ASTM D3039/D3039M-00(2006)

(Test Method)Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials

Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials

SIGNIFICANCE AND USE

This test method is designed to produce tensile property data for material specifications, research and development, quality assurance, and structural design and analysis. Factors that influence the tensile response and should therefore be reported include the following: material, methods of material preparation and lay-up, specimen stacking sequence, specimen preparation, specimen conditioning, environment of testing, specimen alignment and gripping, speed of testing, time at temperature, void content, and volume percent reinforcement. Properties, in the test direction, which may be obtained from this test method include the following:

5.1.1 Ultimate tensile strength,

5.1.2 Ultimate tensile strain,

5.1.3 Tensile chord modulus of elasticity,

5.1.4 Poisson’ratio, and

5.1.5 Transition strain.

SCOPE

1.1 This test method determines the in-plane tensile properties of polymer matrix composite materials reinforced by high-modulus fibers. The composite material forms are limited to continuous fiber or discontinuous fiber-reinforced composites in which the laminate is balanced and symmetric with respect to the test direction.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3039/D3039M–00 (Reapproved 2006)

Standard Test Method for

Tensile Properties of Polymer Matrix Composite Materials

This standard is issued under the fixed designation D3039/D3039M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D5229/D5229M Test Method for Moisture Absorption

Properties and Equilibrium Conditioning of Polymer Ma-

1.1 This test method determines the in-plane tensile prop-

trix Composite Materials

erties of polymer matrix composite materials reinforced by

E4 Practices for Force Verification of Testing Machines

high-modulus fibers.The composite material forms are limited

E6 Terminology Relating to Methods of Mechanical Test-

to continuous fiber or discontinuous fiber-reinforced compos-

ing

ites in which the laminate is balanced and symmetric with

E83 Practice for Verification and Classification of Exten-

respect to the test direction.

someter System

1.2 The values stated in either SI units or inch-pound units

E11 Specification for Wire Cloth and Sieves for Testing

are to be regarded separately as standard. Within the text, the

Purposes

inch-pound units are shown in brackets. The values stated in

E122 Practice for Calculating Sample Size to Estimate,

each system are not exact equivalents; therefore, each system

With a Specified Tolerable Error, the Average for a

must be used independently of the other. Combining values

Characteristic of a Lot or Process

from the two systems may result in nonconformance with the

E132 Test Method for Poisson’s Ratio at Room Tempera-

standard.

ture

1.3 This standard does not purport to address all of the

E177 Practice for Use of the Terms Precision and Bias in

safety concerns, if any, associated with its use. It is the

ASTM Test Methods

responsibility of the user of this standard to establish appro-

E251 Test Methods for Performance Characteristics of

priate safety and health practices and determine the applica-

Metallic Bonded Resistance Strain Gages

bility of regulatory limitations prior to use.

E456 Terminology Relating to Quality and Statistics

2. Referenced Documents E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

2.1 ASTM Standards:

E1012 Practice for Verification of Test Frame and Speci-

D792 TestMethodsforDensityandSpecificGravity(Rela-

men Alignment Under Tensile and Compressive Axial

tive Density) of Plastics by Displacement

Force Application

D883 Terminology Relating to Plastics

E 1237 Guide for Installing Bonded Resistance Strain

D2584 Test Method for Ignition Loss of Cured Reinforced

Gages

Resins

D2734 Test Methods for Void Content of Reinforced Plas-

3. Terminology

tics

3.1 Definitions—TerminologyD3878definestermsrelating

D3171 TestMethodsforConstituentContentofComposite

to high-modulus fibers and their composites. Terminology

Materials

D883 defines terms relating to plastics. Terminology E6

D3878 Terminology for Composite Materials

defines terms relating to mechanical testing. Terminology

E456 and Practice E177 define terms relating to statistics. In

the event of a conflict between terms, Terminology D3878

This test method is under the jurisidiction of ASTM Committee D30 on

shall have precedence over the other standards.

Composite Materials and is the direct responsibility of Subcommittee D30.04 on

3.2 Definitions of Terms Specific to This Standard:

Lamina and Laminate Test Methods.

NOTE—If the term represents a physical quantity, its

Current edition approved Jan. 15, 2006. Published January 2006. Originally

e2

approved in 1971. Last previous edition approved in 2000 as D3039–00 .

analytical dimensions are stated immediately following the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

term (or letter symbol) in fundamental dimension form, using

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the following ASTM standard symbology for fundamental

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. dimensions, shown within square brackets: [M] for mass, [L]

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3039/D3039M–00 (2006)

for length, [T] for time, [Q] for thermodynamic temperature, 4. Summary of Test Method

and [nd] for nondimensional quantities. Use of these symbols

4.1 Athinflatstripofmaterialhavingaconstantrectangular

is restricted to analytical dimensions when used with square

cross section is mounted in the grips of a mechanical testing

brackets, as the symbols may have other definitions when used

machine and monotonically loaded in tension while recording

without the brackets.

load. The ultimate strength of the material can be determined

3.2.1 nominal value, n—a value, existing in name only,

from the maximum load carried before failure. If the coupon

assigned to a measurable property for the purpose of conve-

strainismonitoredwithstrainordisplacementtransducersthen

nient designation. Tolerances may be applied to a nominal

the stress-strain response of the material can be determined,

value to define an acceptable range for the property.

from which the ultimate tensile strain, tensile modulus of

3.2.2 transition region, n—a strain region of a stress-strain

elasticity, Poisson’s ratio, and transition strain can be derived.

or strain-strain curve over which a significant change in the

slope of the curve occurs within a small strain range.

5. Significance and Use

transition

3.2.3 transition strain, e [nd], n—the strain value at

5.1 This test method is designed to produce tensile property

the mid range of the transition region between the two

data for material specifications, research and development,

essentially linear portions of a bilinear stress-strain or strain-

quality assurance, and structural design and analysis. Factors

strain curve.

that influence the tensile response and should therefore be

3.2.3.1 Discussion—Many filamentary composite materials

reported include the following: material, methods of material

showessentiallybilinearbehaviorduringloading,suchasseen

preparation and lay-up, specimen stacking sequence, specimen

in plots of either longitudinal stress versus longitudinal strain

preparation, specimen conditioning, environment of testing,

or transverse strain versus long longitudinal strain. There are

specimen alignment and gripping, speed of testing, time at

varying physical reasons for the existence of a transition

temperature, void content, and volume percent reinforcement.

region. Common examples include: matrix cracking under

Properties, in the test direction, which may be obtained from

tensile loading and ply delamination.

this test method include the following:

3.3 Symbols:

5.1.1 Ultimate tensile strength,

3.3.1 A—minimum cross-sectional area of a coupon.

5.1.2 Ultimate tensile strain,

3.3.2 B —percent bending for a uniaxial coupon of rectan-

y 5.1.3 Tensile chord modulus of elasticity,

gular cross section about y axis of the specimen (about the

5.1.4 Poisson’s ratio, and

narrow direction).

5.1.5 Transition strain.

3.3.3 B —percent bending for a uniaxial coupon of rectan-

z

gularcrosssectionaboutzaxisofthespecimen(aboutthewide

6. Interferences

direction).

6.1 Material and Specimen Preparation—Poor material

3.3.4 CV—coefficient of variation statistic of a sample

fabrication practices, lack of control of fiber alignment, and

population for a given property (in percent).

damage induced by improper coupon machining are known

3.3.5 E—modulus of elasticity in the test direction.

causes of high material data scatter in composites.

tu

3.3.6 F —ultimate tensile strength in the test direction.

6.2 Gripping—A high percentage of grip-induced failures,

su

3.3.7 F —ultimate shear strength in the test direction.

especiallywhencombinedwithhighmaterialdatascatter,isan

3.3.8 h—coupon thickness.

indicator of specimen gripping problems. Specimen gripping

3.3.9 L —extensometer gage length.

g

methods are discussed further in 7.2.4, 8.2, and 11.5.

3.3.10 L —minimum required bonded tab length.

min

6.3 System Alignment—Excessive bending will cause pre-

3.3.11 n—number of coupons per sample population.

mature failure, as well as highly inaccurate modulus of

3.3.12 P—load carried by test coupon.

elasticity determination. Every effort should be made to elimi-

f

3.3.13 P—load carried by test coupon at failure.

nate excess bending from the test system. Bending may occur

max

3.3.14 P —maximum load carried by test coupon before

asaresultofmisalignedgripsorfromspecimensthemselvesif

failure.

improperly installed in the grips or out-of-tolerance caused by

3.3.15 s —standard deviation statistic of a sample popu-

poor specimen preparation. If there is any doubt as to the

n−1

lation for a given property.

alignment inherent in a given test machine, then the alignment

3.3.16 w—coupon width.

should be checked as discussed in 7.2.5.

3.3.17 x—test result for an individual coupon from the 6.4 EdgeEffectsinAnglePlyLaminates—Prematurefailure

i

sample population for a given property. and lower stiffnesses are observed as a result of edge softening

3.3.18 x¯—mean or average (estimate of mean) of a sample in laminates containing off-axis plies. Because of this, the

strengthandmodulusforangleplylaminatescanbedrastically

population for a given property.

underestimated. For quasi-isotropic laminates containing sig-

3.3.19 d—extensional displacement.

nificant 0° plies, the effect is not as significant.

3.3.20 e—general symbol for strain, whether normal strain

or shear strain.

7. Apparatus

3.3.21 e—indicated normal strain from strain transducer or

extensometer.

7.1 Micrometers—A micrometer with a 4- to 5-mm [0.16-

3.3.22 s—normal stress.

to 0.20-in] nominal diameter double-ball interface shall be

3.3.23 n—Poisson’s ratio. used to measure the thickness of the specimen. A micrometer

D3039/D3039M–00 (2006)

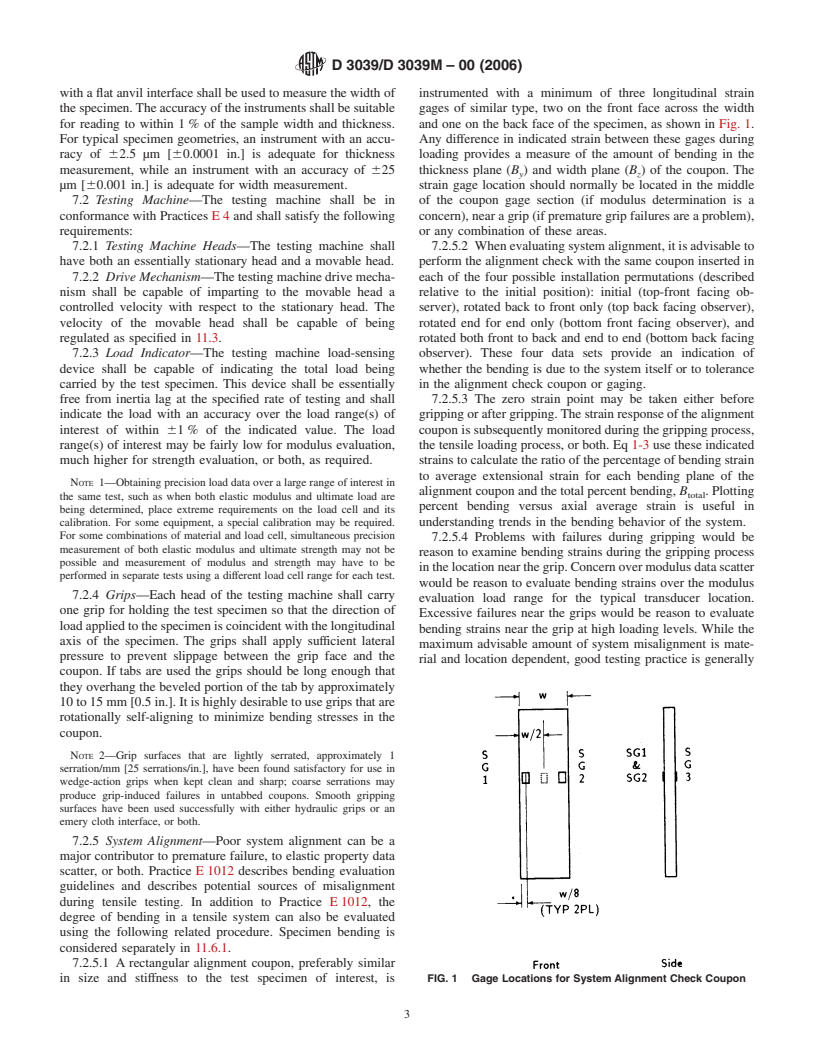

withaflatanvilinterfaceshallbeusedtomeasurethewidthof instrumented with a minimum of three longitudinal strain

thespecimen.Theaccuracyoftheinstrumentsshallbesuitable gages of similar type, two on the front face across the width

for reading to within 1% of the sample width and thickness. and one on the back face of the specimen, as shown in Fig. 1.

For typical specimen geometries, an instrument with an accu- Any difference in indicated strain between these gages during

racy of 62.5 µm [60.0001 in.] is adequate for thickness loading provides a measure of the amount of bending in the

measurement, while an instrument with an accuracy of 625 thickness plane (B ) and width plane (B ) of the coupon. The

y z

µm [60.001 in.] is adequate for width measurement. strain gage location should normally be located in the middle

7.2 Testing Machine—The testing machine shall be in of the coupon gage section (if modulus determination is a

conformance with PracticesE4 and shall satisfy the following concern),nearagrip(ifprematuregripfailuresareaproblem),

requirements: or any combination of these areas.

7.2.1 Testing Machine Heads—The testing machine shall 7.2.5.2 Whenevaluatingsystemalignment,itisadvisableto

have both an essentially stationary head and a movable head. perform the alignment check with the same coupon inserted in

7.2.2 Drive Mechanism—Thetestingmachinedrivemecha- each of the four possible installation permutations (described

nism shall be capable of imparting to the movable head a relative to the initial position): initial (top-front facing ob-

controlled velocity with respect to the stationary head. The server), rotated back to front only (top back facing observer),

velocity of the movable head shall be capable of being rotated end for end only (bottom front facing observer), and

regulated as specified in 11.3. rotated both front to back and end to end (bottom back facing

7.2.3 Load Indicator—The testing machine load-sensing observer). These four data sets provide an indication of

device shall be capable of indicating the total load being whether the bending is due to the system itself or to tolerance

carried by the test specimen. This device shall be essentially in the alignment check coupon or gaging.

free from inertia lag at the specified rate of testing and shall 7.2.5.3 The zero strain point may be taken either before

indicate the load with an accuracy over the load range(s) of grippingoraftergripping.Thestrainresponseofthealignment

interest of within 61% of the indicated value. The load couponissubsequentlymonitoredduringthegrippingprocess,

range(s) of interest may be fairly low for modulus evaluation, the tensile loading process, or both. Eq 1-3 use these indicated

much higher for strength evaluation, or both, as required. strainstocalculatetheratioofthepercentageofbendingstrain

to average extensional strain for each bending plane of the

NOTE 1—Obtaining precision load data over a large range of interest in

alignmentcouponandthetotalpercentbending, B .Plotting

total

the same test, such as when both elastic modulus and ultimate load are

percent bending versus axial average strain is useful in

being determined, place extreme requirements on the load cell and its

calibration. For some equipment, a special calibration may be required. understanding trends in the bending behavior of the system.

For some combinations of material and load cell, simultaneous precision

7.2.5.4 Problems with failures during gripping would be

measurement of both elastic modulus and ultimate strength may not be

reason to examine bending strains during the gripping process

possible and measurement of modulus and strength may have to be

inthelocationnearthegrip.Concernovermodulusdatascatter

performed in separate tests using a different load cell range for each test.

would be reason to evaluate bending strains over the modulus

7.2.4 Grips—Each head of the testing machine shall carry

evaluation load range for the typical transducer location.

one grip for holding the test specimen so that the direction of

Excessive failures near the grips would be reason to evaluate

loadappliedtothespecimeniscoincidentwiththelongitudinal

bending strains near the grip at high loading levels. While the

axis of the specimen. The grips shall apply sufficient lateral

maximum advisable amount of system misalignment is mate-

pressure to prevent slippage between the grip face and the

rial and location dependent, good testing practice is generally

coupon. If tabs are used the grips should be long enough that

they overhang

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.