ASTM G58-85(2015)

(Practice)Standard Practice for Preparation of Stress-Corrosion Test Specimens for Weldments

Standard Practice for Preparation of Stress-Corrosion Test Specimens for Weldments

SIGNIFICANCE AND USE

4.1 The intent of this practice is to indicate standard welded specimens and welding procedures for evaluating the SCC characteristics of weldments in corrosive environments. The practice does not recommend the specific corrosive media that may be selected by the user depending upon the intent of his investigation. Specific corrosive media are included in Practices G35, G36, G37, and G44. Other environments can be used as required.

SCOPE

1.1 This practice covers procedures for the making and utilization of test specimens for the evaluation of weldments in stress-corrosion cracking (SCC) environments.

1.2 Test specimens are described in which (a) stresses are developed by the welding process only, (b) stresses are developed by an externally applied load in addition to the stresses due to welding, and (c) stresses are developed by an externally applied load only with residual welding stresses removed by annealing.

1.3 This practice is concerned only with the welded test specimen and not with the environmental aspects of stress-corrosion testing. Specific practices for the bending and loading of test specimens, as well as the stress considerations involved in preparation of C-rings, U-bend, bent-beam, and tension specimens are discussed in other ASTM standards.

1.4 The actual stress in test specimens removed from weldments is not precisely known because it depends upon the level of residual stress from the welding operation combined with the applied stress. A method for determining the magnitude and direction of residual stress which may be applicable to weldment is described in Test Method E837. The reproducibility of test results is highly dependent on the preparation of the weldment, the type of test specimen tested, and the evaluation criteria used. Sufficient replication should be employed to determine the level of inherent variability in the specific test results that is consistent with the objectives of the test program.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (For more specific safety hazards information, see Section 7.)

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G58 − 85 (Reapproved 2015)

Standard Practice for

Preparation of Stress-Corrosion Test Specimens for

1

Weldments

ThisstandardisissuedunderthefixeddesignationG58;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice covers procedures for the making and

E8Test Methods for Tension Testing of Metallic Materials

utilizationoftestspecimensfortheevaluationofweldmentsin

E399Test Method for Linear-Elastic Plane-Strain Fracture

stress-corrosion cracking (SCC) environments.

Toughness K of Metallic Materials

Ic

1.2 Test specimens are described in which (a) stresses are

E837Test Method for Determining Residual Stresses by the

developed by the welding process only, (b) stresses are

Hole-Drilling Strain-Gage Method

developed by an externally applied load in addition to the

G1Practice for Preparing, Cleaning, and Evaluating Corro-

stresses due to welding, and (c) stresses are developed by an

sion Test Specimens

externally applied load only with residual welding stresses

G30 Practice for Making and Using U-Bend Stress-

removed by annealing.

Corrosion Test Specimens

G35Practice for Determining the Susceptibility of Stainless

1.3 This practice is concerned only with the welded test

Steels and Related Nickel-Chromium-Iron Alloys to

specimen and not with the environmental aspects of stress-

Stress-Corrosion Cracking in Polythionic Acids

corrosion testing. Specific practices for the bending and load-

G36Practice for Evaluating Stress-Corrosion-Cracking Re-

ing of test specimens, as well as the stress considerations

sistance of Metals and Alloys in a Boiling Magnesium

involved in preparation of C-rings, U-bend, bent-beam, and

Chloride Solution

tension specimens are discussed in other ASTM standards.

G37Practice for Use of Mattsson’s Solution of pH 7.2 to

1.4 The actual stress in test specimens removed from

Evaluate the Stress-Corrosion Cracking Susceptibility of

weldments is not precisely known because it depends upon the

Copper-Zinc Alloys

level of residual stress from the welding operation combined

G38 Practice for Making and Using C-Ring Stress-

with the applied stress. A method for determining the magni-

Corrosion Test Specimens

tudeanddirectionofresidualstresswhichmaybeapplicableto

G39Practice for Preparation and Use of Bent-Beam Stress-

weldment is described inTest Method E837.The reproducibil-

Corrosion Test Specimens

ity of test results is highly dependent on the preparation of the

G44PracticeforExposureofMetalsandAlloysbyAlternate

weldment, the type of test specimen tested, and the evaluation

Immersion in Neutral 3.5 % Sodium Chloride Solution

criteria used. Sufficient replication should be employed to

G49Practice for Preparation and Use of Direct Tension

determine the level of inherent variability in the specific test

Stress-Corrosion Test Specimens

resultsthatisconsistentwiththeobjectivesofthetestprogram.

3. Summary of Practice

1.5 This standard does not purport to address all of the

3.1 The following summarizes the test objectives that may

safety concerns, if any, associated with its use. It is the

be evaluated:

responsibility of the user of this standard to establish appro-

3.1.1 Resistance to SCC of a total weldment (weld, heat-

priate safety and health practices and determine the applica-

affected zone, and parent metal) as produced by a specific

bility of regulatory limitations prior to use. (For more specific

welding process;

safety hazards information, see Section 7.)

3.1.2 Resistance to SCC of deposited weld metal;

3.1.3 Determination of a stress level or stress intensity that

will produce SCC in a weldment;

1

This practice is under the jurisdiction ofASTM Committee G01 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.06 on Environmen-

2

tally Assisted Cracking. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2015. Published December 2015. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1985. Last previous edition approved in 2011 as G58–85(2011). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/G0058-85R15. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G58 − 85 (2015)

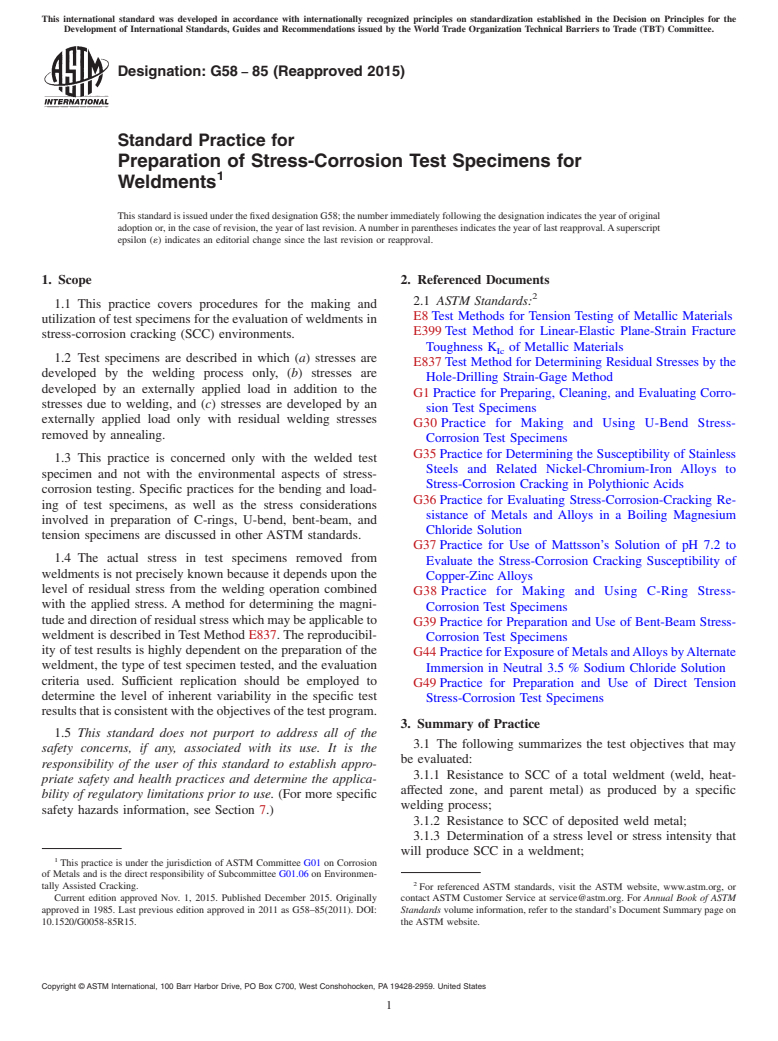

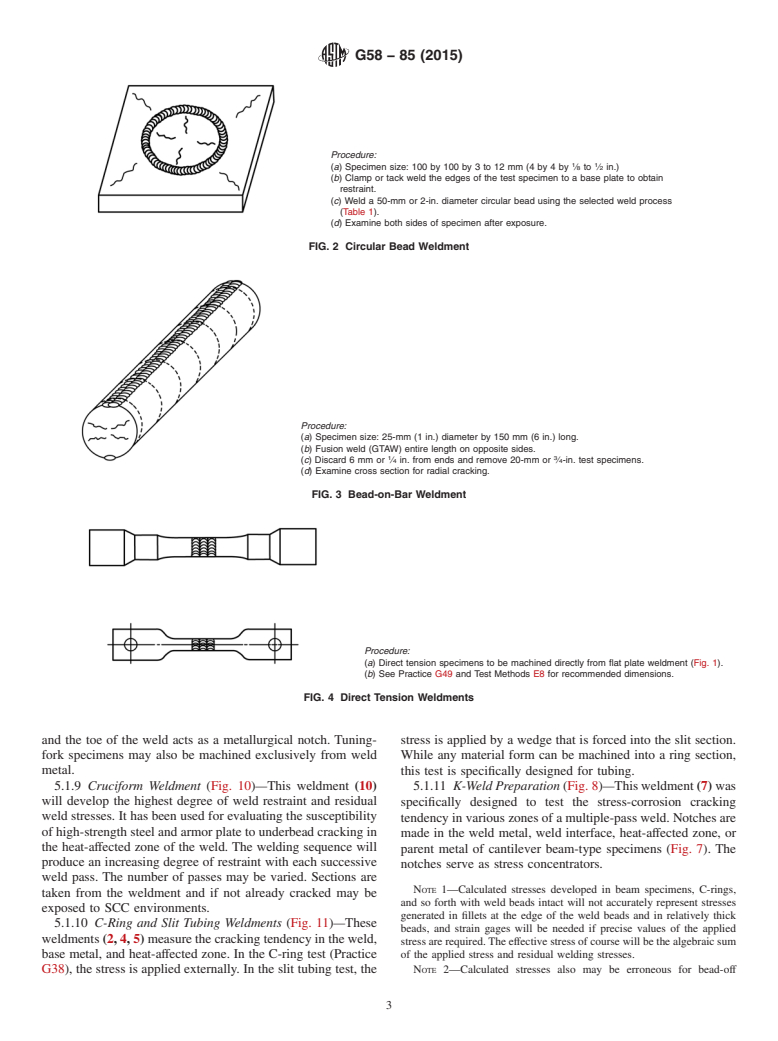

Procedure:

(a) Spec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.