the extreme ends of a scanning pattern. For full-arch scanning, the accuracy has been shown

to be unacceptably poor, but techniques are evolving to improve accuracy. It is therefore desirable that

standard methods for comparing techniques and instrumentation be available by providing measures of

interest by which accuracy can be assessed.4 © ISO 2022 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/TR 20896-2:2022(E)

6.1.35.1.3 Auxiliary methods

Some solutions for reducing uncertainties employ auxiliary methods of measurement or calibration.

These can be both intra- and extra-oral. The auxiliary data are utilisedutilized either directly in the

registration of range images or employed in a separate numerical algorithm to correct for distortion in

the digital impression data. In order to be utilisedutilized directly, the results or data from auxiliary

measurements are available prior to taking the digital impression data.6.25.2 Accuracy

6.2.15.2.1 General

Accuracy is a general concept that includes both trueness and precision or reliability. Operational

procedures for estimating trueness, precision and reliability are presented as means for assessing

accuracy.6.2.25.2.2 Trueness

For digital impression data, the operations by which trueness is assessed can be of two types:

a) Direct comparison with independent, calibrated measurements of particular measures of interest.:

these measures are distances or angles relative to a reference plane which itself is defined by the

dentition, as in Annex A or by one or more auxiliary devices.b) Estimation of a goodness-of-fit statistic derived from overall comparison with reference impression

data.: this method of assessment frequently disguises serious discrepancies that are of limited

spatial extent. It is therefore recommended that assessmentAssessments employing this

methodology can require the digital impression data to fit reference impression data at a clinically

relevant, limited, contiguous subset of points at or near one extreme of the scanning pattern, for

example, a scan body, and then determine the quality of fit of a similar feature (for example,e.g. a

second scan body) near the opposite extreme.Goodness-of-fit statistics expressed in the units of the measures of interest give the user a clearer

basis for comparison than those expressed as in relative terms; i.e. as percentages.

Clinically, trueness is ultimately determined when a prosthetic appliance, which has been designed and

manufactured from the digital impression data, is placed in the patient’s mouth. Quality management

[10[2]procedures and systems can build up data records that, on review, allow assessment of trueness of

the digital impressions upon which prosthesis design and manufacturing are based.

6.2.35.2.3 PrecisionBy precision is meant that repeated measurements with the digital impression device agree to within a

nominated tolerance regardless of operator, provided the scanning is performed within the guidelines

supplied with the device. Assessments of precision are of two types:a) Repeated measurements of measures of interest and evaluation of statistics that describe

variability, as described in Part 1, This is a Type A evaluation of uncertainty.The precision of this determination is expressed as standard uncertainty σ. When the precision in a

value is derived from the standard deviation S of n repeated measurements, the standard

uncertainty is:σ = S/√n

b) Deduction from knowledge of the design and mode of operation of the scanning device and the

algorithms employed to extract a digital impression from raw data. This is a Type B evaluation of

uncertainty.© ISO 2022 – All rights reserved 5

---------------------- Page: 9 ----------------------

ISO/TR 20896-2:2022(E)

6.2.45.2.4 5.2.4 External reliability

Determination of reliability (see Annex D) assesses the precision of given digital impression data

derived from a single scanning procedure. It provides a measure of the contribution of errors in

observations to uncertainties in the digital impression data. The determination of reliability exploits the

excess over the minimum necessary number of measurements, or redundancy, in the data acquired in

the course of a single scanning procedure, and employs it eithera) within the scanning and registration algorithm to indicate when adequate data have been acquired

to achieve a given precision, orb) in post-analysis to detect and eliminate gross errors arising from unpredictable sources and then to

estimate the residual uncertainties.6.35.3 Test objects

6.3.15.3.1 General

Test objects are material models of dentition or edentulous tissue on one jaw employed for assessing

the accuracy of a digital impression device. When scanned in order to assess the accuracy of a digital

impression device, the scanning pattern conforms to that used in a clinical situation.

The principles outlined in this document for assessing precision and accuracy, are not compatible with

the exploitation of the dimensions for the proposed scan body. The scan body design in Annex A

includes features intended to be measured independently as noted in Clause B.3., in order to build up a

redundant set of observations that maycan be assessed for external reliability by the method ofin

Annex D.6.3.25.3.2 Single implant

Annex A describes a test object and measures of interest for assessing accuracy when scanning a single

implant body with an attached scan body.6.3.35.3.3 Multiple implants

Annex B describes a test object with more than one implant where design of a clinically acceptable

prosthetic device requires accuracy in relative position and orientation.6.45.4 Reference measurement of test objects

6.4.15.4.1 Calibrated measures of interest

The dimensions of interest of the test object as designated in Annex B and Annex C are determined by

an independent, calibrated measurement traceable to the internationally adopted standard of length.

The values obtained are considered the true values for the dimensions of interest. The conditions of

temperature and humidity under which the determination is made are measured and recorded.

Where precision is obtained from a Type B evaluation of standard uncertainty as defined by ISO/IEC

Guide 98-3 (GUM: :2008) §, 4.3, an appropriate conversion to standard uncertainty is cited.

The standard uncertainty in the reference values of the measures of interest is not greater than one-

fifth of (i.e. 0,2 times) the accuracy expected, required or claimed for the digitizing device.

6.4.25.4.2 Independent scanning deviceWhere trueness is assessed according to 5.2.2 b), or precision according to 5.2.3 b), the independent

scanning device is capable of creating reference impression data to a precision with a standard

uncertainty no greater than one-half the accuracy expected, required or claimed for the digitizing device

being assessed.6 © ISO 2022 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/TR 20896-2:2022(E)

6.55.5 Auxiliary devices

6.5.15.5.1 General

The purpose of an auxiliary measurement of the geometry of the dentition or mucosal surface is to

allow closure of the linear series of scanning frames acquired by a digital impression device during a

scanning procedure. The auxiliary measurement provides additional and more precise data on the

relative positions within the scan pattern. The following clauses describe methods mentioned in

published reports.6.5.25.5.2 Calliper measurement

Caliper measurement can provide an independent estimate of the distance between an identifiable

feature on each implant scan body on the scanning pattern. The distance between such features is in the

range (40 ± ± 20) mm and the uncertainty in this dimension required for clinical acceptability is

100 µm (at 95 % confidence limit). Since, however, This distance measurement has to imposeimposes a

significant constraint within the registration algorithm, anif its uncertainty is less than or equal to

50 µm is recommended.6.5.35.5.3 Extra-oral photogrammetry

For measuring implant positions and orientations, a device that acquires data in a single range image on

distance and angular direction to specially designed scan bodies. In one implementation, the scan body

has a flag-like superstructure, which is patterned to allow their orientation to be interpreted from a

single optical image or a pair of stereographic images.For this technique to improve to the accuracy of digital impression data, the resolution of the extra-oral

data acquisition device must allow feature identification over approximately 40 mm at a distance of

(100 ± 20) mm to provide a precision of 0,025 mm. To achieve this, features within an angular range of

(25 ± 11)° need)° are to be resolved to one part in two thousand. This requires up to 6000 6 000 sensor

elements in the lateral direction, where a minimum of three elements is required to identify a feature.

76 Accuracy assessment methods7.16.1 Measures of interest

7.1.16.1.1 General

The measures of interest are defined by positions and directions in an appropriate reference system.

Recommended reference systems are described in Annex A and Annex B.7.1.26.1.2 Position of interest

The recommended position of interest for an implant body is the point where the axis of implant body

intersects the connecting interface. The geometrical description of the surface of a scan body takes this

point as its origin.NOTE 1 : The term connecting interface is defined in ISO 16443:2014, 3.2.8

NOTE 2 : Where an implant body is designed to receive an abutment screw, the position of interest can be

defined as the intersection of the axis of the implant body with the surface of the implant body to which the

abutment matches.7.26.2 Assessment of trueness

7.2.16.2.1 Single implant

Annex A describes a test object and measures of interest for assessing accuracy when scanning a single

implant body with an attached scan body.© ISO 2022 – All rights reserved 7

---------------------- Page: 11 ----------------------

ISO/TR 20896-2:2022(E)

7.2.26.2.2 Multiple implants

The principles for the design and calibration of test objects designed to assess the accuracy of a digital

impression device and auxiliary devices are outlined in Annex A and Annex B. Additional measures of

interest are given in Annex C.For assessment of trueness according to 4.1.1 a), it is recommended that the measures of interest beare

extracted from the digital impression data and compared directly with the corresponding reference

values.For assessment of trueness according to 4.1.1 b),

a) The digital impression data acquired by the digital impression device and the reference impression

data are registered to minimize the goodness-of-fit statistic over the surface of one scan body (at

one end of the scanning range where more than two scan bodies are scanned) and the mucosal

surface. The goodness of fit is recorded.b) The goodness of fit for the surface of the neighbouring scan body in the digital impression and in

the reference impression is then evaluated and recorded.Where more than two scan bodies are scanned,

c) the digital impression data are then registered to minimize the goodness-of-fit statistic over both

the first and successive, neighbouring scan bodies, and the minimum goodness of fit evaluated and

recorded.d) steps 2 and 3 are repeated for the surfaces of further neighbouring scan bodies, each time including

only previously assessed scan bodies in the registration.Trueness is evaluated as the difference between the goodness of fit for the ultimate scan body as

evaluated at step in 6.2.2 b) and the goodness of fit evaluated in step 1.6.2.2 a).

7.36.3 Assessment of precision7.3.16.3.1 Repeated scanning procedures

For assessment of precision, the recommended scanning procedure is performed at least five (5) times

according to the instructions provided for the given indication as described in 6.2. Precision is

expressed as the largest standard uncertainty evaluated for the measures of interest or in the goodness

of fit.Data from all repetitions of the scanning procedure are included in the estimation of the standard

uncertainty. Exclusion is allowed if the digitizing device itself identifies a scanning procedure as

improperly or inadequately performed.7.3.26.3.2 Design analysis

Since the major source of uncertainty in intra-oral scanning is registration of successive range images,

the uncertainty in the relative orientation angles and displacements of overlapping frames can be

evaluated from the numbers of data in two orthogonal directions in each overlap. The uncertainty

estimation includes the number of data required to identify features in the overlap.

Where registration is based on overall shape of the scanned surface within an overlap, and determined

by minimizing a goodness-of-fit statistic, the residual misfit is propagated to estimate uncertainties in

the change between overlapping range images in:a) three angles describing camera rotation, and

b) three components of camera displacement.

8 © ISO 2022 – All rights reserved

---------------------- Page: 12 ----------------------

ISO/TR 20896-2:2022(E)

The uncertainty estimates derived above is then propagated to derive the uncertainty in relative

positions and orientations of scan bodies separated as described for the clinical indication for which

assessment of precision is required.7.46.4 Expression of accuracy

The accuracy in the measurement of a measure of interest is assessed as the combination of the

trueness and the precision. The accuracy in the i measure of interest is evaluated as the greater of the

standard uncertainty in the reference value and root-mean-square difference between the measured

values and the reference value; that is by evaluating the statistic:d − d

( )

j ,,i Ri

j=1

s =

𝑛𝑛

�𝑑𝑑 −𝑑𝑑 �

⎛ ⎞

𝑗𝑗,𝑖𝑖 𝑅𝑅,𝑖𝑖

𝑗𝑗=1

𝑠𝑠 = max ,𝜎𝜎�𝑑𝑑 �

𝑖𝑖 𝑅𝑅,𝑖𝑖

⎜ ⎟

𝑛𝑛

⎝ ⎠

where

si is the accuracy of measurement of the i measure of interest

th th

d is the j measured value of the i measure of interest

j,i

d is the reference value for the i measure of interest

R,i

σ(d ) is the standard uncertainty in the reference value for the i measure of

R,i

interest

s is the root-mean-square difference between the measured values and reference value for

the measure of interestth th

d is the j measured value of the i measure of interest;

j,i

d is the reference value for the i measure of interest.

R,i

7.56.5 Assessment of reliability

The principles of estimating the reliability of a scanning procedure are described in Annex D. Reliability

can be improved by increasing redundancy; that is by performing additional scanning on a different

scanning pattern in order to reveal gross errors that can then be eliminated.Reliability can also be improved by incorporating independent, auxiliary observations regarding the

scan bodies or implant bodies into the numerical algorithm that minimizes the goodness of

...PROJET

RAPPORT ISO/DTR

FINAL

TECHNIQUE 20896-2

ISO/TC 106/SC 9

Médecine bucco-dentaire —

Secrétariat: JISC

Dispositifs d'empreinte numérique —

Début de vote:

2022-09-28

Partie 2:

Vote clos le:

Méthodes d'évaluation de l'exactitude

2022-12-21

de dispositifs implantés

Dentistry — Digital impression devices —

Part 2: Methods for assessing accuracy for implanted devices

LES DESTINATAIRES DU PRÉSENT PROJET SONT

INVITÉS À PRÉSENTER, AVEC LEURS OBSER-

VATIONS, NOTIFICATION DES DROITS DE PRO-

PRIÉTÉ DONT ILS AURAIENT ÉVENTUELLEMENT

CONNAISSANCE ET À FOURNIR UNE DOCUMEN-

TATION EXPLICATIVE.

OUTRE LE FAIT D’ÊTRE EXAMINÉS POUR

ÉTABLIR S’ILS SONT ACCEPTABLES À DES FINS

INDUSTRIELLES, TECHNOLOGIQUES ET COM-

Numéro de référence

MERCIALES, AINSI QUE DU POINT DE VUE

ISO/DTR 20896-2:2022(F)

DES UTILISATEURS, LES PROJETS DE NORMES

INTERNATIONALES DOIVENT PARFOIS ÊTRE

CONSIDÉRÉS DU POINT DE VUE DE LEUR POSSI-

BILITÉ DE DEVENIR DES NORMES POUVANT

SERVIR DE RÉFÉRENCE DANS LA RÉGLEMENTA-

TION NATIONALE. © ISO 2022

---------------------- Page: 1 ----------------------

ISO/DTR 20896-2:2022(F)

PROJET

RAPPORT ISO/DTR

FINAL

TECHNIQUE 20896-2

ISO/TC 106/SC 9

Médecine bucco-dentaire —

Secrétariat: JISC

Dispositifs d'empreinte numérique —

Début de vote:

2022-09-28

Partie 2:

Vote clos le:

Méthodes d'évaluation de l'exactitude

2022-12-21

de dispositifs implantés

Dentistry — Digital impression devices —

Part 2: Methods for assessing accuracy for implanted devices

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2022

Tous droits réservés. Sauf prescription différente ou nécessité dans le contexte de sa mise en œuvre, aucune partie de cette

publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique,

LES DESTINATAIRES DU PRÉSENT PROJET SONTy compris la photocopie, ou la diffusion sur l’internet ou sur un intranet, sans autorisation écrite préalable. Une autorisation peut

INVITÉS À PRÉSENTER, AVEC LEURS OBSER-VATIONS, NOTIFICATION DES DROITS DE PRO-

être demandée à l’ISO à l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

PRIÉTÉ DONT ILS AURAIENT ÉVENTUELLEMENTISO copyright office

CONNAISSANCE ET À FOURNIR UNE DOCUMEN-

TATION EXPLICATIVE.

Case postale 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Genève OUTRE LE FAIT D’ÊTRE EXAMINÉS POUR

ÉTABLIR S’ILS SONT ACCEPTABLES À DES FINS

Tél.: +41 22 749 01 11

INDUSTRIELLES, TECHNOLOGIQUES ET COM-

Numéro de référence

E-mail: copyright@iso.org

MERCIALES, AINSI QUE DU POINT DE VUE

ISO/DTR 20896-2:2022(F)

Web: www.iso.org

DES UTILISATEURS, LES PROJETS DE NORMES

INTERNATIONALES DOIVENT PARFOIS ÊTRE

Publié en Suisse

CONSIDÉRÉS DU POINT DE VUE DE LEUR POSSI-

BILITÉ DE DEVENIR DES NORMES POUVANT

SERVIR DE RÉFÉRENCE DANS LA RÉGLEMENTA-

© ISO 2022 – Tous droits réservés

TION NATIONALE. © ISO 2022

---------------------- Page: 2 ----------------------

ISO/DTR 20896-2:2022(F)

Sommaire Page

Avant-propos ...............................................................................................................................................................................................................................v

Introduction .............................................................................................................................................................................................................................. vi

1 Domaine d’application ................................................................................................................................................................................... 1

2 Références normatives ..................................................................................................................................................................................1

3 Termes et définitions ...................................................................................................................................................................................... 1

4 Analyse de la littérature .............................................................................................................................................................................. 3

5 Évaluation de l’exactitude .......................................................................................................................................................................... 4

5.1 Généralités ................................................................................................................................................................................................. 4

5.1.1 Qualité clinique .................................................................................................................................................................... 4

5.1.2 Sources d'incertitude ..................................................................................................................................................... 4

5.1.3 Méthodes supplémentaires ....................................................................................................................................... 4

5.2 Exactitude ................................................................................................................................................................................................... 4

5.2.1 Généralités ............................................................................................................................................................................... 4

5.2.2 Justesse ....................................................................................................................................................................................... 4

5.2.3 Fidélité ......................................................................................................................................................................................... 5

5.2.4 Fiabilité ....................................................................................................................................................................................... 5

5.3 Objets d’essai ............................................................................................................................................................................................ 5

5.3.1 Généralités ............................................................................................................................................................................... 5

5.3.2 Implant unique ..................................................................................................................................................................... 6

5.3.3 Implants multiples ............................................................................................................................................................ 6

5.4 Mesurage de référence d’objets d’essai ............................................................................................................................. 6

5.4.1 Dimensions d’intérêt étalonnées ......................................................................................................................... 6

5.4.2 Dispositif de scannage indépendant ................................................................................................................. 6

5.5 Dispositifs supplémentaires ....................................................................................................................................................... 6

5.5.1 Généralités ............................................................................................................................................................................... 6

5.5.2 Mesurage à l’aide d’un pied à coulisse ............................................................................................................. 6

5.5.3 Photogrammétrie extrabuccale ............................................................................................................................ 7

6 Méthodes d’évaluation de l’exactitude ......................................................................................................................................... 7

6.1 Dimensions d’intérêt ......................................................................................................................................................................... 7

6.1.1 Généralités ............................................................................................................................................................................... 7

6.1.2 Position d’intérêt ................................................................................................................................................................ 7

6.2 Évaluation de l’exactitude ........................................................................................................................................... .................. 7

6.2.1 Implant unique ..................................................................................................................................................................... 7

6.2.2 Implants multiples ............................................................................................................................................................ 7

6.3 Évaluation de la fidélité .................................................................................................................................................................. 8

6.3.1 Modes opératoires de scannage répétés ....................................................................................................... 8

6.3.2 Analyse de la conception ............................................................................................................................................. 8

6.4 Expression de l’exactitude ............................................................................................................................................................ 8

6.5 Évaluation de la fiabilité ................................................................................................................................................................ 9

7 Rapport d’essai ...................................................................................................................................................................................................... 9

7.1 Généralités ................................................................................................................................................................................................. 9

7.2 Dispositif ...................................................................................................................................................................................................... 9

7.3 Objet d’essai ............................................................................................................................................................................................ 10

7.4 Méthode d’essai ................................................................................................................................................................................... 10

7.5 Résultats d'essai ................................................................................................................................................................................. 10

7.6 Données d’essai ................................................................................................................................................................................... 11

Annexe A (informative) Transferts numériques pour l’évaluation de l’exactitude ........................................12

Annexe B (informative) Objet d’essai — Implant unique ............................................................................................................14

Annexe C (informative) Objet d’essai — Implants multiples...................................................................................................17

iii© ISO 2022 – Tous droits réservés

---------------------- Page: 3 ----------------------

ISO/DTR 20896-2:2022(F)

Annexe D (informative) Recommandations relatives à l’évaluation de la fidélité et de

la fiabilité ..................................................................................................................................................................................................................19

Bibliographie ...........................................................................................................................................................................................................................23

© ISO 2022 – Tous droits réservés---------------------- Page: 4 ----------------------

ISO/DTR 20896-2:2022(F)

Avant-propos

L’ISO (Organisation internationale de normalisation) est une fédération mondiale d’organismes

nationaux de normalisation (comités membres de l’ISO). L’élaboration des Normes internationales est

en général confiée aux comités techniques de l’ISO. Chaque comité membre intéressé par une étude

a le droit de faire partie du comité technique créé à cet effet. Les organisations internationales,

gouvernementales et non gouvernementales, en liaison avec l’ISO participent également aux travaux.

L’ISO collabore étroitement avec la Commission électrotechnique internationale (IEC) en ce qui

concerne la normalisation électrotechnique.Les procédures utilisées pour élaborer le présent document et celles destinées à sa mise à jour sont

décrites dans les Directives ISO/IEC, Partie 1. Il convient, en particulier de prendre note des différents

critères d'approbation requis pour les différents types de documents ISO. Le présent document

a été rédigé conformément aux règles de rédaction données dans les Directives ISO/IEC, Partie 2

(voir www.iso.org/directives).L’attention est appelée sur le fait que certains des éléments du présent document peuvent faire l’objet de

droits de propriété intellectuelle ou de droits analogues. L’ISO ne saurait être tenue pour responsable

de ne pas avoir identifié de tels droits de propriété et averti de leur existence. Les détails concernant

les références aux droits de propriété intellectuelle ou autres droits analogues identifiés lors de

l’élaboration du document sont indiqués dans l’Introduction et/ou dans la liste des déclarations de

brevets rédigées par l’ISO (voir www.iso.org/brevets).Les appellations commerciales éventuellement mentionnées dans le présent document sont données

pour information, par souci de commodité, à l’intention des utilisateurs et ne sauraient constituer un