ASTM D2196-99

(Test Method)Standard Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield type) Viscometer

Standard Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield type) Viscometer

SCOPE

1.1 These test methods cover the determination of the apparent viscosity and the shear thinning and thixotropic properties of non-Newtonian materials in the shear rate range from 0.1 to 50 s .

1.2 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 2196 – 99

Standard Test Methods for

Rheological Properties of Non-Newtonian Materials by

Rotational (Brookfield type) Viscometer

This standard is issued under the fixed designation D2196; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4.2 WithTestMethodsBandC,theextentofshearthinning

isindicatedbythedropinviscositywithincreasingviscometer

1.1 These test methods cover the determination of the

speed. The degree of thixotropy is indicated by comparison of

apparent viscosity and the shear thinning and thixotropic

viscosities at increasing and decreasing viscometer speeds

properties of non-Newtonian materials in the shear rate range

−1

(Test Method B), viscosity recovery (Test Method B), or

from 0.1 to 50 s .

viscosities before and after high shear (combination of Test

1.2 This standard does not purport to address the safety

Methods B and C).The high-shear treatment inTest Method C

concerns, if any, associated with its use. It is the responsibility

approximates shearing during paint application. The viscosity

of the user of this standard to establish appropriate safety and

behavior measured after high shear is indicative of the char-

health practices and determine the applicability of regulatory

acteristics of the paint soon after application.

limitations prior to use.

5. Apparatus

2. Referenced Documents

5.1 Rotational-type viscometers having at least four speeds,

2.1 ASTM Standards:

such as:

E1 Specification for ASTM Thermometers

5.1.1 Brookfield Viscometer, ModelLVF,orequivalenthav-

3. Summary of Test Method

ing four rotational speeds, or Model LVT having eight rota-

tional speeds, with set of four spindles; or

3.1 Test Method A consists of determining the apparent

5.1.2 Brookfield Viscometer, Model RVF, having four rota-

viscosity of coatings and related materials by measuring the

tional speeds, or Model RVT or equivalent having eight

torque on a spindle rotating at a constant speed in the material.

rotational speeds, with set of seven spindles.

3.2 Test Methods B and C consist of determining the shear

5.2 Thermometer—ASTM thermometer having a range

thinning and thixotropic (time-dependent) rheological proper-

from 20 to 70°C and conforming to the requirements for

ties of the materials. The viscosities of these materials are

Thermometer 49C as prescribed in Specification E1.

determined at a series of prescribed speeds of a rotational-type

5.3 Containers, round 1-pt (0.5-L) can, 3 ⁄8 in. (85 mm) in

viscometer. The agitation of the material immediately preced-

diameter, or 1-qt (1-L) can, 4 in. (100 mm) in diameter.

ing the viscosity measurements is carefully controlled.

5.4 Shaker, or equivalent machine capable of vigorously

4. Significance and Use

shaking the test specimen.

4.1 Test Method A is used for determining the apparent

6. Materials

viscosityatagivenrotationalspeed,althoughviscositiesattwo

6.1 Standard Oils, calibratedinabsoluteviscosity,millipas-

or more speeds better characterize a non-Newtonian material

cal seconds.

than does the single viscosity measurement.

7. Calibration of Apparatus

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD-1onPaint 7.1 Select at least two standard oils of viscosities differing

and Related Coatings, Materials, and Applications and are the direct responsibility

by at least 5 P (0.5 Pa·s) within the viscosity range of the

of Subcommittee D01.24 on Physical Properties of Liquid Paints and Paint

material being measured and in the range of the viscometer.

Materials.

Condition the oils as closely as possible to 25.0°C (or other

Current edition approved April 10, 1999. Published May 1999. Originally

{1

published as D2196–63T. Last previous edition D2196–86 (1991) .

agreed-upon temperature) for 1 h in a 1-pt (0.5-L) can, 3 ⁄8in.

Annual Book of ASTM Standards, Vol 14.03.

(85 mm) in diameter. Measure the viscosities of each oil as

Pierce, P. E., “Measurement of Rheology of Thixotropic Organic Coatings and

described in Test Method B (Section 13) taking readings only

Resins with the Brookfield Viscometer,” Journal of Paint Technology, Vol 43, No.

557, 1971, pp. 35–43.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2196

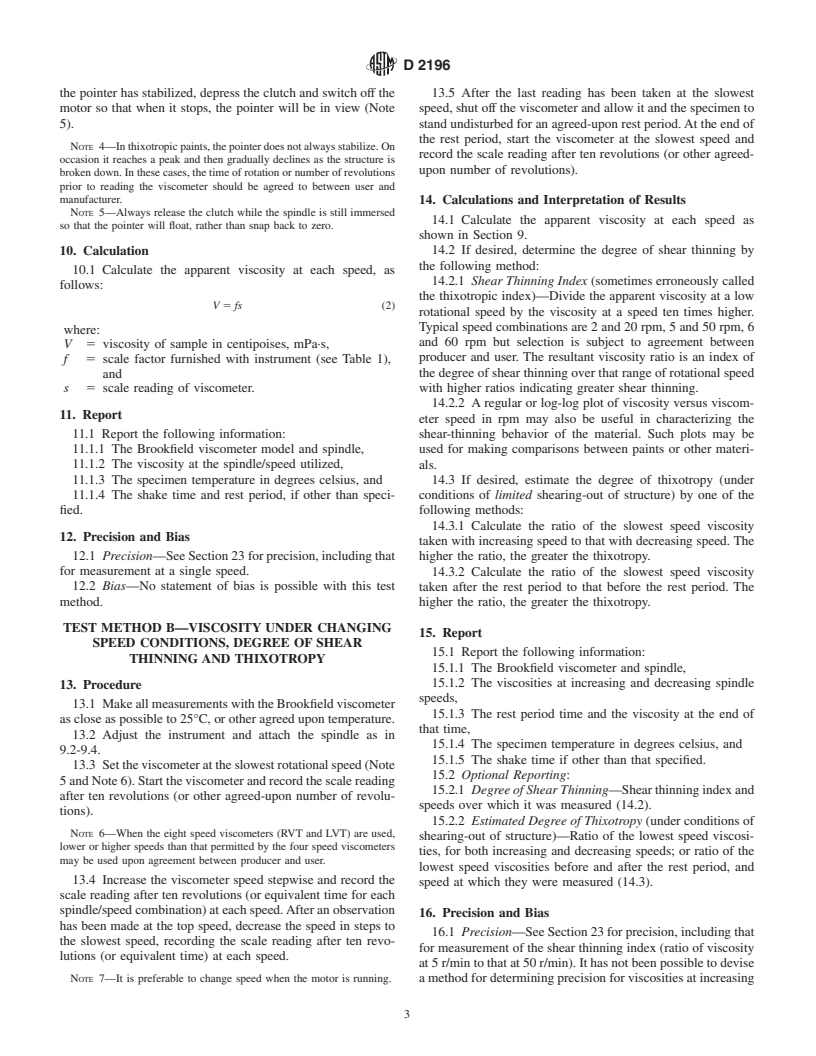

TABLE 2 Viscosity Variation of Cannon Viscosity Standards

at increasing speeds (13.7). Make certain that the spindle is

About the 25°C Temperature Point

centered in the container prior to taking measurements.

Cannon Viscosity Viscosity at 25°C, Viscosity Change With + 1°C

Standard cP (mPa·s) at 25°C, cP (mPa·s)

NOTE 1—The Brookfield LV and RV series viscometers are equipped

with a spindle guard leg. The spindle/speed multiplying factors (Table 1)

S-600 1 400 87.7 (6.26 %)

are designed for use with the guard leg in place except for the following S-2000 4 900 332 (6.77 %)

S-8000 20 000 1462.3 (7.31 %)

conditions: RV series when the factors are the same with or without the

guard leg for spindles No. 3 through 7; or LV series when the factors are

the same with or without the guard leg for spindles No. 3 and 4.

7.1.1 Calibration in a 1-pt (0.5-L) can is always possible

7.3 Prepare a table of new factors similar to that furnished

with the LV series viscometer with the guard leg attached.

with the viscometer (Table 1) for the spindle/speed combina-

Calibration of the RVseries viscometer in the 1-pt can must be tions worked out in 7.2. Spindle/speed factors vary inversely

donewithspindlesNo.3through7withouttheguardleg.Ifthe with speed.

No.1orNo.2spindlesaretobeused,calibrationiscarriedout

in the 1-qt (1-L) can with the guard leg attached. 8. Preparation of Specimen

7.2 Combining the tolerance of the viscometer (61%,

8.1 Fill a 1-pt or 1-qt can with sample to within 1 in. (25

equal to the spindle/speed factor) and the tolerance of the

mm)ofthetopwiththesampleandbringitascloseaspossible

temperaturecontrol(typically 60.5°Cat25°C)itisreasonable

to a temperature of 25°C or other agreed-upon temperature

to assume that a viscometer is calibrated if the calculated prior to test.

viscositiesarewithin 65%ofthestatedvalues(seeTable2for

8.2 Vigorously shake the specimen on the shaker or equiva-

examplesoftheconsiderablechangeinviscositywithtempera- lentfor10min,removeitfromtheshaker,andallowittostand

ture exhibited by standard oils). If measurements are not made undisturbed for 60 min at 25°C prior to testing (Note 2). Start

at 25°C, then the stated viscosities should be corrected to the the test no later than 65 min after removing the can from the

temperature at which they are measured. If the viscosities shaker. Do not transfer the specimen from the container in

which it was shaken.

determined in 7.1 differ from the stated values of the viscosity

standard by more than 5%, calculate new factors for each

NOTE 2—Shake time may be reduced if necessary, or as agreed upon

spindle/speed combination as follows:

between the purchaser and manufacturer, but, in any case, should not be

less than 3 min.

f 5 V/s (1)

TEST METHOD A—APPARENT VISCOSITY

where:

f 5 new factor for converting scale reading to viscosity,

cP (mPa·s),

9. Procedure

V 5 viscosity of standard oil, mPa·s, and

9.1 Make all measurements as close as possible to 25°C, or

s 5 scale reading of the viscometer.

other agreed-upon temperature.

9.2 Place the instrument on the adjustable stand. Lower the

viscometertoalevelthatwillimmersethespindletotheproper

TABLE 1 Factors for Converting Brookfield Dial Readings to depth. Level the instrument using the attached spirit level.

Centipoises (Millipascal Seconds)

9.3 Tilt the selected spindle (Note 3), insert it into one side

of the center of the surface of the material, and attach the

NOTE 1—M 51000.

spindle to the instrument as follows: Firmly hold the upper

RV Series Factors Spindles

Speed, rpm

shaft coupling with thumb and forefinger; screw left-hand

1 2 345 6 7

thread spindle coupling securely to the upper shaft coupling

0.5 200 800 2000 4000 8000 20M 80M

being very careful when connecting to avoid undue side

1 100 400 1000 2000 4000 10M 40M

pressure which might affect alignment.Avoid rotating the dial

2 50 200 500 1000 2000 5M 20M

2.5 40 160 400 800 1600 4M 16M

so that pointer touches the stops at either extreme of the scale.

4 25 100 250 500 1000 2.5M 10M

5 20 80 200 400 800 2M 8M NOTE 3—Select the spindle/speed combination that will give a mini-

10 10 40 100 200 400 1M 4M

mum scale reading of 10 but preferably in the middle or upper portion of

20 5 20 50 100 200 500 2M

the scale. The speed and spindle to be used may differ from this by

50 2 8 20 40 80 200 800

agreement between user and producer.

100 1 4 10 20 40 100 400

LV Series Factors Spindles

9.4 Lower the viscometer until the groove (immersion

Speed, rpm

12 3 4 mark) on the shaft just touches the material. Adjust the

viscometer level if necessary. Move the container slowly in a

0.3 200 1000 4000 20M

0.6 100 500 2000 10M

horizontal plane until the spindle is located in approximately

1.5 40 200 800 4M

thecenterofthecontainersothatthetestwillberuninaregion

3.0 20 100 400 2M

undisturbed by the lowering of the spindle.

6 10 50 200 1M

12 5 25 100 500

9.5 Turn on the viscometer. Adjust the viscometer to the

30 2 10 40 200

rpm selected (Note 3) for the material under test. Allow the

60 1 5 20 100

viscometertorununtilthepointerhasstabilized(Note4).After

D 2196

the pointer has stabilized, depress the clutch and switch off the 13.5 After the last reading has been taken at the slowest

motor so that when it stops, the pointer will be in view (Note speed, shut off the viscometer and allow it and the specimen to

5). stand undisturbed for an agreed-upon rest period.At the end of

the rest period, start the viscometer at the slowest speed and

NOTE 4—Inthixotropicpaints,thepointerdoesnotalwaysstabilize.On

record the scale rea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.