ASTM D7498-09

(Test Method)Standard Test Method for Vertical Strip Drains Using a Large Scale Consolidation Test

Standard Test Method for Vertical Strip Drains Using a Large Scale Consolidation Test

SIGNIFICANCE AND USE

As this is a time intensive test, it should not be considered as an acceptance test for commercial shipments of prefabricated vertical strip drains.

Prior to the development of vertical strip drains, when it was desired to increase the rate of consolidation of a compressible soil on a construction project, large diameter sand drains were installed. Vertical strip drains can be installed in areas where it is desired to increase the rate of soils consolidation in place of these large diameter sand drains.

This test method can be used to compare the performance of vertical strip drains to that of sand drains.

SCOPE

1.1 This test method is a performance test, which measures the effectiveness of vertical strip drains on the time rates of consolidation of compressible soils from construction project sites.

1.1.1 It is expected that the design agency will be responsible for performing this test. It is not intended to be a manufacturer performed test.

1.2 This test method is applicable to all vertical strip drains.

1.3 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7498 − 09

StandardTest Method for

Vertical Strip Drains Using a Large Scale Consolidation

Test

This standard is issued under the fixed designation D7498; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method is a performance test, which measures

4.1 This test method describes procedures for determining

the effectiveness of vertical strip drains on the time rates of

the effectiveness of vertical strip drains used under specified

consolidation of compressible soils from construction project

soil conditions to enhance the time rate of consolidation of

sites.

compressible soils.

1.1.1 It is expected that the design agency will be respon-

4.2 A specimen of the vertical strip drain is inserted in the

sible for performing this test. It is not intended to be a

test chamber and compressible soil from the project site is

manufacturer performed test.

remolded around the vertical strip drain, such that the drain is

1.2 This test method is applicable to all vertical strip drains.

in a similar position as it would be on the project site.

1.3 The values stated in SI units are to be regarded as the

4.3 The top of the soil is sealed with a wax seal, such that

standard. No other units of measurement are included in this

drainage only occurs through the vertical strip drain. The

standard.

vertical strip drain protrudes up through the seal.

1.4 This standard does not purport to address all of the

4.4 Asanddrainageblanketisplacedontopofthewaxseal,

safety concerns, if any, associated with its use. It is the

such that the vertical strip drain drains into the sand blanket.

responsibility of the user of this standard to establish appro-

4.5 A rubber cup seal provides the means of applying

priate safety and health practices and determine the applica-

incremental loads in a similar manner to a standard soils

bility of regulatory limitations prior to use.

consolidation test.

2. Referenced Documents

4.6 A similar setup is used, only with a 50 mm (2 in.) sand

drain in place of the vertical strip drain.

2.1 ASTM Standards:

D4354 Practice for Sampling of Geosynthetics for Testing

4.7 The Coefficients of Consolidation are determined from

D4439 Terminology for Geosynthetics

the test results for both the vertical strip drain and the sand

drain. Time rates of consolidation are then compared.

3. Terminology

4.8 Personsperformingthistestshallhaveknowledgeinthe

3.1 Definitions— For definitions related to geosynthetics,

consolidation testing of soils.

see Terminology D4439.

3.2 Definitions of Terms Specific to This Standard:

5. Significance and Use

3.2.1 vertical strip drains, n—a geocomposite consisting of

5.1 As this is a time intensive test, it should not be

a geotextile cover and drainage core installed vertically into

considered as an acceptance test for commercial shipments of

soil to provide drainage for accelerated consolidation of soils.

prefabricated vertical strip drains.

5.2 Prior to the development of vertical strip drains, when it

wasdesiredtoincreasetherateofconsolidation ofacompress-

This test method is under the jurisdiction of ASTM Committee D35 on

Geosynthetics and is the direct responsibility of Subcommittee D35.03 on Perme- ible soil on a construction project, large diameter sand drains

ability and Filtration.

were installed. Vertical strip drains can be installed in areas

Current edition approved June 1, 2009. Published July 2009. DOI: 10.1520/

where it is desired to increase the rate of soils consolidation in

D7498-09.

2 place of these large diameter sand drains.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.3 This test method can be used to compare the perfor-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. mance of vertical strip drains to that of sand drains.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7498 − 09

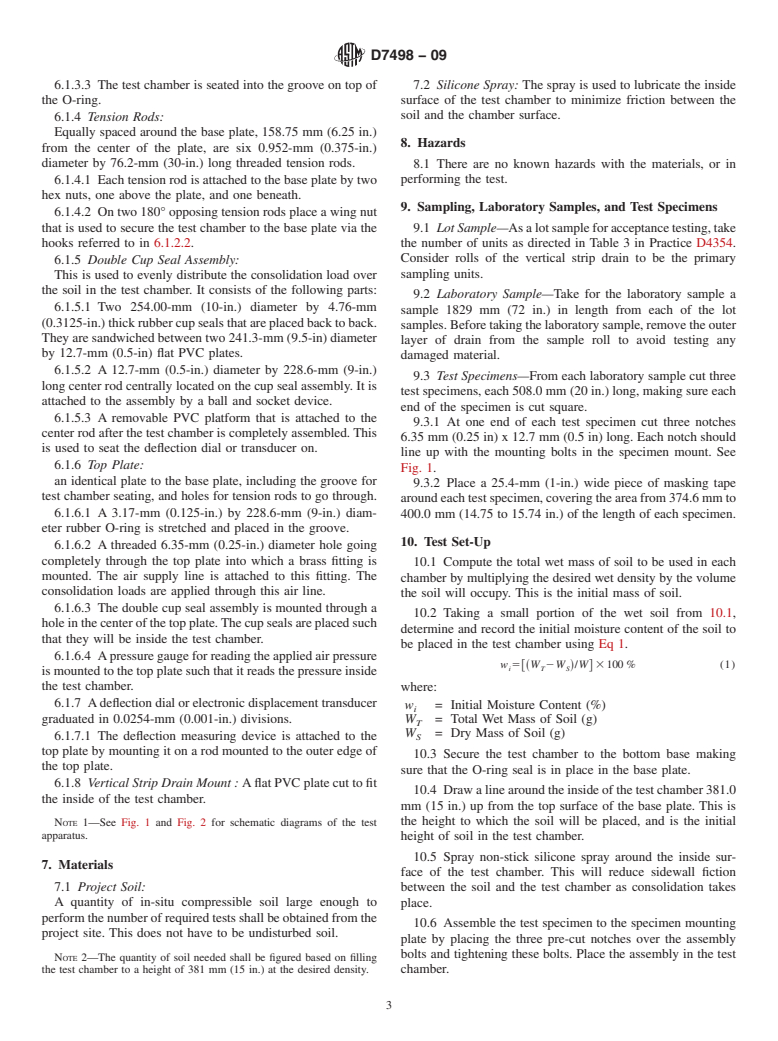

6. Apparatus 6.1.2.2 On the outside of the cylinder, at 180° to one

another, two 19.05-mm (0.75-in.) thick acrylic hooks are

6.1 The apparatus for this test method is a specialty piece of

located25.4mm(1in.)fromthebottomofthetestchamberfor

equipment that must be capable of safely handling loads up to

the purpose of fastening the test chamber to the base plate.

206.8 kPa (30 psi) using compressed air.

6.1.3 Base Plate:

6.1.1 As this is a time intensive test, it is recommended to

A 361.95-mm (14.25-in.) diameter PVC flat plate, 38.1 mm

have three test apparatus setups. This will allow simultaneous

(1.5 in.) thick.

testing of three vertical strip drain specimens.

6.1.3.1 The base plate has a 12.7-mm (0.5-in.) wide by

6.1.2 Test Chamber—A 254.0-mm (10-in.) diameter by

6.35-mm (0.25-in.) deep concentric groove, having an inside

558.6-mm (22-in.) high by 12.7-mm (0.5-in.) wall thickness

diameter of 254.0 mm (10 in.), located on the top side of the

PVC pipe. (Fig. 1)

base plate.

6.1.2.1 Drainage Ports—Six 3.18-mm (0.125-in.) drainage

ports are located 152.4-mm (6-in.) from the top, and equally 6.1.3.2 A 3.17-mm (0.125-in.) by 228.6-mm (9-in.) diam-

spaced around the perimeter of the cylinder. eter rubber O-ring is stretched and placed in this groove.

FIG. 1 Large Scale Consolidator

D7498 − 09

6.1.3.3 The test chamber is seated into the groove on top of 7.2 Silicone Spray: The spray is used to lubricate the inside

the O-ring. surface of the test chamber to minimize friction between the

soil and the chamber surface.

6.1.4 Tension Rods:

Equally spaced around the base plate, 158.75 mm (6.25 in.)

8. Hazards

from the center of the plate, are six 0.952-mm (0.375-in.)

diameter by 76.2-mm (30-in.) long threaded tension rods.

8.1 There are no known hazards with the materials, or in

performing the test.

6.1.4.1 Each tension rod is attached to the base plate by two

hex nuts, one above the plate, and one beneath.

9. Sampling, Laboratory Samples, and Test Specimens

6.1.4.2 On two 180° opposing tension rods place a wing nut

that is used to secure the test chamber to the base plate via the

9.1 LotSample—Asalotsampleforacceptancetesting,take

hooks referred to in 6.1.2.2. the number of units as directed in Table 3 in Practice D4354.

Consider rolls of the vertical strip drain to be the primary

6.1.5 Double Cup Seal Assembly:

sampling units.

This is used to evenly distribute the consolidation load over

the soil in the test chamber. It consists of the following parts:

9.2 Laboratory Sample—Take for the laboratory sample a

6.1.5.1 Two 254.00-mm (10-in.) diameter by 4.76-mm

sample 1829 mm (72 in.) in length from each of the lot

(0.3125-in.)thickrubbercupsealsthatareplacedbacktoback.

samples.Beforetakingthelaboratorysample,removetheouter

They are sandwiched between two 241.3-mm (9.5-in) diameter

layer of drain from the sample roll to avoid testing any

by 12.7-mm (0.5-in) flat PVC plates.

damaged material.

6.1.5.2 A 12.7-mm (0.5-in.) diameter by 228.6-mm (9-in.)

9.3 Test Specimens—From each laboratory sample cut three

long center rod centrally located on the cup seal assembly. It is

test specimens, each 508.0 mm (20 in.) long, making sure each

attached to the assembly by a ball and socket device.

end of the specimen is cut square.

6.1.5.3 A removable PVC platform that is attached to the

9.3.1 At one end of each test specimen cut three notches

center rod after the test chamber is completely assembled.This

6.35 mm (0.25 in) x 12.7 mm (0.5 in) long. Each notch should

is used to seat the deflection dial or transducer on.

line up with the mounting bolts in the specimen mount. See

6.1.6 Top Plate:

Fig. 1.

an identical plate to the base plate, including the groove for

9.3.2 Place a 25.4-mm (1-in.) wide piece of masking tape

test chamber seating, and holes for tension rods to go through.

aroundeachtestspecimen,coveringtheareafrom374.6mmto

6.1.6.1 A 3.17-mm (0.125-in.) by 228.6-mm (9-in.) diam- 400.0 mm (14.75 to 15.74 in.) of the length of each specimen.

eter rubber O-ring is stretched and placed in the groove.

10. Test Set-Up

6.1.6.2 A threaded 6.35-mm (0.25-in.) diameter hole going

completely through the top plate into which a brass fitting is

10.1 Compute the total wet mass of soil to be used in each

mounted. The air supply line is attached to this fitting. The

chamber by multiplying the desired wet density by the volume

consolidation loads are applied through this air line.

the soil will occupy. This is the initial mass of soil.

6.1.6.3 The double cup seal assembly is mounted through a

10.2 Taking a small portion of the wet soil from 10.1,

holeinthecenterofthetopplate.Thecupsealsareplacedsuch

determine and record the initial moisture content of the soil to

that they will be inside the test chamber.

be placed in the test chamber using Eq 1.

6.1.6.4 Apressuregaugeforreadingtheappliedairpressure

w 5 W 2W /W 3100 % (1)

@~ ! #

i T S

is mounted to the top plate such that it reads the pressure inside

the test chamber. where:

6.1.7 Adeflectiondialorelectronicdisplacementtransducer

w = Initial Moisture Content (%)

i

graduated in 0.0254-mm (0.001-in.) divisions. W = Total Wet Mass of Soil (g)

T

W = Dry Mass of Soil (g)

6.1.7.1 The deflection measuring device is attached to the S

top plate by mounting it on a rod mounted to the outer edge of

10.3 Secure the test chamber to the bottom base making

the top plate.

sure that the O-ring seal is in place in the base plate.

6.1.8 Vertical Strip Drain Mount : Aflat PVC plate cut to fit

10.4 Drawalinearoundtheinsideofthetestchamber381.0

the inside of the test chamber.

mm (15 in.) up from the top surface of the base plate. This is

the height to which the soil will be placed, and is the initial

NOTE 1—See Fig. 1 and Fig. 2 for schematic diagrams of the test

apparatus.

height of soil in the test chamber.

10.5 Spray non-stick silicone spray around the inside sur-

7. Materials

face of the test chamber. This will reduce sidewall fiction

7.1 Project Soil:

between the soil and the test chamber as consolidation takes

A quantity of in-situ compressible soil large enough to place.

performthenumberofrequiredtestsshallbeobtainedfromthe

10.6 Assemble the test specimen to the specimen mounting

project site. This does not have to be undisturbed soil.

plate by placing the three pre-cut notches over the assembly

bolts and tightening these bolts. Place the assembly in the test

NOTE 2—The quantity of soil needed shall be figured based on filling

the test chamber to a height of 381 mm (15 in.) at the desired density. chambe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.