ASTM D5931-20

(Test Method)Standard Test Method for Density and Relative Density of Engine Coolant Concentrates and Aqueous Engine Coolants by Digital Density Meter

Standard Test Method for Density and Relative Density of Engine Coolant Concentrates and Aqueous Engine Coolants by Digital Density Meter

SIGNIFICANCE AND USE

5.1 Density is a fundamental physical property that can be used in conjunction with other properties to characterize engine coolant concentrates and aqueous engine coolants.

5.2 Determination of the density or relative density of these products is necessary for the conversion of measured volumes to volumes at the standard temperature of choice. ASTM specifications normally state the temperatures for density and relative density of fluids; 25 °C, 20 °C, and 15.6 °C are commonly used temperatures.

SCOPE

1.1 This test method covers the determination of the density or relative density of glycols, glycerin, heat transfer fluids, engine coolant concentrates, and aqueous engine coolants.

1.2 This test method should not be applied to samples so dark in color that the absence of air bubbles in the sample cell cannot be established with certainty.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 The accepted units of measure for density are grams per milliliter or kilograms per cubic meter.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 7.4.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5931 − 20

Standard Test Method for

Density and Relative Density of Engine Coolant

Concentrates and Aqueous Engine Coolants by Digital

1

Density Meter

This standard is issued under the fixed designation D5931; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 Thistestmethodcoversthedeterminationofthedensity 3.1 Definitions:

or relative density of glycols, glycerin, heat transfer fluids, 3.1.1 relative density, n—the ratio of the density of a

engine coolant concentrates, and aqueous engine coolants. material at a stated temperature to the density of water at the

same stated temperature.

1.2 This test method should not be applied to samples so

dark in color that the absence of air bubbles in the sample cell

4. Summary of Test Method

cannot be established with certainty.

4.1 A small volume of liquid sample is introduced into an

1.3 The values stated in SI units are to be regarded as

oscillatingsampletube,andthechangeinoscillatingfrequency

standard. No other units of measurement are included in this

caused by the change in the mass of the tube is used in

standard.

conjunction with calibration data to determine the density of

1.3.1 The accepted units of measure for density are grams

the sample.

per milliliter or kilograms per cubic meter.

1.4 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

5.1 Density is a fundamental physical property that can be

responsibility of the user of this standard to establish appro-

usedinconjunctionwithotherpropertiestocharacterizeengine

priate safety, health, and environmental practices and deter-

coolant concentrates and aqueous engine coolants.

mine the applicability of regulatory limitations prior to use.

For specific hazard statements, see 7.4.

5.2 Determination of the density or relative density of these

1.5 This international standard was developed in accor-

products is necessary for the conversion of measured volumes

dance with internationally recognized principles on standard-

to volumes at the standard temperature of choice. ASTM

ization established in the Decision on Principles for the

specifications normally state the temperatures for density and

Development of International Standards, Guides and Recom-

relative density of fluids; 25°C, 20°C, and 15.6°C are

mendations issued by the World Trade Organization Technical

commonly used temperatures.

Barriers to Trade (TBT) Committee.

6. Apparatus

2. Referenced Documents

6.1 Digital Density Analyzer, consisting of a U-shaped,

2

2.1 ASTM Standards:

oscillating sample tube and a system for electronic excitation,

D1193Specification for Reagent Water

frequency counting, and display.The analyzer must accommo-

E230/E230MSpecification for Temperature-Electromotive

date the accurate measurement of the sample temperature

Force (emf) Tables for Standardized Thermocouples

duringmeasurementormustcontrolthesampletemperatureas

described in 6.2. The instrument must meet the precision

requirements described in this test method.

1

This test method is under the jurisdiction ofASTM Committee D15 on Engine

6.2 Circulating Constant—Temperature Bath, (optional) ca-

Coolants and Related Fluids and is the direct responsibility of Subcommittee

D15.03 on Physical Properties.

pable of maintaining the temperature of the circulating liquid

Current edition approved May 15, 2020. Published June 2020. Originally

constantto 60.05°Cinthedesiredrange.Temperaturecontrol

approved in 1996. Last previous edition approved in 2017 as D5931–13(2017).

can be maintained as part of the density analyzer instrument

DOI: 10.1520/D5931-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or package.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.3 Syringes, at least 2 mL in volume with a tip or an

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. adapter tip that will fit the opening of the oscillating tube.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5931 − 20

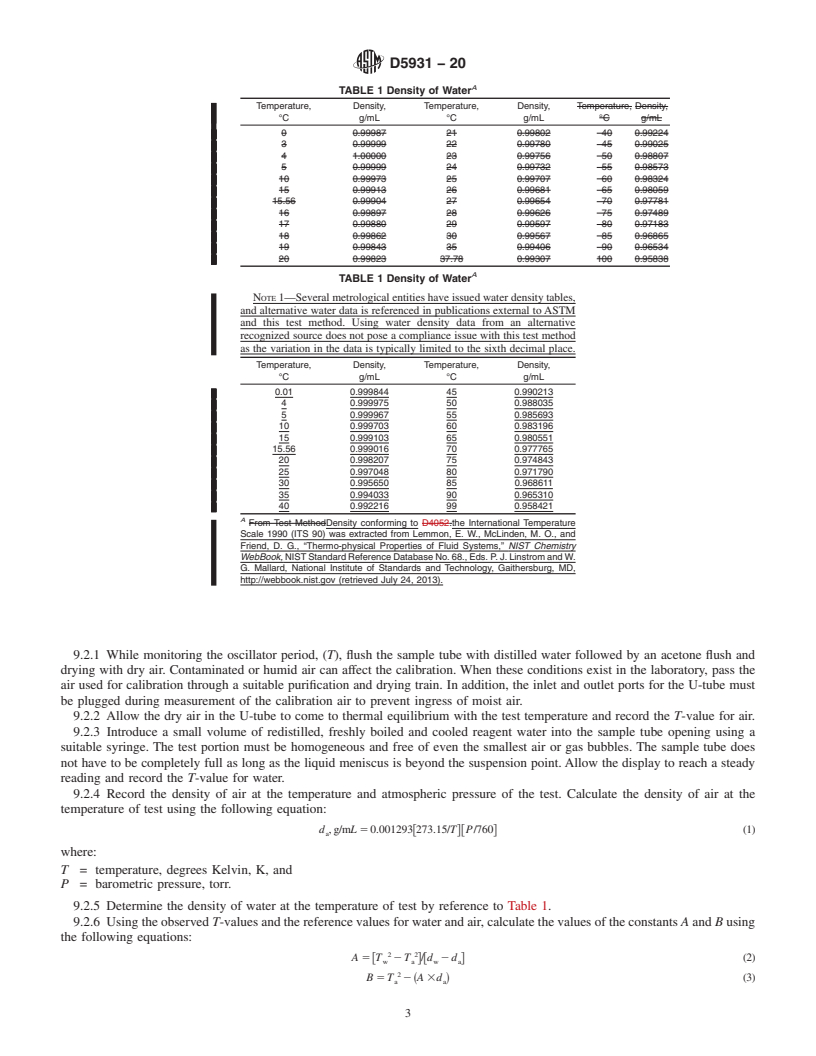

A

TABLE 1 Density of Water

6.4 Flow-Through or Pressure Adapter, for use as an alter-

native means of introducing the sample into the density

NOTE1—

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5931 − 13 (Reapproved 2017) D5931 − 20

Standard Test Method for

Density and Relative Density of Engine Coolant

Concentrates and Aqueous Engine Coolants by Digital

1

Density Meter

This standard is issued under the fixed designation D5931; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the density or relative density of glycols, glycerin, heat transfer fluids, engine

coolant concentrates, and aqueous engine coolants.

1.2 This test method should not be applied to samples so dark in color that the absence of air bubbles in the sample cell cannot

be established with certainty.

1.3 The accepted units of measure for density are grams per milliliter or kilograms per cubic meter.values stated in SI units are

to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 The accepted units of measure for density are grams per milliliter or kilograms per cubic meter.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific hazard statements, see Note 17.4.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

E230/E230M Specification for Temperature-Electromotive Force (emf) Tables for Standardized Thermocouples

3. Terminology

3.1 Definitions:

3.1.1 relative density, n—the ratio of the density of a material at a stated temperature to the density of water at the same stated

temperature.

4. Summary of Test Method

4.1 A small volume of liquid sample is introduced into an oscillating sample tube, and the change in oscillating frequency

caused by the change in the mass of the tube is used in conjunction with calibration data to determine the density of the sample.

5. Significance and Use

5.1 Density is a fundamental physical property that can be used in conjunction with other properties to characterize engine

coolant concentrates and aqueous engine coolants.

1

This test method is under the jurisdiction of ASTM Committee D15 on Engine Coolants and Related Fluids and is the direct responsibility of Subcommittee D15.03 on

Physical Properties.

Current edition approved Nov. 1, 2017May 15, 2020. Published November 2017June 2020. Originally approved in 1996. Last previous edition approved in 20132017 as

D5931D5931–13(2017).–13. DOI: 10.1520/D5931-13R17.10.1520/D5931-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5931 − 20

5.2 Determination of the density or relative density of these products is necessary for the conversion of measured volumes to

volumes at the standard temperature of 20 °C (68 °F).choice. ASTM specifications normally state the temperatures for density and

relative density of fluids; 25 °C, 20 °C, and 15.6 °C are commonly used temperatures.

6. Apparatus

6.1 Digital Density Analyzer, consisting of a U-shaped, oscillating sample tube and a system for electronic excitation, frequency

counting, and display. The analyzer must accommodate the accurate measurement of the sample temperature during measurement

or must control the sample temperature as described in 6.2. The instrument must meet the precision requirements described in this

test method.

6.2 Circulating Constant—Temperature Bath, (optional) capab

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.