SIST ISO 8217:2024

(Main)Products from petroleum, synthetic and renewable sources - Fuels (class F) - Specifications of marine fuels

Products from petroleum, synthetic and renewable sources - Fuels (class F) - Specifications of marine fuels

This document in its entirety defines the general requirements and specifications for fuels used in marine diesel engines and boilers, prior to onboard fuel handling (storage, settling, centrifuging, filtration, heating) before use.

For the purposes of this document, the term “fuels” comprises of the following:

- hydrocarbons from petroleum crude oil, oil sands and shale oil;

- synthetic hydrocarbons, renewable hydrocarbons or hydrocarbons from recycled sources, with molecular structures that are indistinguishable from petroleum hydrocarbons;

- fatty acid methyl ester (FAME), where permitted as specified in this document;

- blends of any of the above, where permitted as specified in this document.

The general requirements and specifications for fuels in this document can also be applied to fuels used in stationary diesel engines of the same or similar type as those used for marine purposes.

This document specifies seven categories of distillate fuels, one of which is for diesel engines used for emergency purposes. It also specifies four categories of residual fuels for sulfur content at or below 0,50 % by mass, five categories of residual fuels containing FAME and five categories of residual fuels for sulfur content exceeding 0,50 % by mass.

Produits d’origine pétrolière, synthétique ou renouvelable — Combustibles (classe F) — Spécifications des combustibles pour la marine

Le présent document, dans son intégralité, définit les exigences générales et les spécifications relatives aux combustibles utilisés dans les moteurs diesel et les chaudières des navires, avant toute opération conventionnelle à bord (stockage, décantation, centrifugation, filtration, chauffage) préalable à leur utilisation.

Pour les besoins du présent document, le terme «combustibles» est utilisé couramment pour désigner:

— les hydrocarbures provenant du pétrole brut, des sables bitumineux et du schiste;

— les hydrocarbures synthétiques, les hydrocarbures renouvelables ou les hydrocarbures provenant de sources recyclées, dont les structures moléculaires ne se distinguent pas de celles des hydrocarbures pétroliers;

— esters méthyliques d’acides gras (EMAG), lorsqu’ils sont autorisés tel que spécifié dans le présent document;

— mélange des éléments ci-dessus, lorsqu’ils sont autorisés tel que spécifié dans le présent document.

Les exigences et spécifications générales relatives aux combustibles figurant dans le présent document peuvent aussi s'appliquer aux combustibles utilisés dans les moteurs diesel stationnaires, de type identique ou similaire à ceux utilisés pour des applications marines.

Le présent document spécifie sept catégories de distillats, dont l'une est utilisée dans les moteurs diesel des dispositifs de secours. Il spécifie également quatre catégories de combustibles résiduels dont la teneur en soufre est inférieure ou égale à 0,50 % en masse, cinq catégories de combustibles résiduels contenant des esters méthyliques d'acides gras (EMAG) et cinq catégories de combustibles résiduels dont la teneur en soufre est supérieure à 0,50 % en masse.

Proizvodi iz naftnih, sintetičnih in obnovljivih virov - Goriva (Razred F) - Specifikacije za ladijska goriva

Ta dokument celostno določa splošne zahteve in specifikacije za goriva za ladijske dizelske motorje in kotle pred ravnanjem z gorivom na krovu (shranjevanje, namestitev, centrifugiranje, filtracija, segrevanje) pred uporabo.

V tem dokumentu uporabljen izraz »goriva« vključuje naslednje:

– ogljikovodike iz surove nafte, naftni pesek in olje iz skrilavca;

– sintetične ogljikovodike, obnovljive ogljikovodike ali ogljikovodike iz recikliranih virov z molekularno strukturo, ki se ne razlikuje od ogljikovodikov iz nafte;

– metil ester maščobne kisline (FAME), kjer je to dovoljeno v skladu s tem dokumentom;

– mešanice zgoraj navedenega, kjer je to dovoljeno v skladu s tem dokumentom.

Splošne zahteve in specifikacije za goriva v tem dokumentu je mogoče uporabiti tudi za goriva za nepremične dizelske motorje enake ali podobne vrste, kot so ladijski motorji.

Ta dokument določa sedem kategorij destiliranega goriva, pri čemer ena kategorija zajema dizelske motorje za nujne primere. Določa tudi štiri kategorije goriv iz destilacijskega ostanka z vsebnostjo žvepla 0,50 % ali manj glede na maso, pet kategorij goriv iz destilacijskega ostanka, ki vsebujejo metil ester maščobne kisline, in pet kategorij goriv iz destilacijskega ostanka z vsebnostjo žvepla več kot 0,50 % glede na maso.

General Information

Relations

Overview

ISO 8217:2024 is the seventh edition of the international specification for marine fuels used in diesel engines and boilers. It defines general requirements, test methods and fuel categories for fuels derived from petroleum, synthetic, renewable or recycled sources, including fatty acid methyl ester (FAME) and permitted blends. The standard applies to fuels as supplied prior to onboard fuel handling (storage, settling, centrifuging, filtration, heating) and can also be used for similar stationary diesel engines.

Key topics and requirements

- Fuel types covered: hydrocarbons from petroleum, synthetic/renewable hydrocarbons indistinguishable from petroleum, FAME (where permitted), and blends.

- Fuel categories:

- Seven distillate categories (e.g., DMX, DMA, DMB, DMZ, DFA, DFB, DFZ).

- Multiple residual fuel categories (RMA, RME, RMG, RMK, RF) with classifications for sulfur ≤ 0.50% and > 0.50% by mass, and categories addressing FAME content.

- Test methods and properties specified (examples included in the standard):

- Density, CCAI (ignition characteristic), sulfur content, flash point, hydrogen sulfide, acid number, oxidation stability.

- Total sediment (existent, accelerated, potential), FAME content, cold-flow properties (pour point/cloud point/CFPP), appearance/water content, lubricity.

- Contaminants and markers: vanadium, sodium, aluminium + silicon, organic chlorides, unrefined used lubricating oil.

- Energy properties: specific energy, net heat of combustion (reporting required for distillate fuels), cetane index/number.

- New/updated requirements in 2024 edition:

- Reporting of FAME content for distillate fuels (allowing up to 100% where permitted).

- Minimum cetane number and oxidation stability requirements for DF grades.

- Additional annexes and revised terms, tables and clauses (including specific clauses for 100% FAME and paraffinic diesel).

Practical applications and users

ISO 8217:2024 is used to:

- Define bunkering and procurement specifications for ship owners and operators.

- Guide fuel testing laboratories and fuel testing programs for compliance verification.

- Inform engine designers, manufacturers and fuel treatment equipment suppliers about compatible fuel properties.

- Support classification societies, regulators and port/state authorities in enforcement and fuel conformity assessment.

- Aid fuel suppliers and blenders in formulating products to meet global marine fuel categories.

Typical users: ship operators, bunkering suppliers, testing labs, engine and fuel treatment manufacturers, classification societies, regulators.

Related standards and regulatory context

- ISO 8217 refers to fuel classification guidance in ISO 8216-1.

- Fuel safety and regulatory constraints (flash point, sulfur limits) interact with SOLAS and MARPOL Annex VI; users must ensure compliance with applicable regional and statutory emission requirements.

Keywords: ISO 8217:2024, marine fuels, FAME, distillate fuels, residual fuels, sulfur content, fuel specifications, marine diesel engines, fuel testing.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2024

Nadomešča:

SIST ISO 8217:2018

Proizvodi iz naftnih, sintetičnih in obnovljivih virov - Goriva (Razred F) -

Specifikacije za ladijska goriva

Products from petroleum, synthetic and renewable sources — Fuels (class F) —

Specifications of marine fuels

Produits d’origine pétrolière, synthétique ou renouvelable — Combustibles (classe F) —

Spécifications des combustibles pour la marine

Ta slovenski standard je istoveten z: ISO 8217:2024

ICS:

75.160.20 Tekoča goriva Liquid fuels

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

International

Standard

ISO 8217

Seventh edition

Products from petroleum, synthetic

2024-05

and renewable sources — Fuels

(class F) — Specifications of

marine fuels

Produits d’origine pétrolière, synthétique ou renouvelable —

Combustibles (classe F) — Spécifications des combustibles pour

la marine

Reference number

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

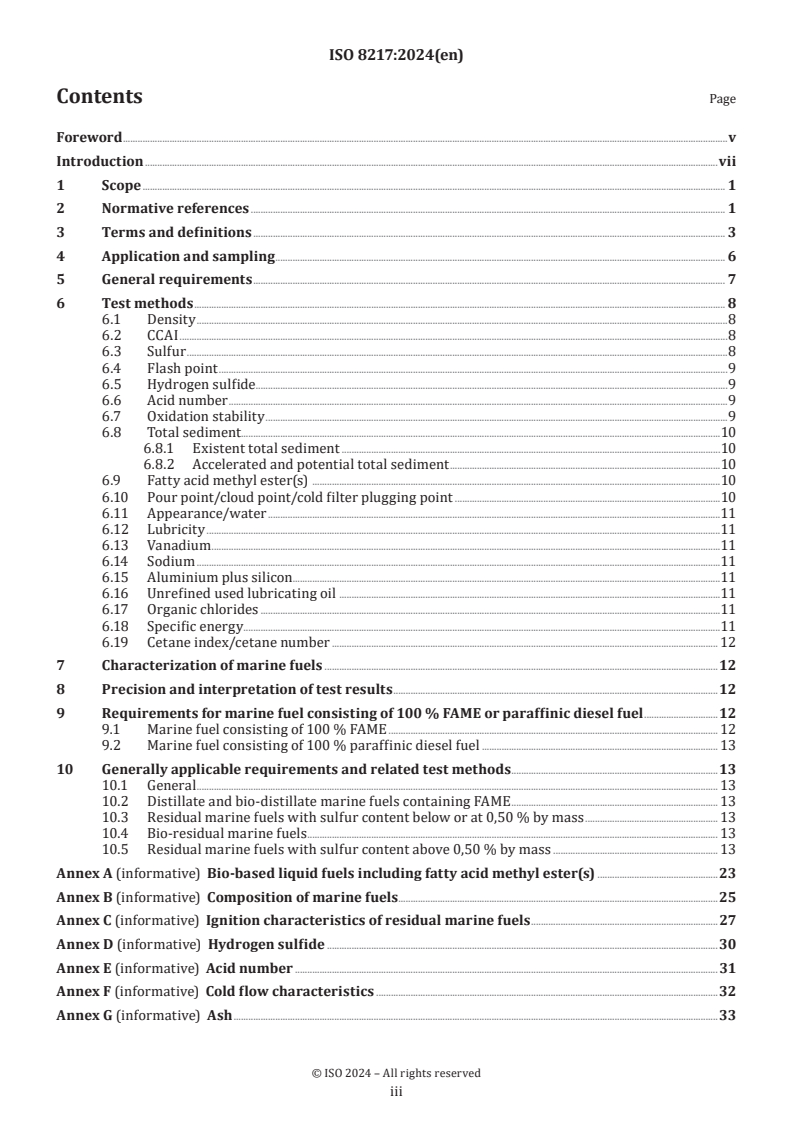

Contents Page

Foreword .v

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 3

4 Application and sampling . 6

5 General requirements . 7

6 Test methods . 8

6.1 Density .8

6.2 CCAI .8

6.3 Sulfur .8

6.4 Flash point .9

6.5 Hydrogen sulfide . .9

6.6 Acid number .9

6.7 Oxidation stability .9

6.8 Total sediment.10

6.8.1 Existent total sediment .10

6.8.2 Accelerated and potential total sediment .10

6.9 Fatty acid methyl ester(s) .10

6.10 Pour point/cloud point/cold filter plugging point .10

6.11 Appearance/water .11

6.12 Lubricity .11

6.13 Vanadium .11

6.14 Sodium .11

6.15 Aluminium plus silicon.11

6.16 Unrefined used lubricating oil .11

6.17 Organic chlorides .11

6.18 Specific energy .11

6.19 Cetane index/cetane number . 12

7 Characterization of marine fuels .12

8 Precision and interpretation of test results .12

9 Requirements for marine fuel consisting of 100 % FAME or paraffinic diesel fuel .12

9.1 Marine fuel consisting of 100 % FAME . 12

9.2 Marine fuel consisting of 100 % paraffinic diesel fuel . 13

10 Generally applicable requirements and related test methods .13

10.1 General . 13

10.2 Distillate and bio-distillate marine fuels containing FAME . 13

10.3 Residual marine fuels with sulfur content below or at 0,50 % by mass . 13

10.4 Bio-residual marine fuels . 13

10.5 Residual marine fuels with sulfur content above 0,50 % by mass . 13

Annex A (informative) Bio-based liquid fuels including fatty acid methyl ester(s) .23

Annex B (informative) Composition of marine fuels .25

Annex C (informative) Ignition characteristics of residual marine fuels .27

Annex D (informative) Hydrogen sulfide .30

Annex E (informative) Acid number .31

Annex F (informative) Cold flow characteristics .32

Annex G (informative) Ash .33

iii

Annex H (informative) Stability of residual fuels .34

Annex I (informative) Unrefined used lubricating oil .36

Annex J (informative) Specific energy .37

Annex K (informative) Characterization of residual marine fuels .38

Bibliography .40

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 28, Petroleum and related products, fuels and

lubricants from natural or synthetic sources, Subcommittee SC 4, Classifications and specifications.

This seventh edition cancels and replaces the sixth edition (ISO 8217:2017), which has been technically

revised.

The main changes are as follows:

— terms and definitions (Clause 3) have been updated;

— the Scope and the general requirements in Clause 5 have been amended;

— Tables 2 and 3 have been added;

— former Table 2 has been modified and has become Table 4;

— changes to the distillate fuels, including the following:

— the requirement to report the fatty acid methyl ester(s) content (FAME) of DF grades has been

changed, allowing up to 100 %;

— the distinction between winter and summer quality for cloud point and cold filter plugging point has

been removed;

— the requirement to report the net heat of combustion for DF grades has been added;

— a minimum cetane number requirement for DF grades has been added;

— the requirement for oxidation stability for DF grades has been added;

— Clauses 9 and 10 have been added;

— new Annexes F, H and K have been added (the former Annex F has become Annex G, the former Annex G

has become Annex I, and the former Annex H has become Annex J);

v

— existing annexes have been reviewed and updated.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

vi

Introduction

This document was prepared in cooperation with ship owners, ship operators, shipping associations,

national standards bodies, classification societies, fuel testing services, engine designers, fuel treatment

equipment manufacturers, marine fuel suppliers, fuel additive suppliers and the petroleum industry to meet

the requirements for marine fuels supplied on a world-wide basis for consumption on board ships.

The increased focus on environmental concerns and legislation to address them is leading to a transition in

the nature of marine fuels. There is a shift away from marine fuels supplied from traditional oil products

derived from the processing of petroleum crude, and a shift towards oil products derived from synthetic and

renewable, recycled or alternative sources. This document takes into consideration the diverse nature of

these fuels and incorporates a number of categories of distillate and residual fuels, even though it is possible

that not all categories are available in every supply location. This document facilitates the transition,

however sustainability aspects and accounting are not within the scope.

The categories of fuel in this document have been classified according to ISO 8216-1 and include the distillate fuel

categories DMX, DMA, DMB, DMZ, DFA, DFB, DFZ and the residual fuel categories RMA, RME, RMG, RMK and RF.

In the instances where a fuel, which does not conform exactly to any of these distillate or residual fuel

categories, is offered to a purchaser, the fuel characteristics or limits can be agreed between the buyer and

the seller, and defined by both a category of fuel given by this document, together with any different or

additional fuel characteristics or limits, as necessary to adequately define that fuel.

This document specifies the permitted minimum flash point limits following the provisions given in the

[3]

SOLAS Convention.

[4]

MARPOL Annex VI, which controls air pollution from ships, includes a requirement that either the fuel

does not exceed a specified maximum sulfur content, or an approved equivalent alternative means is

used. During the lifetime of this document, regional and/or national authorities can introduce their own

local emission requirements, which can impact the allowable sulfur content. It is the buyer’s and the user’s

responsibility to establish which statutory requirements are necessary to meet and specify on that basis the

corresponding maximum fuel sulfur content to the seller.

vii

International Standard ISO 8217:2024(en)

Products from petroleum, synthetic and renewable sources —

Fuels (class F) — Specifications of marine fuels

WARNING — The handling and use of products specified in this document can be hazardous

if precautions as mentioned in the Safety Data Sheet (SDS) are not taken into consideration

when product is handled. This document does not purport to address all the safety and health

considerations that can be associated with its use. It is the responsibility of the users of this document

to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use.

1 Scope

This document in its entirety defines the general requirements and specifications for fuels used in marine

diesel engines and boilers, prior to onboard fuel handling (storage, settling, centrifuging, filtration, heating)

before use.

For the purposes of this document, the term “fuels” comprises of the following:

— hydrocarbons from petroleum crude oil, oil sands and shale oil;

— synthetic hydrocarbons, renewable hydrocarbons or hydrocarbons from recycled sources, with

molecular structures that are indistinguishable from petroleum hydrocarbons;

— fatty acid methyl ester (FAME), where permitted as specified in this document;

— blends of any of the above, where permitted as specified in this document.

The general requirements and specifications for fuels in this document can also be applied to fuels used in

stationary diesel engines of the same or similar type as those used for marine purposes.

This document specifies seven categories of distillate fuels, one of which is for diesel engines used for

emergency purposes. It also specifies four categories of residual fuels for sulfur content at or below

0,50 % by mass, five categories of residual fuels containing FAME and five categories of residual fuels for

sulfur content exceeding 0,50 % by mass.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 2719, Determination of flash point — Pensky-Martens closed cup method

ISO 3015, Petroleum and related products from natural or synthetic sources — Determination of cloud point

ISO 3016, Petroleum and related products from natural or synthetic sources — Determination of pour point

ISO 3104, Petroleum products — Transparent and opaque liquids — Determination of kinematic viscosity and

calculation of dynamic viscosity

ISO 3675, Crude petroleum and liquid petroleum products — Laboratory determination of density —

Hydrometer method

ISO 3733, Petroleum products and bituminous materials — Determination of water — Distillation method

ISO 4259-2, Petroleum and related products — Precision of measurement methods and results — Part 2:

Interpretation and application of precision data in relation to methods of test

ISO 4264, Petroleum products — Calculation of cetane index of middle-distillate fuels by the four variable

equation

ISO 5165, Petroleum products — Determination of the ignition quality of diesel fuels — Cetane engine method

ISO 6245, Petroleum products — Determination of ash

ISO 8754, Petroleum products — Determination of sulfur content — Energy-dispersive X-ray fluorescence

spectrometry

ISO 10307-1, Petroleum products — Total sediment in residual fuel oils — Part 1: Determination by hot filtration

ISO 10307-2, Petroleum products — Total sediment in residual fuel oils — Part 2: Determination using standard

procedures for ageing

ISO 10370, Petroleum products — Determination of carbon residue — Micro method

ISO 10478, Petroleum products — Determination of aluminium and silicon in fuel oils — Inductively coupled

plasma emission and atomic absorption spectroscopy methods

ISO 12156-1, Diesel fuel — Assessment of lubricity using the high-frequency reciprocating rig (HFRR) — Part 1:

Test method

ISO 12185, Crude petroleum, petroleum products and related products — Determination of density —

Laboratory density meter with an oscillating U-tube sensor

ISO 12205, Petroleum products — Determination of the oxidation stability of middle-distillate fuels

ISO 12937, Petroleum products — Determination of water — Coulometric Karl Fischer titration method

ISO 14596, Petroleum products — Determination of sulfur content — Wavelength-dispersive X-ray fluorescence

spectrometry

ISO 14597, Petroleum products — Determination of vanadium and nickel content — Wavelength-dispersive

X-ray fluorescence spectrometry

EN 116, Diesel and domestic heating fuels — Determination of cold filter plugging point — Stepwise cooling

bath method

EN 14077, Petroleum products — Determination of organic halogen content — Oxidative microcoulometric method

EN 14078, Liquid petroleum products — Determination of fatty methyl ester (FAME) content in middle distillates

- Infrared spectrometry method

EN 14214, Liquid petroleum products — Fatty acid methyl esters (FAME) for use in diesel engines and heating

applications — Requirements and test methods

EN 15195, Liquid petroleum products — Determination of ignition delay and derived cetane number (DCN) of

middle distillate fuels by combustion in a constant volume chamber

EN 15751, Automotive fuels — Fatty acid methyl ester (FAME) fuel and blends with diesel fuel — Determination

of oxidation stability by accelerated oxidation method

EN 15940, Automotive fuels — Paraffinic diesel fuel from synthesis or hydrotreatment — Requirements and

test methods

EN 16329, Diesel and domestic heating fuels — Determination of cold filter plugging point — Linear cooling

bath method

EN 16715, Liquid petroleum products — Determination of ignition delay and derived cetane number (DCN) of

middle distillate fuels — Ignition delay and combustion delay determination using a constant volume combustion

chamber with direct fuel injection

EN 17155, Liquid petroleum products — Determination of indicated cetane number (ICN) of middle distillate

fuels — Primary reference fuels calibration method using a constant volume combustion chamber

ASTM D240, Standard Test Method for Heat of combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter

ASTM D664, Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration

ASTM D2622, Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray

Fluorescence Spectrometry

ASTM D4294, Standard Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray

Fluorescence Spectrometry

ASTM D6751, Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels

ASTM D6890, Determination of Ignition Delay and Derived Cetane Number (DCN) of Diesel Fuel Oils by

Combustion in a Constant Volume Chamber

ASTM D7371, Standard Test Method for Determination of Biodiesel (Fatty Acid Methyl Esters) Content in Diesel

Fuel Oil Using Mid Infrared Spectroscopy (FTIR-ATR-PLS Method)

ASTM D7668, Standard Test Method for Determination of Derived Cetane Number (DCN) of Diesel Fuel Oils—

Ignition Delay and Combustion Delay Using a Constant Volume Combustion Chamber Method

ASTM D7963, Standard Test Method for Determination of Contamination Level of Fatty Acid Methyl Esters in

Middle Distillate and Residual Fuels Using Flow Analysis by Fourier-Transform Infrared Spectroscopy-Rapid

Screening Method

ASTM D8183, Standard Test Method for Determination of Indicated Cetane Number (ICN) of Diesel Fuel Oils

using a Constant Volume Combustion Chamber—Reference Fuels Calibration Method

IP 470, Determination of aluminium, silicon, vanadium, nickel, iron, calcium, zinc and sodium in residual fuel oil

by ashing, fusion and atomic absorption spectrometry

IP 500, Determination of the phosphorus content of residual fuels by ultra-violet spectrometry

IP 501, Determination of aluminium, silicon, vanadium, nickel, iron, sodium, calcium, zinc and phosphorus in

residual fuel oil by ashing, fusion and inductively coupled plasma emission spectrometry

IP 570, Determination of hydrogen sulfide in fuel oils — Rapid liquid phase extraction method

IP 631, Determination of the contamination level of fatty acid methyl esters in middle distillate and residual fuels

using Flow Analysis by Fourier Transform Infrared Spectroscopy — Rapid Screening Method

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

ultra low sulfur fuel oil

ULSFO

marine fuel with a maximum sulfur content of 0,10 % by mass

3.2

very low sulfur fuel oil

VLSFO

marine fuel with a maximum sulfur content of 0,50 % by mass

3.3

high sulfur fuel oil

HSFO

marine fuel with a sulfur content exceeding 0,50 % by mass

3.4

fatty acid methyl ester

FAME

ester derived by transesterification or esterification of fats and oils of vegetal or animal origin

Note 1 to entry: See Annex A for information on bio-based liquid fuels including fatty acid methyl ester(s).

3.5

bio-based

wholly or partly derived from biomass (3.7)

[SOURCE: ISO 16559:2022, 3.23, modified — “wholly or partly” added.]

3.6

biofuel

fuel produced directly or indirectly from biomass (3.7)

[SOURCE: ISO 16559:2022, 3.27, modified — “solid, liquid or gaseous” deleted.]

3.7

biomass

material of biological origin excluding material embedded in geological formations and/or fossilized

[SOURCE: ISO 16559:2022, 3.32, modified — Example and Note 1 to entry deleted.]

3.8

biodiesel

generic name for bio-based (3.5) fuel with properties similar to diesel or diesel containing bio-based blends

Note 1 to entry: The term is often used to describe fatty acid methyl ester (FAME) (3.4), but it is not exclusive to describe

FAME or fuel containing FAME.

3.9

bio-distillate marine fuel

blend of a petroleum distillate marine fuel with bio-based (3.5) liquid fuel

Note 1 to entry: DF grade is used to describe bio-distillate marine fuel grade.

3.10

bio-residual marine fuel

blend of a petroleum residual marine fuel with bio-based (3.5) liquid fuel

Note 1 to entry: RF grade is used to describe bio-residual marine fuel grade.

3.11

synthetic hydrocarbon

liquid hydrocarbon obtained from synthesis

3.12

renewable hydrocarbon

liquid hydrocarbon produced from renewable resources

Note 1 to entry: Biomass (3.7) is an example of a renewable resource.

3.13

paraffinic diesel fuel

liquid hydrocarbons obtained by synthesis or hydrotreatment

EXAMPLE Synthetic diesel, renewable diesel, hydrotreated vegetable oil (HVO) (3.14).

3.14

hydrotreated vegetable oil

HVO

liquid hydrocarbon produced from renewable feedstock by hydrotreatment

Note 1 to entry: Also called renewable diesel or paraffinic diesel fuel (3.13).

3.15

gas to liquid

GTL

liquid hydrocarbons obtained by the conversion of natural gas or other fossil gaseous hydrocarbons

3.16

biomass to liquid

BTL

liquid hydrocarbons obtained by the conversion of biomass (3.7) via thermochemical processes (gasification)

3.17

power to liquid

PtL

liquid hydrocarbons obtained by conversion of electricity

3.18

stability

stability of a residual fuel

resistance to the breakdown and precipitation of asphaltenic sludge despite being subjected to forces, such

as thermal and ageing stresses, while stored, handled and treated under normal operating conditions

[SOURCE: ISO/PAS 23263:2019, 3.1, modified — “handled and stored” replaced by “stored, handled and

treated”.]

3.19

compatibility

ability of two or more fuels to be commingled at a defined ratio without evidence of material separation,

which can result in the formation of multiple phases, such as flocculation, where dispersed particles of

asphaltenes form bigger clusters which can lead to sludge formation

[SOURCE: ISO/PAS 23263:2019, 3.2, modified — “could” and “might” replaced by “can”.]

3.20

cloud point

CP

temperature at which a cloud of wax crystals first appears in a transparent liquid when it is cooled under

specified conditions

[SOURCE: ISO/PAS 23263:2019, 3.4]

3.21

cold filter plugging point

CFPP

highest temperature at which a given volume of distillate fuel fails to pass through a standardized filtration

device in a specified time when cooled under standardized conditions

[SOURCE: ISO/PAS 23263:2019, 3.5]

3.22

pour point

PP

lowest temperature at which a fuel will continue to flow when it is cooled under specified standard conditions

[SOURCE: ISO/PAS 23263:2019, 3.6]

3.23

existent total sediment

TSE

sum of insoluble organic and inorganic material, separated from the bulk of the sample by filtration through

a specified filter, and also insoluble in a predominantly paraffinic solvent

Note 1 to entry: TSE is obtained by hot filtration.

[SOURCE: ISO 10307-1:2009, 3.1, modified — “existent” added to the term; “TSE” added as a preferred term;

Note 1 to entry added.]

3.24

potential total sediment

TSP

total sediment after ageing a sample of residual fuel for 24 h at 100 °C under prescribed conditions

[SOURCE: ISO 10307-2:2009, 3.1, modified — “TSP” added as a preferred term; “determined by ISO 10307-1,”

deleted from the definition.]

3.25

accelerated total sediment

TSA

total sediment after dilution of a sample of residual fuel with hexadecane in the ratio of 1 ml per 10 g of

sample under carefully controlled conditions, followed by storage for 1 h at 100 °C

[SOURCE: ISO 10307-2:2009, 3.2, modified — “TSA” added as a preferred term; “determined by ISO 10307-1,”

deleted from the definition.]

3.26

unrefined used lubricating oil

unrefined ULO

oil that has not been processed and filtered to remove lube oil additives and contaminants

Note 1 to entry: Refined used lubricating oil can be suitable as blend stock for marine fuel.

4 Application and sampling

This document specifies the required properties for a fuel at the time and place of custody transfer, prior to

onboard handling and treatment.

NOTE Appropriate guidance about fuel treatment systems for diesel engines can be found in Reference [5].

Sampling of a fuel is an important part of the fuel’s quality verification and should be carried out in

accordance with ISO 13739 or an equivalent national standard. The sample shall be representative for the

entire quantity of fuel loaded onto the receiving ship and may be taken in any location agreed between the

parties.

Testing of the fuel shall be carried out in accordance with the test methods given in Table 1, Table 2, Table 3

or Table 4, as appropriate.

5 General requirements

5.1 The fuel as supplied shall be homogeneous and conform to the characteristics and limits given in

Table 1, Table 2, Table 3 or Table 4, as appropriate, when tested in accordance with the methods specified.

The test methods and references listed in Tables 1, 2, 3 and 4 shall apply.

The fuel composition shall consist of:

— predominantly hydrocarbons from petroleum sources;

or

— hydrocarbons, with molecular structures that are indistinguishable from petroleum hydrocarbons,

derived from:

— synthetic or renewable sources such as paraffinic diesel e.g. hydrotreated vegetable oil (HVO), gas to

liquid (GTL), biomass to liquid (BTL) and power to liquid (PtL);

— co-processing of renewable or recycled feedstock at refineries with petroleum feedstock;

or

— fatty acid methyl ester (FAME) as defined in this document;

or

— a mixture of the above.

With regards to FAME, there are grades in this document for fuels not including FAME and for fuels including

an agreed percentage of FAME.

For fuels not including FAME:

— The DMA, DMZ, DMB and RM grades shall not include FAME other than a de minimis level. In the context

of this document, de minimis amount of FAME means an amount not exceeding approximately 0,5 %.

DMX shall be free of FAME.

NOTE See Annex A for further information.

For fuels with an agreed FAME content:

— the DF and RF grades are fuels including an amount of FAME where the FAME used for blending of the

fuel shall be in accordance with the requirements of EN 14214, except for

a) sulfur content, which is a statutory requirement;

b) cloud point (CP) and cold filter plugging point (CFPP) requirements as these are covered by the final

marine blend specifications in Table 1 of this document;

or ASTM D6751, except for sulfur content.

— The FAME content of the fuel (percentage by mass or volume) and the FAME standards (EN 14214 or

ASTM D6751) shall be reported prior to the time of the delivery and in line with original equipment

manufacturer’s guidance. In the event that other national FAME standards are offered, see Annex A.

5.2 The fuel shall be free from any materials, including added substances and chemical species, at a

concentration that causes the fuel to be unacceptable for use by way of:

a) jeopardizing the safety of the ship; or

b) adversely affecting the performance of the machinery; or

c) being harmful to personnel.

NOTE See Annex B for information on the composition of marine fuels.

5.3 The fuel shall be free from inorganic acids and organic chlorides (chlorinated hydrocarbons).

NOTE 1 See 6.6 and 6.17.

NOTE 2 See Annex B for information on the composition of marine fuels.

5.4 Subject to the requirements of 5.1, 5.2 and 5.3, additives that improve some aspects of the fuel’s

characteristics or performance are permitted.

6 Test methods

6.1 Density

In case of disagreement concerning density, all parties shall agree, prior to additional testing, upon the test

method to be used.

6.2 CCAI

The calculated carbon aromaticity index (CCAI) shall be as specified in Table 2, Table 3 or Table 4.

[6]

The CCAI value, I , is calculated in accordance with Lewis, et al. , using Formula (1):

CCA

T +273

I =−ρν81−⋅141 lg lg(,+085)l−⋅483 g (1)

[]

CCA 15

323

where

ρ is the density at 15 °C, expressed in kilograms per cubic metre;

ν is the kinematic viscosity at temperature T, expressed in square millimetres per second;

T is the temperature, expressed in degrees Celsius, at which the kinematic viscosity is determined.

Density, ρ , and viscosity, v, shall be determined in accordance with the test methods specified in Tables 2, 3 or 4.

NOTE 1 See Annex C for information on ignition characteristics of residual marine fuels.

NOTE 2 For engines and/or applications where the ignition quality is known to be particularly critical, Annex C

provides a basis for buyers and sellers of residual fuels to agree on tighter ignition quality characteristics.

NOTE 3 For some fuels when blending at or close to the maximum density, the CCAI limit restricts the combination

of density and viscosity.

NOTE 4 CCAI was originally developed for petroleum-derived fuels. As such, its applicability to bio-residual marine

fuels and the density/viscosity correlation to ignition performance has not been established.

6.3 Sulfur

Table 1, Table 3 and Table 4 do not set sulfur limits, since the buyer is responsible for specifying the maximum

sulfur content when ordering the fuel, based on the regulatory requirement applicable to where the fuel will

be used or any existing exhaust gas cleaning system requirement. For fuels ordered to Table 2, the buyer

shall still specify the required sulfur content to the seller.

Sulfur test precision for fuels containing FAME has not been established for the test methods specified in

ISO 8754 and ISO 14596. The sulfur test precision for distillate fuels containing FAME has been established

for the test method specified in ASTM D4294.

The reference test method shall be as specified in ISO 8754 for distillate marine (DM) and residual marine

(RM) fuels, in ASTM D4294 for distillate fuels including FAME (DF), and in ASTM D4294 or ASTM D2622 for

residual fuels including FAME (RF).

In case of disagreement concerning sulfur content, all parties shall agree, prior to additional testing, upon

the same sulfur certified reference material, and for RF grades upon the reference test method.

6.4 Flash point

[3]

The International Convention for Safety of Life at Sea (SOLAS) sets the flash point limit for all fuels at

60 °C minimum. An exception to this is DMX, which has a flash point limit of 43 °C minimum.

Fuels have the potential to produce a flammable atmosphere in a tank headspace, even when stored at a

temperature below the measured flash point. Appropriate precautions are necessary, therefore, to ensure

the safety of the ship and personnel. Further information and advice on precautionary measures are given in

References [7] to [9].

The flash point is not a physical constant, but is dependent on the test method, the apparatus and the

procedure used.

The flash point for fuels in Table 1 shall be determined in accordance with ISO 2719, Procedure A. For 100 %

FAME, ISO 2719, Procedure C shall be applied. The flash point of fuels in Table 2, Table 3 and Table 4 shall be

determined in accordance with ISO 2719, Procedure B.

6.5 Hydrogen sulfide

The reference test method shall be IP 570, Procedure A.

WARNING — Hydrogen sulfide (H S) is a highly toxic gas. Exposure to any significant vapour

concentrations is hazardous and, in extreme cases, can be fatal. It is critical that ship owners,

operators and other responsible parties continue to maintain appropriate safety practices designed

to protect the crew and others who can be exposed to H S vapours.

NOTE See Annex D for further information.

6.6 Acid number

The fuel shall be free of inorganic acids. The acid number of DM and RM fuels shall be determined in

accordance with ASTM D664, Procedure A. The acid number of DF and RF fuels shall be tested in accordance

with ASTM D664, Procedure B.

In case of dispute concerning acid number, all parties shall agree, prior to additional testing, upon which

procedure of ASTM D664 shall be used.

NOTE See Annex E for further information.

6.7 Oxidation stability

The oxidation stability shall be as specified in Table 1.

For fuels not including FAME or containing less than 2 % of FAME by volume, oxidation stability shall be

tested in accordance with ISO 12205.

For DF grades, oxidation stability shall be tested in accordance with EN 15751.

NOTE See Annex A for further information.

6.8 Total sediment

6.8.1 Existent total sediment

If the appearance of DMB or DFB is assessed as not clear and bright (see 6.11), the total sediment by hot

filtration, typically called existent total sediment (TSE) shall be determined in accordance with the test

method ISO 10307-1.

For the fuels listed in Table 2 and Table 3, the existent total sediment shall be reported.

NOTE The International Council on Combustion Engines (CIMAC) has developed a guideline regarding the

[10]

interpretation of total sediment test results.

6.8.2 Accelerated and potential total sediment

For the fuels listed in Table 2 and Table 4, statistical analysis of data gathered since 2020 on residual type

very low sulfur fuel oil (VLSFO) and high sulfur fuel oil (HSFO) shows that HSFO are more sensitive to

chemical ageing whereas VLSFO with viscosity typically below 200 mm /s (200 cSt) at 50 °C are sensitive to

both thermal and chemical ageing, due to the different nature of the fuels.

For fuels in Table 3, there is insufficient data at the time of writing to assess the sensitivity of bio-residual

marine fuels to thermal versus chemical ageing.

Therefore, the following applies:

— For the fuels listed in Tables 2 and 3 only potential total sediment (TSP) shall be used.

— Accelerated total sediment (TSA) shall be reported for all fuels listed in Tables 2 and 3.

— For the fuels listed in Table 4, either of the standard procedures for ageing in ISO 10307-2 can be used: the

TSA or TSP test. The reference test method for the fuels listed in Table 4 shall be the TSP in accordance

with ISO 10307-2.

NOTE 1 See Annex H for information on stability of residual fuels.

NOTE 2 The International Council on Combustion Engines (CIMAC) has developed a guideline regarding the

[10]

interpretation of total sediment test results.

6.9 Fatty acid methyl ester(s)

The test methods specified in ASTM D7963 and IP 631 are applicable to all DM and RM, DF and RF grades.

The test method specified in EN 14078 is not applicable to RM and RF grades at the

...

International

Standard

ISO 8217

Seventh edition

Products from petroleum, synthetic

2024-05

and renewable sources — Fuels

(class F) — Specifications of

marine fuels

Produits d’origine pétrolière, synthétique ou renouvelable —

Combustibles (classe F) — Spécifications des combustibles pour

la marine

Reference number

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

Contents Page

Foreword .v

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 3

4 Application and sampling . 6

5 General requirements . 7

6 Test methods . 8

6.1 Density .8

6.2 CCAI .8

6.3 Sulfur .8

6.4 Flash point .9

6.5 Hydrogen sulfide . .9

6.6 Acid number .9

6.7 Oxidation stability .9

6.8 Total sediment.10

6.8.1 Existent total sediment .10

6.8.2 Accelerated and potential total sediment .10

6.9 Fatty acid methyl ester(s) .10

6.10 Pour point/cloud point/cold filter plugging point .10

6.11 Appearance/water .11

6.12 Lubricity .11

6.13 Vanadium .11

6.14 Sodium .11

6.15 Aluminium plus silicon.11

6.16 Unrefined used lubricating oil .11

6.17 Organic chlorides .11

6.18 Specific energy .11

6.19 Cetane index/cetane number . 12

7 Characterization of marine fuels .12

8 Precision and interpretation of test results .12

9 Requirements for marine fuel consisting of 100 % FAME or paraffinic diesel fuel .12

9.1 Marine fuel consisting of 100 % FAME . 12

9.2 Marine fuel consisting of 100 % paraffinic diesel fuel . 13

10 Generally applicable requirements and related test methods .13

10.1 General . 13

10.2 Distillate and bio-distillate marine fuels containing FAME . 13

10.3 Residual marine fuels with sulfur content below or at 0,50 % by mass . 13

10.4 Bio-residual marine fuels . 13

10.5 Residual marine fuels with sulfur content above 0,50 % by mass . 13

Annex A (informative) Bio-based liquid fuels including fatty acid methyl ester(s) .23

Annex B (informative) Composition of marine fuels .25

Annex C (informative) Ignition characteristics of residual marine fuels .27

Annex D (informative) Hydrogen sulfide .30

Annex E (informative) Acid number .31

Annex F (informative) Cold flow characteristics .32

Annex G (informative) Ash .33

iii

Annex H (informative) Stability of residual fuels .34

Annex I (informative) Unrefined used lubricating oil .36

Annex J (informative) Specific energy .37

Annex K (informative) Characterization of residual marine fuels .38

Bibliography .40

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 28, Petroleum and related products, fuels and

lubricants from natural or synthetic sources, Subcommittee SC 4, Classifications and specifications.

This seventh edition cancels and replaces the sixth edition (ISO 8217:2017), which has been technically

revised.

The main changes are as follows:

— terms and definitions (Clause 3) have been updated;

— the Scope and the general requirements in Clause 5 have been amended;

— Tables 2 and 3 have been added;

— former Table 2 has been modified and has become Table 4;

— changes to the distillate fuels, including the following:

— the requirement to report the fatty acid methyl ester(s) content (FAME) of DF grades has been

changed, allowing up to 100 %;

— the distinction between winter and summer quality for cloud point and cold filter plugging point has

been removed;

— the requirement to report the net heat of combustion for DF grades has been added;

— a minimum cetane number requirement for DF grades has been added;

— the requirement for oxidation stability for DF grades has been added;

— Clauses 9 and 10 have been added;

— new Annexes F, H and K have been added (the former Annex F has become Annex G, the former Annex G

has become Annex I, and the former Annex H has become Annex J);

v

— existing annexes have been reviewed and updated.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

vi

Introduction

This document was prepared in cooperation with ship owners, ship operators, shipping associations,

national standards bodies, classification societies, fuel testing services, engine designers, fuel treatment

equipment manufacturers, marine fuel suppliers, fuel additive suppliers and the petroleum industry to meet

the requirements for marine fuels supplied on a world-wide basis for consumption on board ships.

The increased focus on environmental concerns and legislation to address them is leading to a transition in

the nature of marine fuels. There is a shift away from marine fuels supplied from traditional oil products

derived from the processing of petroleum crude, and a shift towards oil products derived from synthetic and

renewable, recycled or alternative sources. This document takes into consideration the diverse nature of

these fuels and incorporates a number of categories of distillate and residual fuels, even though it is possible

that not all categories are available in every supply location. This document facilitates the transition,

however sustainability aspects and accounting are not within the scope.

The categories of fuel in this document have been classified according to ISO 8216-1 and include the distillate fuel

categories DMX, DMA, DMB, DMZ, DFA, DFB, DFZ and the residual fuel categories RMA, RME, RMG, RMK and RF.

In the instances where a fuel, which does not conform exactly to any of these distillate or residual fuel

categories, is offered to a purchaser, the fuel characteristics or limits can be agreed between the buyer and

the seller, and defined by both a category of fuel given by this document, together with any different or

additional fuel characteristics or limits, as necessary to adequately define that fuel.

This document specifies the permitted minimum flash point limits following the provisions given in the

[3]

SOLAS Convention.

[4]

MARPOL Annex VI, which controls air pollution from ships, includes a requirement that either the fuel

does not exceed a specified maximum sulfur content, or an approved equivalent alternative means is

used. During the lifetime of this document, regional and/or national authorities can introduce their own

local emission requirements, which can impact the allowable sulfur content. It is the buyer’s and the user’s

responsibility to establish which statutory requirements are necessary to meet and specify on that basis the

corresponding maximum fuel sulfur content to the seller.

vii

International Standard ISO 8217:2024(en)

Products from petroleum, synthetic and renewable sources —

Fuels (class F) — Specifications of marine fuels

WARNING — The handling and use of products specified in this document can be hazardous

if precautions as mentioned in the Safety Data Sheet (SDS) are not taken into consideration

when product is handled. This document does not purport to address all the safety and health

considerations that can be associated with its use. It is the responsibility of the users of this document

to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use.

1 Scope

This document in its entirety defines the general requirements and specifications for fuels used in marine

diesel engines and boilers, prior to onboard fuel handling (storage, settling, centrifuging, filtration, heating)

before use.

For the purposes of this document, the term “fuels” comprises of the following:

— hydrocarbons from petroleum crude oil, oil sands and shale oil;

— synthetic hydrocarbons, renewable hydrocarbons or hydrocarbons from recycled sources, with

molecular structures that are indistinguishable from petroleum hydrocarbons;

— fatty acid methyl ester (FAME), where permitted as specified in this document;

— blends of any of the above, where permitted as specified in this document.

The general requirements and specifications for fuels in this document can also be applied to fuels used in

stationary diesel engines of the same or similar type as those used for marine purposes.

This document specifies seven categories of distillate fuels, one of which is for diesel engines used for

emergency purposes. It also specifies four categories of residual fuels for sulfur content at or below

0,50 % by mass, five categories of residual fuels containing FAME and five categories of residual fuels for

sulfur content exceeding 0,50 % by mass.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 2719, Determination of flash point — Pensky-Martens closed cup method

ISO 3015, Petroleum and related products from natural or synthetic sources — Determination of cloud point

ISO 3016, Petroleum and related products from natural or synthetic sources — Determination of pour point

ISO 3104, Petroleum products — Transparent and opaque liquids — Determination of kinematic viscosity and

calculation of dynamic viscosity

ISO 3675, Crude petroleum and liquid petroleum products — Laboratory determination of density —

Hydrometer method

ISO 3733, Petroleum products and bituminous materials — Determination of water — Distillation method

ISO 4259-2, Petroleum and related products — Precision of measurement methods and results — Part 2:

Interpretation and application of precision data in relation to methods of test

ISO 4264, Petroleum products — Calculation of cetane index of middle-distillate fuels by the four variable

equation

ISO 5165, Petroleum products — Determination of the ignition quality of diesel fuels — Cetane engine method

ISO 6245, Petroleum products — Determination of ash

ISO 8754, Petroleum products — Determination of sulfur content — Energy-dispersive X-ray fluorescence

spectrometry

ISO 10307-1, Petroleum products — Total sediment in residual fuel oils — Part 1: Determination by hot filtration

ISO 10307-2, Petroleum products — Total sediment in residual fuel oils — Part 2: Determination using standard

procedures for ageing

ISO 10370, Petroleum products — Determination of carbon residue — Micro method

ISO 10478, Petroleum products — Determination of aluminium and silicon in fuel oils — Inductively coupled

plasma emission and atomic absorption spectroscopy methods

ISO 12156-1, Diesel fuel — Assessment of lubricity using the high-frequency reciprocating rig (HFRR) — Part 1:

Test method

ISO 12185, Crude petroleum, petroleum products and related products — Determination of density —

Laboratory density meter with an oscillating U-tube sensor

ISO 12205, Petroleum products — Determination of the oxidation stability of middle-distillate fuels

ISO 12937, Petroleum products — Determination of water — Coulometric Karl Fischer titration method

ISO 14596, Petroleum products — Determination of sulfur content — Wavelength-dispersive X-ray fluorescence

spectrometry

ISO 14597, Petroleum products — Determination of vanadium and nickel content — Wavelength-dispersive

X-ray fluorescence spectrometry

EN 116, Diesel and domestic heating fuels — Determination of cold filter plugging point — Stepwise cooling

bath method

EN 14077, Petroleum products — Determination of organic halogen content — Oxidative microcoulometric method

EN 14078, Liquid petroleum products — Determination of fatty methyl ester (FAME) content in middle distillates

- Infrared spectrometry method

EN 14214, Liquid petroleum products — Fatty acid methyl esters (FAME) for use in diesel engines and heating

applications — Requirements and test methods

EN 15195, Liquid petroleum products — Determination of ignition delay and derived cetane number (DCN) of

middle distillate fuels by combustion in a constant volume chamber

EN 15751, Automotive fuels — Fatty acid methyl ester (FAME) fuel and blends with diesel fuel — Determination

of oxidation stability by accelerated oxidation method

EN 15940, Automotive fuels — Paraffinic diesel fuel from synthesis or hydrotreatment — Requirements and

test methods

EN 16329, Diesel and domestic heating fuels — Determination of cold filter plugging point — Linear cooling

bath method

EN 16715, Liquid petroleum products — Determination of ignition delay and derived cetane number (DCN) of

middle distillate fuels — Ignition delay and combustion delay determination using a constant volume combustion

chamber with direct fuel injection

EN 17155, Liquid petroleum products — Determination of indicated cetane number (ICN) of middle distillate

fuels — Primary reference fuels calibration method using a constant volume combustion chamber

ASTM D240, Standard Test Method for Heat of combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter

ASTM D664, Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration

ASTM D2622, Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray

Fluorescence Spectrometry

ASTM D4294, Standard Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray

Fluorescence Spectrometry

ASTM D6751, Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels

ASTM D6890, Determination of Ignition Delay and Derived Cetane Number (DCN) of Diesel Fuel Oils by

Combustion in a Constant Volume Chamber

ASTM D7371, Standard Test Method for Determination of Biodiesel (Fatty Acid Methyl Esters) Content in Diesel

Fuel Oil Using Mid Infrared Spectroscopy (FTIR-ATR-PLS Method)

ASTM D7668, Standard Test Method for Determination of Derived Cetane Number (DCN) of Diesel Fuel Oils—

Ignition Delay and Combustion Delay Using a Constant Volume Combustion Chamber Method

ASTM D7963, Standard Test Method for Determination of Contamination Level of Fatty Acid Methyl Esters in

Middle Distillate and Residual Fuels Using Flow Analysis by Fourier-Transform Infrared Spectroscopy-Rapid

Screening Method

ASTM D8183, Standard Test Method for Determination of Indicated Cetane Number (ICN) of Diesel Fuel Oils

using a Constant Volume Combustion Chamber—Reference Fuels Calibration Method

IP 470, Determination of aluminium, silicon, vanadium, nickel, iron, calcium, zinc and sodium in residual fuel oil

by ashing, fusion and atomic absorption spectrometry

IP 500, Determination of the phosphorus content of residual fuels by ultra-violet spectrometry

IP 501, Determination of aluminium, silicon, vanadium, nickel, iron, sodium, calcium, zinc and phosphorus in

residual fuel oil by ashing, fusion and inductively coupled plasma emission spectrometry

IP 570, Determination of hydrogen sulfide in fuel oils — Rapid liquid phase extraction method

IP 631, Determination of the contamination level of fatty acid methyl esters in middle distillate and residual fuels

using Flow Analysis by Fourier Transform Infrared Spectroscopy — Rapid Screening Method

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

ultra low sulfur fuel oil

ULSFO

marine fuel with a maximum sulfur content of 0,10 % by mass

3.2

very low sulfur fuel oil

VLSFO

marine fuel with a maximum sulfur content of 0,50 % by mass

3.3

high sulfur fuel oil

HSFO

marine fuel with a sulfur content exceeding 0,50 % by mass

3.4

fatty acid methyl ester

FAME

ester derived by transesterification or esterification of fats and oils of vegetal or animal origin

Note 1 to entry: See Annex A for information on bio-based liquid fuels including fatty acid methyl ester(s).

3.5

bio-based

wholly or partly derived from biomass (3.7)

[SOURCE: ISO 16559:2022, 3.23, modified — “wholly or partly” added.]

3.6

biofuel

fuel produced directly or indirectly from biomass (3.7)

[SOURCE: ISO 16559:2022, 3.27, modified — “solid, liquid or gaseous” deleted.]

3.7

biomass

material of biological origin excluding material embedded in geological formations and/or fossilized

[SOURCE: ISO 16559:2022, 3.32, modified — Example and Note 1 to entry deleted.]

3.8

biodiesel

generic name for bio-based (3.5) fuel with properties similar to diesel or diesel containing bio-based blends

Note 1 to entry: The term is often used to describe fatty acid methyl ester (FAME) (3.4), but it is not exclusive to describe

FAME or fuel containing FAME.

3.9

bio-distillate marine fuel

blend of a petroleum distillate marine fuel with bio-based (3.5) liquid fuel

Note 1 to entry: DF grade is used to describe bio-distillate marine fuel grade.

3.10

bio-residual marine fuel

blend of a petroleum residual marine fuel with bio-based (3.5) liquid fuel

Note 1 to entry: RF grade is used to describe bio-residual marine fuel grade.

3.11

synthetic hydrocarbon

liquid hydrocarbon obtained from synthesis

3.12

renewable hydrocarbon

liquid hydrocarbon produced from renewable resources

Note 1 to entry: Biomass (3.7) is an example of a renewable resource.

3.13

paraffinic diesel fuel

liquid hydrocarbons obtained by synthesis or hydrotreatment

EXAMPLE Synthetic diesel, renewable diesel, hydrotreated vegetable oil (HVO) (3.14).

3.14

hydrotreated vegetable oil

HVO

liquid hydrocarbon produced from renewable feedstock by hydrotreatment

Note 1 to entry: Also called renewable diesel or paraffinic diesel fuel (3.13).

3.15

gas to liquid

GTL

liquid hydrocarbons obtained by the conversion of natural gas or other fossil gaseous hydrocarbons

3.16

biomass to liquid

BTL

liquid hydrocarbons obtained by the conversion of biomass (3.7) via thermochemical processes (gasification)

3.17

power to liquid

PtL

liquid hydrocarbons obtained by conversion of electricity

3.18

stability

stability of a residual fuel

resistance to the breakdown and precipitation of asphaltenic sludge despite being subjected to forces, such

as thermal and ageing stresses, while stored, handled and treated under normal operating conditions

[SOURCE: ISO/PAS 23263:2019, 3.1, modified — “handled and stored” replaced by “stored, handled and

treated”.]

3.19

compatibility

ability of two or more fuels to be commingled at a defined ratio without evidence of material separation,

which can result in the formation of multiple phases, such as flocculation, where dispersed particles of

asphaltenes form bigger clusters which can lead to sludge formation

[SOURCE: ISO/PAS 23263:2019, 3.2, modified — “could” and “might” replaced by “can”.]

3.20

cloud point

CP

temperature at which a cloud of wax crystals first appears in a transparent liquid when it is cooled under

specified conditions

[SOURCE: ISO/PAS 23263:2019, 3.4]

3.21

cold filter plugging point

CFPP

highest temperature at which a given volume of distillate fuel fails to pass through a standardized filtration

device in a specified time when cooled under standardized conditions

[SOURCE: ISO/PAS 23263:2019, 3.5]

3.22

pour point

PP

lowest temperature at which a fuel will continue to flow when it is cooled under specified standard conditions

[SOURCE: ISO/PAS 23263:2019, 3.6]

3.23

existent total sediment

TSE

sum of insoluble organic and inorganic material, separated from the bulk of the sample by filtration through

a specified filter, and also insoluble in a predominantly paraffinic solvent

Note 1 to entry: TSE is obtained by hot filtration.

[SOURCE: ISO 10307-1:2009, 3.1, modified — “existent” added to the term; “TSE” added as a preferred term;

Note 1 to entry added.]

3.24

potential total sediment

TSP

total sediment after ageing a sample of residual fuel for 24 h at 100 °C under prescribed conditions

[SOURCE: ISO 10307-2:2009, 3.1, modified — “TSP” added as a preferred term; “determined by ISO 10307-1,”

deleted from the definition.]

3.25

accelerated total sediment

TSA

total sediment after dilution of a sample of residual fuel with hexadecane in the ratio of 1 ml per 10 g of

sample under carefully controlled conditions, followed by storage for 1 h at 100 °C

[SOURCE: ISO 10307-2:2009, 3.2, modified — “TSA” added as a preferred term; “determined by ISO 10307-1,”

deleted from the definition.]

3.26

unrefined used lubricating oil

unrefined ULO

oil that has not been processed and filtered to remove lube oil additives and contaminants

Note 1 to entry: Refined used lubricating oil can be suitable as blend stock for marine fuel.

4 Application and sampling

This document specifies the required properties for a fuel at the time and place of custody transfer, prior to

onboard handling and treatment.

NOTE Appropriate guidance about fuel treatment systems for diesel engines can be found in Reference [5].

Sampling of a fuel is an important part of the fuel’s quality verification and should be carried out in

accordance with ISO 13739 or an equivalent national standard. The sample shall be representative for the

entire quantity of fuel loaded onto the receiving ship and may be taken in any location agreed between the

parties.

Testing of the fuel shall be carried out in accordance with the test methods given in Table 1, Table 2, Table 3

or Table 4, as appropriate.

5 General requirements

5.1 The fuel as supplied shall be homogeneous and conform to the characteristics and limits given in

Table 1, Table 2, Table 3 or Table 4, as appropriate, when tested in accordance with the methods specified.

The test methods and references listed in Tables 1, 2, 3 and 4 shall apply.

The fuel composition shall consist of:

— predominantly hydrocarbons from petroleum sources;

or

— hydrocarbons, with molecular structures that are indistinguishable from petroleum hydrocarbons,

derived from:

— synthetic or renewable sources such as paraffinic diesel e.g. hydrotreated vegetable oil (HVO), gas to

liquid (GTL), biomass to liquid (BTL) and power to liquid (PtL);

— co-processing of renewable or recycled feedstock at refineries with petroleum feedstock;

or

— fatty acid methyl ester (FAME) as defined in this document;

or

— a mixture of the above.

With regards to FAME, there are grades in this document for fuels not including FAME and for fuels including

an agreed percentage of FAME.

For fuels not including FAME:

— The DMA, DMZ, DMB and RM grades shall not include FAME other than a de minimis level. In the context

of this document, de minimis amount of FAME means an amount not exceeding approximately 0,5 %.

DMX shall be free of FAME.

NOTE See Annex A for further information.

For fuels with an agreed FAME content:

— the DF and RF grades are fuels including an amount of FAME where the FAME used for blending of the

fuel shall be in accordance with the requirements of EN 14214, except for

a) sulfur content, which is a statutory requirement;

b) cloud point (CP) and cold filter plugging point (CFPP) requirements as these are covered by the final

marine blend specifications in Table 1 of this document;

or ASTM D6751, except for sulfur content.

— The FAME content of the fuel (percentage by mass or volume) and the FAME standards (EN 14214 or

ASTM D6751) shall be reported prior to the time of the delivery and in line with original equipment

manufacturer’s guidance. In the event that other national FAME standards are offered, see Annex A.

5.2 The fuel shall be free from any materials, including added substances and chemical species, at a

concentration that causes the fuel to be unacceptable for use by way of:

a) jeopardizing the safety of the ship; or

b) adversely affecting the performance of the machinery; or

c) being harmful to personnel.

NOTE See Annex B for information on the composition of marine fuels.

5.3 The fuel shall be free from inorganic acids and organic chlorides (chlorinated hydrocarbons).

NOTE 1 See 6.6 and 6.17.

NOTE 2 See Annex B for information on the composition of marine fuels.

5.4 Subject to the requirements of 5.1, 5.2 and 5.3, additives that improve some aspects of the fuel’s

characteristics or performance are permitted.

6 Test methods

6.1 Density

In case of disagreement concerning density, all parties shall agree, prior to additional testing, upon the test

method to be used.

6.2 CCAI

The calculated carbon aromaticity index (CCAI) shall be as specified in Table 2, Table 3 or Table 4.

[6]

The CCAI value, I , is calculated in accordance with Lewis, et al. , using Formula (1):

CCA

T +273

I =−ρν81−⋅141 lg lg(,+085)l−⋅483 g (1)

[]

CCA 15

323

where

ρ is the density at 15 °C, expressed in kilograms per cubic metre;

ν is the kinematic viscosity at temperature T, expressed in square millimetres per second;

T is the temperature, expressed in degrees Celsius, at which the kinematic viscosity is determined.

Density, ρ , and viscosity, v, shall be determined in accordance with the test methods specified in Tables 2, 3 or 4.

NOTE 1 See Annex C for information on ignition characteristics of residual marine fuels.

NOTE 2 For engines and/or applications where the ignition quality is known to be particularly critical, Annex C

provides a basis for buyers and sellers of residual fuels to agree on tighter ignition quality characteristics.

NOTE 3 For some fuels when blending at or close to the maximum density, the CCAI limit restricts the combination

of density and viscosity.

NOTE 4 CCAI was originally developed for petroleum-derived fuels. As such, its applicability to bio-residual marine

fuels and the density/viscosity correlation to ignition performance has not been established.

6.3 Sulfur

Table 1, Table 3 and Table 4 do not set sulfur limits, since the buyer is responsible for specifying the maximum

sulfur content when ordering the fuel, based on the regulatory requirement applicable to where the fuel will

be used or any existing exhaust gas cleaning system requirement. For fuels ordered to Table 2, the buyer

shall still specify the required sulfur content to the seller.

Sulfur test precision for fuels containing FAME has not been established for the test methods specified in

ISO 8754 and ISO 14596. The sulfur test precision for distillate fuels containing FAME has been established

for the test method specified in ASTM D4294.

The reference test method shall be as specified in ISO 8754 for distillate marine (DM) and residual marine

(RM) fuels, in ASTM D4294 for distillate fuels including FAME (DF), and in ASTM D4294 or ASTM D2622 for

residual fuels including FAME (RF).

In case of disagreement concerning sulfur content, all parties shall agree, prior to additional testing, upon

the same sulfur certified reference material, and for RF grades upon the reference test method.

6.4 Flash point

[3]

The International Convention for Safety of Life at Sea (SOLAS) sets the flash point limit for all fuels at

60 °C minimum. An exception to this is DMX, which has a flash point limit of 43 °C minimum.

Fuels have the potential to produce a flammable atmosphere in a tank headspace, even when stored at a

temperature below the measured flash point. Appropriate precautions are necessary, therefore, to ensure

the safety of the ship and personnel. Further information and advice on precautionary measures are given in

References [7] to [9].

The flash point is not a physical constant, but is dependent on the test method, the apparatus and the

procedure used.

The flash point for fuels in Table 1 shall be determined in accordance with ISO 2719, Procedure A. For 100 %

FAME, ISO 2719, Procedure C shall be applied. The flash point of fuels in Table 2, Table 3 and Table 4 shall be

determined in accordance with ISO 2719, Procedure B.

6.5 Hydrogen sulfide

The reference test method shall be IP 570, Procedure A.

WARNING — Hydrogen sulfide (H S) is a highly toxic gas. Exposure to any significant vapour

concentrations is hazardous and, in extreme cases, can be fatal. It is critical that ship owners,

operators and other responsible parties continue to maintain appropriate safety practices designed

to protect the crew and others who can be exposed to H S vapours.

NOTE See Annex D for further information.

6.6 Acid number

The fuel shall be free of inorganic acids. The acid number of DM and RM fuels shall be determined in

accordance with ASTM D664, Procedure A. The acid number of DF and RF fuels shall be tested in accordance

with ASTM D664, Procedure B.

In case of dispute concerning acid number, all parties shall agree, prior to additional testing, upon which

procedure of ASTM D664 shall be used.

NOTE See Annex E for further information.

6.7 Oxidation stability

The oxidation stability shall be as specified in Table 1.

For fuels not including FAME or containing less than 2 % of FAME by volume, oxidation stability shall be

tested in accordance with ISO 12205.