ASTM G31-72(2004)

(Practice)Standard Practice for Laboratory Immersion Corrosion Testing of Metals

Standard Practice for Laboratory Immersion Corrosion Testing of Metals

SIGNIFICANCE AND USE

Corrosion testing by its very nature precludes complete standardization. This practice, rather than a standardized procedure, is presented as a guide so that some of the pitfalls of such testing may be avoided.

Experience has shown that all metals and alloys do not respond alike to the many factors that affect corrosion and that “accelerated” corrosion tests give indicative results only, or may even be entirely misleading. It is impractical to propose an inflexible standard laboratory corrosion testing procedure for general use, except for material qualification tests where standardization is obviously required.

In designing any corrosion test, consideration must be given to the various factors discussed in this practice, because these factors have been found to affect greatly the results obtained.

SCOPE

1.1 This practice describes accepted procedures for and factors that influence laboratory immersion corrosion tests, particularly mass loss tests. These factors include specimen preparation, apparatus, test conditions, methods of cleaning specimens, evaluation of results, and calculation and reporting of corrosion rates. This practice also emphasizes the importance of recording all pertinent data and provides a checklist for reporting test data. Other ASTM procedures for laboratory corrosion tests are tabulated in the Appendix. (Warning-In many cases the corrosion product on the reactive metals titanium and zirconium is a hard and tightly bonded oxide that defies removal by chemical or ordinary mechanical means. In many such cases, corrosion rates are established by mass gain rather than mass loss.)

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G31–72 (Reapproved 2004)

Standard Practice for

1

Laboratory Immersion Corrosion Testing of Metals

ThisstandardisissuedunderthefixeddesignationG31;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope G16 Guide forApplying Statistics toAnalysis of Corrosion

2

Data

1.1 This practice describes accepted procedures for and

G46 Guide for Examination and Evaluation of Pitting

factors that influence laboratory immersion corrosion tests,

Corrosion

particularly mass loss tests. These factors include specimen

preparation, apparatus, test conditions, methods of cleaning

3. Significance and Use

specimens, evaluation of results, and calculation and reporting

3.1 Corrosion testing by its very nature precludes complete

of corrosion rates. This practice also emphasizes the impor-

standardization. This practice, rather than a standardized pro-

tance of recording all pertinent data and provides a checklist

cedure, is presented as a guide so that some of the pitfalls of

for reporting test data. Other ASTM procedures for laboratory

such testing may be avoided.

corrosion tests are tabulated in the Appendix. (Warning—In

3.2 Experience has shown that all metals and alloys do not

many cases the corrosion product on the reactive metals

respond alike to the many factors that affect corrosion and that

titanium and zirconium is a hard and tightly bonded oxide that

“accelerated” corrosion tests give indicative results only, or

defies removal by chemical or ordinary mechanical means. In

mayevenbeentirelymisleading.Itisimpracticaltoproposean

many such cases, corrosion rates are established by mass gain

inflexible standard laboratory corrosion testing procedure for

rather than mass loss.)

general use, except for material qualification tests where

1.2 The values stated in SI units are to be regarded as the

standardization is obviously required.

standard. The values given in parentheses are for information

3.3 In designing any corrosion test, consideration must be

only.

given to the various factors discussed in this practice, because

1.3 This standard does not purport to address all of the

these factors have been found to affect greatly the results

safety concerns, if any, associated with its use. It is the

obtained.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Interferences

bility of regulatory limitations prior to use.

4.1 The methods and procedures described herein represent

the best current practices for conducting laboratory corrosion

2. Referenced Documents

3 tests as developed by corrosion specialists in the process

2.1 ASTM Standards:

industries. For proper interpretation of the results obtained, the

A262 Practices for Detecting Susceptibility to Intergranular

specific influence of certain variables must be considered.

Attack in Austenitic Stainless Steels

These include:

E8 Test Methods for Tension Testing of Metallic Materials

4.1.1 Metal specimens immersed in a specific hot liquid

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

may not corrode at the same rate or in the same manner as in

sion Test Specimens

equipment where the metal acts as a heat transfer medium in

G4 Guide for Conducting Corrosion Tests in FieldApplica-

heating or cooling the liquid. If the influence of heat transfer

tions

effects is specifically of interest, specialized procedures (in

which the corrosion specimen serves as a heat transfer agent)

1

This practice is under the jurisdiction of ASTM Committee J01 on Corrosion 4

must be employed (1).

and is the direct responsibility of Subcommittee J01.01 on Working Group on

4.1.2 In laboratory tests, the velocity of the environment

Laboratory Immersion Tests.

Current edition approved May 1, 2004. Published May 2004. Originally

relative to the specimens will normally be determined by

approved in 1972. Last previous edition approved in 1998 as G31 – 72 (1998). DOI:

convection currents or the effects induced by aeration or

10.1520/G0031-72R04.

2 boiling or both. If the specific effects of high velocity are to be

This practice is based upon NACE Standard TM-01-69, “Test Method-

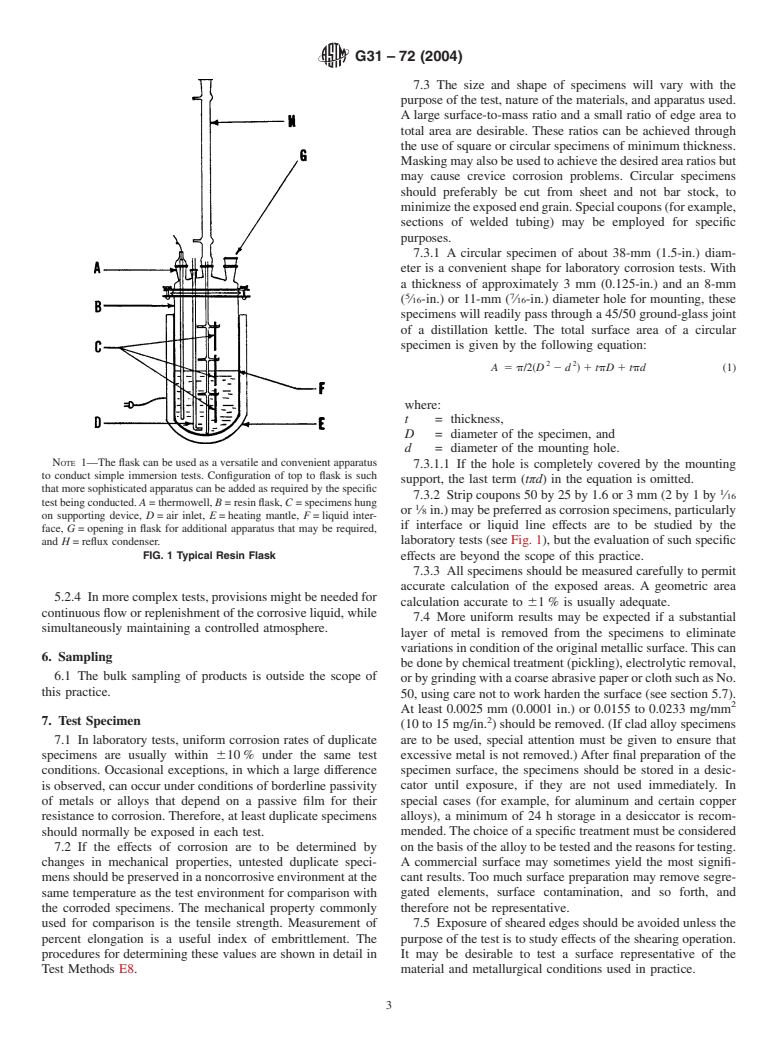

studied, special techniques must be employed to transfer the

Laboratory Corrosion Testing of Metals for the Process Industries,” with modifica-

tions to relate more directly to Practices G1 and G1 and Guide G4.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on The boldface number

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.