ASTM B439-07

(Specification)Standard Specification for Iron-Base Powder Metallurgy (PM) Bearings (Oil Impregnated)

Standard Specification for Iron-Base Powder Metallurgy (PM) Bearings (Oil Impregnated)

SCOPE

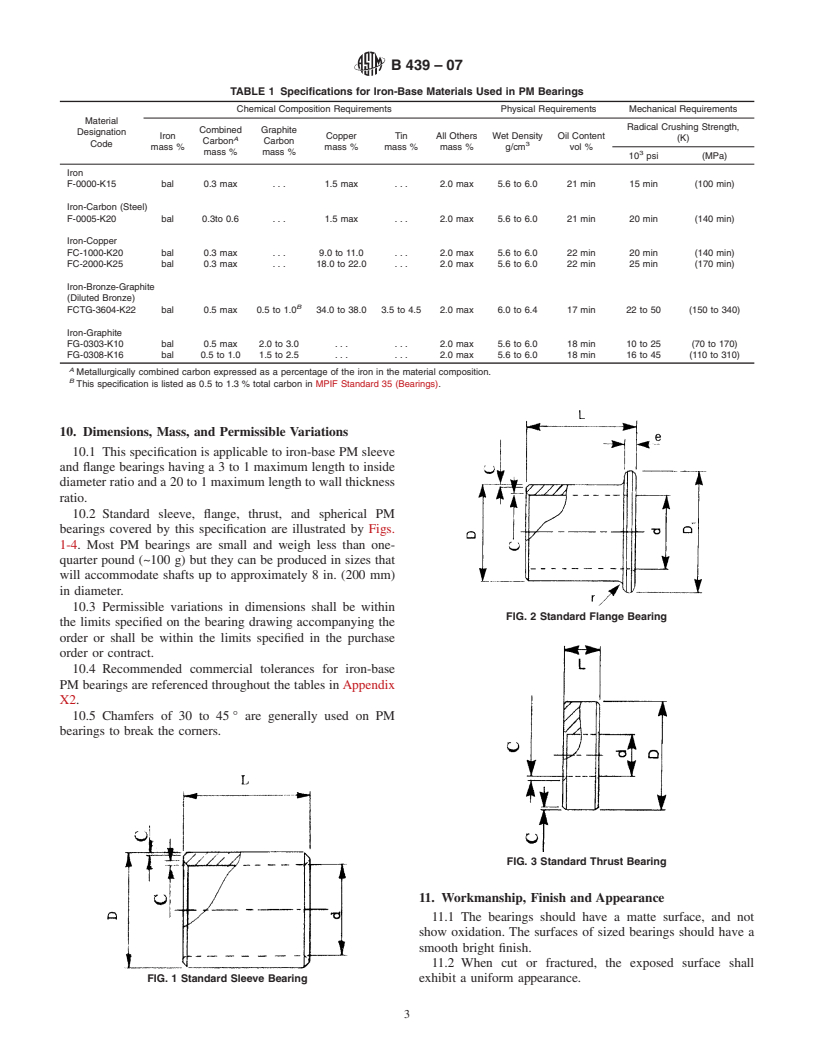

1.1 This specification covers porous metallic sleeve, flange, thrust, and spherical iron-base bearings that are produced from mixed metal powder utilizing powder metallurgy (PM) technology and then impregnated with oil to supply operating lubrication.

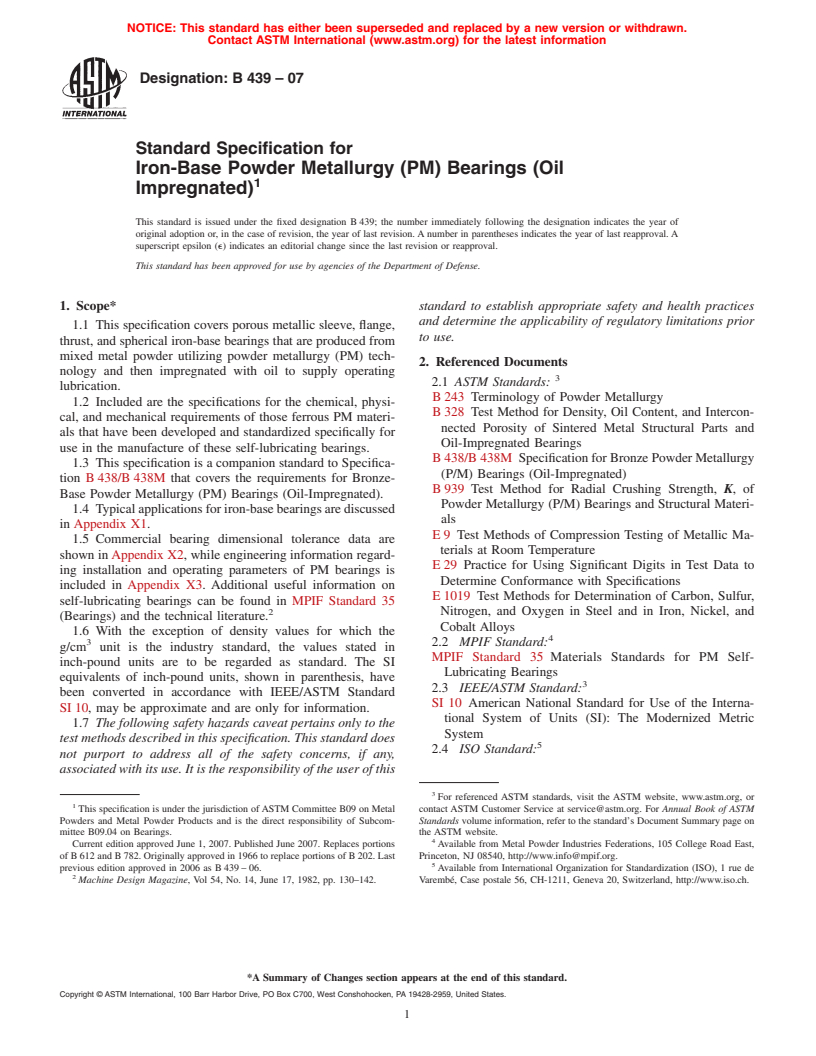

1.2 Included are the specifications for the chemical, physical, and mechanical requirements of those ferrous PM materials that have been developed and standardized specifically for use in the manufacture of these self-lubricating bearings.

1.3 This specification is a companion standard to Specification B 438/B 438M that covers the requirements for Bronze-Base Powder Metallurgy (PM) Bearings (Oil-Impregnated).

1.4 Typical applications for iron-base bearings are discussed in .

1.5 Commercial bearing dimensional tolerance data are shown in , while engineering information regarding installation and operating parameters of PM bearings is included in . Additional useful information on self-lubricating bearings can be found in MPIF Standard 35 (Bearings) and the technical literature.

1.6 With the exception of density values for which the g/cm3 unit is the industry standard, the values stated in inch-pound units are to be regarded as standard. The SI equivalents of inch-pound units, shown in parenthesis, have been converted in accordance with IEEE/ASTM Standard SI 10, may be approximate and are only for information.

1.7 The following safety hazards caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 439 – 07

Standard Specification for

Iron-Base Powder Metallurgy (PM) Bearings (Oil

1

Impregnated)

This standard is issued under the fixed designation B 439; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior

1.1 This specification covers porous metallic sleeve, flange,

to use.

thrust, and spherical iron-base bearings that are produced from

mixed metal powder utilizing powder metallurgy (PM) tech-

2. Referenced Documents

nology and then impregnated with oil to supply operating

3

2.1 ASTM Standards:

lubrication.

B 243 Terminology of Powder Metallurgy

1.2 Included are the specifications for the chemical, physi-

B 328 Test Method for Density, Oil Content, and Intercon-

cal, and mechanical requirements of those ferrous PM materi-

nected Porosity of Sintered Metal Structural Parts and

als that have been developed and standardized specifically for

Oil-Impregnated Bearings

use in the manufacture of these self-lubricating bearings.

B 438/B 438M SpecificationforBronzePowderMetallurgy

1.3 This specification is a companion standard to Specifica-

(P/M) Bearings (Oil-Impregnated)

tion B 438/B 438M that covers the requirements for Bronze-

B 939 Test Method for Radial Crushing Strength, K,of

Base Powder Metallurgy (PM) Bearings (Oil-Impregnated).

Powder Metallurgy (P/M) Bearings and Structural Materi-

1.4 Typicalapplicationsforiron-basebearingsarediscussed

als

in Appendix X1.

E9 Test Methods of Compression Testing of Metallic Ma-

1.5 Commercial bearing dimensional tolerance data are

terials at Room Temperature

shown inAppendix X2, while engineering information regard-

E29 Practice for Using Significant Digits in Test Data to

ing installation and operating parameters of PM bearings is

Determine Conformance with Specifications

included in Appendix X3. Additional useful information on

E 1019 Test Methods for Determination of Carbon, Sulfur,

self-lubricating bearings can be found in MPIF Standard 35

2 Nitrogen, and Oxygen in Steel and in Iron, Nickel, and

(Bearings) and the technical literature.

Cobalt Alloys

1.6 With the exception of density values for which the

4

3

2.2 MPIF Standard:

g/cm unit is the industry standard, the values stated in

MPIF Standard 35 Materials Standards for PM Self-

inch-pound units are to be regarded as standard. The SI

Lubricating Bearings

equivalents of inch-pound units, shown in parenthesis, have

3

2.3 IEEE/ASTM Standard:

been converted in accordance with IEEE/ASTM Standard

SI 10 American National Standard for Use of the Interna-

SI 10, may be approximate and are only for information.

tional System of Units (SI): The Modernized Metric

1.7 The following safety hazards caveat pertains only to the

System

test methods described in this specification. This standard does

5

2.4 ISO Standard:

not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This specification is under the jurisdiction ofASTM Committee B09 on Metal contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Powders and Metal Powder Products and is the direct responsibility of Subcom- Standards volume information, refer to the standard’s Document Summary page on

mittee B09.04 on Bearings. the ASTM website.

4

Current edition approved June 1, 2007. Published June 2007. Replaces portions Available from Metal Powder Industries Federations, 105 College Road East,

of B 612 and B 782. Originally approved in 1966 to replace portions of B 202. Last Princeton, NJ 08540, http://www.info@mpif.org.

5

previous edition approved in 2006 as B 439 – 06. Available from International Organization for Standardization (ISO), 1 rue de

2

Machine Design Magazine, Vol 54, No. 14, June 17, 1982, pp. 130–142. Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B439–07

ISO 2795 Plain Bearings from Sintered Metal—Dimension 6. Materials and Manufacture

and Tolerances

6.1 Porous Metallic Bearing:

6.1.1 Porous iron-base bearings shall be produced by first

3. Terminology

compacting a mixture of elemental iron powder and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.