ASTM C900-14

(Test Method)Standard Test Method for Pullout Strength of Hardened Concrete

Standard Test Method for Pullout Strength of Hardened Concrete

SIGNIFICANCE AND USE

5.1 For a given concrete and a given test apparatus, pullout strengths can be related to compressive strength test results. Such strength relationships are affected by the configuration of the embedded insert, bearing ring dimensions, depth of embedment, and the type of aggregate (lightweight or normal weight). Before use, the relationships must be established for each test system and each new concrete mixture. Such relationships are more reliable if both pullout test specimens and compressive strength test specimens are of similar size, consolidated to similar density, and cured under similar conditions.

Note 1: Published reports (1-17)4 by different researchers present their experiences in the use of pullout test equipment. Refer to ACI 228.1R (14) for guidance on establishing a strength relationship and interpreting test results. The Appendix provides a means for comparing pullout strengths obtained using different configurations.

5.2 If a strength relationship has been established experimentally and accepted by the specifier of tests, pullout tests are used to determine whether the in-place strength of concrete has reached a specified level so that, for example:

(1) post-tensioning may proceed;

(2) forms and shores may be removed;

(3) structure may be placed into service; or

(4) winter protection and curing may be terminated.

In addition, post-installed pullout tests may be used to estimate the strength of concrete in existing constructions.

5.3 When planning pullout tests and analyzing test results, consideration should be given to the normally expected decrease of concrete strength with increasing height within a given concrete placement in a structural element.

5.4 The measured pullout strength is indicative of the strength of concrete within the region represented by the conic frustum defined by the insert head and bearing ring. For typical surface installations, pullout strengths are indicative of the quality of the outer zone of con...

SCOPE

1.1 This test method covers determination of the pullout strength of hardened concrete by measuring the force required to pull an embedded metal insert and the attached concrete fragment from a concrete test specimen or structure. The insert is either cast into fresh concrete or installed in hardened concrete. This test method does not provide statistical procedures to estimate other strength properties.

1.2 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this test method.

1.3 The text of this test method references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.2)

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C900 − 14

StandardTest Method for

Pullout Strength of Hardened Concrete

This standard is issued under the fixed designation C900; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 This test method covers determination of the pullout 3.1 Definitions:

strength of hardened concrete by measuring the force required 3.1.1 For definitions of terms used in this practice, refer to

to pull an embedded metal insert and the attached concrete Terminology C125.

fragmentfromaconcretetestspecimenorstructure.Theinsert

4. Summary of Test Method

is either cast into fresh concrete or installed in hardened

concrete. This test method does not provide statistical proce-

4.1 A metal insert is either cast into fresh concrete or

dures to estimate other strength properties.

installed into hardened concrete. When a measure of the

in-place pullout strength is desired, the insert is pulled by

1.2 The values stated in SI units are to be regarded as the

means of a jack reacting against a bearing ring. The pullout

standard. No other units of measurement are included in this

strength is determined by measuring the maximum force

test method.

required to pull the insert from the concrete mass.

1.3 The text of this test method references notes and

Alternatively, the insert is loaded to a specified load to verify

footnoteswhichprovideexplanatorymaterial.Thesenotesand

whether a minimum level of in-place pullout strength has been

footnotes (excluding those in tables and figures) shall not be

attained.

considered as requirements of this test method.

1.4 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

5.1 For a given concrete and a given test apparatus, pullout

responsibility of the user of this standard to establish appro-

strengths can be related to compressive strength test results.

priate safety and health practices and determine the applica-

Such strength relationships are affected by the configuration of

bility of regulatory limitations prior to use. (Warning—Fresh

the embedded insert, bearing ring dimensions, depth of

hydraulic cementitious mixtures are caustic and may cause

embedment, and the type of aggregate (lightweight or normal

chemical burns to skin and tissue upon prolonged exposure. )

weight). Before use, the relationships must be established for

each test system and each new concrete mixture. Such rela-

2. Referenced Documents

tionships are more reliable if both pullout test specimens and

2.1 ASTM Standards:

compressive strength test specimens are of similar size, con-

C125Terminology Relating to Concrete and Concrete Ag-

solidatedtosimilardensity,andcuredundersimilarconditions.

gregates

NOTE1—Publishedreports (1-17) bydifferentresearcherspresenttheir

C670Practice for Preparing Precision and Bias Statements

experiencesintheuseofpullouttestequipment.RefertoACI228.1R (14)

for Test Methods for Construction Materials

for guidance on establishing a strength relationship and interpreting test

E4Practices for Force Verification of Testing Machines

results. The Appendix provides a means for comparing pullout strengths

E74Practice of Calibration of Force-Measuring Instruments

obtained using different configurations.

for Verifying the Force Indication of Testing Machines

5.2 If a strength relationship has been established experi-

mentallyandacceptedbythespecifieroftests,pullouttestsare

This test method is under the jurisdiction of ASTM Committee C09 on

usedtodeterminewhetherthein-placestrengthofconcretehas

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

reached a specified level so that, for example:

C09.64 on Nondestructive and In-Place Testing.

(1)post-tensioning may proceed;

Current edition approved Oct. 1, 2014. Published November 2014. Originally

(2)forms and shores may be removed;

approved in 1978. Last previous edition approved in 2013 as C900–13a. DOI:

10.1520/C0900-14.

(3)structure may be placed into service; or

Section on Safety Precautions, Manual of Aggregate and Concrete Testing,

(4)winter protection and curing may be terminated.

Annual Book of ASTM Standards, Vol 04.02.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers refer to the list of references at the end of this test

the ASTM website. method.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C900 − 14

NOTE 2—A center-pull hydraulic jack with a pressure gauge that has

In addition, post-installed pullout tests may be used to

beenstandardizedaccordingtoAnnexA1andthatreactsagainstabearing

estimate the strength of concrete in existing constructions.

ring has been used satisfactorily.

5.3 When planning pullout tests and analyzing test results,

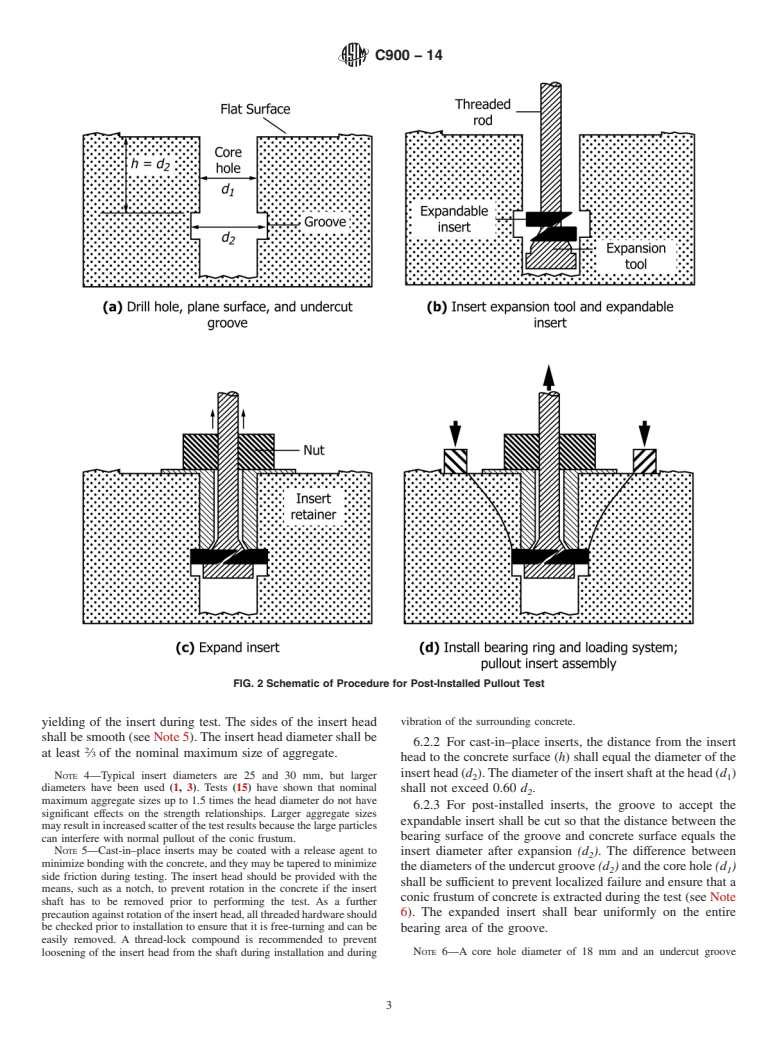

6.1.1 Cast-in-place inserts shall be made of metal that does

consideration should be given to the normally expected de-

not react with the constituents of the concrete. The insert shall

crease of concrete strength with increasing height within a

consist of a cylindrical head and a shaft to fix embedment

given concrete placement in a structural element.

depth. The shaft shall be attached firmly to the center of the

5.4 The measured pullout strength is indicative of the

head(seeFig.1).Theinsertshaftshallbethreadedtotheinsert

strength of concrete within the region represented by the conic

headsothatitcanberemovedandreplacedbyastrongershaft

frustumdefinedbytheinsertheadandbearingring.Fortypical

to pullout the insert, or it shall be an integral part of the insert

surface installations, pullout strengths are indicative of the

and also function as the pullout shaft. Metal components of

quality of the outer zone of concrete members and can be of

cast-in-place inserts and attachment hardware shall be of

benefit in evaluating the cover zone of reinforced concrete

similar material to prevent galvanic corrosion. Post-installed

members.

inserts shall be designed so that they will fit into the drilled

holes,andcanbeexpandedsubsequentlytofitintothegrooves

5.5 Cast-in-place inserts require that their locations in the

that are undercut at a predetermined depth (see Fig. 2).

structure be planned in advance of concrete placement. Post-

installed inserts can be placed at any desired location in the

NOTE 3—A successful post-installed system uses a split ring that is

structure provided the requirements of 7.1 are satisfied.

coiled to fit into the core hole and then expanded into the groove.

5.6 This test method is not applicable to other types of

6.1.2 The loading system shall consist of a bearing ring to

post-installed tests that, if tested to failure, do not involve the

be placed against the hardened concrete surface (see Figs. 1

same failure mechanism and do not produce the same conic

and 2) and a tensile loading apparatus, with a load-measuring

frustum as for the cast-in-place test described in this test

device that can be attached to the pullout shaft.

method (16).

6.1.3 The test apparatus shall include centering features to

ensure that the bearing ring is concentric with the insert, and

6. Apparatus

that the applied load is axial to the pullout shaft, perpendicular

6.1 The apparatus requires three basic sub-systems: a pull-

to the bearing ring, and uniform on the bearing ring.

out insert, a loading system, and a load-measuring system

6.2 Equipment dimensions shall be determined as follows

(Note 2). For post-installed inserts, additional equipment

(see Fig. 1):

includes a core drill, a planing tool to prepare a flat bearing

surface, a grinding tool to undercut a groove to engage the 6.2.1 The diameter of the insert head (d ) is the basis for

insert, and an expansion tool to expand the insert into the definingthetestgeometry.Thethicknessoftheinsertheadand

groove. the yield strength of the metal shall be sufficient to prevent

FIG. 1 Schematic Cross Section of Cast-in-Place Pullout Test

C900 − 14

FIG. 2 Schematic of Procedure for Post-Installed Pullout Test

vibration of the surrounding concrete.

yielding of the insert during test. The sides of the insert head

shallbesmooth(seeNote5).Theinsertheaddiametershallbe

6.2.2 For cast-in–place inserts, the distance from the insert

at least ⁄3of the nominal maximum size of aggregate.

head to the concrete surface (h) shall equal the diameter of the

inserthead(d ).Thediameteroftheinsertshaftatthehead(d )

NOTE 4—Typical insert diameters are 25 and 30 mm, but larger

2 1

diameters have been used (1, 3). Tests (15) have shown that nominal shall not exceed 0.60 d .

maximum aggregate sizes up to 1.5 times the head diameter do not have

6.2.3 For post-installed inserts, the groove to accept the

significant effects on the strength relationships. Larger aggregate sizes

expandable insert shall be cut so that the distance between the

mayresultinincreasedscatterofthetestresultsbecausethelargeparticles

bearing surface of the groove and concrete surface equals the

can interfere with normal pullout of the conic frustum.

NOTE 5—Cast-in–place inserts may be coated with a release agent to insert diameter after expansion (d ). The difference between

minimizebondingwiththeconcrete,andtheymaybetaperedtominimize

thediametersoftheundercutgroove(d )andthecorehole(d )

2 1

side friction during testing. The insert head should be provided with the

shall be sufficient to prevent localized failure and ensure that a

means, such as a notch, to prevent rotation in the concrete if the insert

conicfrustumofconcreteisextractedduringthetest(seeNote

shaft has to be removed prior to performing the test. As a further

6). The expanded insert shall bear uniformly on the entire

precautionagainstrotationoftheinserthead,allthreadedhardwareshould

be checked prior to installation to ensure that it is free-turning and can be

bearing area of the groove.

easily removed. A thread-lock compound is recommended to prevent

loosening of the insert head from the shaft during installation and during NOTE 6—A core hole diameter of 18 mm and an undercut groove

C900 − 14

diameter of 25 mm have been used successfully.

7.3 When pullout tests are used for other purposes, the

number of tests shall be determined by the specifier of the test.

6.2.4 The bearing ring shall have an inside diameter (d)of

2.0to2.4timestheinsertheaddiameter (d ),andshallhavean

8. Procedure

outside diameter (d ) of at least 1.25 times the inside diameter.

8.1 Cast-in-Place Inserts:

The thickness of the ring (t) shall be at least 0.4 times the

8.1.1 Attach the pullout inserts to the forms using bolts or

pullout insert head diameter. For a given test system, the same

by other methods that firmly secure the insert in its proper

bearing ring dimensions shall be used.

location prior to concrete placement. All inserts shall be

6.2.5 Tolerances for dimensions of the pullout test inserts,

embedded to the same depth. The axis of each shaft shall be

bearing ring and embedment depth shall be 62% within a

perpendicular to the formed surface.

given system.

8.1.2 Alternatively,wheninstructedbythespecifieroftests,

NOTE 7—The limits for dimensions and configurations for pullout test

manually place inserts into unformed horizontal concrete

inserts and apparatus are intended to accommodate various systems.

surfaces.The inserts shall be embedded into the fresh concrete

6.2.6 Theloadingapparatusshallhavesufficientcapacityto

bymeansthatensureauniformembedmentdepthandasurface

provide the loading rate prescribed in 8.4.

to support the bearing ring that is plane and perpendicular to

the axis of the insert shaft. Installation of inserts shall be

NOTE 8—Hydraulic pumps that permit continuous loading may give

more uniform test results than pumps that apply load intermittently. performed or supervised by personnel trained by the manufac-

turer or manufacturer’s representative.

6.2.7 The gauge to measure pullout force is permitted to be

of the analog or digital type.Analog gauges shall be designed

NOTE11—Experienceindicatesthatpulloutstrengthsareoflowervalue

sothatthepulloutforcecanbeestimatedtothenearest0.5kN. and more variable for manually-placed surface inserts than for inserts

attached to formwork (12).

Digital gauges shall display the pullout force to the nearest 0.1

kN.

8.1.3 When pullout strength of the concrete is to be

6.2.8 The force gauge shall have a means to preserve the

measured, remove all hardware used for securing the pullout

maximum value of the load during a test.

inserts in position. Before mounting the loading system,

6.2.9 Pullout apparatus shall be standardized in accordance

remove any debris or surface abnormalities to ensure a flat

with Annex A1 at least once a year and after all repairs.

bearing surface that is perpendicular to the axis of the insert.

Standardize the pullout apparatus using a testing machine

8.2 Post-Installed Inserts:

verifiedinaccordancewithPracticesE4orusingaClassAload

8.2.1 The selected test surface shall be flat to provide a

cell as defined in Practice E74. The indicated pullout force

suitable working surface for drilling the core and undercutting

based on the developed relationship shall be within 62%of

the groove. Drill a core hole perpendicular to the surface to

the force measured by the testing machine or load cell.

provide a reference point for subsequent operations and to

accommodate the expandable insert and associated hardware.

7. Sampling

The use of an impact drill is not permitted.

7.1 Pullout test locations shall be separated so that the clear

8.2.2 Ifnecessary,useasurfaceplaningtooltoprepareaflat

spacingbetweeninsertsisatleastseventimesthepulloutinsert

surface so that the base of the tool for cutting the groove is

headdiameter.Clearspacingbetweentheinsertsandtheedges

supported firmly and so that the bearing ring is supported

of the concrete shall be at least 3.5 times the head diameter.

uniformly during testing. The prepared surface shall be per-

Inserts shall be placed so that reinforcement is outside the

pendicular to the axis of the core hole.

expectedconicalfailuresurfacebymorethanonebardiameter,

8.2.3 Use the grinding tool in accordance with the manu-

or the maximum size of aggregate, whichever is greater.

facturer

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C900 − 13a C900 − 14

Standard Test Method for

Pullout Strength of Hardened Concrete

This standard is issued under the fixed designation C900; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers determination of the pullout strength of hardened concrete by measuring the force required to pull

an embedded metal insert and the attached concrete fragment from a concrete test specimen or structure. The insert is either cast

into fresh concrete or installed in hardened concrete. This test method does not provide statistical procedures to estimate other

strength properties.

1.2 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this test

method.

1.3 The text of this test method references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of this test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and

tissue upon prolonged exposure. )

2. Referenced Documents

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Aggregates

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

E4 Practices for Force Verification of Testing Machines

E74 Practice of Calibration of Force-Measuring Instruments for Verifying the Force Indication of Testing Machines

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this practice, refer to Terminology C125.

4. Summary of Test Method

4.1 A metal insert is either cast into fresh concrete or installed into hardened concrete. When an estimatea measure of the

in-place pullout strength is desired, the insert is pulled by means of a jack reacting against a bearing ring. The pullout strength is

determined by measuring the maximum force required to pull the insert from the concrete mass. Alternatively, the insert is loaded

to a specified load to verify whether a minimum level of in-place pullout strength has been attained.

5. Significance and Use

5.1 For a given concrete and a given test apparatus, pullout strengths can be related to compressive strength test results. Such

strength relationships are affected by the configuration of the embedded insert, bearing ring dimensions, depth of embedment, and

the type of aggregate (lightweight or normal weight). Before use, the relationships must be established for each test system and

This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.64 on

Nondestructive and In-Place Testing.

Current edition approved Dec. 1, 2013Oct. 1, 2014. Published January 2014November 2014. Originally approved in 1978. Last previous edition approved in 2013 as

C900 – 13.C900 – 13a. DOI: 10.1520/C0900-13a.10.1520/C0900-14.

Section on Safety Precautions, Manual of Aggregate and Concrete Testing, Annual Book of ASTM Standards, Vol 04.02.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C900 − 14

each new concrete mixture. Such relationships are more reliable if both pullout test specimens and compressive strength test

specimens are of similar size, consolidated to similar density, and cured under similar conditions.

NOTE 1—Published reports (1-17) by different researchers present their experiences in the use of pullout test equipment. Refer to ACI 228.1R (14)

for guidance on establishing a strength relationship and interpreting test results. The Appendix provides a means for comparing pullout strengths obtained

using different configurations.

5.2 Pullout If a strength relationship has been established experimentally and accepted by the specifier of tests, pullout tests are

used to determine whether the in-place strength of concrete has reached a specified level so that, for example:

(1) post-tensioning may proceed;

(2) forms and shores may be removed;

(3) structure may be placed into service; or

(4) winter protection and curing may be terminated.

In addition, post-installed pullout tests may be used to estimate the strength of concrete in existing constructions.

5.3 When planning pullout tests and analyzing test results, consideration should be given to the normally expected decrease of

concrete strength with increasing height within a given concrete placement in a structural element.

5.4 The measured pullout strength is indicative of the strength of concrete within the region represented by the conic frustum

defined by the insert head and bearing ring. For typical surface installations, pullout strengths are indicative of the quality of the

outer zone of concrete members and can be of benefit in evaluating the cover zone of reinforced concrete members.

5.5 Cast-in-place inserts require that their locations in the structure be planned in advance of concrete placement. Post-installed

inserts can be placed at any desired location in the structure provided the requirements of 7.1 are satisfied.

5.6 This test method is not applicable to other types of post-installed tests that, if tested to failure, do not involve the same failure

mechanism and do not produce the same conic frustum as for the cast-in-place test described in this test method (16).

6. Apparatus

6.1 The apparatus requires three basic sub-systems: a pullout insert, a loading system, and a load-measuring system (Note 2).

For post-installed inserts, additional equipment includes a core drill, a planing tool to prepare a flat bearing surface, a grinding tool

to undercut a groove to engage the insert, and an expansion tool to expand the insert into the groove.

NOTE 2—A center-pull hydraulic jack with a pressure gauge that has been standardized according to Annex A1 and that reacts against a bearing ring

has been used satisfactorily.

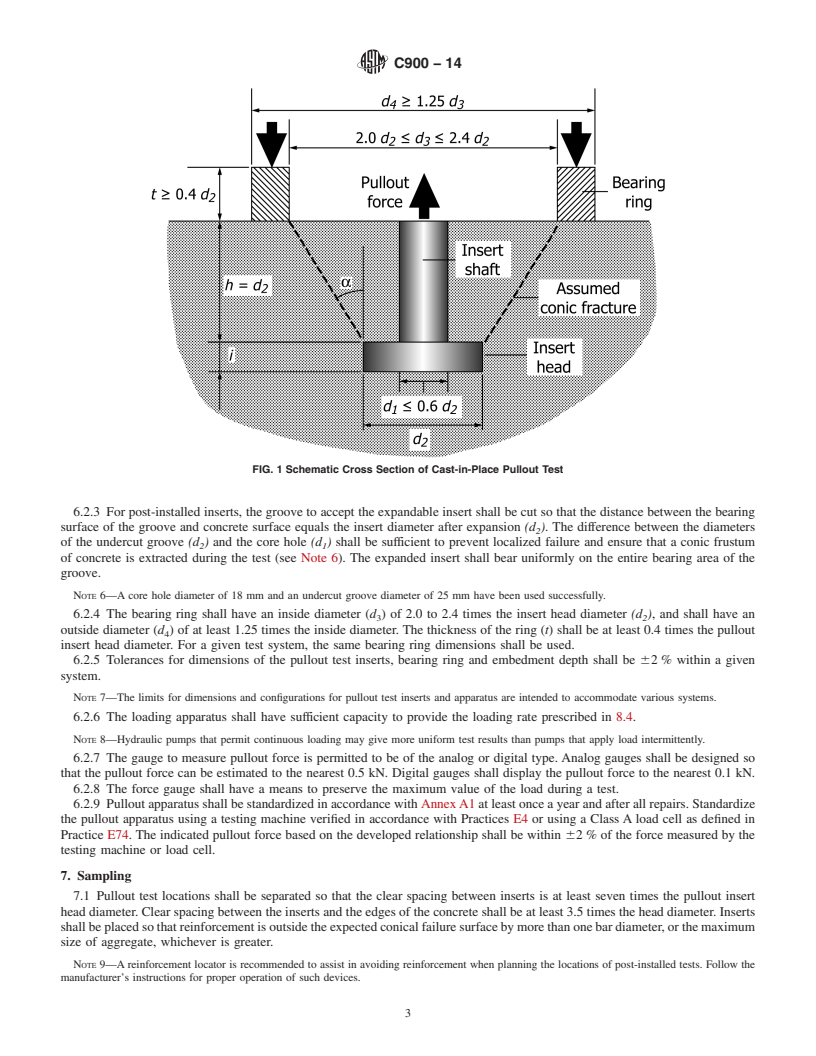

6.1.1 Cast-in-place inserts shall be made of metal that does not react with the constituents of the concrete. The insert shall

consist of a cylindrical head and a shaft to fix embedment depth. The shaft shall be attached firmly to the center of the head (see

Fig. 1). The insert shaft shall be threaded to the insert head so that it can be removed and replaced by a stronger shaft to pullout

the insert, or it shall be an integral part of the insert and also function as the pullout shaft. Metal components of cast-in-place inserts

and attachment hardware shall be of similar material to prevent galvanic corrosion. Post-installed inserts shall be designed so that

they will fit into the drilled holes, and can be expanded subsequently to fit into the grooves that are undercut at a predetermined

depth (see Fig. 2).

NOTE 3—A successful post-installed system uses a split ring that is coiled to fit into the core hole and then expanded into the groove.

6.1.2 The loading system shall consist of a bearing ring to be placed against the hardened concrete surface (see Figs. 1 and 2)

and a tensile loading apparatus, with a load-measuring device that can be attached to the pullout shaft.

6.1.3 The test apparatus shall include centering features to ensure that the bearing ring is concentric with the insert, and that

the applied load is axial to the pullout shaft, perpendicular to the bearing ring, and uniform on the bearing ring.

6.2 Equipment dimensions shall be determined as follows (see Fig. 1):

6.2.1 The diameter of the insert head (d ) is the basis for defining the test geometry. The thickness of the insert head and the

yield strength of the metal shall be sufficient to prevent yielding of the insert during test. The sides of the insert head shall be

smooth (see Note 5). The insert head diameter shall be at least ⁄3 of the nominal maximum size of aggregate.

NOTE 4—Typical insert diameters are 25 and 30 mm, but larger diameters have been used (1, 3). Tests (15) have shown that nominal maximum

aggregate sizes up to 1.5 times the head diameter do not have significant effects on the strength relationships. Larger aggregate sizes may result in

increased scatter of the test results because the large particles can interfere with normal pullout of the conic frustum.

NOTE 5—Cast-in–place inserts may be coated with a release agent to minimize bonding with the concrete, and they may be tapered to minimize side

friction during testing. The insert head should be provided with the means, such as a notch, to prevent rotation in the concrete if the insert shaft has to

be removed prior to performing the test. As a further precaution against rotation of the insert head, all threaded hardware should be checked prior to

installation to ensure that it is free-turning and can be easily removed. A thread-lock compound is recommended to prevent loosening of the insert head

from the shaft during installation and during vibration of the surrounding concrete.

6.2.2 For cast-in–place inserts, the distance from the insert head to the concrete surface (h) shall equal the diameter of the insert

head (d ). The diameter of the insert shaft at the head (d ) shall not exceed 0.60 d .

2 1 2

The boldface numbers refer to the list of references at the end of this test method.

C900 − 14

FIG. 1 Schematic Cross Section of Cast-in-Place Pullout Test

6.2.3 For post-installed inserts, the groove to accept the expandable insert shall be cut so that the distance between the bearing

surface of the groove and concrete surface equals the insert diameter after expansion (d ). The difference between the diameters

of the undercut groove (d ) and the core hole (d ) shall be sufficient to prevent localized failure and ensure that a conic frustum

2 1

of concrete is extracted during the test (see Note 6). The expanded insert shall bear uniformly on the entire bearing area of the

groove.

NOTE 6—A core hole diameter of 18 mm and an undercut groove diameter of 25 mm have been used successfully.

6.2.4 The bearing ring shall have an inside diameter (d ) of 2.0 to 2.4 times the insert head diameter (d ), and shall have an

3 2

outside diameter (d ) of at least 1.25 times the inside diameter. The thickness of the ring (t) shall be at least 0.4 times the pullout

insert head diameter. For a given test system, the same bearing ring dimensions shall be used.

6.2.5 Tolerances for dimensions of the pullout test inserts, bearing ring and embedment depth shall be 62 % within a given

system.

NOTE 7—The limits for dimensions and configurations for pullout test inserts and apparatus are intended to accommodate various systems.

6.2.6 The loading apparatus shall have sufficient capacity to provide the loading rate prescribed in 8.4.

NOTE 8—Hydraulic pumps that permit continuous loading may give more uniform test results than pumps that apply load intermittently.

6.2.7 The gauge to measure pullout force is permitted to be of the analog or digital type. Analog gauges shall be designed so

that the pullout force can be estimated to the nearest 0.5 kN. Digital gauges shall display the pullout force to the nearest 0.1 kN.

6.2.8 The force gauge shall have a means to preserve the maximum value of the load during a test.

6.2.9 Pullout apparatus shall be standardized in accordance with Annex A1 at least once a year and after all repairs. Standardize

the pullout apparatus using a testing machine verified in accordance with Practices E4 or using a Class A load cell as defined in

Practice E74. The indicated pullout force based on the developed relationship shall be within 62 % of the force measured by the

testing machine or load cell.

7. Sampling

7.1 Pullout test locations shall be separated so that the clear spacing between inserts is at least seven times the pullout insert

head diameter. Clear spacing between the inserts and the edges of the concrete shall be at least 3.5 times the head diameter. Inserts

shall be placed so that reinforcement is outside the expected conical failure surface by more than one bar diameter, or the maximum

size of aggregate, whichever is greater.

NOTE 9—A reinforcement locator is recommended to assist in avoiding reinforcement when planning the locations of post-installed tests. Follow the

manufacturer’s instructions for proper operation of such devices.

C900 − 14

FIG. 2 Schematic of Procedure for Post-Installed Pullout Test

7.2 When pullout test results are used to assess the in-place strength in order to allow the start of critical construction operations,

such as formwork removal or application of post tensioning, at least five individual pullout tests shall be performed as follows:

7.2.1 For every 115 m , or a fraction thereof, of a given placement; or

7.2.2 For every 470 m , or a fraction thereof, of the surface area of one face of a slab or wall.

NOTE 10—More than the minimum number of inserts should be provided in case a test result is not valid or testing begins before adequate strength

has developed.

7.2.3 Inserts shall be located in those portions of the structure that are critical in terms of exposure conditions and structural

requirements.

7.3 When pullout tests are used for other purposes, the number of tests shall be determined by the specifier of the test.

8. Procedure

8.1 Cast-in-Place Inserts:

8.1.1 Attach the pullout inserts to the forms using bolts or by other methods that firmly secure the insert in its proper location

prior to concrete placement. All inserts shall be embedded to the same depth. The axis of each shaft shall be perpendicular to the

formed surface.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.