kSIST FprEN 853:2026

(Main)Rubber hoses and hose assemblies - Wire braid reinforced hydraulic type - Specification

Rubber hoses and hose assemblies - Wire braid reinforced hydraulic type - Specification

This document specifies requirements for four types of wire braid reinforced hoses and hose assemblies of nominal bore from 5 to 76: Types 1SN, 2SN, 1ST and 2ST. They are suitable for use with:

— hydraulic fluids in accordance with ISO 6743 4 with the exception of all flame retardant HFD fluids at temperatures ranging from −40 °C to +100 °C;

— water based fluids at temperatures ranging from −40 °C to +70 °C;

— water at temperatures ranging from 0 °C to +70 °C.

The hoses are not suitable for use with castor oil based and ester-based fluids.

This document does not include requirements for end fittings. It is limited to the performance of hoses and hose assemblies.

NOTE Requirements for hydraulic hoses for underground mining are covered in other documents.

Gummischläuche und -schlauchleitungen - Hydraulikschläuche mit Drahtgeflechteinlage - Spezifikation

Dieses Dokument legt Anforderungen für vier Typen von Schläuchen und Schlauchleitungen mit Drahtgeflechteinlagen vom Nenndurchmesser 5 bis 76 fest: Typ 1SN, Typ 2SN, Typ 1ST und Typ 2ST. Sie sind geeignet zur Verwendung mit:

- Hydraulikflüssigkeiten nach ISO 6743 4 mit Ausnahme von allen flammhemmenden HFD-Flüssigkeiten in einem Temperaturbereich von −40 °C bis +100 °C;

- wässrigen Flüssigkeiten in einem Temperaturbereich von −40 °C bis +70 °C;

- Wasser in einem Temperaturbereich von 0 °C bis +70 °C.

Die Schläuche sind für Flüssigkeiten auf Rizinusöl- oder Esterbasis nicht geeignet.

Dieses Dokument enthält keine Anforderungen an die Endarmaturen. Es beschränkt sich auf die Leistungsfähigkeit der Schläuche und Schlauchleitungen.

ANMERKUNG Anforderungen an Hydraulikschläuche für den untertägigen Bergbau werden in anderen Dokumenten behandelt.

Tuyaux et flexibles en caoutchouc - Type hydraulique avec armature de fils métalliques tressés - Spécification

Le présent document spécifie les exigences pour quatre types de tuyaux et assemblages flexibles à armature tressée de fils métalliques, d’alésage nominal de 5 à 76 : Types 1SN, 2SN, 1ST et 2ST. Ils sont destinés à être utilisés avec :

— les fluides hydrauliques conformes à l'ISO 6743-4, à l'exception de tous les fluides HFD retardateurs de flamme, et dans une plage de températures de −40 °C à +100 °C ;

— les fluides aqueux dans une plage de températures de −40 °C à +70 °C ;

— l'eau dans une plage de températures de 0 °C à +70 °C.

Les tuyaux ne conviennent pas pour des utilisations avec des fluides à base d'huile de ricin ou d'ester.

Le présent document ne contient pas d'exigences relatives aux extrémités de raccordement. Il se limite aux performances des tuyaux et assemblages flexibles.

NOTE Les exigences pour les tuyaux hydrauliques pour mines souterraines font l'objet d'un autre document.

Gumene cevi in cevni priključki - Z jeklenim kordom ojačene hidravlične cevi - Specifikacija

General Information

- Status

- Not Published

- Public Enquiry End Date

- 30-Dec-2024

- Technical Committee

- IPMA - Polimer materials and products

- Current Stage

- 5020 - Formal vote (FV) (Adopted Project)

- Start Date

- 05-Jan-2026

- Due Date

- 23-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

Overview

The European standard oSIST prEN 853:2024:2024 specifies the requirements for wire braid reinforced hydraulic rubber hoses and hose assemblies. It covers four hose types-1SN, 2SN, 1ST, and 2ST-designed for nominal bore sizes ranging from 5 to 76 millimeters. These hoses are engineered for fluid power applications involving hydraulic fluids (per ISO 6743-4), water-based fluids, and water, across specified temperature ranges. This standard updates and supersedes EN 853:2015, reflecting technical enhancements and harmonization with related EN standards.

Key Topics

Hose Types and Construction

- Type 1SN and 2SN: Single and double wire braid reinforcements with thinner covers suitable for fittings that do not require cover removal. Recommended for new hydraulic fluid power designs.

- Type 1ST and 2ST: Single and double wire braid reinforcements with thicker covers; no longer recommended for new hydraulic fluid applications.

- Hose construction consists of synthetic rubber linings resistant to oil and water, layers of high tensile steel wire reinforcement, and oil/weather-resistant rubber covers with synthetic rubber insulation layers separating wire braids.

Performance Requirements

- Hydrostatic pressure thresholds including maximum working, proof, and burst pressures tailored by hose type and nominal bore.

- Minimum bend radii ensuring hose integrity without significant deformation during operation.

- Impulse testing at elevated temperatures (100 °C) to simulate dynamic pressure variations in hydraulic systems.

- Cold flexibility performance down to −40 °C.

- Resistance to vacuum, ozone, abrasion, and fluid exposure aligned with stringent testing criteria.

Material Compatibility

- Suitable for hydraulic fluids (excluding flame retardant HFD R, S, and T types), water-based fluids between −40 °C and +70 °C, and water between 0 °C and +70 °C.

- Not suitable for castor oil or ester-based fluid applications.

Dimensions and Tolerances

- Detailed specifications on hose diameters, concentricity, and length tolerances for both hoses and hose assemblies, conforming to EN ISO 4671.

- Strict limits on wall thickness variation to ensure consistent hose performance and safety.

Applications

This standard is critical for industries requiring reliable, high-performance hydraulic hose solutions, including:

Industrial Hydraulic Systems

- Machinery and manufacturing equipment that operate under high pressure and varying temperatures.

Mobile Hydraulics

- Agricultural machinery, construction vehicles, and other off-road equipment relying on fluid power systems.

Water-Based Fluid Systems

- Cooling, lubrication, or fluid transport systems using water or water-based hydraulic fluids within specified temperature ranges.

General Engineering Applications

- Wherever wire braid reinforced hydraulic hoses are needed to maintain pressure integrity, flexibility, and resistance to environmental stressors.

The standard ensures that hose assemblies produced and installed conform to stringent performance and safety criteria, reducing downtime and failure risk in hydraulic operations.

Related Standards

- EN ISO 6743-4 - Classification of hydraulic fluids suitable for use with hoses under this standard.

- EN ISO 1402 - Procedures for hydrostatic testing of hoses and assemblies.

- EN ISO 4671 - Measurement methods for hose dimensions and assembly lengths.

- EN ISO 6803 - Methods for hydraulic-pressure impulse testing without flexing.

- EN ISO 7233 - Determination of resistance to vacuum in hoses.

- EN ISO 7326 - Assessment of ozone resistance under static conditions.

- EN ISO 8033 - Testing adhesion between hose components.

- EN ISO 10619-2 - Evaluating hose flexibility and stiffness at sub-ambient temperatures.

- ISO 1817 - Testing effects of liquids on vulcanized or thermoplastic rubber.

Keywords: rubber hydraulic hoses, wire braid reinforced hoses, hydraulic hose assemblies, oSIST prEN 853:2024, hydraulic fluid power, hose performance standards, wire braid hoses, hydraulic hose specifications, EN 853 replacement, industrial hydraulic hoses, hose testing methods, hydraulic hose dimensions, hose pressure ratings, hose flexibility, hose abrasion resistance, hydraulic hose temperature range.

Frequently Asked Questions

kSIST FprEN 853:2026 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Rubber hoses and hose assemblies - Wire braid reinforced hydraulic type - Specification". This standard covers: This document specifies requirements for four types of wire braid reinforced hoses and hose assemblies of nominal bore from 5 to 76: Types 1SN, 2SN, 1ST and 2ST. They are suitable for use with: — hydraulic fluids in accordance with ISO 6743 4 with the exception of all flame retardant HFD fluids at temperatures ranging from −40 °C to +100 °C; — water based fluids at temperatures ranging from −40 °C to +70 °C; — water at temperatures ranging from 0 °C to +70 °C. The hoses are not suitable for use with castor oil based and ester-based fluids. This document does not include requirements for end fittings. It is limited to the performance of hoses and hose assemblies. NOTE Requirements for hydraulic hoses for underground mining are covered in other documents.

This document specifies requirements for four types of wire braid reinforced hoses and hose assemblies of nominal bore from 5 to 76: Types 1SN, 2SN, 1ST and 2ST. They are suitable for use with: — hydraulic fluids in accordance with ISO 6743 4 with the exception of all flame retardant HFD fluids at temperatures ranging from −40 °C to +100 °C; — water based fluids at temperatures ranging from −40 °C to +70 °C; — water at temperatures ranging from 0 °C to +70 °C. The hoses are not suitable for use with castor oil based and ester-based fluids. This document does not include requirements for end fittings. It is limited to the performance of hoses and hose assemblies. NOTE Requirements for hydraulic hoses for underground mining are covered in other documents.

kSIST FprEN 853:2026 is classified under the following ICS (International Classification for Standards) categories: 23.040.70 - Hoses and hose assemblies; 23.100.40 - Piping and couplings. The ICS classification helps identify the subject area and facilitates finding related standards.

kSIST FprEN 853:2026 has the following relationships with other standards: It is inter standard links to SIST EN 853:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase kSIST FprEN 853:2026 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN 853:2024

01-december-2024

Gumene cevi in cevni priključki - Z jeklenim kordom ojačene hidravlične cevi -

Specifikacija

Rubber hoses and hose assemblies - Wire braid reinforced hydraulic type - Specification

Gummischläuche und -schlauchleitungen - Hydraulikschläuche mit Drahtgeflechteinlage

- Spezifikation

Tuyaux et flexibles en caoutchouc - Type hydraulique avec armature de fils métalliques

tressés - Spécification

Ta slovenski standard je istoveten z: prEN 853

ICS:

23.040.70 Gumene cevi in armature Hoses and hose assemblies

23.100.40 Cevna napeljava in sklopke Piping and couplings

oSIST prEN 853:2024 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN 853:2024

oSIST prEN 853:2024

DRAFT

EUROPEAN STANDARD

prEN 853

NORME EUROPÉENNE

EUROPÄISCHE NORM

October 2024

ICS 23.040.70 Will supersede EN 853:2015

English Version

Rubber hoses and hose assemblies - Wire braid reinforced

hydraulic type - Specification

Tuyaux et flexibles en caoutchouc - Type hydraulique Gummischläuche und -schlauchleitungen -

avec armature de fils métalliques tressés - Spécification Hydraulikschläuche mit Drahtgeflechteinlage -

Spezifikation

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 218.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 853:2024 E

worldwide for CEN national Members.

oSIST prEN 853:2024

prEN 853:2024 (E)

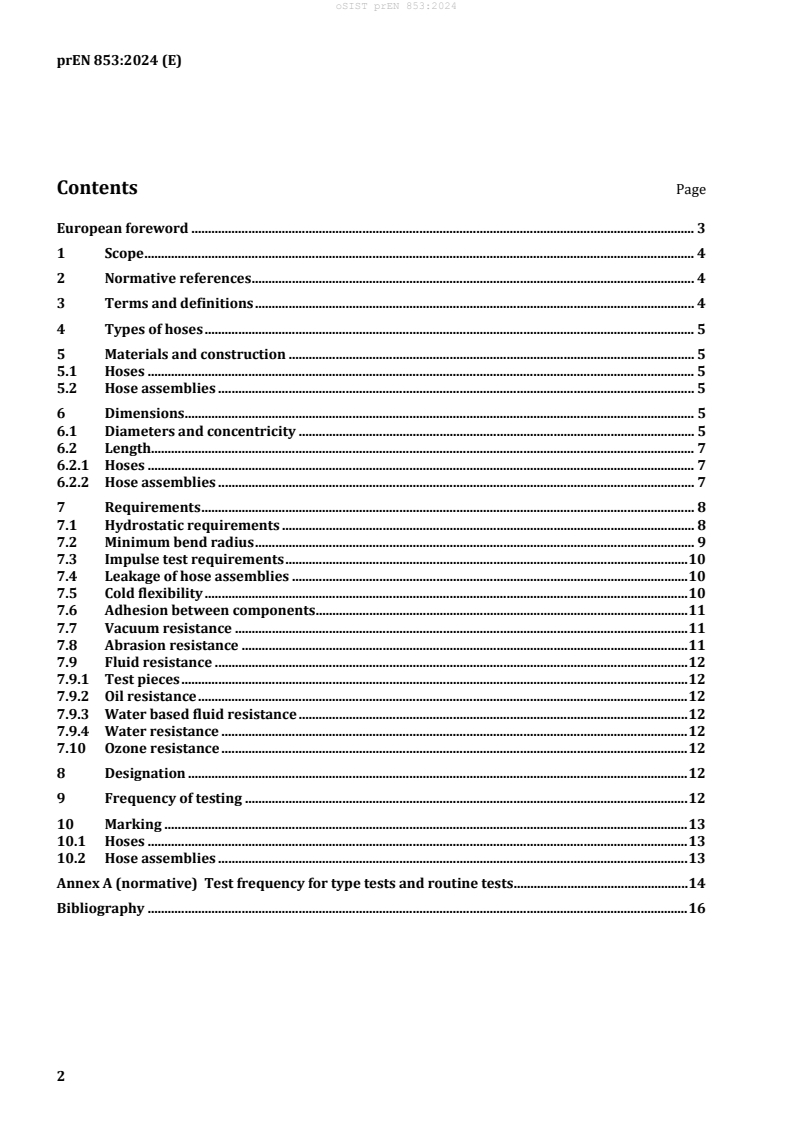

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 4

4 Types of hoses . 5

5 Materials and construction . 5

5.1 Hoses . 5

5.2 Hose assemblies . 5

6 Dimensions. 5

6.1 Diameters and concentricity . 5

6.2 Length. 7

6.2.1 Hoses . 7

6.2.2 Hose assemblies . 7

7 Requirements . 8

7.1 Hydrostatic requirements . 8

7.2 Minimum bend radius . 9

7.3 Impulse test requirements . 10

7.4 Leakage of hose assemblies . 10

7.5 Cold flexibility . 10

7.6 Adhesion between components . 11

7.7 Vacuum resistance . 11

7.8 Abrasion resistance . 11

7.9 Fluid resistance . 12

7.9.1 Test pieces . 12

7.9.2 Oil resistance . 12

7.9.3 Water based fluid resistance . 12

7.9.4 Water resistance . 12

7.10 Ozone resistance . 12

8 Designation . 12

9 Frequency of testing . 12

10 Marking . 13

10.1 Hoses . 13

10.2 Hose assemblies . 13

Annex A (normative) Test frequency for type tests and routine tests . 14

Bibliography . 16

oSIST prEN 853:2024

prEN 853:2024 (E)

European foreword

This document (prEN 853:2024) has been prepared by Technical Committee CEN/TC 218 “Rubber and

plastics hoses and hose assemblies”, the secretariat of which is held by BSI.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 853:2015.

This document includes the following significant technical changes with respect to EN 853:2015:

— scope changed (nominal bore extended: 5 to 76);

— EN 853, 854, 856 and 857 have been aligned;

— updated normative references;

— Table 7 added;

— Annex A deleted;

— Annex C deleted.

oSIST prEN 853:2024

prEN 853:2024 (E)

1 Scope

This document specifies requirements for four types of wire braid reinforced hoses and hose assemblies

of nominal bore from 5 to 76: Types 1SN, 2SN, 1ST and 2ST. They are suitable for use with:

— hydraulic fluids in accordance with ISO 6743-4 with the exception of HFD R, HFD S and HFD T at

temperatures ranging from −40 °C to +100 °C;

— water based fluids at temperatures ranging from −40 °C to +70 °C;

— water at temperatures ranging from 0 °C to +70 °C.

The hoses are not suitable for use with castor oil based and ester-based fluids.

This document does not include requirements for end fittings. It is limited to the performance of hoses

and hose assemblies.

NOTE Requirements for hydraulic hoses for underground mining are covered in other documents.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 1402, Rubber and plastics hoses and hose assemblies — Hydrostatic testing (ISO 1402)

EN ISO 4671, Rubber and plastics hoses and hose assemblies — Methods of measurement of the dimensions

of hoses and the lengths of hose assemblies (ISO 4671)

EN ISO 6803, Rubber or plastics hoses and hose assemblies — Hydraulic-pressure impulse test without

flexing (ISO 6803)

EN ISO 7233, Rubber and plastics hoses and hose assemblies — Determination of resistance to vacuum

(ISO 7233)

EN ISO 7326:2016, Rubber and plastics hoses — Assessment of ozone resistance under static conditions

(ISO 7326:2016)

EN ISO 8033, Rubber and plastics hoses — Determination of adhesion between components (ISO 8033)

EN ISO 10619-2:2021, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness —

Part 2: Bending tests at sub-ambient temperatures (ISO 10619-2:2021)

ISO 1817:2024, Rubber, vulcanized or thermoplastic — Determination of the effect of liquids

ISO/TS 20444, Rubber and plastics hoses — Determination of abrasion resistance of the outer cover

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

Under preparation. Stage at time of preparation: ISO/DTS 20444

oSIST prEN 853:2024

prEN 853:2024 (E)

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

4 Types of hoses

Four types of hoses are specified, distinguished by their construction and maximum working pressure:

1) Type 1ST – hoses with a single braid of wire reinforcement;

2) Type 2ST – hoses with two braids of wire reinforcement;

3) Type 1SN – hoses with a single braid of wire reinforcement;

4) Type 2SN – hoses with two braids of wire reinforcement.

Types 1SN and 2SN shall be of the same reinforcement construction as types 1ST and 2ST, except that

they shall have thinner covers designed to assemble with fittings that do not require removal of the cover

or a portion of the cover.

For new designs of braided hoses in hydraulic fluid power applications hose types 1SN and 2SN, specified

in this document, and 1SC and 2SC, specified in EN 857, shall be used. Hose types 1ST and 2ST shall not

be used for new designs in hydraulic fluid power applications.

Hoses and hose assemblies shall not be operated outside the limits of this document.

5 Materials and construction

5.1 Hoses

Hoses shall consist of an oil and water resistant synthetic rubber lining, one or two layers of high tensile

steel wire and an oil and weather resistant rubber cover. Each wire ply shall be separated by an insulating

layer of synthetic rubber.

5.2 Hose assemblies

Hose assemblies shall only be manufactured with those hose fittings whose functionality as a defined

hose and fitting combination has been verified in accordance with 7.1, 7.3, 7.4 and 7.5 of this document.

The manufacturer’s instructions shall be followed for the preparation and fabrication of hose assemblies.

6 Dimensions

6.1 Diameters and concentricity

The diameters of the hoses shall be measured in accordance with EN ISO 4671 and as such shall conform

to the values in Table 1.

oSIST prEN 853:2024

prEN 853:2024 (E)

Table 1 — Diameters of hoses

Dimensions in millimetres except nominal bore

All types Type 1ST Type 1SN Type 2ST Type 2SN

Outside Outside Outside Outside

Nominal Inside Diameter over Cover Diameter over Cover

diameter of diameter diameter of diameter

bore diameter reinforcement thickness reinforcement thickness

hose of hose hose of hose

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...