ASTM D8280-20

(Test Method)Standard Test Method for Determination of the Blooming of Brominated Flame Retardants onto the Surface of Plastic Materials by Ion Chromatography

Standard Test Method for Determination of the Blooming of Brominated Flame Retardants onto the Surface of Plastic Materials by Ion Chromatography

SIGNIFICANCE AND USE

5.1 This test method will allow the quantitative determination of the bromine originating from the flame retardant that has bloomed onto the surface after aging under specified conditions. Based on the known structure of the flame retardant used, the amount of the flame retardant that bloomed can also be calculated.

5.2 Section 14 contains some safety recommendations.

SCOPE

1.1 This test method covers the quantification of the blooming of brominated flame retardants onto the surface of plastic materials by an ion chromatographic method.

1.2 The test method involves recovery of the deposits on the surface of plastic materials, containing brominated flame retardants, on unaged specimens, on specimens aged at 70°C for 14 days and on specimens aged at 70°C for 35 days. These deposits are quantitatively analyzed to obtain the fraction of brominated flame retardant that has bloomed onto the surface.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D8280 − 20

Standard Test Method for

Determination of the Blooming of Brominated Flame

Retardants onto the Surface of Plastic Materials by Ion

1

Chromatography

This standard is issued under the fixed designation D8280; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

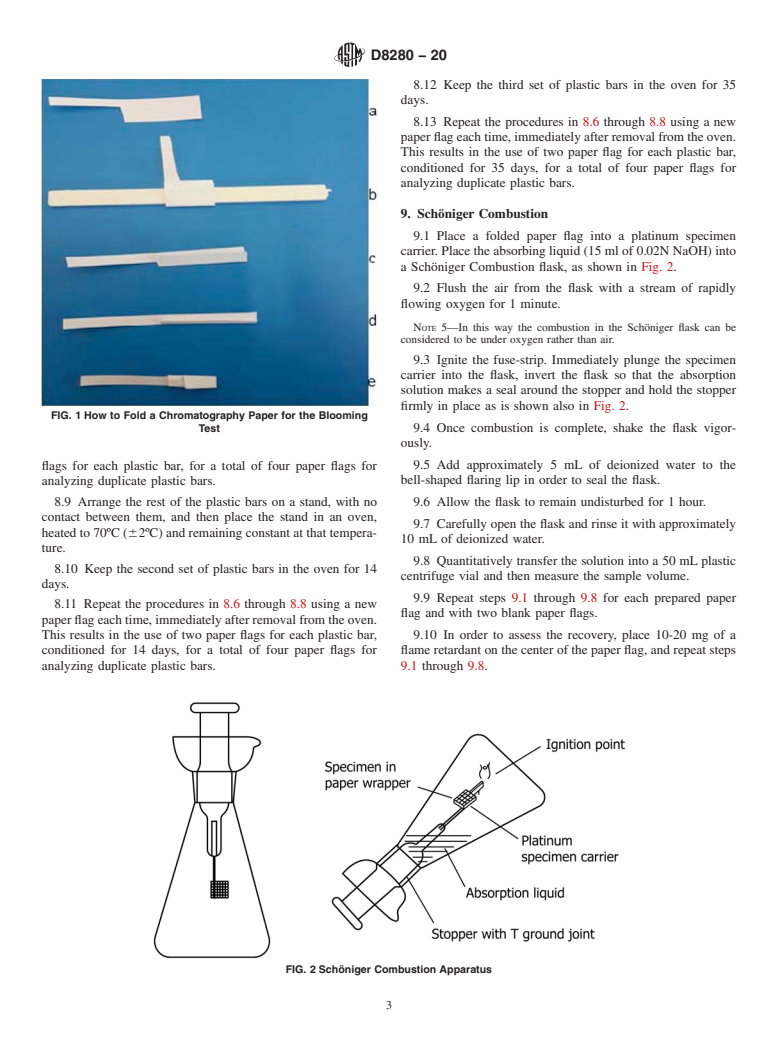

1. Scope D3045Practice for Heat Aging of Plastics Without Load

E176Terminology of Fire Standards

1.1 This test method covers the quantification of the bloom-

3

2.2 ISO Standards:

ing of brominated flame retardants onto the surface of plastic

ISO188Rubber, vulcanized or thermoplastic—Accelerated

materials by an ion chromatographic method.

ageing and heat resistance tests

1.2 Thetestmethodinvolvesrecoveryofthedepositsonthe

surface of plastic materials, containing brominated flame

3. Terminology

retardants, on unaged specimens, on specimens aged at 70°C

3.1 Definitions of Terms:

for 14 days and on specimens aged at 70°C for 35 days. These

3.1.1 For definitions of terms used in this test method and

deposits are quantitatively analyzed to obtain the fraction of

associated with plastics refer to Terminology D883.

brominated flame retardant that has bloomed onto the surface.

3.2 Definitions of Terms Specific to This Standard:

1.3 The values stated in SI units are to be regarded as

3.2.1 blooming, n—the formation of a visible exudation or

standard. No other units of measurement are included in this

efflorescence on the surface of a plastic.

standard.

3.2.1.1 Discussion—Additives typically have a higher solu-

1.4 This standard does not purport to address all of the

bility in the polymer at processing temperature than at ambient

safety concerns, if any, associated with its use. It is the

temperature (since processing temperature is usually above

responsibility of the user of this standard to establish appro-

ambient). Blooming occurs when, after cooling, a portion of

priate safety, health, and environmental practices and deter-

the additive segregates out of the cooled polymer at ambient

mine the applicability of regulatory limitations prior to use.

temperature and in some instances, migrates to the surface of

NOTE 1—There is no known ISO equivalent to this standard.

the polymer.

1.5 This international standard was developed in accor-

3.2.2 flame retardant, n—a substance which, when added to

dance with internationally recognized principles on standard-

a combustible material, inhibits flame spread of the resulting

ization established in the Decision on Principles for the

substance or material when exposed to flame impingement

Development of International Standards, Guides and Recom-

(Terminology E176).

mendations issued by the World Trade Organization Technical

3.2.2.1 Discussion—Flame retardants may be incorporated

Barriers to Trade (TBT) Committee.

inplasticsasadditives(additiveflameretardant)oraschemical

groups in the base polymer by use of reactive intermediates in

2. Referenced Documents

the polymerization process (reactive flame retardant).

2

2.1 ASTM Standards:

4. Summary of Test Method

D573Test Method for Rubber—Deterioration in an Air

Oven

4.1 The test method presents a procedure for the quantifi-

D883Terminology Relating to Plastics

cation of the blooming of brominated flame retardants onto the

surface of plastic materials.

4.2 The first stage involves the aging of two sets of samples

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

of plastic materials at 70°C for 14 and 35 days, respectively,

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved Jan. 1, 2020. Published January 2020. DOI: 10.1520/

which are compared to a set of unaged materials.

D8280-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8280 − 20

NOTE 2—Test Method D573, Practice D3045, and ISO188 provide

7. Reagents

guidance on heat aging of plastics or rubbers.

7.1 Sodium Carbonate, analytical grade.

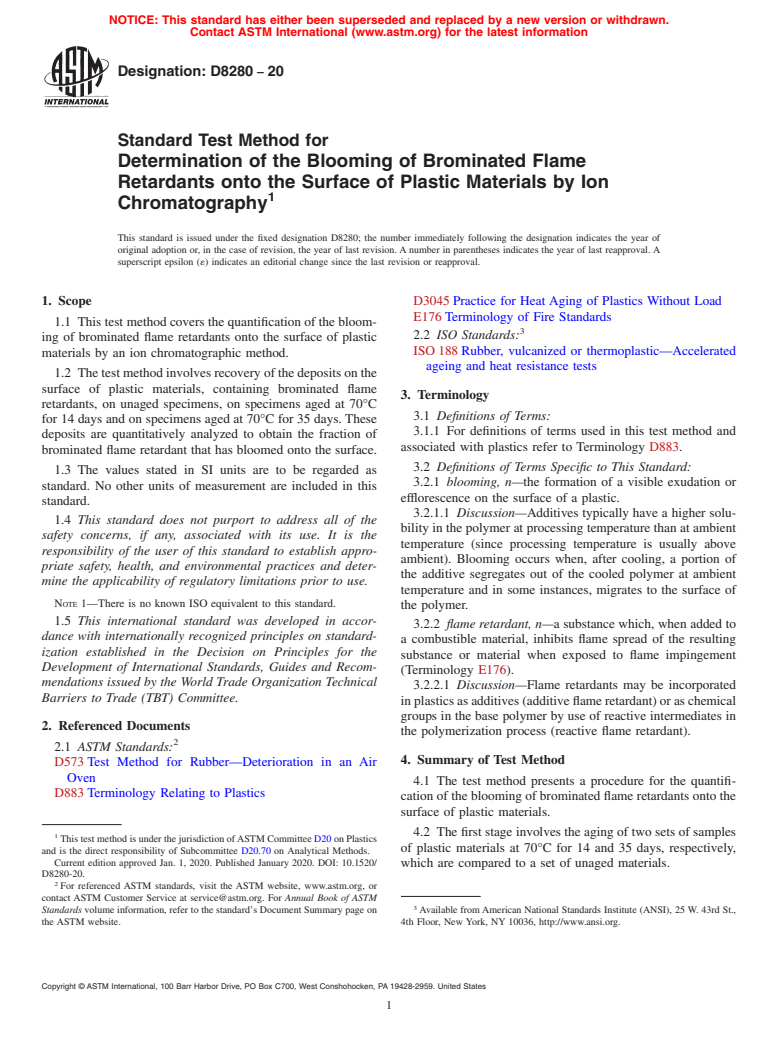

4.3 The second stage involves using a flag made from

7.2 Potassium Bromide, analytical grade.

chromatography paper to sweep the deposits from the surface

of both unaged and aged plastic materials.

7.3 Sodium Hydroxide

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.