ASTM D746-04

(Test Method)Standard Test Method for Brittleness Temperature of Plastics and Elastomers by Impact

Standard Test Method for Brittleness Temperature of Plastics and Elastomers by Impact

SCOPE

1.1 This test method covers the determination of the temperature at which plastics and elastomers exhibit brittle failure under specified impact conditions. Two routine inspection and acceptance procedures are also provided. Note 1

When testing rubbers for impact brittleness use Test Methods D 2137.

1.2 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 2

This test method and ISO 974-2000 (E) are technically equivalent when using the Type B fixture and the Type III specimen, however, the minimum number of specimens that are required to be tested is significantly different when using this test method. The ISO method requires that a minimum of 100 specimens be tested.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 746–04

Standard Test Method for

Brittleness Temperature of Plastics and Elastomers by

1

Impact

This standard is issued under the fixed designation D 746; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* E1137 Specification for Industrial Platinum Resistance

Thermometers

1.1 This test method covers the determination of the tem-

2.2 ISO Standard:

perature at which plastics and elastomers exhibit brittle failure

ISO974-1980 (E) Plastics—Determination of the Brittle-

under specified impact conditions. Two routine inspection and

3

ness Temperature by Impact

acceptance procedures are also provided.

NOTE 1—When testing rubbers for impact brittleness useTest Methods 3. Terminology

D2137.

3.1 General—The definitions of plastics used in this test

1.2 The values stated in SI units are to be regarded as the

method are in accordance with Test Method D883 unless

standard.

otherwise specified.

1.3 This standard does not purport to address all of the

3.2 brittleness temperature—that temperature, estimated

safety concerns, if any, associated with its use. It is the

statistically, at which 50% of the specimens would probably

responsibility of the user of this standard to establish appro-

fail.

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use.

4.1 To determine the brittleness temperature, specimens are

NOTE 2—This test method and ISO974–2000 (E) are technically

secured to a specimen holder with a torque wrench. The

equivalent when using the Type B fixture and the Type III specimen,

specimen holder is immersed in a bath containing a heat-

however,theminimumnumberofspecimensthatarerequiredtobetested

is significantly different when using this test method. The ISO method transfer medium that is cooled. The specimens are struck at a

requires that a minimum of 100 specimens be tested.

specified linear speed and then examined. The brittleness

temperature is defined as the temperature at which 50% of the

2. Referenced Documents

specimens fail.

2

2.1 ASTM Standards:

5. Significance and Use

D618 Practice for Conditioning Plastics for Testing

D 832 Practice for Rubber Conditioning for Low-

5.1 This test method establishes the temperature at which

Temperature Testing

50% of the specimens tested fail when subjected to the

D883 Terminology Relating to Plastics

conditionsspecifiedherein.Thetestprovidesfortheevaluation

D2137 Test Methods for Rubber Property—Brittleness

oflong-timeeffectssuchascrystallization,orthoseeffectsthat

Point of Flexible Polymers and Coated Fabrics

areintroducedbylow-temperatureincompatibilityofplasticiz-

E77 Test Method for the Inspection and Verification of

ers in the material under test. Plastics and elastomers are used

Thermometers

inmanyapplicationsrequiringlow-temperatureflexingwithor

E220 Test Method for Calibration of Thermocouples by

withoutimpact.Usedataobtainedbythismethodtopredictthe

Comparison Techniques

behavior of plastic and elastomeric materials at low tempera-

E644 Test Methods for Testing Industrial Resistance Ther-

tures only in applications in which the conditions of deforma-

mometers

tion are similar to those specified in this test method. This test

method has been found useful for specification purposes, but

does not necessarily measure the lowest temperature at which

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

the material is suitable for use.

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties

(Section D20.30.07).

NOTE 3—Suitable apparatus is commercially available from several

Current edition approved May 1, 2004. Published May 2004. Originally

approved in 1943. Last previous edition approved in 1998 as D746-98.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM ISO Standards Handbook 21, Vol 1. ISO Standards are available from

Standards volume information, refer to the standard’s Document Summary page on AmericanNationalStandardsInstitute(ANSI),25W.43rdSt.,4thFloor,NewYork,

the ASTM website. NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D746–04

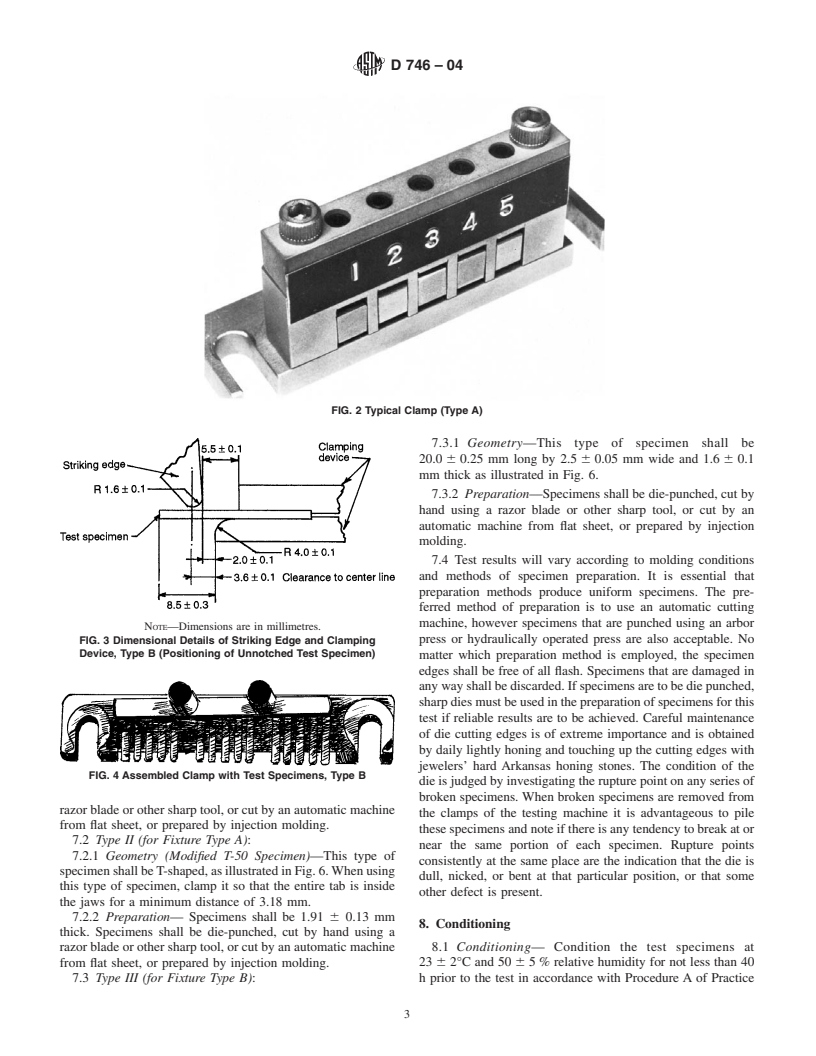

6.3 Torque Wrench, 0 to 8.5 N·m.

NOTE 4—Because of the difference in geometry of the specimen

clamps, test results obtained when using the TypeAspecimen clamp and

strikingmembermaynotcorrelatewiththoser

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.