oSIST prEN 534:2020

(Main)Corrugated bitumen sheets - Product specification and test methods

Corrugated bitumen sheets - Product specification and test methods

This European Standard specifies the technical properties and establishes the test and inspection methods for finished corrugated bitumen sheets on leaving the factory. It also provides for the evaluation of conformity of products with the requirements of this standard.

Bitumen-Wellplatten - Produktfestlegungen und Prüfverfahren

Dieses Dokument legt die technischen Eigenschaften von fertiggestellten Bitumen-Wellplatten bei Verlassen des Werks sowie die für sie geltenden Prüf und Überwachungsverfahren fest. Es dient auch der Prüfung und Verifizierung der Leistungsbeständigkeit (AVCP) der Produkte im Hinblick auf die Anforderungen des vorliegenden Dokuments.

Plaques ondulées bitumées - Spécifications des produits et méthodes d'essai

Le présent document spécifie les propriétés techniques ainsi que les méthodes d'essai et de contrôle portant sur les plaques ondulées bitumées finies sorties d'usine. Il prévoit également l'évaluation et la vérification de la constance des performances (EVCP) des produits par rapport aux exigences du présent document.

Valovite bitumenske plošče - Specifikacija proizvoda in preskusne metode

General Information

- Status

- Not Published

- Public Enquiry End Date

- 19-May-2020

- Technical Committee

- IKER - Ceramics

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 09-Apr-2020

- Due Date

- 27-Aug-2020

- Completion Date

- 02-Jun-2020

Relations

- Revised

SIST EN 534:2006+A1:2010 - Corrugated bitumen sheets - Product specification and test methods - Effective Date

- 18-Jan-2023

- Revised

SIST EN 534:2006+A1:2010 - Corrugated bitumen sheets - Product specification and test methods - Effective Date

- 01-May-2020

Overview

The European Standard oSIST prEN 534:2020:2020 titled Corrugated bitumen sheets - Product specification and test methods has been developed by the CEN Technical Committee CEN/TC 128. This standard specifies technical properties and testing procedures for finished corrugated bitumen sheets as they leave the factory. It establishes mandatory test and inspection methods, outlines product requirements, and provides a framework for verifying conformity. The standard supersedes EN 534:2006+A1:2010 and aligns with EU regulations, ensuring consistent quality and safety that supports both roofing and cladding applications.

Corrugated bitumen sheets are manufactured from a blend of organic and inorganic fibers combined with bitumen, which guarantees durability and mechanical strength. The sheets may also have surface coatings or be spun-dyed to enhance aesthetics and performance. They are categorized based on mechanical performance into two classes: Category R for robust applications suitable in most climates, and Category S for less demanding environments, requiring careful installation.

Key Topics

Technical Characteristics

- Geometrical properties such as length, width, thickness, height and pitch of corrugations, and squareness with defined tolerances.

- Mechanical properties including bending strength, impact resistance, and tearing strength classified for categories R and S.

- Physical properties covering water impermeability, bitumen content (minimum 40%), mass tolerance, product homogeneity, water absorption limits, and slip resistance.

- Durability aspects like resistance after freeze/thaw cycling and thermal expansion coefficient values.

- Fire performance requirements, including reaction to fire and external fire exposure performance tests as per EN 13501 series.

Testing and Inspection Methods

- Detailed procedures for sampling and preparing test specimens.

- Specific test methods targeting geometrical dimensions, mechanical behavior under load, physical property verification, durability tests, and fire classification.

- Procedures for factory production control (FPC) and assessment & verification of constancy of performance (AVCP).

Installation Guidance

- Manufacturers’ installation instructions must be followed to ensure correct application of sheets depending on their performance category and intended use.

Applications

Corrugated bitumen sheets covered by oSIST prEN 534:2020:2020 find significant usage mainly in:

- Roofing Systems: Category R products are recommended for roofing applications across diverse climatic conditions due to their enhanced durability and mechanical strength.

- External Wall Cladding: Both Category R and S sheets are suitable for cladding, offering water resistance and long-term weather protection.

- Building Envelope Solutions: Their impermeable, impact-resistant, and fire-rated properties make these sheets a reliable choice for safeguarding building structures.

- Construction Industry: Applicable in both new construction and renovation projects, ensuring compliance with European safety and quality standards.

Related Standards

- EN 13501-1:2018 - Fire classification of construction products and building elements (reaction to fire tests).

- EN 13501-5:2016 - Fire classification using data from external fire exposure to roofs tests.

- CEN/TS 1187:2012 - Methods for testing external fire exposure to roofs.

- ISO 7892:1988 - Vertical building elements impact resistance testing.

- EU Construction Products Regulation (EU) No. 305/2011 - Relates to product conformity and CE marking requirements.

Keywords: Corrugated bitumen sheets, product specification, test methods, roofing materials, cladding sheets, mechanical properties, fire performance, water impermeability, durability, European Standard oSIST prEN 534:2020, CEN standard, factory production control, conformity assessment, building envelope, roofing products.

Frequently Asked Questions

oSIST prEN 534:2020 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Corrugated bitumen sheets - Product specification and test methods". This standard covers: This European Standard specifies the technical properties and establishes the test and inspection methods for finished corrugated bitumen sheets on leaving the factory. It also provides for the evaluation of conformity of products with the requirements of this standard.

This European Standard specifies the technical properties and establishes the test and inspection methods for finished corrugated bitumen sheets on leaving the factory. It also provides for the evaluation of conformity of products with the requirements of this standard.

oSIST prEN 534:2020 is classified under the following ICS (International Classification for Standards) categories: 75.140 - Waxes, bituminous materials and other petroleum products; 91.060.20 - Roofs. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 534:2020 has the following relationships with other standards: It is inter standard links to SIST EN 534:2006+A1:2010, SIST EN 534:2006+A1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 534:2020 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/121, M/122. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase oSIST prEN 534:2020 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2020

Valovite bitumenske plošče - Specifikacija proizvoda in preskusne metode

Corrugated bitumen sheets - Product specification and test methods

Bitumen-Wellplatten - Produktfestlegungen und Prüfverfahren

Plaques ondulées bitumées - Spécifications des produits et méthodes d'essai

Ta slovenski standard je istoveten z: prEN 534

ICS:

75.140 Voski, bitumni in drugi naftni Waxes, bituminous materials

proizvodi and other petroleum products

91.060.20 Strehe Roofs

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

April 2020

ICS 91.100.50 Will supersede EN 534:2006+A1:2010

English Version

Corrugated bitumen sheets - Product specification and test

methods

Plaques ondulées bitumées - Spécifications des Bitumen-Wellplatten - Produktfestlegungen und

produits et méthodes d'essai Prüfverfahren

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 128.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 534:2020 E

worldwide for CEN national Members.

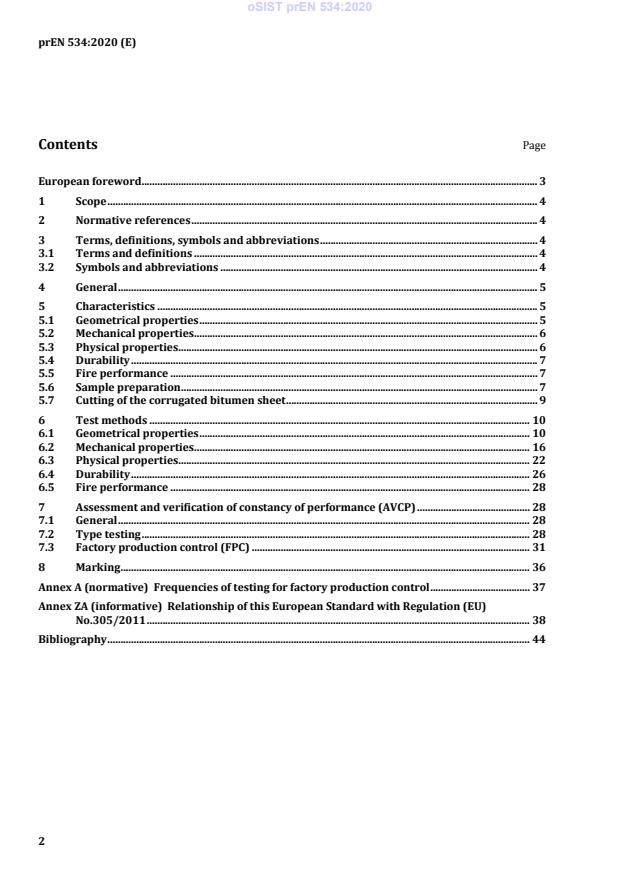

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms, definitions, symbols and abbreviations . 4

3.1 Terms and definitions . 4

3.2 Symbols and abbreviations . 4

4 General . 5

5 Characteristics . 5

5.1 Geometrical properties . 5

5.2 Mechanical properties . 6

5.3 Physical properties . 6

5.4 Durability . 7

5.5 Fire performance . 7

5.6 Sample preparation . 7

5.7 Cutting of the corrugated bitumen sheet . 9

6 Test methods . 10

6.1 Geometrical properties . 10

6.2 Mechanical properties . 16

6.3 Physical properties . 22

6.4 Durability . 26

6.5 Fire performance . 28

7 Assessment and verification of constancy of performance (AVCP) . 28

7.1 General . 28

7.2 Type testing . 28

7.3 Factory production control (FPC) . 31

8 Marking . 36

Annex A (normative) Frequencies of testing for factory production control . 37

Annex ZA (informative) Relationship of this European Standard with Regulation (EU)

No.305/2011 . 38

Bibliography . 44

European foreword

This document (prEN 534:2020) has been prepared by Technical Committee CEN/TC 128 “Roof

covering products for discontinuous laying and products for wall cladding”, the secretariat of which is

held by NBN.

This document will supersede EN 534:2006+A1:2010.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association.

For relationship with EU Regulation 305/2011, see informative Annex ZA, which is an integral part of

this document.

1 Scope

This document specifies the technical properties and establishes the test and inspection methods for

finished corrugated bitumen sheets on leaving the factory. It also provides assessment and verification

of constancy of performance (AVCP) of products with the requirements of this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

CEN/TS 1187:2012, Test methods for external fire exposure to roofs

EN 13501-1:2018, Fire classification of construction products and building elements - Part 1:

Classification using data from reaction to fire tests

EN 13501-5:2016, Fire classification of construction products and building elements - Part 5:

Classification using data from external fire exposure to roofs tests

ISO 7892:1988, Vertical building elements - Impact resistance tests - Impact bodies and general test

procedures

3 Terms, definitions, symbols and abbreviations

3.1 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.2 Symbols and abbreviations

L length of the sheet [mm]

w width of the sheet [mm]

H height of corrugations [mm]

f deflection of the sheet under stress [mm]

e nominal thickness [mm]

P mass of the sheet [kg/m ]

F load [N]

p pitch of corrugations [mm]

E squareness [mm/m]

α thermal coefficient [1/K]

4 General

Corrugated bitumen sheets are produced using a homogeneous mixture of organic and/or inorganic

fibres and bitumen. The shape and the structure of corrugated bitumen sheets and the quality of the

raw materials guarantee the properties.

Corrugated bitumen sheets may be spun-dyed. They may also be supplied with a coloured or colourless

adhesive surface coating, which in turn may or may not have a covering of granules or fine flakes.

Corrugated bitumen sheets may be manufactured as a mono-layer or a multi-layer product.

Corrugated bitumen sheets are divided into category R and category S depending on their mechanical

properties. For category R, all mechanical properties have to pass the threshold values of that category.

For roofing applications, category R products are suitable for most climatic conditions, while Category S

products may require special installation depending on the climatic conditions.

For cladding applications, both categories are suitable.

The manufacturer’s installation guide shall be consulted to ensure that the product is installed in the

correct manner for its category.

5 Characteristics

5.1 Geometrical properties

5.1.1 Length

When tested according to 6.1.1, the tolerance on length L shall be + 1,0 %, – 0,2 %.

5.1.2 Width

When tested according to 6.1.2, the tolerance on width w shall be ± 2 %.

5.1.3 Thickness

When tested according to 6.1.3, the tolerance on thickness e shall be ± 10 %.

The thickness of the corrugated bitumen sheets shall be measured including any surface relief (surface

pattern) on the upper and lower sides (see Figure 4).

NOTE Due to the fact that the relief of the surfaces may be very different (e.g. from one manufacturer to the

other), the measurement of the thickness will give only some descriptive information and therefore cannot be

directly compared between different products.

5.1.4 Height of corrugations

When tested according to 6.1.4, the tolerance on the height of corrugations H shall be ± 6 %.

For corrugated bitumen sheets with various corrugation heights, all the declared corrugation heights

shall be measured.

5.1.5 Pitch of corrugations

When tested according to 6.1.5, the tolerance on the pitch of corrugations p shall be ± 3 %.

For corrugated bitumen sheets with various pitches and/or period of corrugation, all the declared

pitches and/or periods shall be measured.

5.1.6 Squareness

When tested according to 6.1.6, the squareness E shall be less than or equal to 4 mm/m.

5.2 Mechanical properties

5.2.1 Bending under downward load

When tested according to 6.2.1, the minimum load for a deflection of 1/200 of a span of 620 mm shall

be:

— category R ≥ 1 400 N/m

— category S > 700 N/m

NOTE For calculation of maximum permissible load in manufacturers' installation guides, other methods can

be used particularly in case of sheet shapes that do not allow the distributed downward load described in 6.2.1 to

be applied.

5.2.2 Impact strength

When tested according to 6.2.2, the falling height with a span of 620 mm shall be:

— category R = 400 mm;

— category S = 250 mm.

This characteristic is not relevant for external wall finishing products.

5.2.3 Tearing strength

When tested according to 6.2.3, the tear threshold value shall be greater than:

— category R = 200 N;

— category S = 150 N.

Where, in the case of a corrugated bitumen sheet with various corrugation heights, the manufacturer

defines which corrugation has to be used for fixing, only this corrugation has to be tested.

5.3 Physical properties

5.3.1 Water impermeability

When tested according to 6.3.1, no drop of water shall pass through the sheet after 48 h.

5.3.2 Proportion of bitumen

When tested according to 6.3.2, the bitumen content shall be equal to or greater than 40 %.

The properties are measured without any covering of granules or fine flakes.

5.3.3 Mass

When tested according to 6.3.3, the tolerance on the declared mass (expressed in kg/m ) shall be

± 10 %.

5.3.4 Homogeneity of the product

When tested according to 6.3.4, there shall be no area larger than 1 cm without bitumen.

5.3.5 Water absorption

When tested according to 6.3.5, the water absorption shall be less than 20 % of the mass of the sheet.

The properties are measured without any covering of granules or fine flakes.

5.3.6 Slip resistance

Due to their rough surfaces, corrugated bitumen sheets are not slippery products.

5.3.7 Load bearing capacity on the roof

Load bearing capacity depends on the method of support and fixing, which are not included in the scope

of this product standard.

NOTE The load level, the levels of safety and permissible deflection are defined in EUROCODES and/or

national building regulations.

5.4 Durability

5.4.1 Tearing strength after freeze/thaw ageing

When tested according to 6.4.1, the tearing strength shall not be lower than the initial threshold values

(5.2.3).

5.4.2 Water impermeability after freeze/thaw ageing

When tested according to 6.4.2, no drop of water shall pass through the sheet after 48 h.

5.4.3 Thermal coefficient

-6

When tested according to 6.4.3, the value of α shall be less than 100 x 10 1/K.

5.5 Fire performance

5.5.1 Reaction to fire

When declared, the reaction to fire shall be tested and classified in accordance with 6.5.1.

5.5.2 External fire performance

When declared, the external fire performance shall be assessed according to 6.5.2.

5.6 Sample preparation

Details of sampling and sample preparation for both type testing and factory production control testing

are given in Table 1.

Table 1 — Sampling and conditions of test specimens

Number Length

Width of Cutting of

of of Conditioning

samples the sheet

samples samples

6.1 Geometrical properties

6.1.1 Length No

Entire Entire

a

3 Required A

sheet sheet

6.1.2 Width No

Only if

6.1.3 Thickness

necessary

6.1.4 Height of corrugation No

Entire Entire

a

1 Required A

sheet sheet

Only if

6.1.5 Pitch of corrugation

necessary

6.1.6 Squareness No

6.2 Mechanical properties

Bending under downward Entire

6.2.1 5 Required B No

load sheet

Entire

6.2.2 Impact strength 5 Required B No

sheet

b

6.2.3 Tearing strength 5 3 corrug. 150 mm Required B See Figure 1

6.3 Physical properties

b a

6.3.1 Water impermeability 1 3 corrug 150 mm Required A See Figure 2

a

6.3.2 Proportion of bitumen 3 50 mm 100 mm Required A See Figure 2

Entire

a

6.3.3 Mass 3 Required B No

sheet

b a

6.3.4 Homogeneity of the product 12 ½ corrug 200 mm Required A See Figure 2

b a

6.3.5 Water absorption 3 2 corrug 200 mm Required B See Figure 2

6.4 Durability

Tearing strength after

b a

6.4.1 5 3 corrug 150 mm Required A See Figure 1

freeze/thaw ageing

Water impermeability after

b a

6.4.2 1 3 corrug 150 mm Required A See Figure 1

freeze/thaw ageing

a

6.4.3 Thermal coefficient 2 1 corrug. 250 mm Required B See Figure 1

A The test pieces shall be stored at laboratory conditions for at least 7 days.

B The test pieces shall be conditioned at (23 ± 2) °C and (50 ± 10) % relative humidity for at least 7 days.

a

In case of testing during production, the corrugated bitumen sheet may be tested without conditioning (A or

B). If the test cannot be performed immediately, the corrugated bitumen sheet shall be stored right away at

laboratory conditions.

b

If the corrugated bitumen sheet has a flat part, this shall be considered as one corrugation.

For reaction to fire and external fire performance, the number of samples and the conditioning shall be

according to the requirements of EN 13501-1:2018 and EN 13501-5:2016 respectively.

5.7 Cutting of the corrugated bitumen sheet

Figures 1 and 2 show the positions from which samples shall be taken, with the numbers referring to

the test subclause in the standard. Samples shall not be taken within the area of 200 mm from either

end.

Dimensions in millimeters

Figure 1 — Positions from which samples are taken

Dimensions in millimetres

Figure 2 — Positions from which samples are taken

6 Test methods

6.1 Geometrical properties

6.1.1 Length

6.1.1.1 Equipment

The test equipment is shown in Figure 3 and consists of a precision ruler with 0,5 mm divisions and a

stable flat plane.

6.1.1.2 Procedure

The measurement shall be taken while the sheet is supported on a stable flat plane.

The length shall be measured either at the crown of the corrugation or in the valley of the corrugation

on the second and penultimate corrugations.

The test is carried out on 3 different corrugated bitumen sheets.

6.1.1.3 Results

The result is the mean of the three mean values of the two measured values of each corrugated bitumen

sheet.

Dimensions in millimetres

Key

1 test piece

2 stable flat plane

Figure 3 — Length and width measurement

6.1.2 Width

6.1.2.1 Equipment

The test equipment is shown in Figure 3 and consists of a precision ruler with 0,5 mm divisions and a

stable flat plane.

6.1.2.2 Procedure

The measurement shall be taken while the sheet is supported on a stable flat plane.

The width shall be measured at a position 100 mm from each end of the sheet.

The test is carried out on 3 different corrugated bitumen sheets.

6.1.2.3 Results

The result is the mean of the three mean values of the two measured values of each corrugated bitumen

sheet.

6.1.3 Thickness

6.1.3.1 Equipment

The equipment is shown schematically in Figure 4 and consists of a precision measuring device with 0,1

mm divisions and with flat contact surfaces of minimum 5 mm diameter.

6.1.3.2 Procedure

The measurements shall be taken on the flank of the corrugation or on the flat part, 50 mm from the

edge of the sheet. 10 different flanks and/or flat parts positions shall be measured, 5 measurements at

each end of the sheet.

NOTE Cutting of the sheet can be necessary to ensure that the measurement can be taken correctly.

The measurement shall be performed with a maximum pressure of 2 N/cm , which guarantees a stable

measurement without compression of the surface.

The test is carried out on one corrugated bitumen sheet.

6.1.3.3 Results

The result is the arithmetic mean of the 10 measured values.

The result shall be expressed to the nearest 0,1 mm.

Dimensions in millimetres

Key

1 test piece

Figure 4 — Thickness measurement

6.1.4 Height of corrugations

6.1.4.1 Equipment

The test equipment is shown in Figure 5 and consists of a precision measuring device with 0,1 mm

divisions, a flat bar with a length longer than the corrugation pitch and a stable flat plane.

6.1.4.2 Procedure

The measurement shall be taken while the sheet is supported on a stable flat plane. The zero shall be

obtained by measuring the thickness of the flat bar before inserting the sheet.

The flat bar shall be placed on two adjacent corrugations of the same height. The height of corrugations

shall be measured at 50 mm from each end of the sheet.

Four measurements, evenly distributed over the width of the corrugated sheet, leaving out the first and

last corrugations, shall be taken.

The test is carried out on one corrugated bitumen sheet.

6.1.4.3 Results

The result is the arithmetic mean of the 8 measured values.

The result shall be expressed to the nearest 0,1 mm.

Key

1 test piece

2 stable flat plane

3 measuring device

4 flat bar

Figure 5 — Height of corrugation measurement

6.1.5 Pitch of corrugations

6.1.5.1 Equipment

The equipment is shown in Figure 6 and consists of a precision metal ruler with 0,5 mm divisions, a

stable flat plane and a set of at least three iron tubes with the same diameter of 200 mm length (the

diameter of the tube shall be such as to touch both flanks of the corrugations).

6.1.5.2 Procedure

Before measuring the pitch, the edge shall be free of burrs so that the tube is lying properly on the

flanks.

The measurement shall be taken while the sheet is supported on the stable flat plane, ensuring that the

valley of every corrugation is in contact with it.

At one end of the sheet, lay the tubes into the valleys of the corrugations with the end slightly out from

the end of the sheet. Measure the distance between the tubes to at least the nearest 0,5 mm.

On each side of the sheet, three measurements of the pitch and/or period shall be taken, evenly

distributed over the width of the corrugated sheet, leaving out the first and last pitch of corrugation.

The test is carried out on one corrugated bitumen sheet.

6.1.5.3 Results

The result is the arithmetic mean of the six measured values.

The result shall be expressed to at least the nearest 0,5 mm.

Key

1 test piece

2 metal tube

Figure 6 — Examples of pitch and period of corrugations

6.1.6 Squareness

6.1.6.1 Equipment

The equipment is shown in Figure 7 and consists of a stable flat plane exactly cut with 90° angle and

with a square edge on the bottom, one tube with a length 5 % longer than the length of the corrugated

bitumen sheet and a diameter such that it touches both flanks of the corrugations, and a precision metal

ruler with 0,5 mm divisions.

6.1.6.2 Procedure

The corrugated bitumen sheet shall be put on a stable flat plane, so that the corrugated end of the sheet

is resting on the square edge at the end of the plane. The tube shall be put in the middle of the

corrugated bitumen sheet centrally into a valley of the corrugation.

The distances x and x , from the side of the tube to the edge of the stable flat plane shall be measured

1 2

(Figure 7).

The distance Lx is then measured between x and x .

1 2

After this the corrugated bitumen sheet shall be turned around so that the other corrugated end of the

sheet is resting against the square edge. The same measurements as before shall be taken.

The test is carried out on one corrugated bitumen sheet.

6.1.6.3 Result

The squareness E is calculated as:

E = │(x – x )│/ Lx [mm/m]

1 2

The result is the arithmetic mean of the two calculated values.

The result is expressed to the nearest 1 mm.

Key

1 test piece

2 stable flat plane

3 tube

Figure 7 — Squareness measurement

6.2 Mechanical properties

6.2.1 Bending under downward load

6.2.1.1 Equipment

The equipment is shown in Figure 8. It consists of:

— strong horizontal bench larger than the corrugated bitumen sheet;

— four square tubes MSH 60 / 60 / 5 mm with a minimum length 10 % longer than the width of the

sheet;

— six channels 40 / 35 / 5 mm, with a length 10 % longer than the width of the sheet;

— three supports;

— three square bars 20 / 20 mm x 40 mm;

— I-beam HEA 140 x 1 500 mm;

— hydraulic or electro-mechanical cylinder capable of supplying a force of 10 kN;

— force receiver, mounted between I-beam and the cylinder;

— one electronic elongation device accurate to 0,01 mm with a fixed disk of 20 mm on the top;

— precision metal ruler with 0,5 mm divisions.

6.2.1.2 Procedure

6.2.1.2.1 Set up

With reference to Figure 8, the four square tubes are placed on the bench, adjusted to the span of 620

mm and properly fixed to the bench. The corrugated bitumen sheet is placed on the square tubes and

adjusted centrally under the cylinder. In the case of an irregular profile, the nearest bottom of a

corrugation is always at the centre of the cylinder.

The six channels with the three supports are placed loose on the sheet and adjusted. In the middle of

each support a square bar is placed as a joint for the I-beam.

The total mass of the preload shall be equal to (60 ± 5) kg.

The elongation device is mounted rigid and vertical underneath the test piece. The position shall be

exactly in the middle between the two square tubes and at the bottom of a corrugation directly central

under the cylinder.

After applying the six channels, three supports, I-beam, the force receiver and the elongation device,

ensure that there is no gap between the corrugated bitumen sheet and the two central square tubes. If a

gap exists, the corrugated bitumen sheet is not suitable for this test and shall be changed.

Once this check has been made, the electronic elongation device is set to zero.

6.2.1.2.2 Area of the load

The width w of the corrugated bitumen sheet is measured before the test according to 6.1.2. The length

shall be three times the distance between the square tubes, i.e. 3 x 620 mm = 1 860 mm.

The area over which the load is distributed shall be calculated as:

6 2

load area = w x 1 860 / 1 x 10 [m ]

All dimensions are in millimetres

Key

1 test piece 5 three supports 9 force receiver

2 four square tubes 6 three square bars 10 elongation device

3 horizontal bench 7 I-beam 11 check

4 six channels 8 cylinder

Figure 8 — Bending under downward load

6.2.1.2.3 Test execution

The speed of the cylinder shall be between 1 mm/min to 3 mm/min.

Force and elongation shall be recorded simultaneously, until the deflection is greater than 4,0 mm.

The test is carried out on five different corrugated bitumen sheets.

6.2.1.3 Results

Five graphs (one for each sheet) giving deflection as a function of force shall be produced. The force at

an elongation of 3,1 mm shall be read off these graphs. The uniform load for each sheet shall be

calculated using:

uniform load = force / load area [N/m ]

The result is the arithmetic mean of the five corrugated bitumen sheets, expressed to the nearest

10 N/m .

6.2.2 Impact strength

6.2.2.1 Equipment

The equipment is shown in Figure 9 and comprises:

— strong horizontal bench with a minimum height of 700 mm;

— four supports made of a metal square tube profile MSH 60 / 60 / 5 mm;

— four supports made of wood 60 / 60 mm;

— eight clamps;

— sphero-conical bag (ISO 7892:1988) filled with sand having a total mass of 40 kg;

— release hook.

6.2.2.2 Procedure

The corrugated bitumen sheet shall be laid on the construction and fixed by the four wooden supports,

using clamps or screws without compressing the height of the sheet.

The sack shall be positioned to have a height of fall between the bottom of the sack and the crown of the

corrugations, at mid-point between two supports and at the centre of the sheet, depending on the

category.

The sack shall be released without any initial momentum.

The test is carried out on five different corrugated bitumen sheets.

6.2.2.3 Results

The sheet shall resist the impact of the bag. The test is deemed to have failed if the sack passes

completely through the sheet.

For the test to be passed, all five corrugated bitumen sheet shall pass.

All dimensions are in millimetres

Key

1 test piece 5 eight clamps

2 four metal support 6 sphero-conical bag

3 horizontal bench 7 release hook

4 four wooden supports H height of fall

Figure 9 — Impact strength test

6.2.3 Tearing strength

6.2.3.1 Equipment

The test equipment is shown in Figure 10 and consists of:

— tensile machine with a speed of 50 mm/min;

— counter plate with a hole of 50 mm in the centre;

— two clamps, to prevent the test piece from moving;

— spacer to prevent the test piece from moving;

— steel disk with a diameter of 13 mm and a thickness of 6 mm minimum;

— one nail with a diameter of 3 mm.

6.2.3.2 Procedure

A 3 mm hole is drilled in the middle of the central corrugation of the test piece.

The nail is placed in the middle of the central corrugation with the disk resting on the crown of the

corrugation. The shank of the nail is fixed in the jaw of the tensile machine.

The maximum force required to pull the disk through the test piece shall be measured.

The test is carried out on five different sheets.

If a manufacturer declares that a certain corrugation has to be nailed, only that corrugation on each

sheet shall be tested.

6.2.3.3 Results

The result is the arithmetic mean of the five measurements, expressed to the nearest Newton.

All dimensions are in millimetres

Key

1 tensile machine

2 counter plate

3 two clamps

4 spacer

5 disk

6 nail

Figure 10 — Tearing strength test

6.3 Physical properties

6.3.1 Water impermeability

6.3.1.1 Equipment

The equipment is shown in Figure 11 and comprises a frame adapted to the test piece and a seal.

Demineralised water is also used.

6.3.1.2 Procedure

The frame shall be placed around the test piece and the edges between test piece and the wall of the

frame shall be sealed watertight.

Demineralised water shall be poured into this container to a height of 100 mm above the crown of the

corrugation. The temperature of the water shall be (23 ± 2) °C.

The resulting test specimen shall be left for (48 ± 2) h in laboratory conditions, temperature (23 ± 3) °C,

after which the underside of the test piece shall be examined to see if there is any water penetration.

The test is carried out on one sample.

NOTE Three corrugations when the product includes a flat area.

Key

1 test piece

2 three corrugations

3 frame

4 demineralized water

5 seal

Figure 11 — Water impermeability test

6.3.1.3 Results

The test shall be judged to have passed or failed using visual assessment.

6.3.2 Proportion of bitumen

6.3.2.1 Equipment

The equipment necessary consists of a bitumen extractor apparatus (e.g. Kumagawa or Soxhlet) and a

drying cabinet. Methylene chloride, Trichloroethylene or Toluene are also required.

6.3.2.2 Procedure

The test pieces shall be put into the drying cabinet at least for 48 h at 70 °C. The test pieces are then

weighed to the nearest 0,01 g, this being the mass before extraction.

The test pieces shall then be placed into the hot extraction apparatus, and extraction shall continue until

the solvent remains clear.

The test pieces shall then be removed and the solvent allowed to evaporate under a ventilated hood.

When the solvent has evaporated, the test pieces are put into the drying cabinet for at least for 12 h at

105 °C. The test pieces are then weighed to the nearest 0,01 g, this being the mass after extraction.

The test is carried out on three different samples.

6.3.2.3 Results

The bitumen content is calculated using:

content = [(mass before extraction – mass after extraction) / mass before extraction] x 100 [%].

The test is passed when all three tested samples meet the requirement.

6.3.3 Mass

6.3.3.1 Equipment

The equipment consists of a balance with a precision of ± 10 g.

6.3.3.2 Procedure

The total mass of each corrugated bitumen sheet shall be divided by the length (6.1.1) and width (6.1.2)

of the sheet.

The test is carried out on five different corrugated bitumen sheets.

6.3.3.3 Results

The result shall be the arithmetic mean of all five tested corrugated bitumen sheets, expressed to the

nearest 0,02 kg/m .

6.3.4 Homogeneity of the product

6.3.4.1 Equipment

The equipment consists of a cutter.

6.3.4.2 Procedure

Each test piece shall be peeled by hand (or with the help of a cutter) so as to reveal the largest possible

torn surface (see Figure 12).

Each surface shall be checked to see if there is any area without bitumen larger than 1 cm .

The test is carried out on twelve samples.

6.3.4.3 Results

The test is passed if, for all twelve samples, no surface contains any area without bitumen larger than

1 cm .

Figure 12 — Homogeneity of the product

6.3.5 Water absorption

6.3.5.1 Equipment

The equipment consists of a water bath, a drying cabinet and a balance. Demineralized water is also

required.

6.3.5.2 Procedure

The test pieces shall be put into the drying cabinet for at least 48 h at 70 °C until their mass becomes

constant. The test pieces are then weighed to the nearest 0,01 g, this being the mass before absorption.

The test pieces shall then be placed horizontally in a container of demineralised water, without

protection of the cut surfaces. The temperature of the water shall be (23 ± 2) °C and its level shall be

100 mm above the crown of the corrugations. The test pieces shall not touch each other.

After (24 ± 1) h, the test pieces shall be removed from the water and their surfaces wiped to remove any

drops of water. The test pieces are then weighed to the nearest 0,01 g, this being the mass after

absorption.

The test is carried out on three samples.

6.3.5.3 Results

The water absorption is calculated using:

absorption = [(mass after absorption – mass before absorption)/mass before absorption] x 100 [%].

The test is passed when all three tested samples meet the requirement.

6.4 Durability

6.4.1 Tearing strength after freeze/thaw ageing

6.4.1.1 Procedure

First the frost resistance conditioning procedure (6.4.4) shall be performed on each test piece. After the

last cycle, the test pieces shall be stored for 24 h at laboratory conditions and then the tearing strength

test (6.2.3) shall be performed.

The test is carried out on five samples.

6.4.1.2 Results

The result is the mean of the five measurements, expressed to the nearest newton.

6.4.2 Water impermeability after freeze/thaw ageing

6.4.2.1 Procedure

First the frost resistance conditioning procedure (6.4.4) shall be performed on the test piece. After the

last cycle, the test pieces shall be stored for at least 24 h at laboratory conditions and then the water

impermeability test (6.3.1) shall be performed. After (48 ± 2) h the underside of the test piece shall be

examined to see if there is any water penetration.

The test is carried out on one sample.

6.4.2.2 Results

The test shall be judged to have been passed or failed using visual assessment.

6.4.3 Thermal coefficient

6.4.3.1 Equipment

The equipment consists of two small needles, a heating chamber and a slide gauge.

6.4.3.2 Procedure

The two needles shall be affixed on the side of the test piece 200 mm apart. The distance between the

needles shall be measured with the slide gauge to an accuracy of ± 0,1 mm.

The test piece shall then be placed in the heating chamber, heated to (73 ± 2) °C and maintained at this

temperature for (4 ± 1) h. The test piece shall then be taken out and the distance between the two

needles shall be measured immediately with the slide gauge.

The test is carried out on two samples.

6.4.3.3 Results

The thermal coefficient α shall be calculated using:

α = (length after heating – length before heating) / (length before heating x ∆T) [1/K].

-6

The result is the mean of the two measurements, expressed in 10 1/K.

6.4.4 Frost resistance conditioning

6.4.4.1 Equipment

The equipment consists of a water bath, a ventilated oven capable of maintaining +50 °C and a freezer

capable of maintaining –20 °C. Demineralized water is also used.

6.4.4.2 Procedure

6.4.4.2.1 Absorption

The test pieces are placed horizontally in a container of demineralised water, without protection of the

cut surfaces. The temperature of the water shall be (23 ± 2) °C and the water level shall be 100 mm

above the crown of the corrugations. The test pieces shall not touch each other.

The test piece shall be removed from the water without wiping the water from the surface.

6.4.4.2.2 Freezing

The test piece shall be put immediately from the water bath into the freezer at –20 °C.

6.4.4.2.3 Thawing

The test piece shall be put immediately from the freezer into a ventilated oven at +50 °C.

6.4.4.2.4 Test cycles

The test piece shall be subject to the following cycles:

— Step 1 : absorption for (24 ± 1) h;

— Step 2 : cycle of:

— freezing (16 ± 1) h;

— thawing (4 ± 0,5) h;

— absorption (4 ± 0,5) h.

Repeat this cycle 22 times.

— Step 3 : last cycle:

— (16 ± 1) h freezing;

— (72 ± 2) h thawing.

In case of interruption of this test, the cycle may only be stopped during the freezing cycle, in which case

the test piece shall be left in the freezer.

NOTE This procedure is used only as conditioning for the tests in 6.4.1 and 6.4.2.

6.5 Fire performance

6.5.1 Reaction to fire

The reaction to fire of corrugated bitumen sheets shall be tested and classified in accordance with the

provisions of EN 13501-1:2018. Where a specific test method requires it, products shall be mounted

and fixed in the test apparatus in a manner representative of the product's intended end use conditions.

6.5.2 External fire performance

The external fire performance of corrugated bitumen sheets shall be tested according to one or more of

the methods described in CEN/TS 1187:2012 and shall be classified in accordance with the provisions

of EN 13501-5:2016. Products shall be mounted and fixed in the test apparatus in a manner

representative of the product's intended end use conditions.

7 Assessment and verification of constancy of performance (AVCP)

7.1 General

The compliance of corrugated bitumen sheets with the requirements of this standard and with the

declared values shall be demonstrated by:

— determination of the product type

— factory production control by the manufacturer, including product assessment.

The manufacturer shall always retain the overall control and shall have the necessary means to take

responsibility for the product, responsibility for the conformity of the product with its declared

performance(s).

NOTE Products may be grouped in different families for different characteristics.

7.2 Type testing

7.2.1 General

The determination of the product type shall be performed for all the performances related to essential

characteristics defined in this standard included in the declaration of performance drawn up by the

manufacturer.

All performances related to characteristics included in this standard shall be determined when the

manufacturer intends to declare the respective performances unless the standard gives provisions for

declaring them without performing tests (e.g. use of previously existing data, CWFT and conventionally

accepted performance).

Assessment previously performed in accordance with the provisions of this standard, may be taken into

account provided that they were made to the same or a more rigorous test method, under the same

AVCP system on the same product or products of similar design, construction and functionality, such

that the results are applicable to the product in question

NOTE Same AVCP system of means testing by an independent third party.

In addition, the determination of the product type shall be performed for all characteristics included in

the standard for which the manufacturer declares performances:

— at the beginning of the production of a new or modified corrugated bitumen sheets (unless a

member of the same family), or

— at the beginning of a new or modified method of production (where this may affect the stated

properties); or

they shall be repeated for the appropriate characteristic(s), whenever a change occurs in the corrugated

bitumen sheets design, in the raw material or in the supplier of the components, or in the production

process (subject to the definition of a family), which would affect significantly one or more of the

characteristics.

Where components are used whose characteristics have already been determined, by the component

manufacturer, on the basis of compliance with other product standards, these characteristics need not

be re-assessed. The specifications of these components shall be documented, as shall be included in the

inspection scheme for ensuring their compliance.

Products marked in accordance with appropriate harmonized European specifications may be

presumed to have the performances stated with the marking, although this does not replace the

responsibility on the corrugated bitumen sheets designer to ensure that the corrugated bitumen sheets

as a whole is correctly designed and its component products have the necessary performance values to

meet the design.

The number of samples of corrugated bitumen sheets to be tested/assessed shall be in accordance with

Table 2.

Table 2— Number of samples to be tested and compliance criteria

Characteristic Requirement Assessment No. of Compliance criteria

method samples

Geometrical 5.1

properties

Length 5.1.1 6.1.1 See 5.6 L [+1% ; -0.2%]

Width 5.1.2 6.1.2 See 5.6 w [+2% ; -2%]

Thickness 5.1.3 6.1.3 See 5.6 e [+10% ; -10%]

Height of 5.1.4 6.1.4 See 5.6 H [+6% ; -6%]

corrugations

P

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...